Glass fiber-reinforced flame-retardant polystyrene resin composition and preparation method thereof

A technology of polystyrene resin and composition, which is applied in the field of glass fiber reinforced flame-retardant polystyrene resin composition and its preparation, and can solve the problems of low impact strength, few market applications, and poor fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

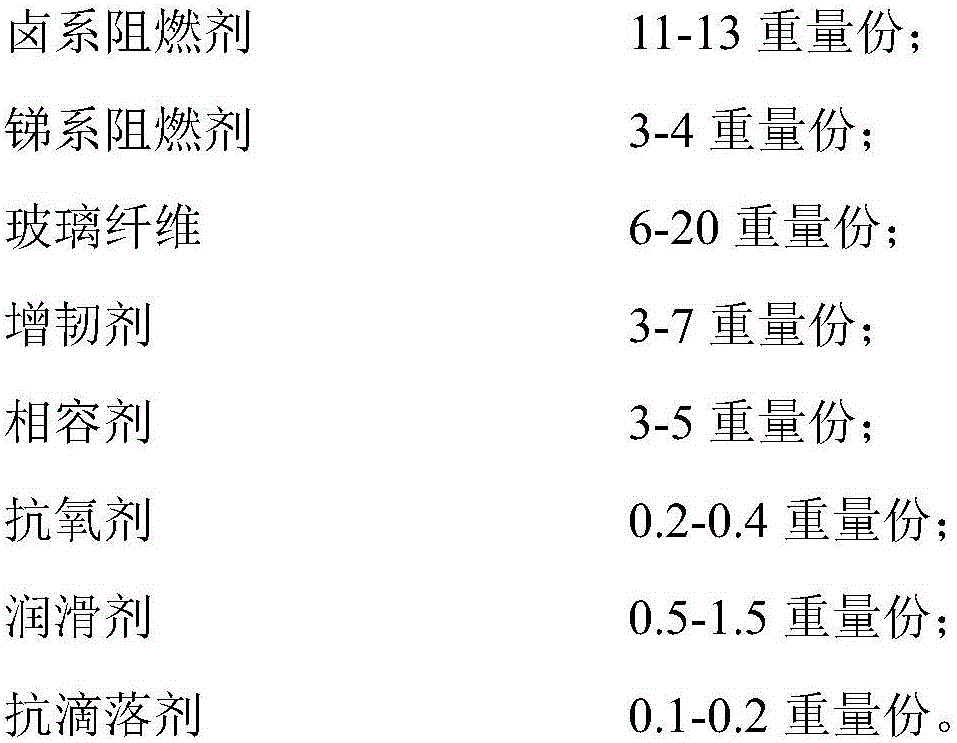

[0032] The components and content of the glass fiber reinforced flame retardant polystyrene resin composition are:

[0033]

[0034] in:

[0035] The melt flow rate of polystyrene resin is 9g / 10min;

[0036] The halogenated flame retardant is bromotriazine;

[0037] The antimony-based flame retardant is antimony trioxide;

[0038] The glass fiber is an alkali-free glass fiber with a diameter of 10um;

[0039] The toughening agent is a mixture of styrene / butadiene / styrene and styrene / butadiene;

[0040] The compatibilizer is polyphenylene ether-maleic anhydride;

[0041] The flow modifier is triphenyl phosphate;

[0042] The antioxidant is Irganox 1010;

[0043] The lubricant is a mixture of modified ethylene bis stearamide and pentaerythritol stearate.

[0044] The anti-dripping agent is polytetrafluoroethylene with a molecular weight of 5 million.

Embodiment 2

[0046] The components and content of the glass fiber reinforced flame retardant polystyrene resin composition are:

[0047]

[0048] in:

[0049] The melt flow rate of polystyrene resin is 11g / 10min;

[0050] The halogenated flame retardant is decabromodiphenylethane;

[0051] The antimony-based flame retardant is a mixture of antimony trioxide and sodium antimonate;

[0052] The glass fiber is an alkali-free glass fiber with a diameter of 10um;

[0053] The toughening agent is styrene / butadiene / styrene;

[0054] The compatibilizer is polyphenylene ether-maleic anhydride;

[0055] The flow modifier is triphenyl phosphate;

[0056] The antioxidant is a mixture of Irganox 1010 and Irganox 168;

[0057] The lubricant is a mixture of modified ethylene bis stearamide, pentaerythritol stearate and silicone masterbatch.

[0058] The anti-dripping agent is polytetrafluoroethylene with a molecular weight of 3.5 million.

Embodiment 3

[0060] The components and content of the glass fiber reinforced flame retardant polystyrene resin composition are:

[0061]

[0062] in:

[0063] The melt flow rate of polystyrene resin is 9g / 10min;

[0064] The halogenated flame retardant is tetrabromobisphenol A;

[0065] The antimony-based flame retardant is antimony pentoxide;

[0066] The glass fiber is an alkali-free glass fiber with a diameter of 10um;

[0067] The toughening agent is styrene / isoprene / styrene;

[0068] The compatibilizer is polyphenylene ether-maleic anhydride;

[0069] The flow modifier is bisphenol A-diphenyl phosphate;

[0070] The antioxidant is a mixture of Irganox 1010 and Irganox 168;

[0071] The lubricant is a mixture of modified ethylene bis stearamide and pentaerythritol stearate.

[0072] The anti-dripping agent is polytetrafluoroethylene with a molecular weight of 2 million.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com