Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

240 results about "Polymethylhydrosiloxane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

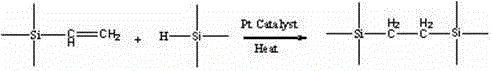

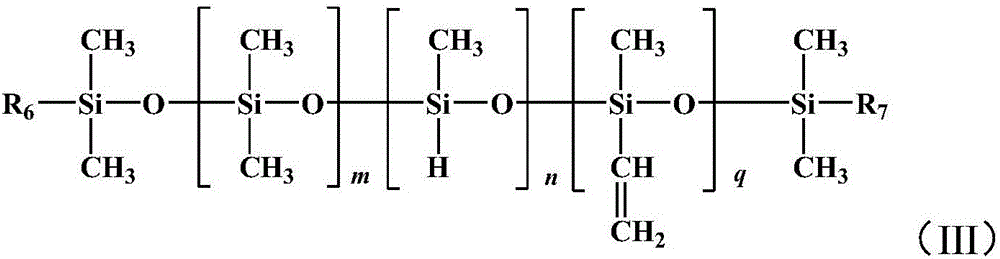

Polymethylhydrosiloxane (PMHS) is a polymer with the general structure -(CH₃(H)Si-O)-. It is used in organic chemistry as a mild and stable reducing agent easily transferring hydrides to metal centers. A variety of related materials are available under the following CAS registry numbers 9004-73-3, 16066-09-4, 63148-57-2, 178873-19-3. These include the tetramer ((MeSiHO)₄), copolymers of dimethylsiloxane and methylhydrosiloxane, and trimethylsilyl terminated materials.

Low release quantity additive halogen-free flame-retardant heat-conduction organic silicon pouring sealant and preparation method thereof

InactiveCN104804705AImprove liquidityImprove thermal conductivityNon-macromolecular adhesive additivesRubber materialHydrogen

The invention belongs to the technical field of organic silicon pouring sealants, and particularly relates to a low release quantity additive halogen-free flame-retardant heat-conduction organic silicon pouring sealant and a preparation method thereof. The pouring sealant comprises an A component and a B component, wherein the A component and the B components are mixed in weight ratio of 1:1; the A component comprises basic rubber materials, polymethyl hydrogen siloxane and crosslink breaker; the weight ratio of the basic rubber materials, the polymethyl hydrogen siloxane and the crosslink breaker is 100:2.5-4:0.01-0.5; the B component comprises basic rubber materials and catalyzer; the weight ratio of the rubber materials and the catalyzer is 100:0.15-0.2; the A component and the B component are uniformly mixed according to the equal weight ratio and are defoaming to obtain the pouring sealant. The pouring sealant is good in flowability, can be heat and cured at room temperature, has favorable heat conductivity and flame retardancy, has the release quantity being lower than 0.5 percent under the condition of 120 DEG C*24h, and is particularly applicable to pouring with the heat-conduction and flame-retardant requirements under a seal system in the LED (Light-emitting Diode) industry.

Owner:CHENGDU TALY TECH CO LTD

Antistatic finishing agent for wool and wool blended fabrics and preparation method thereof

The invention discloses an antistatic finishing agent for wool and wool blended fabrics and a preparation method thereof. The antistatic finishing agent comprises the following components in parts by weight: 2-5 parts of polydimethylsiloxane, 1-3 parts of polymethyl hydrogen siloxane, 10-20 parts of butyl acrylate, 1-3 parts of methylparaben, 10-20 parts of glycerol, 0.2-0.6 part of potassium alkyl benzene sulfonate, 3-8 parts of 2-hydroxypropyl acrylate, 2-5 parts of calcium chloride, 5-8 parts of polyethyleneglycol stearate and 80-100 parts of water. The fabric treated by the antistatic finishing agent has greatly lower surface resistance, higher soaping resistance and favorable softness.

Owner:吴江市钱氏纺织有限公司

Preparation method for gas separation composite membrane

ActiveCN102008909AImprove permeabilityEasy to separateSemi-permeable membranesDispersed particle separationCross-linkPlatinum complex

The invention discloses a preparation method for a gas separation composite membrane, comprising the following steps: dissolving a siloxane prepolymer in isooctane, adding a cross-linking agent (pelyntethylhydrosiloxane) and a catalyst (1,3-diethenyl-1,1,3,3-tetramethyldisiloxane platinum complex), stirring to prepare into separation layer membrane liquid; and evenly coating the separation layer membrane liquid on a polyacrylonitrile basement membrane, airing and performing thermal cross linking to obtain the gas separation composite membrane, wherein the adopted basement membrane is a commercialized polyacrylonitrile ultrafiltration membrane, the airing time is 2-20min, the thermal cross linking temperature is 60-120 DEG C, and the thermal cross linking time is 5-30 minutes. The permeation and separation properties of the gas separation composite membrane on O2, N2 and C2H6 determined under the temperature of 25 DEG C are respectively as follows: JN2>0.2m<3>.m<-2>.atm<-1>.h<-1>, alpha (O2 / N2)>2.3, and alpha (C3H6 / N2) >24. The preparation method for the composite membrane is also suitable to preparation of nanofiltration, hyperfiltration and pervaporation composite membranes.

Owner:DALIAN EUROFILM IND

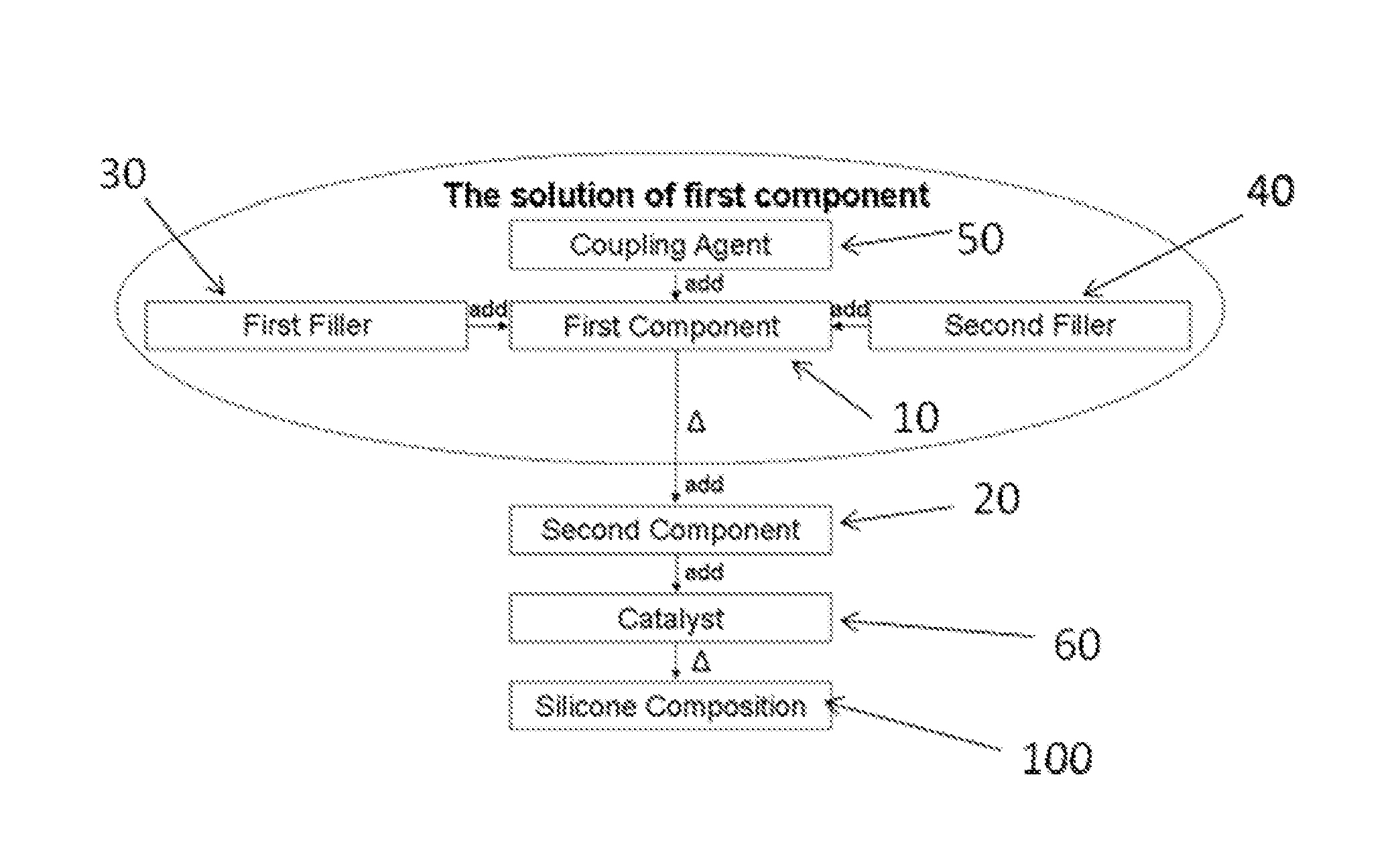

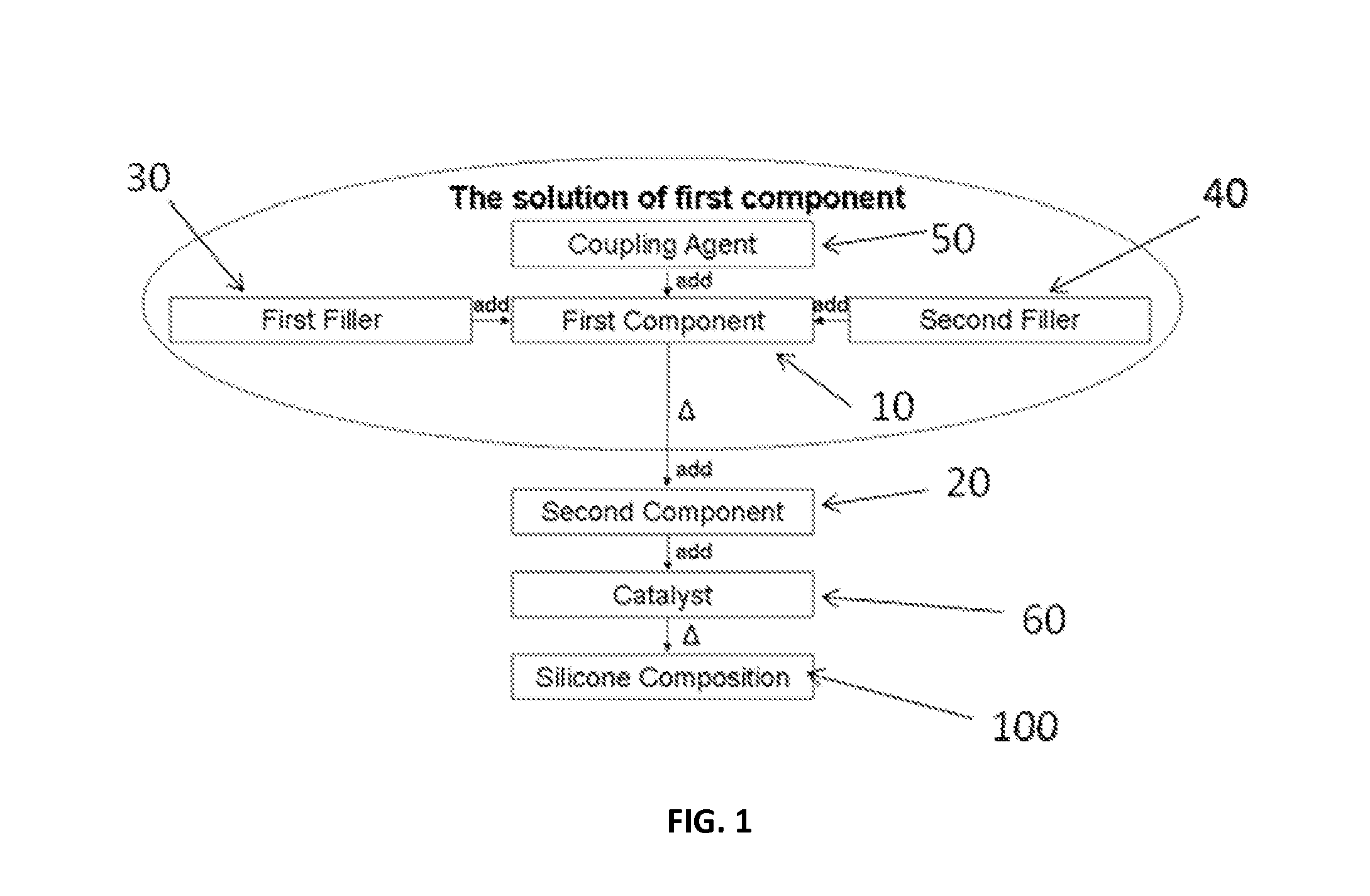

Silicone composition and devices incorporating same

InactiveUS8257827B1Low costEvenly distributedLayered productsPharmaceutical delivery mechanismCross-linkSilicone Elastomers

A silicone composition having anti-microbial properties contains well distributed silica and nanoparticles of a noble metal. Silica and nanoparticles of a noble metal are added to liquid vinyl-terminated polydimethylsiloxane. A coupling agent is then added to the mixture and heated, the coupling agent comprising trialkoxysilane having a formula R1Si(OR2)3, wherein R1 is vinyl or allyl, and R2 is an alkyl radical having from 1 to 3 carbon atoms. In one embodiment, trimethylsiloxy terminated polymethylhydrosiloxane is then added to the mixture and heated in the presence of a catalyst so as to cross-link and cure the same into a silicone elastomer. In another embodiment, in place of the trimethylsiloxy terminated polymethylhydrosiloxane, a peroxide is added to mixture and heated to form the silicone. In this later example, no catalyst is needed.

