Polyethylene terephthalate composite material and method for preparing same

A technology of polyethylene terephthalate and phthalate, which is applied in the field of polyethylene terephthalate composite materials and its preparation, and can solve problems such as poor rigidity and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

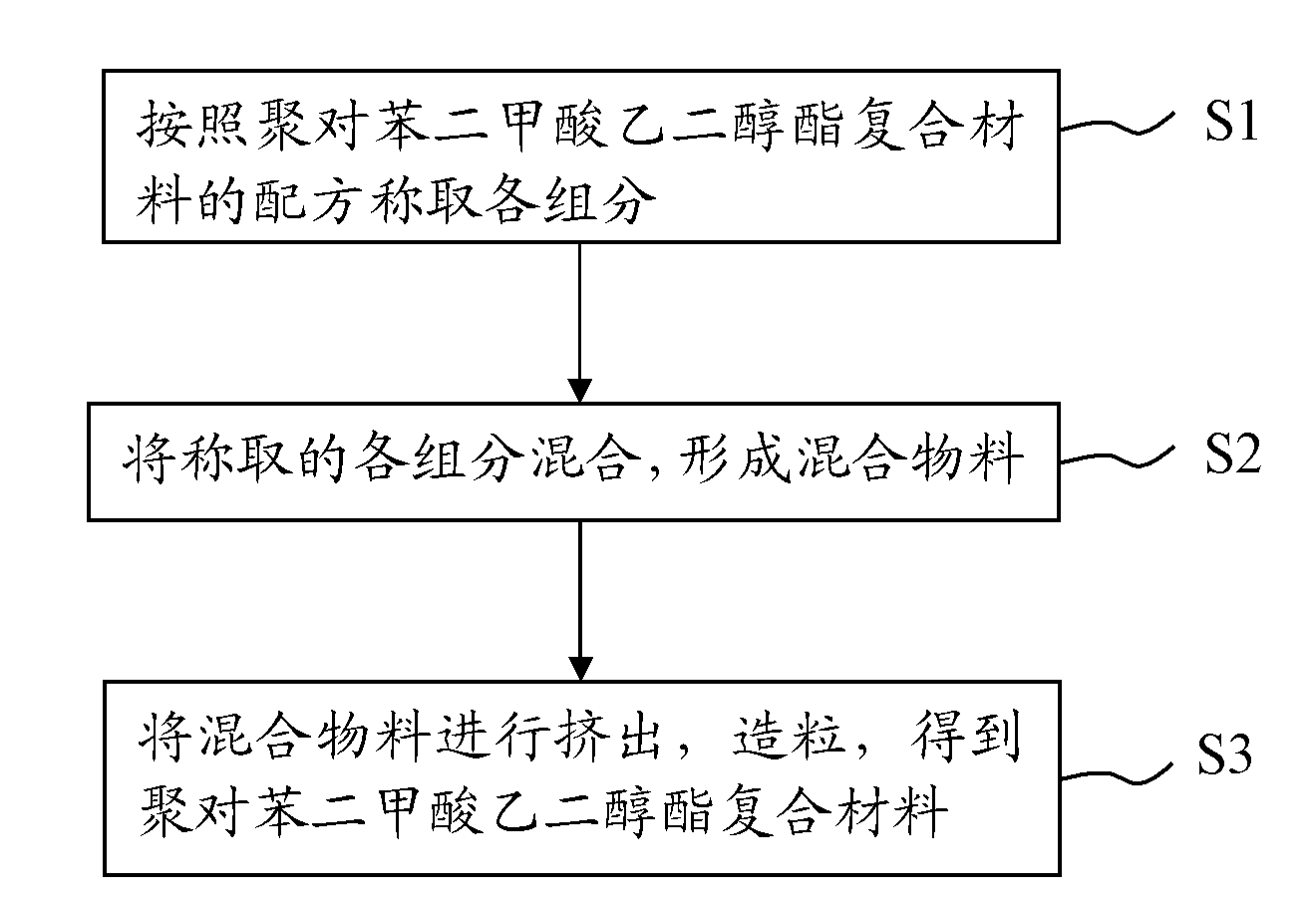

Method used

Image

Examples

preparation example Construction

[0029] The above compound nucleating agent is preferably a compound nucleating agent prepared by compounding activated magnesium silicate, nano-calcium carbonate, and carboxylate. This compound nucleating agent preparation method preferably comprises the steps:

[0030] The activated magnesium silicate and nano-calcium carbonate are heat-treated at 70-90°C for 1-3 hours under the action of a coupling agent to obtain an inorganic mixture; the inorganic mixture is mixed with carboxylates and heated at 60-90 Heat treatment at 80°C for 0.5-2 hours to obtain the compound nucleating agent.

[0031] Specifically, the mass ratio of the magnesium silicate in the above-mentioned activated magnesium silicate solution to the nano-calcium carbonate in the nano-calcium carbonate solution is preferably 1~2: 3~4; Under the action of the coupling agent, it is further preferably heat-treated at 85° C. for 2 hours to obtain an inorganic mixture. The mass ratio of the inorganic component to the...