Owner:RGT UNIV OF CALIFORNIA

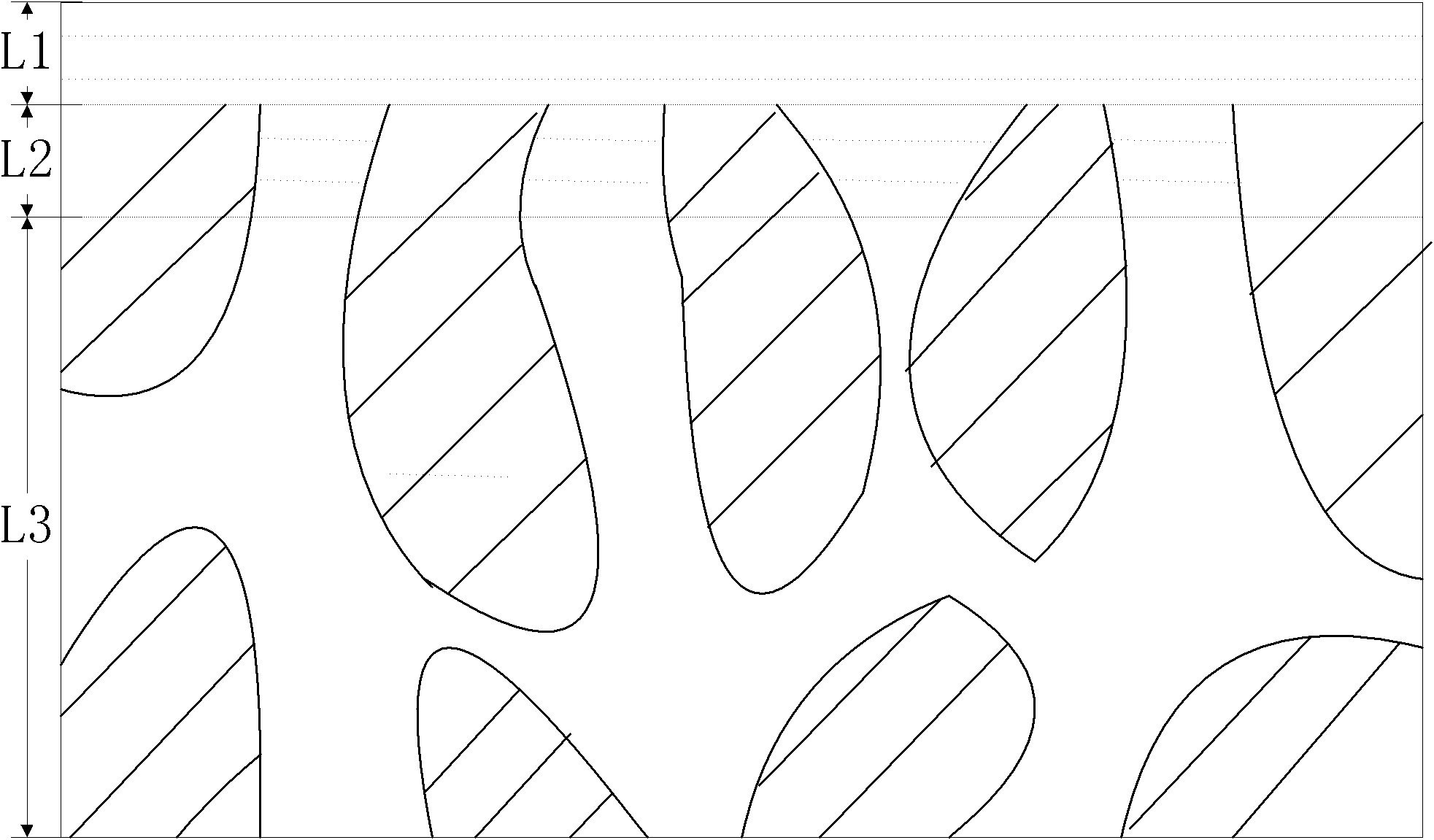

Frame-sealing glue, packaging method of display panel and display panel

ActiveCN103980832ASlow down or avoid pollutionQuality improvementMacromolecular adhesive additivesNon-linear opticsCross-linkLiquid-crystal display

The invention belongs to the technical field of display and relates to frame-sealing glue, a packaging method of a display panel and a display panel. The frame-sealing glue comprises a frame-sealing glue base and also comprises a siloxane side chain-type liquid crystal elastomer. A polymethylhydrosiloxane main chain, a liquid crystal monomer and a cross-linking agent undergo a hydrosilylation reaction to produce the siloxane side chain-type liquid crystal elastomer. The liquid crystal monomer is a cholesterol derivative. The cross-linking agent is a binaphthol derivative. The frame-sealing glue can effectively relieve or prevent the liquid crystal pollution caused by micromolecules in the frame-sealing glue in array substrate and color film substrate closing, reduce the impact produced by liquid crystal on the frame-sealing glue and improve liquid crystal display panel quality.

Owner:BOE TECH GRP CO LTD +1

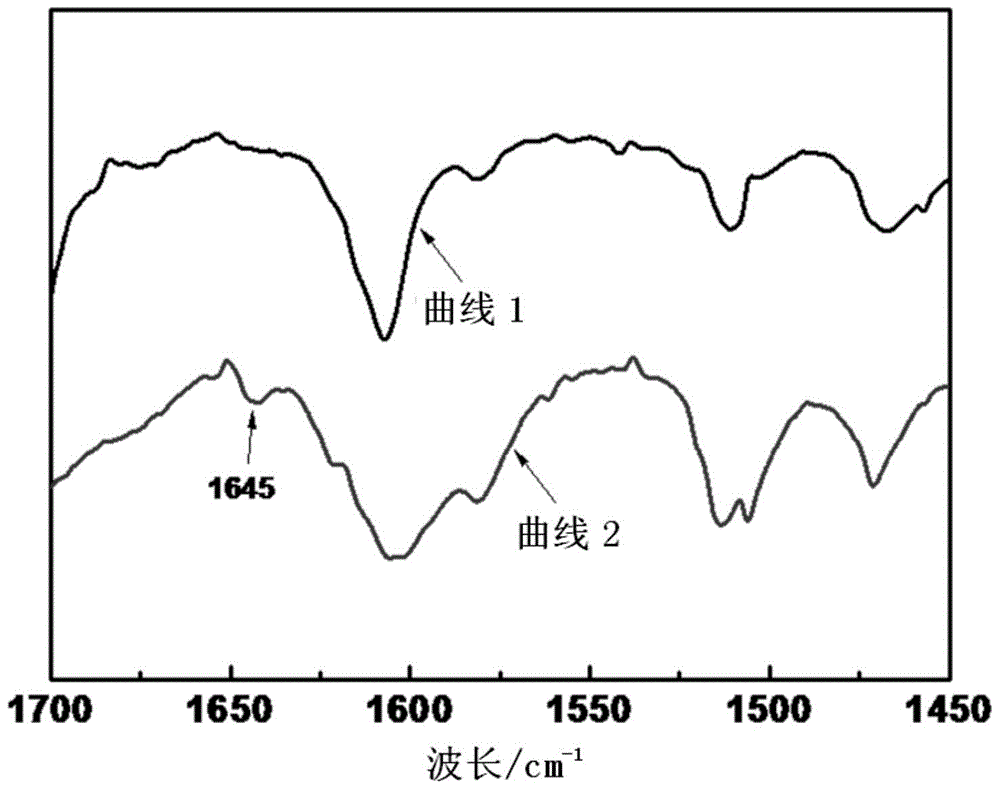

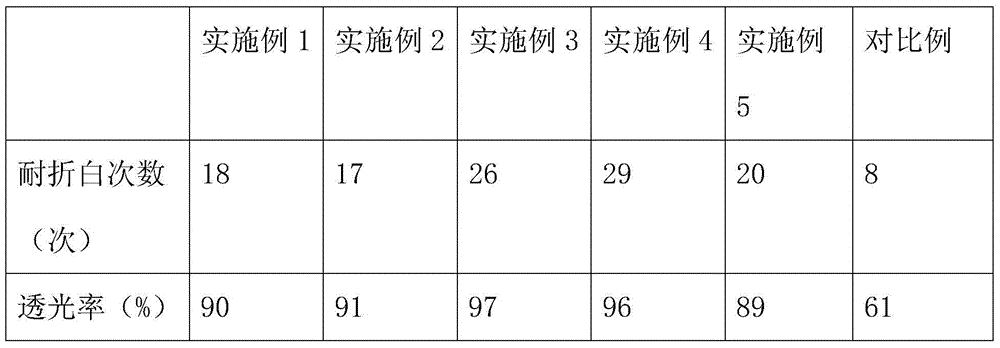

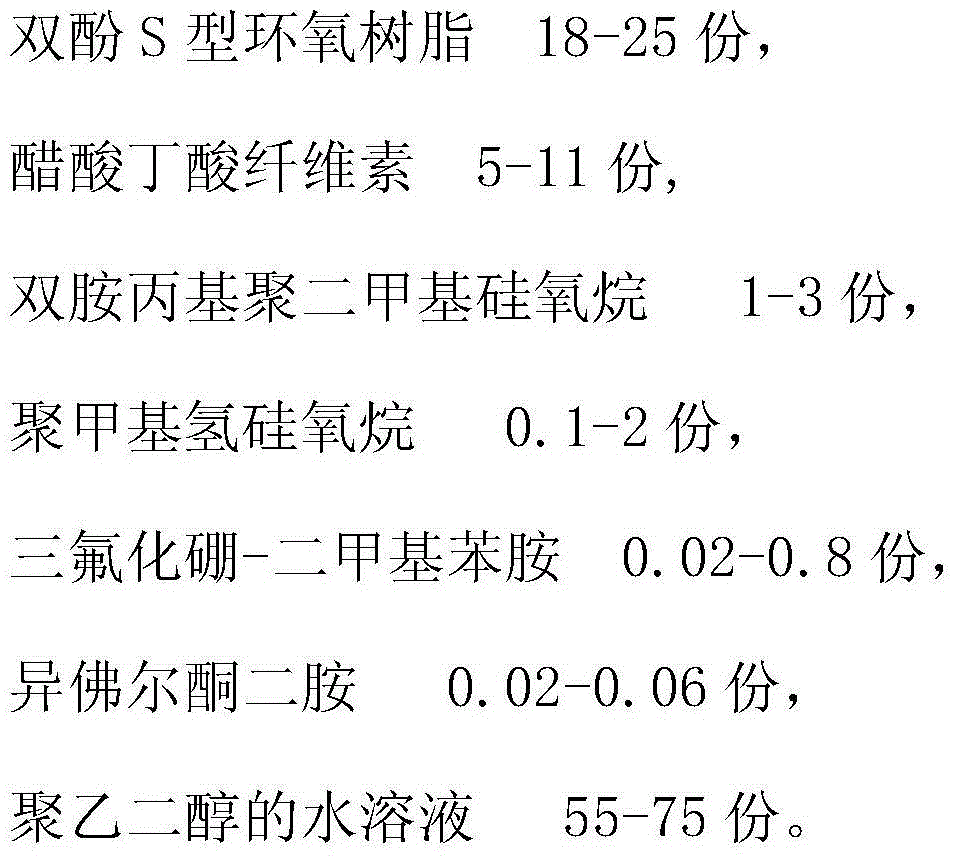

Fold-resistant white plastic film and preparation method thereof

InactiveCN104877310AGood light transmissionImprove high temperature resistanceEpoxyDimethylaniline N-oxide

The invention relates to a fold-resistant white plastic film and a preparation method thereof. The fold-resistant white plastic film is prepared from the following components in parts by weight: 18 to 25 parts of bisphenol S-type epoxy resin, 5 to 11 parts of cellulose acetate butyrate, 1 to 3 parts of diaminopropyl polydimethylsiloxane, 0.1 to 2 parts of polymethyl hydrogen siloxane, 0.02 to 0.8 parts of boron trifluoride-dimethylaniline, 0.02 to 0.06 parts of isophorone diamine and 55 to 75 parts of aqueous solution of polyethylene glycol. The invention also provides the preparation method of the fold-resistant white plastic film.

Owner:苏州靖羽新材料有限公司

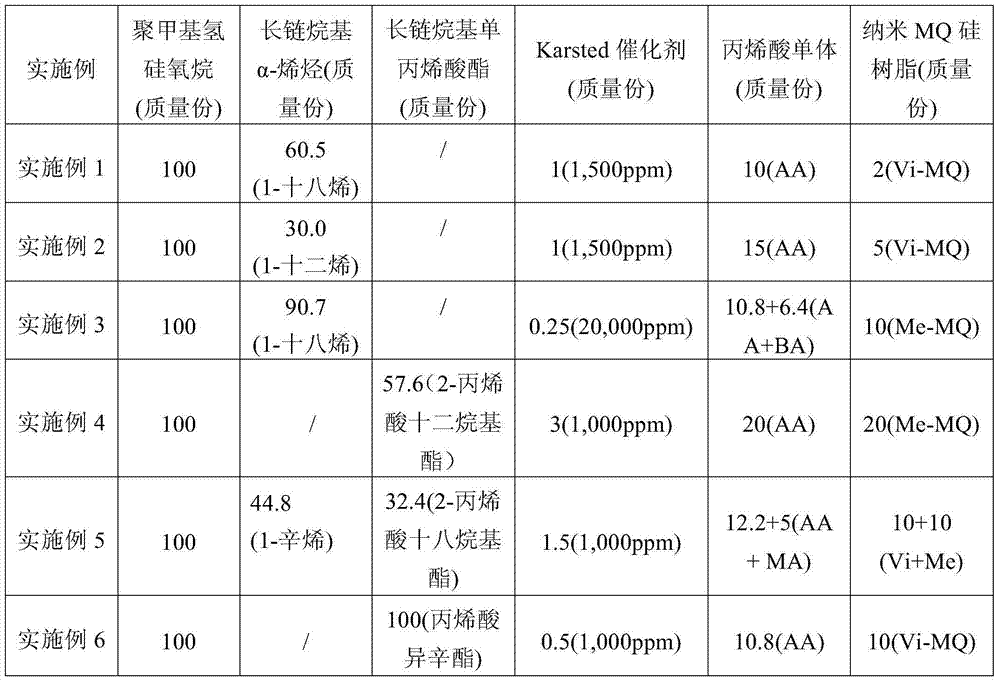

Self-emulsifying acrylic acid organic silicon wax protection material as well as preparation method and application thereof

InactiveCN103613717AImproves UV resistanceIncreased durabilityFibre treatmentCoatingsAlpha-olefinSelf emulsifying

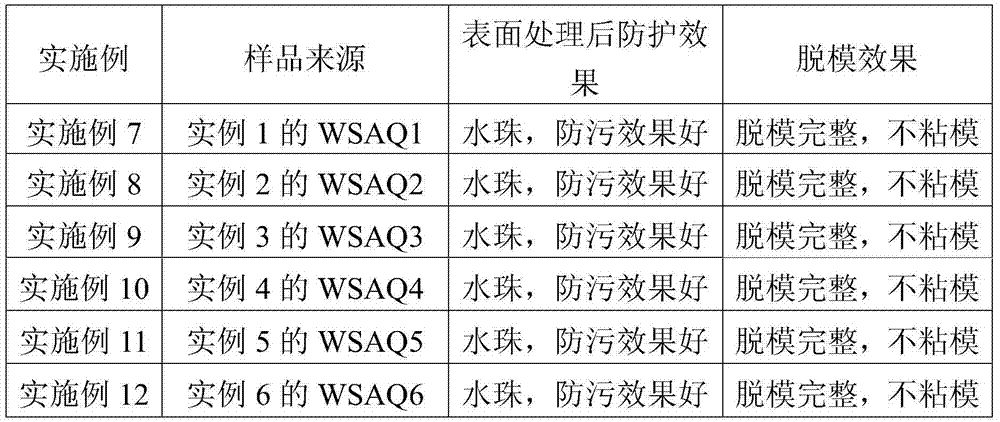

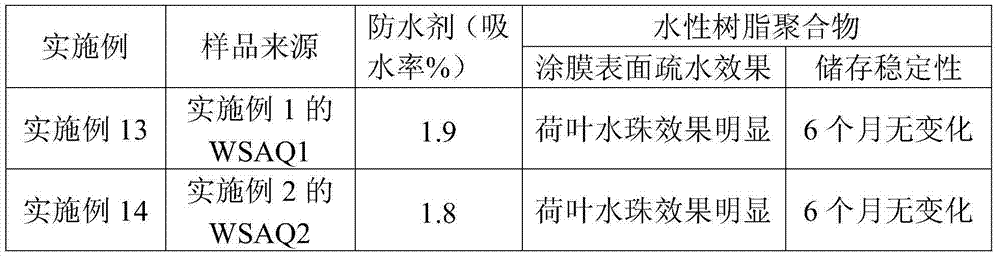

The invention discloses a self-emulsifying acrylic acid organic silicon wax protection material as well as a preparation method and application thereof. The preparation method comprises the following steps: reacting 30 to 100 parts by mass of long-chain alkyl alpha-olefin or / and long-chain alkyl monoacrylate with 100 parts by mass of polymethylhydrosiloxane in the presence of a platinum complex catalyst, cooling, adding 10 to 20 parts by mass of acrylic monomer and 2 to 20 parts by mass of nanometer MQ silicon resin, and performing heat-preservation reaction, thereby preparing the acrylic acid organic silicon wax polymer; adding ammonium hydroxide for neutralizing the polymer, thereby preparing self-emulsifying acrylic acid organic silicon wax protection material. The self-emulsifying acrylic acid organic silicon wax protection material prepared through the method is good in stability, environment-friendly, good in dispersibility, excellent in waterproof hydrophobic property and remarkable in mold stripping effect; the self-emulsifying acrylic acid organic silicon wax protection material can be used as a nursing agent, a waterproof agent, a mold stripping agent, a waterborne polymer resin additive and the like in the fields of ceramics, natural stone, concrete, metal casting, cosmetics, paint and the like.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

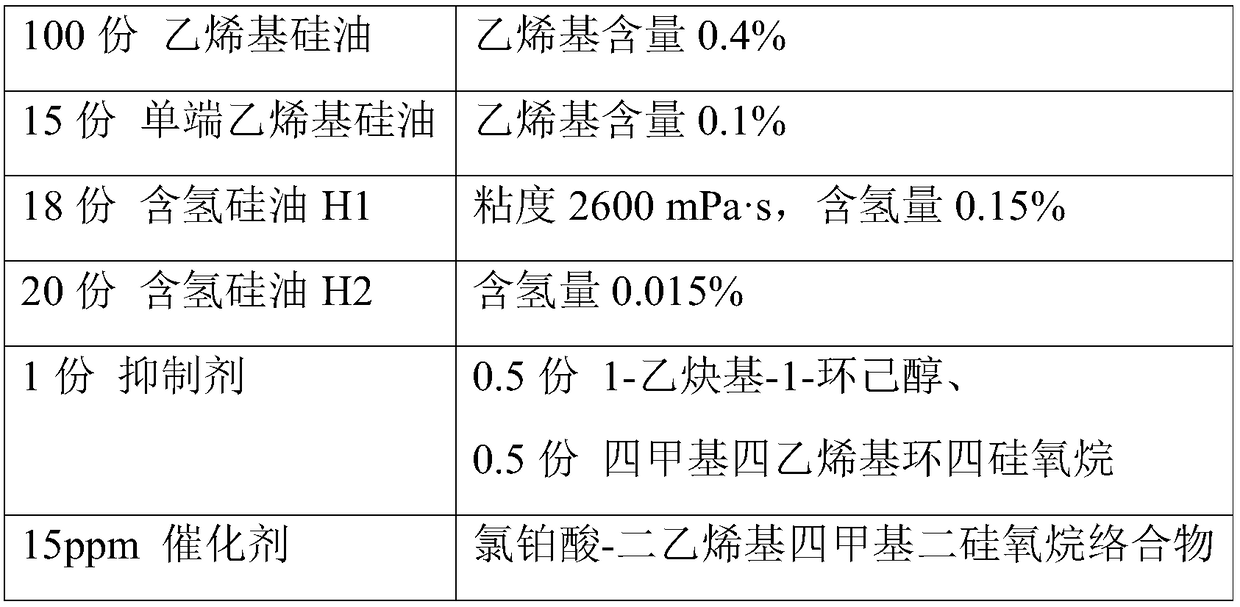

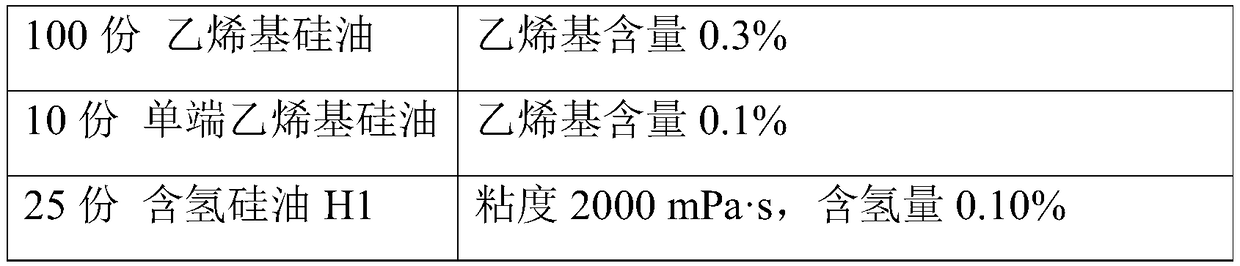

Low-oil-permeability high-strength addition-type silica gel and preparation method thereof

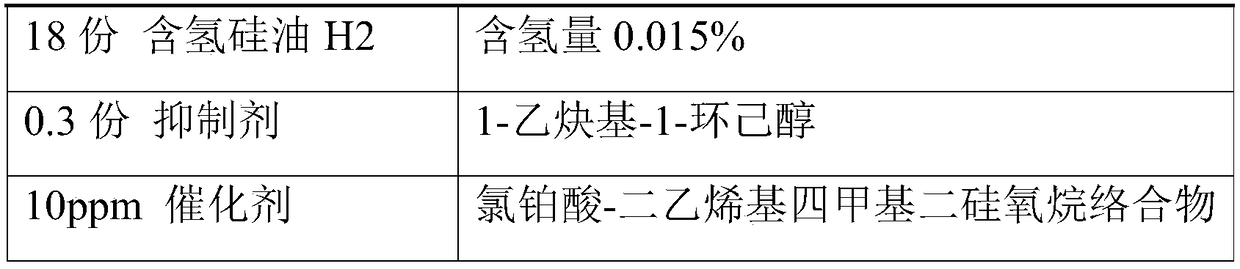

The invention relates to low-oil-permeability high-strength addition-type silica gel and a preparation method thereof. The addition-type silica gel is prepared from the following raw material components in parts by weight: 100 parts of alpha,omega-vinyl polydimethylsiloxane, 5 to 15 parts of single-ended vinyl polydimethylsiloxane, 15 to 30 parts of polymethylhydrosiloxane H1, 10 to 25 parts of polymethylhydrosiloxane H2, 0.01 to 2 parts of inhibitor, and platinum catalyst containing 0.5 to 50 ppm of platinum by mass, wherein nSi-H / nSi-Vi is greater than 1 in the addition-type silica gel. Theaddition-type silica gel has not only higher tensile strength and elongation at break, but superior oil permeability resistance, and stable adhesive performance and dielectric property, and can meet the encapsulating protection requirements of high-end precise electronic parts and components.