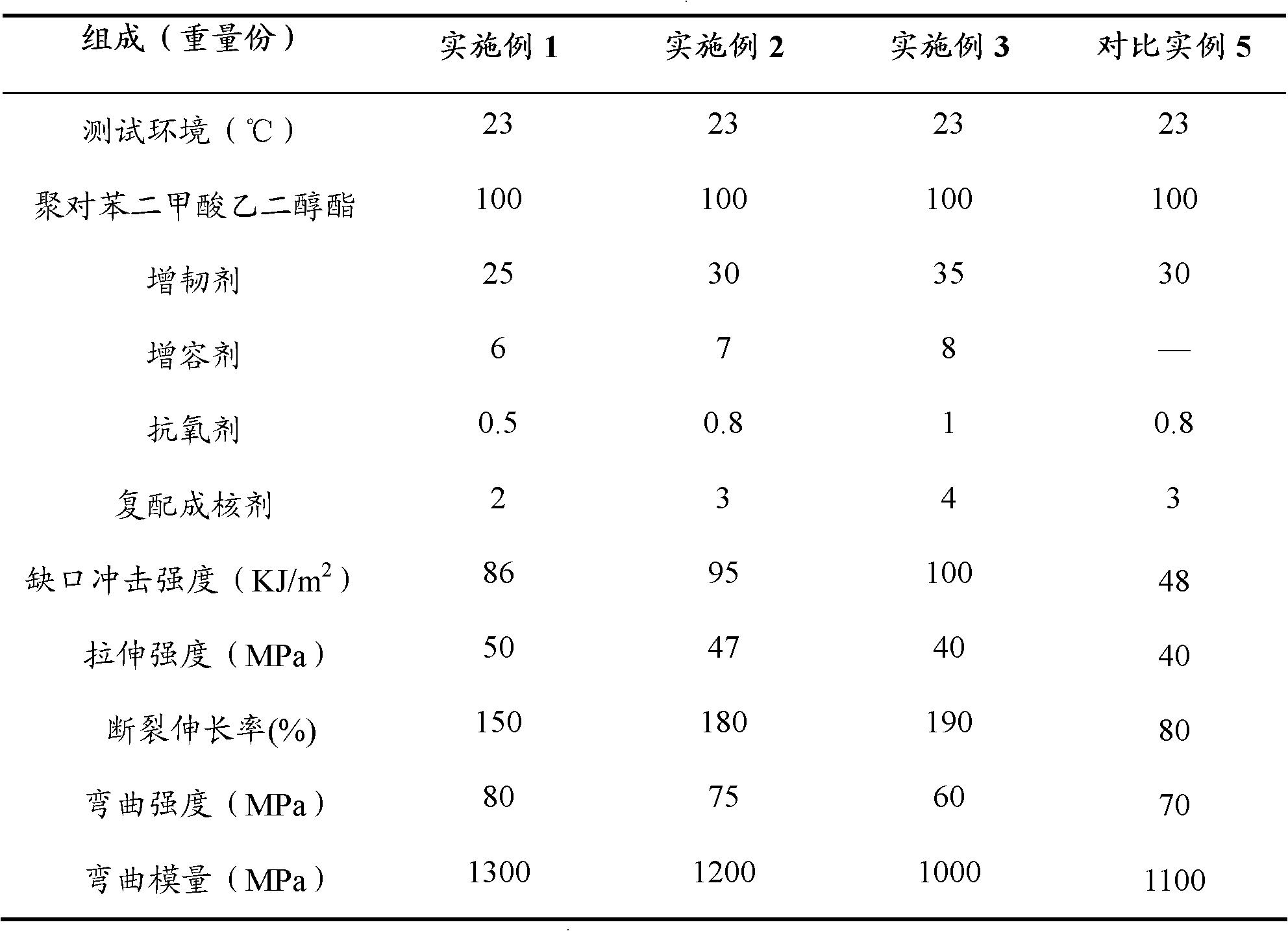

Embodiment 1

[0053] The formula component of polyethylene terephthalate composite material parts by weight is as follows:

[0054] 100 parts of polyethylene terephthalate, 25 parts of toughening agent, 6 parts of compatibilizer, 0.5 part of antioxidant, 2 parts of compound nucleating agent. Among them, the relative density of polyethylene terephthalate is 1.38g / cm 3 , the melting point is 260°C, and its dynamic viscosity in the molten state is 1.1 Pa·s; the toughening agent is a copolymerized methyl methacrylate-butadiene-styrene core-shell toughening agent; the compatibilizer is ethyl Olene-octene copolymer (POE) grafted methacrylate-glycidyl acrylate compatibilization modifier; antioxidant is triethylene glycol bis-3-(3-tert-butyl-4-hydroxy-5- Methylphenyl) acrylonitrile; the composite nucleating agent is a composite nucleating agent prepared by activating magnesium silicate, nano-calcium carbonate, carboxylate, and its preparation method is: the mass ratio is 1:3 The activated magnesi...

Embodiment 2

[0060] The formula component of polyethylene terephthalate composite material parts by weight is as follows:

[0061] 100 parts of polyethylene terephthalate, 30 parts of toughening agent, 7 parts of compatibilizer, 0.8 part of antioxidant, 3 parts of compound nucleating agent. Among them, the relative density of polyethylene terephthalate is 1.35g / cm 3 , the melting point is 250°C, and its dynamic viscosity in the molten state is 0.65 Pa·s; the toughening agent is a copolymerized methyl methacrylate-butadiene-styrene core-shell toughening agent; the compatibilizer is ethyl Olene-octene copolymer (POE) grafted methacrylate-glycidyl acrylate compatibilization modifier; antioxidant is tris(2,4-di-tert-butylphenol) phosphite; complex nucleation The agent is a composite nucleating agent prepared by compounding activated magnesium silicate, nano-calcium carbonate, and carboxylate. Please refer to Example 1 for its preparation method.

[0062] The preparation method of polyethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com