Owner:GUANGZHOU BAIYUN CHEM IND

Ultrahard organosilicone hydrophobic glass resin and preparation method thereof

InactiveCN107722283AUniform coatingTransparent filmAntifouling/underwater paintsPaints with biocidesHydrogenAutocatalysis

The invention relates to ultrahard organosilicone hydrophobic glass resin which is prepared by mixing hydrogen-containing polymethylhydrosiloxane, vinyl MQ silicon resin, polyhydroxy polysiloxane, amino silicon oil and a diluent for reaction with a silane coupling agent and polyvinylsilazane under the action of a Karsted catalyst. The invention further provides a preparation method of the ultrahard organosilicone jydrophobic glass resin. The ultrahard organosilicone jydrophobic glass resin prepared according to the preparation method disclosed by the invention can realize autocatalysis for crosslinking solidification at room temperature, and a coating film is uniform, transparent and not cracked; furthermore, the ultrahard organosilicone hydrophobic glass resin is high in compactness, hydrophobicity and stain resistance; a contact angle between the coating film and water is greater than 120 degrees, and the visible light transmittance is higher than 85 percent, and the ultrahard organosilicone hydrophobic glass resin can resist a temperature being 500 DEG C or higher.

Owner:UNION FOSHAN CHEM +1

Preparation method of gas separation composite film

ActiveCN102068914ASave pre-wetting stepSimple processSemi-permeable membranesDispersed particle separationPolyesterCross-link

The invention discloses a preparation method of a gas separation composite film. The method comprises the following steps of: dissolving polyacrylonitrile (PAN) in dimethyl formamide (DMF) so as to obtain 10 to 18 weight percent of solution, adding additives (chlorides of lithium, calcium and the like), filtering, defoaming, performing curtain coating on a polyester non-woven fabric, volatilizing a solvent and gelling in gelling bath (10 to 15 percent of aqueous solution serving as an additive) so as to obtain a base film; dissolving a siloxane prepolymer in isooctane and adding a cross-linking agent (polymethyl hydrogen siloxane) and a catalyst (1,3-divinyl-1,1,3,3-tetramethyldisiloxane platinum complex) so as to obtain separation layer film liquid; and uniformly coating the separation layer film liquid on a PAN base film, drying in the air, performing thermal treatment and soaking in deionized water. The permeation and separation performance of the film on O2 / N2 are that: JN2 is more than 0.3m<3>.m<-2>.atm<-1>; alpha (O2 / N2) is more than 2.3; and alpha (C3H6 / N2) is more than 24. The preparation method is suitable for nanofiltration, reverse osmosis and preparation of a pervaporation composite film.

Owner:DALIAN EUROFILM IND

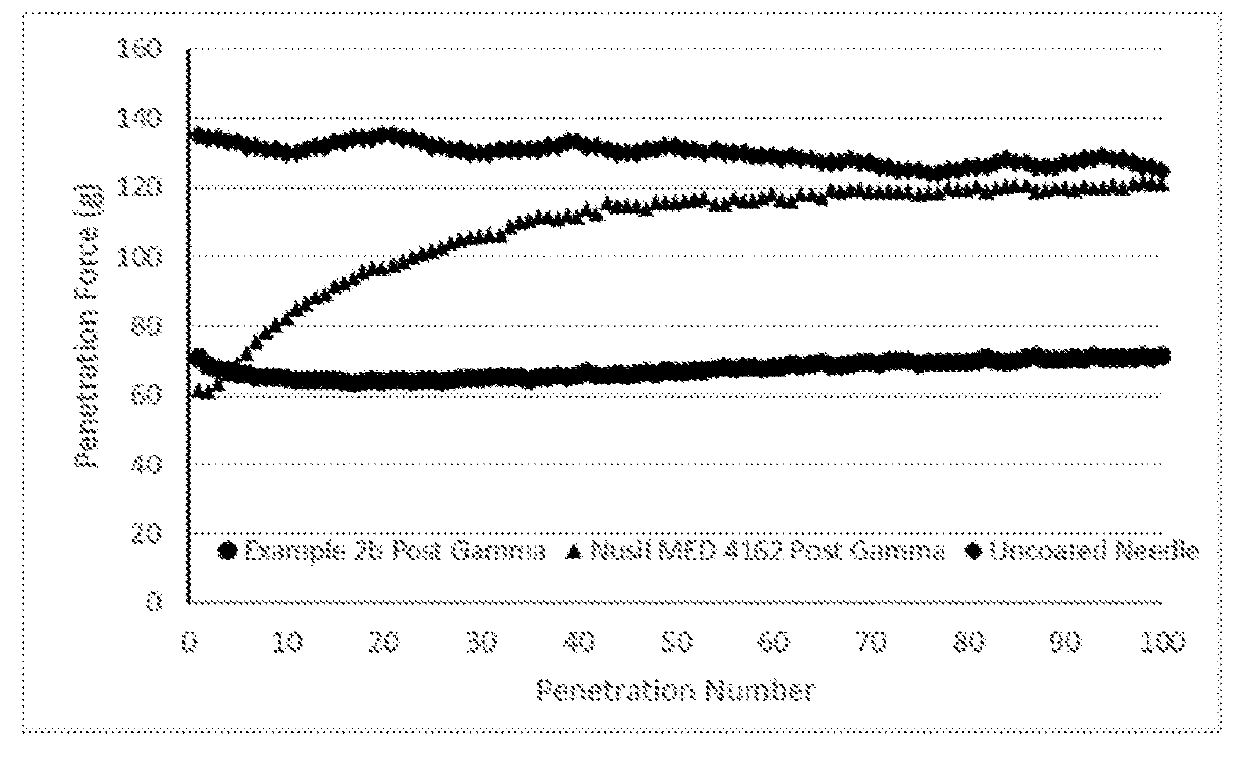

Method of Applying Rapid Cure Silicone Lubricious Coatings

A silicone coating process that improves the durability of silicone coatings on the surfaces of surgical needles and other medical devices. The silicone coated surgical needles or medical devices produced by this process have both superior lubricity and durability for ease of repeated and successive passes through tissue. The coating compositions used in the novel process contain an excess amount of polymethylhydrosiloxane cross-linker. After curing, the process utilizes gamma radiation to treat the lubricious coatings. The coatings have improved durability and performance. The penetration performance of needles coated by this novel method remains constant and flat over at least one hundred repeat passes through tissue or tissue simulation media. This provides a consistent or flat tactile response from the needles to the hand of the surgeon during a lengthy closure process, rather than an unpredictably increasing force profile. The process is also advantageous to coat reusable instruments, robotic instruments, and instruments used in minimally invasive procedures.

Owner:ETHICON INC

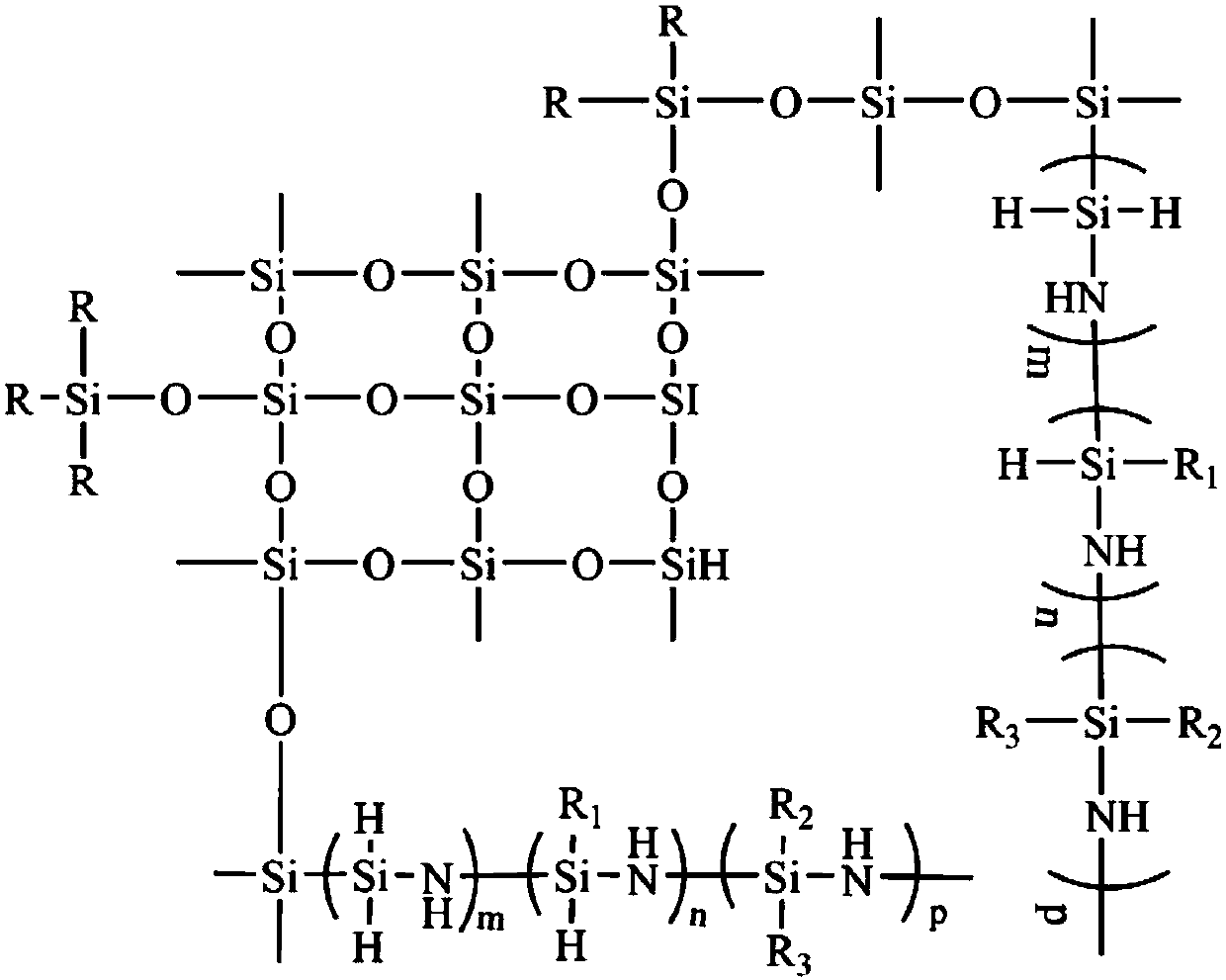

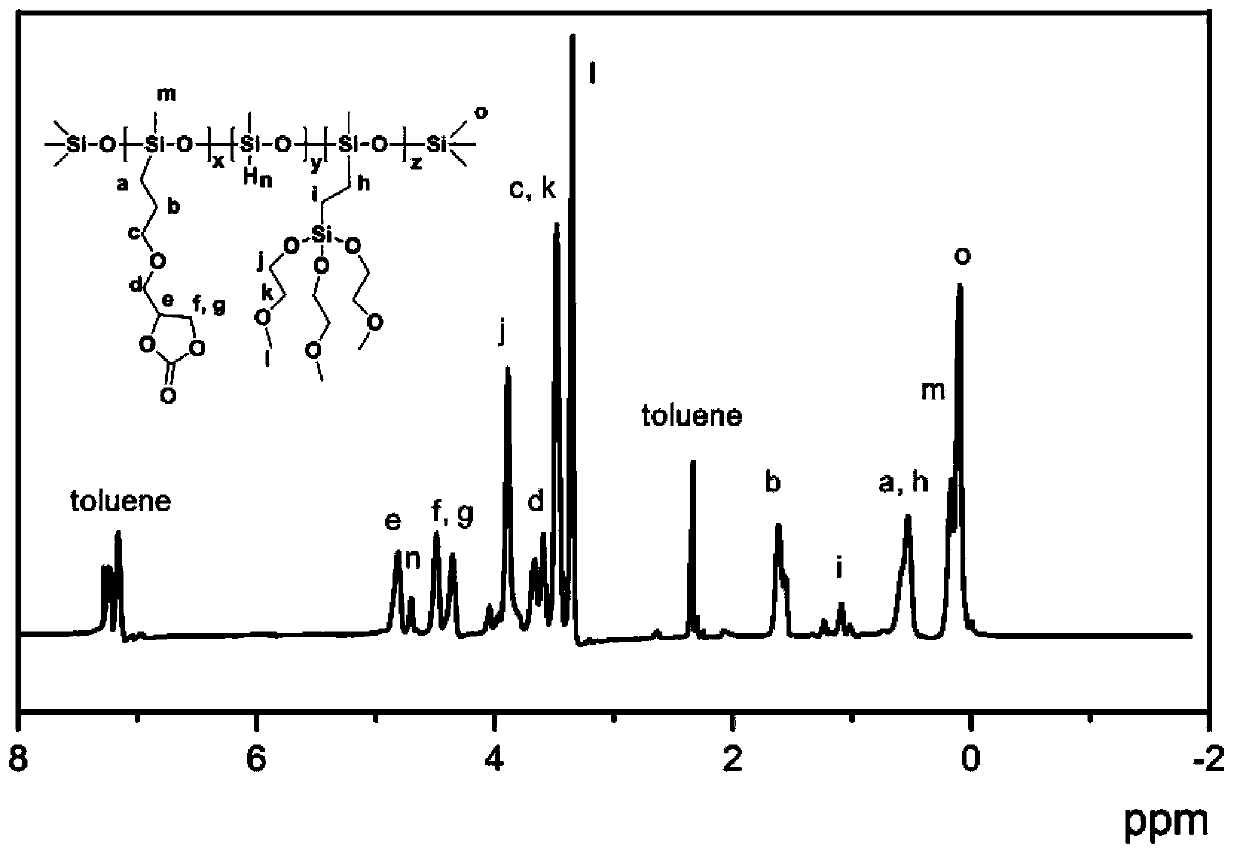

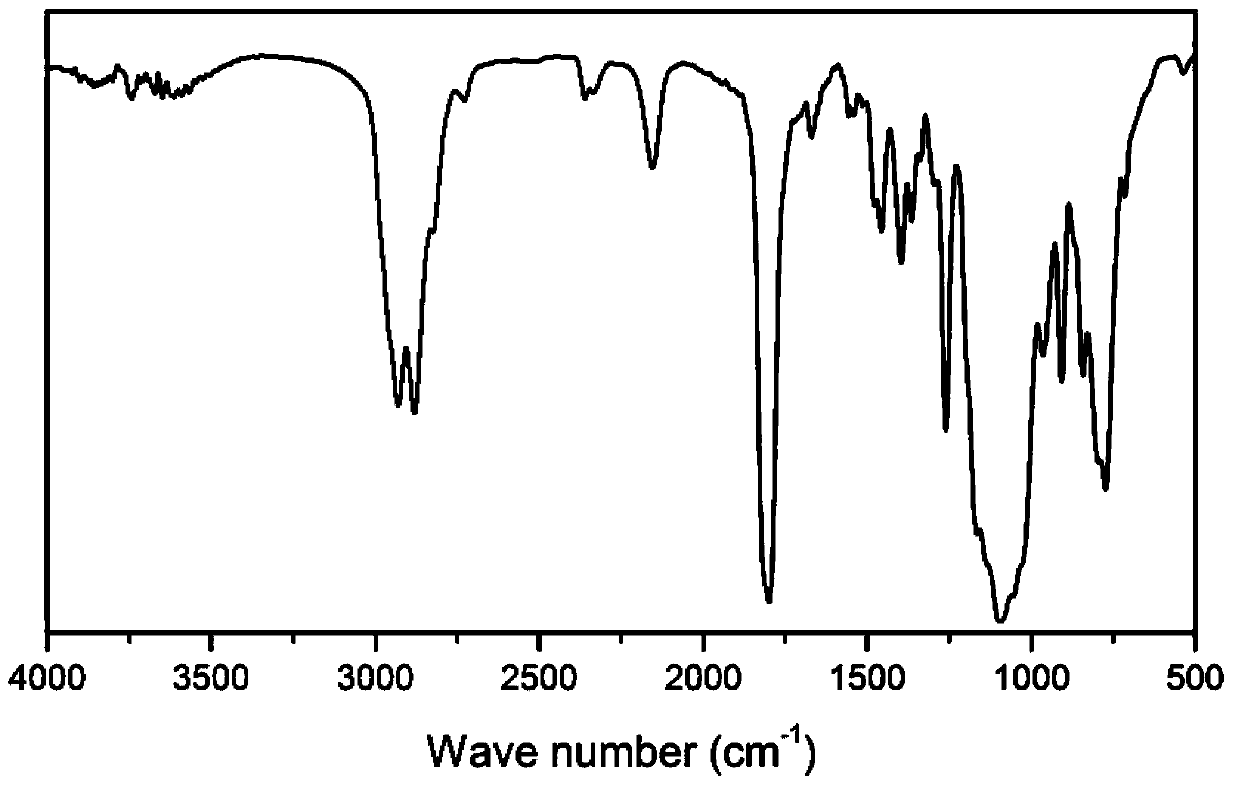

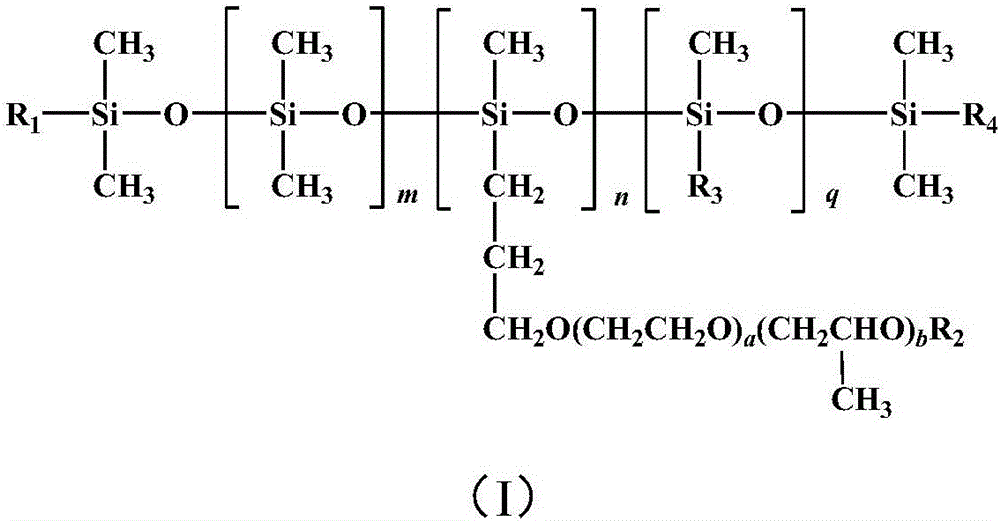

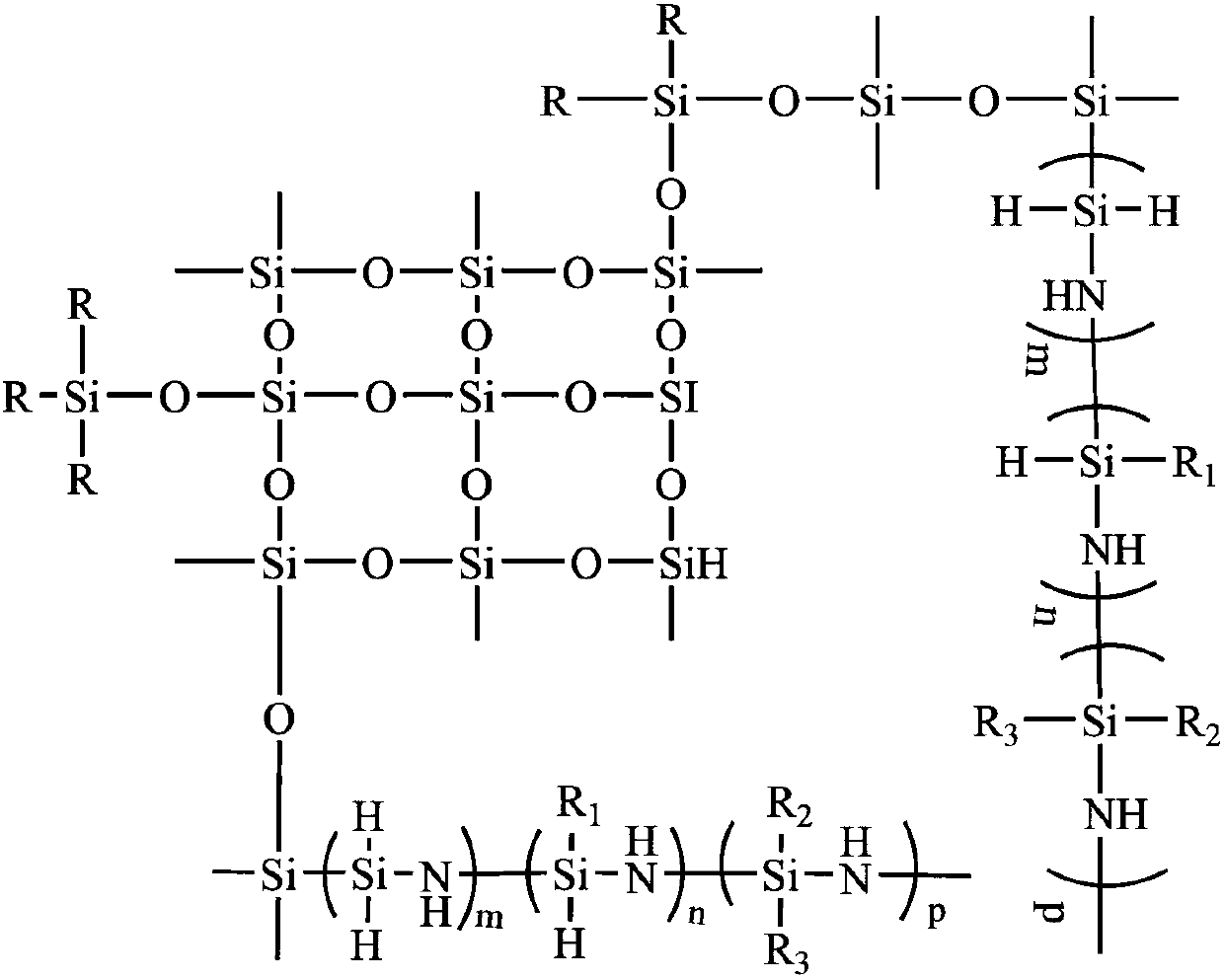

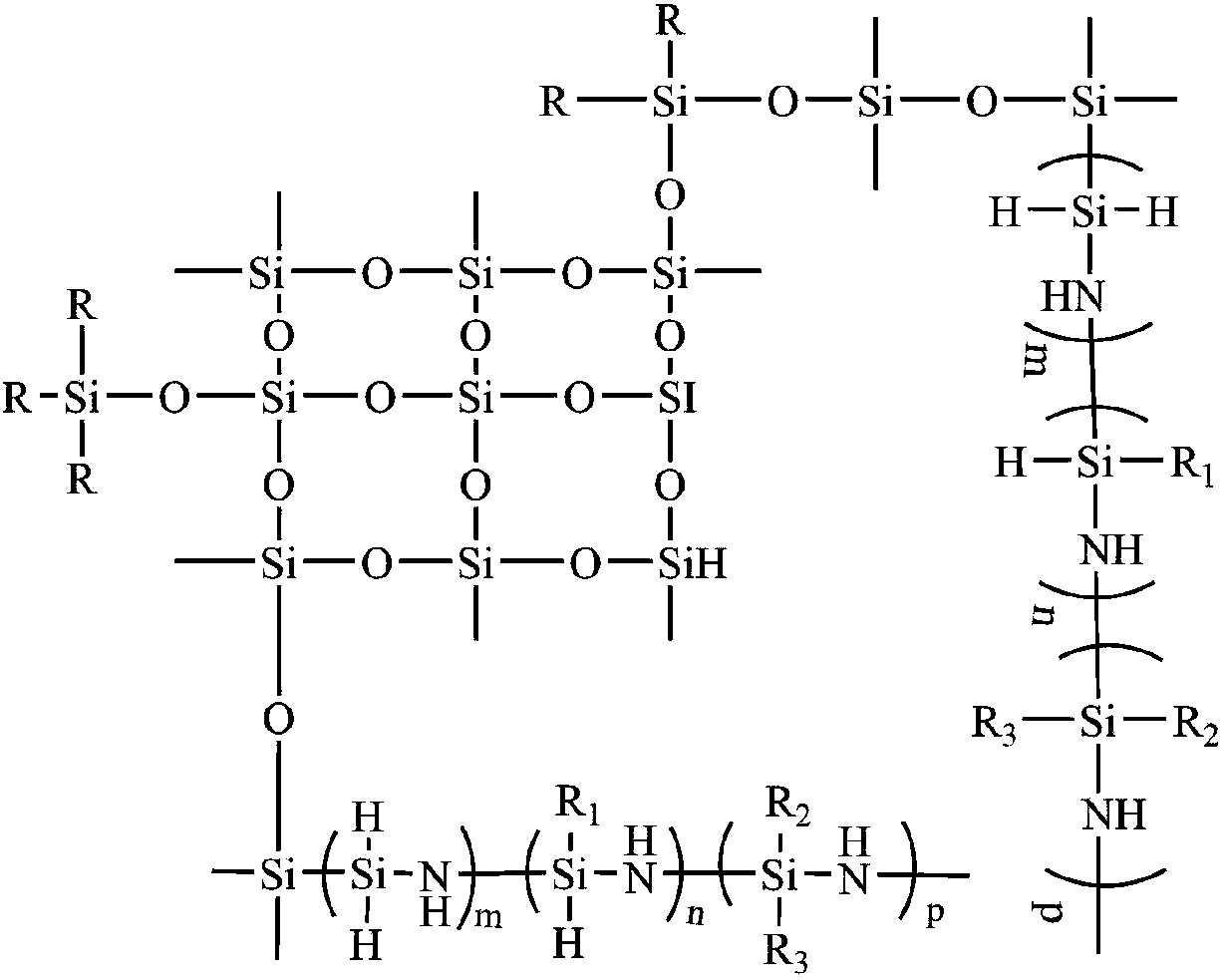

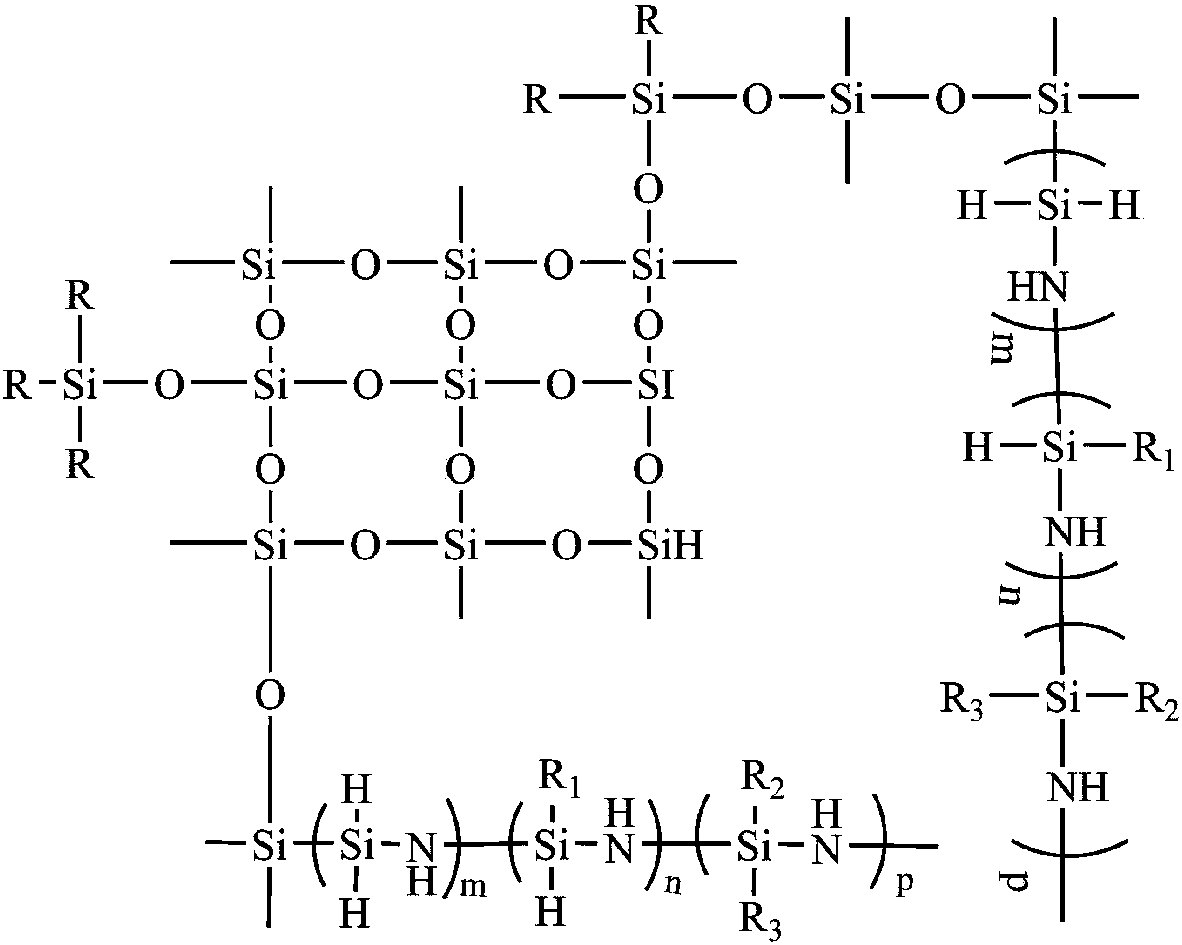

Comb polysilicone and solid electrolyte, preparation method and application thereof

ActiveCN103421190AExcellent mechanical propertiesFacilitate dissociationSecondary cellsElectricityHydrogen

The invention discloses a comb polysilicone and solid electrolyte, a preparation method and application thereof. Through additive reaction of polymethyl hydrogen siloxane with olefinic hydrocarbon, an alkoxysilane group and a carbonic ester group are led onto a branch chain, and the comb polysilicone is prepared. The preparation method is simple and the cost is low; the solid electrolyte prepared by taking the comb polysilicone as main raw material is high in electric conductivity at a low temperature, the electric cycling performance of the prepared all solid lithium ion battery is excellent, and the select range and the application field of the solid electrolyte material are expanded.

Owner:王海斌

Two-component tire bladder anti-adhesive agent

InactiveCN101962513AEffective protectionExtended service lifeAntifouling/underwater paintsPaints with biocidesEmulsionPulp and paper industry

The invention relates to a tire bladder anti-adhesive agent, which is a two-component tire bladder anti-adhesive agent, wherein component A emulsion mainly comprises hydroxyl dimethylsiloxane; component B emulsion mainly comprises poly(methylhydrosiloxane); and the tire bladder anti-adhesive agent also comprises an emulsifying agent, a defoaming agent, a bactericide deionized water. The tire bladder anti-adhesive agent can be used for spraying the inner surface of a green tire, and also can be directly used as a coating layer on a bladder. The tire bladder anti-adhesive agent provides good demolding property, lubricating property and exhausting property between the bladder and the tire, prolongs the service life of the bladder, makes the appearance of the tire smooth, prevents a mold from being polluted, does not contain any volatile organic matters, and reduces environmental pollution.

Owner:北京金源化学集团有限公司

Stable and efficacious soft solid product

InactiveUS6986885B2Improve efficacyImprove stabilityCosmetic preparationsToilet preparationsPolymer scienceActive agent

A low residue antiperspirant and / or deodorant composition in the form of an anhydrous, surfactant-free and antiseptic alcohol-free suspension exhibiting a syneresis of less than 8% is disclosed which comprises: (a) a dimethicone / vinyldimethicone crosspolymer composition made by reacting a polymethylhydrogensiloxane with an alpha, omega-divinylpolydimethyl siloxane for which the dimethicone / vinyldimethicone crosspolymer composition is used at a concentration of 0.5–10% in cyclomethicone; (b) polyethylene beads having a density in the range of 0.91–0.98 grams / cm3 and a particle size in the range of 5–40 microns, wherein the polyethylene beads are used in an amount of at least 2% by weight based on the total weight of the composition; (c) a volatile silicone; (d) an emollient or mixture of two or more emollients; and (e) an effective amount of an antiperspirant active material.

Owner:COLGATE PALMOLIVE CO

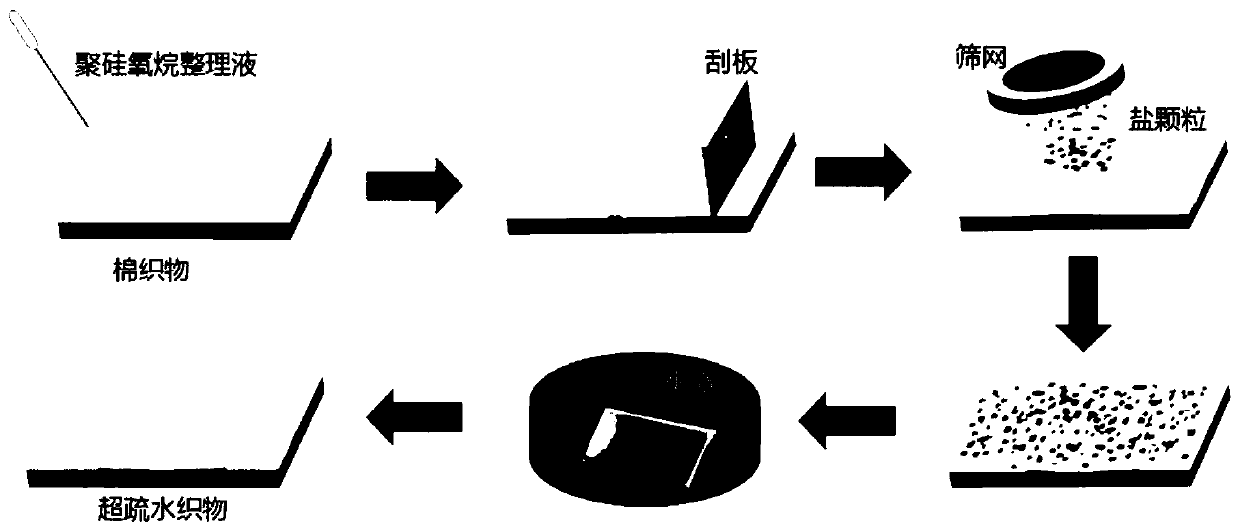

Fabric super-hydrophobic surface preparation method

ActiveCN109837758AGood chemical stabilityIncreased durabilityPhysical treatmentVegetal fibresWater bathsCross-link

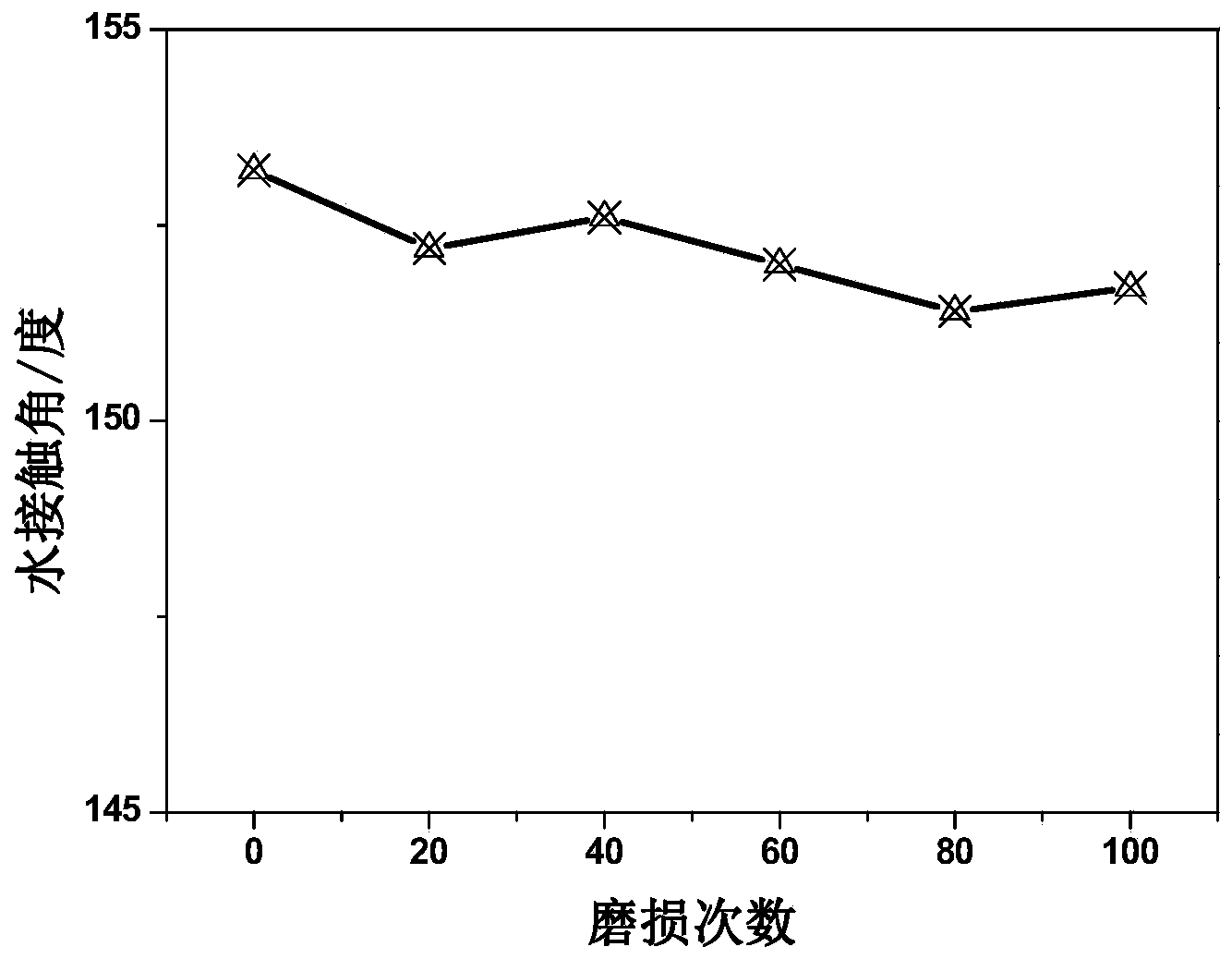

The invention provides a fabric super-hydrophobic surface preparation method. The method at least includes steps: well mixing polydimethylsiloxane, hydroxyl polydimethylsiloxane, polymethylhydrosiloxane and a cross-linking agent to obtain polysiloxane finishing liquid; coating the fabric surface with the polysiloxane finishing liquid, and uniformly spreading a layer of sodium chloride particles onthe fabric surface to obtain a deposited coating; curing the deposited coating, subjecting the cured fabric to water-bath ultrasonic treatment, and drying to form the fabric super-hydrophobic surface. A super-hydrophobic fabric prepared according to the method is excellent in chemical stability and mechanical durability and has great water pressure resistance and breathability, a static contact angle of the super-hydrophobic surface reaches 155.47 degrees, a rolling angle is 5.5 degrees, breathability reaches 90.06mm / s, water pressure resistance reaches 2733Pa, and hydrophobicity of the fabric is almost unchanged after repeated washing and wear.

Owner:HEBEI BENFA GARMENT CO LTD

Heat-resistant and flame-retardant nylon tube

InactiveCN105482448AImprove the disadvantage of high water absorptionImprove water absorptionPolymer scienceMagnesium borate

The invention discloses a heat-resistant and flame-retardant nylon tube. The heat-resistant and flame-retardant nylon tube is prepared from nylon 66, nylon 6, polymethylhydrosiloxane, epoxy resin, titanate coupling agent modification nano-zinc oxide, modification needle-like wollastonite, an amination carbon nano-tube, nano-silicon dioxide, red phosphorus, melamine cyanurate, organic nano-montmorillonite, glass fibers, magnesium borate whiskers, basic zinc carbonate nanofibers, ethylene-propylene-diene monomer, ethylene-bis-stearamide, calcium pimelate, zinc pimelate, silane coupling agent, aluminum diethylphosphinate and lanthanum stearate. The heat-resistant and flame-retardant nylon tube is good in heat resistance and flame retardancy, high in strength and excellent in impact resistance, and a nylon tube formed by the heat-resistant and flame-retardant nylon tube is good in overall performance and long in service life.

Owner:安徽都邦电器有限公司

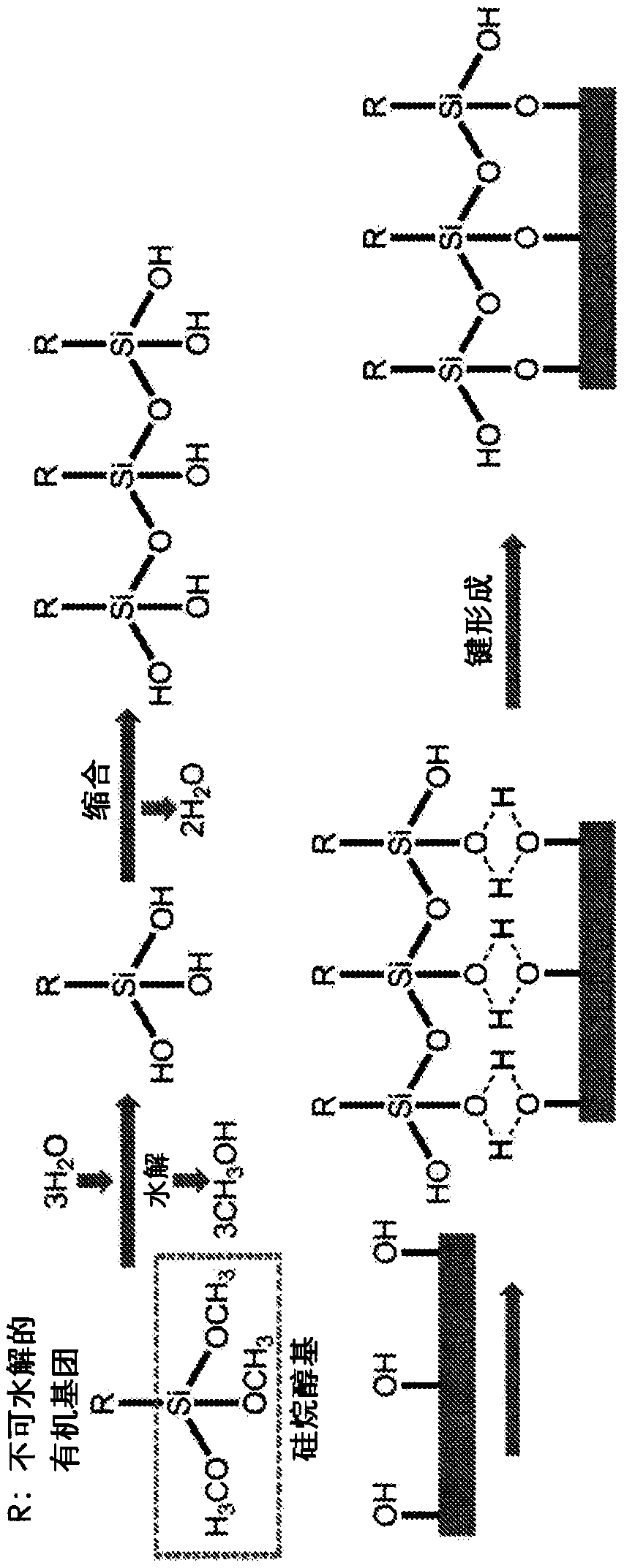

Method for preparing hydrophobic material on basis of polymethylhydrosiloxane

The invention relates to a method for preparing a hydrophobic material on the basis of polymethylhydrosiloxane and belongs to the field of materials. The method comprises the following steps: (1) after an alkaline catalyst is dissolved in a solvent, adding polymethylhydrosiloxane and mixing uniformly, adding a silicon dioxide precursor and mixing uniformly, adding water and mixing uniformly; and (2) soaking a matrix in a product obtained in the step (1) and drying the matrix. The method has the beneficial effects that polymethylhydrosiloxane with low price is adopted for replacing fluorine-containing silane which is high in price in the prior art, so that the cost is saved; the preparation method is simple, the reaction condition is mild, a complex reaction device is not needed and the preparation method is suitable for industrial production.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Solvent-type organic silicon stone protectant and preparation method thereof

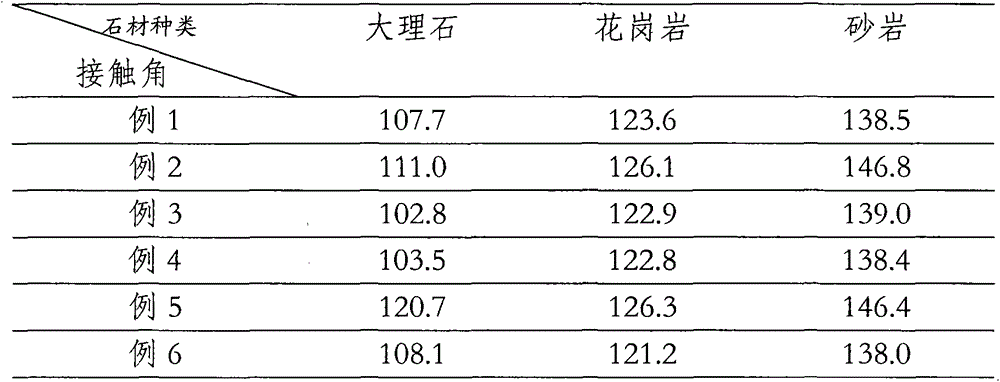

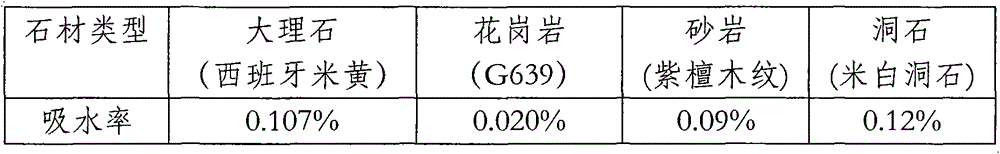

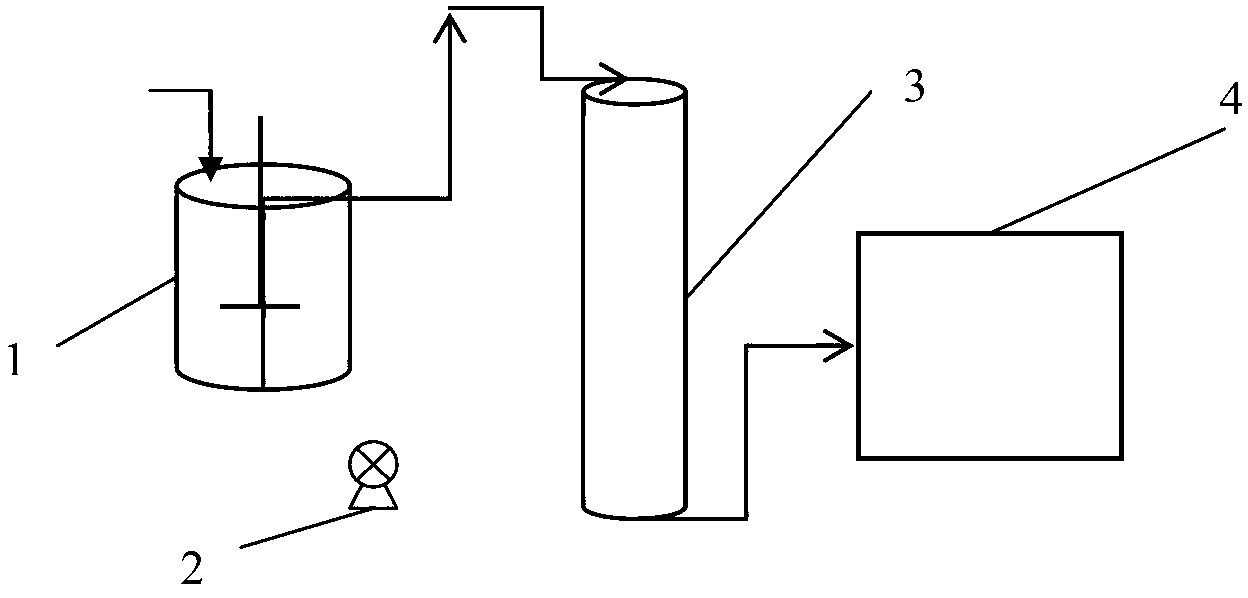

The invention discloses a solvent-type organic silicon stone protectant and a preparation method thereof. The protectant is characterized by comprising the following polymer monomers by volume percent: at least one alkyl alkoxy silane of which the adding volume accounts for 1% to 10% of the total volume of the polymers, at least one polymethylhydrosiloxane of which the adding volume accounts for 1% to 10% of the total volume of the polymers, at least one titanate catalyst of which the adding volume accounts for 0.05% to 1% of the total volume of the polymers, and at least one solvent oil-type organic solvent of which the adding volume accounts for 79% to 97.95% of the total volume of the polymers. The preparation method comprises the following steps: evenly mixing the alkyl alkoxy silane and the polymethylhydrosiloxane in proportion in partial organic solvents at a room temperature; then carrying out a catalytic reaction by adding the catalyst; and finally, adding the organic solvent and diluting to reach a certain concentration. The protectant which has good permeability can be used for deeply protecting stone and is good in air permeability and recoatability. The protectant is simple in preparation method, simple and convenient to coat as well as relatively low in cost, thereby being suitable for industrial mass production.

Owner:XIAMEN NORNS TECH

Silicon oil preparation method

InactiveCN103275323ASolve the problem of molecular weight too broadLow monomer residueSide reactionCopolymer

The invention discloses a silicon oil preparation method. The method comprises the following steps: adding reaction raw materials comprising octamethylcyclotetrasiloxane, hexamethyldisiloxane and polymethylhydrosiloxane, or octamethylcyclotetrasiloxane and tetramethyldisiloxane, or octamethylcyclotetrasiloxane and heptamethyltrisiloxane to a mixing kettle, uniformly mixing, carrying out preheating treatment, metering through a catalysis bed filled with an acidic anion resin catalyst, and reacting to obtain silicon oil. A fluidized bed is utilized to substitute a production technology grating an organosilicon copolymer intermediate through a general catalyst continuous process. The monomer residual quantity is reduced to below 5%, a too wide problem of the polymer molecule weight is solved, and the polymer molecule weight distribution index is less than 1.1. The reaction time is shortened, and the generation of side reactions is effectively avoided. The method has the characteristics of product quality improvement, simple operation, low energy consumption and the like.

Owner:JIANGSU OSIC PERFORMANCE MATERIALS CO LTD

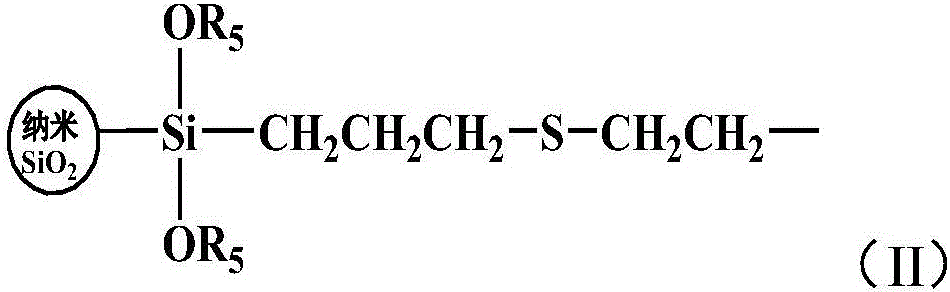

Mercapto nano-silica and polyether dual modified organosilicon surfactant and preparation method

InactiveCN106633078AAvoid technical problems of uneven dispersionRegulation and control of hydrophilicity and hydrophobicityTransportation and packagingMixingClick chemistryCompound (substance)

The invention belongs to the technical field of organosilicon surfactants, and particularly relates to a mercapto nano-silica and polyether dual modified organosilicon surfactant and a preparation method. The invention discloses a method for preparing the organosilicon surfactant by combining a mercapto-ene-click chemical method and a hydrosilylation method for dual modification. The mercapto nano-silica and polyether dual modified organosilicon surfactant is successfully synthesized from vinyl-containing polymethylhydrosiloxane as a structural main body, and the product has both good oleophilic and Hydrophilically properties and compatibility due to the introduction of double functional groups. Besides, the application prospect of the organosilicon surfactant is broadened by introducing the mercapto functional group with high chemical stability.

Owner:JIANGSU MAYSTA CHEM

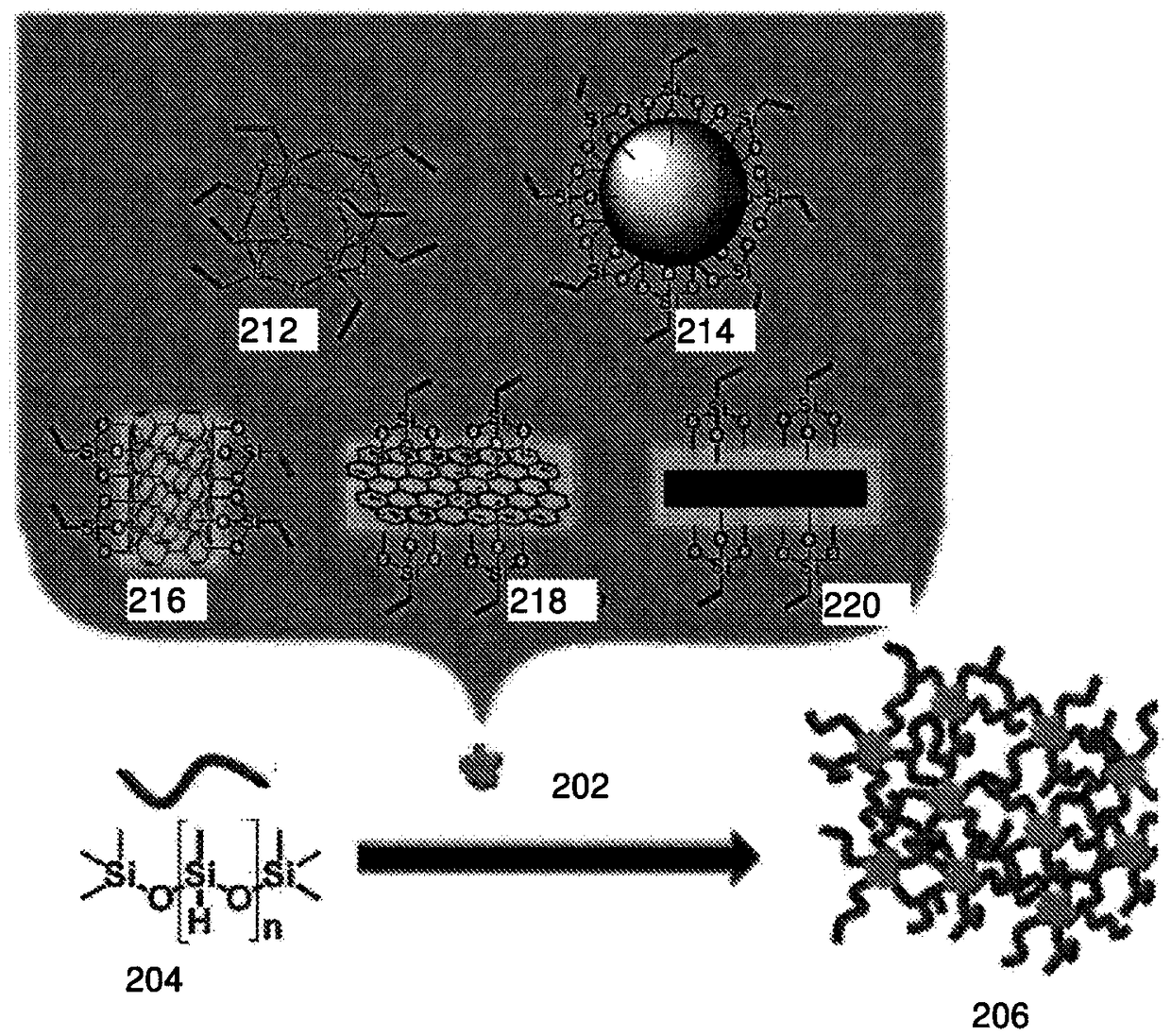

Durable superhydrophobic coating

The invention relates to a polymeric coating material comprising a surface-functionalized such as vinyl functionalized nanoadditive covalently bound to an organopolysiloxane, such as poly(methylhydrosiloxane) (PMHS), wherein the nanoadditive comprises (a) a nanoadditive substrate and (b) a linker covalently bound by a silyloxy moiety to the nanoadditive substrate at one end and said organopolysiloxane at the other end. The invention also relates to a method of making such a coating material, the use of such a coating material, a method for coating a substrate with such a coating material, anda coated substrate obtainable by such a method.

Owner:AGENCY FOR SCI TECH & RES

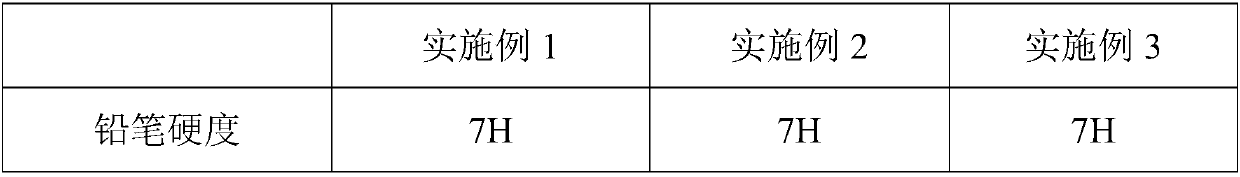

Super-hard organic silicone hydrophobic glass resin and preparation method thereof

The invention relates to super-hard organic silicone hydrophobic glass resin and a preparation method thereof. Under the catalysis of a Karsted catalyst, active silicon-hydrogen bonds and carbon-carbon double bonds in hydrogen-containing polymethylhydrogensiloxane, vinyl MQ silicone resin, polyhydroxy polysiloxane, and amino silicone oil are crosslinked, and active silicon-hydrogen bonds and hydroxyl or amino in the hydrogen-containing polymethylhydrogensiloxane, the vinyl MQ silicone resin, the polyhydroxy polysiloxane, and the amino silicone oil are crosslinked, so that three-dimensional network-shaped organic silicone resin is formed, and then in the presence of a catalyst, polysilazane reacts with hydroxyl, amino or carbon-carbon double bonds in the organic silicone resin through active -Si-H to be grafted on the molecular chain of the organic silicone resin. The glass resin provided by the invention can be self-catalyzed and cured at a room temperature, and has uniform film formation without cracking or powdering; the film has good water resistance and stain resistance, and the contact angle of water and the film formed after the glass resin coats the surface of a tile can reach 130 degrees; the transparency is good, and the light transmittance is up to 80%; and the hardness of the film is high, the pencil hardness is up to 7H or above, and the film can withstand the hightemperature of 300 DEG C.

Owner:HUNAN QIWEI TECH CO LTD

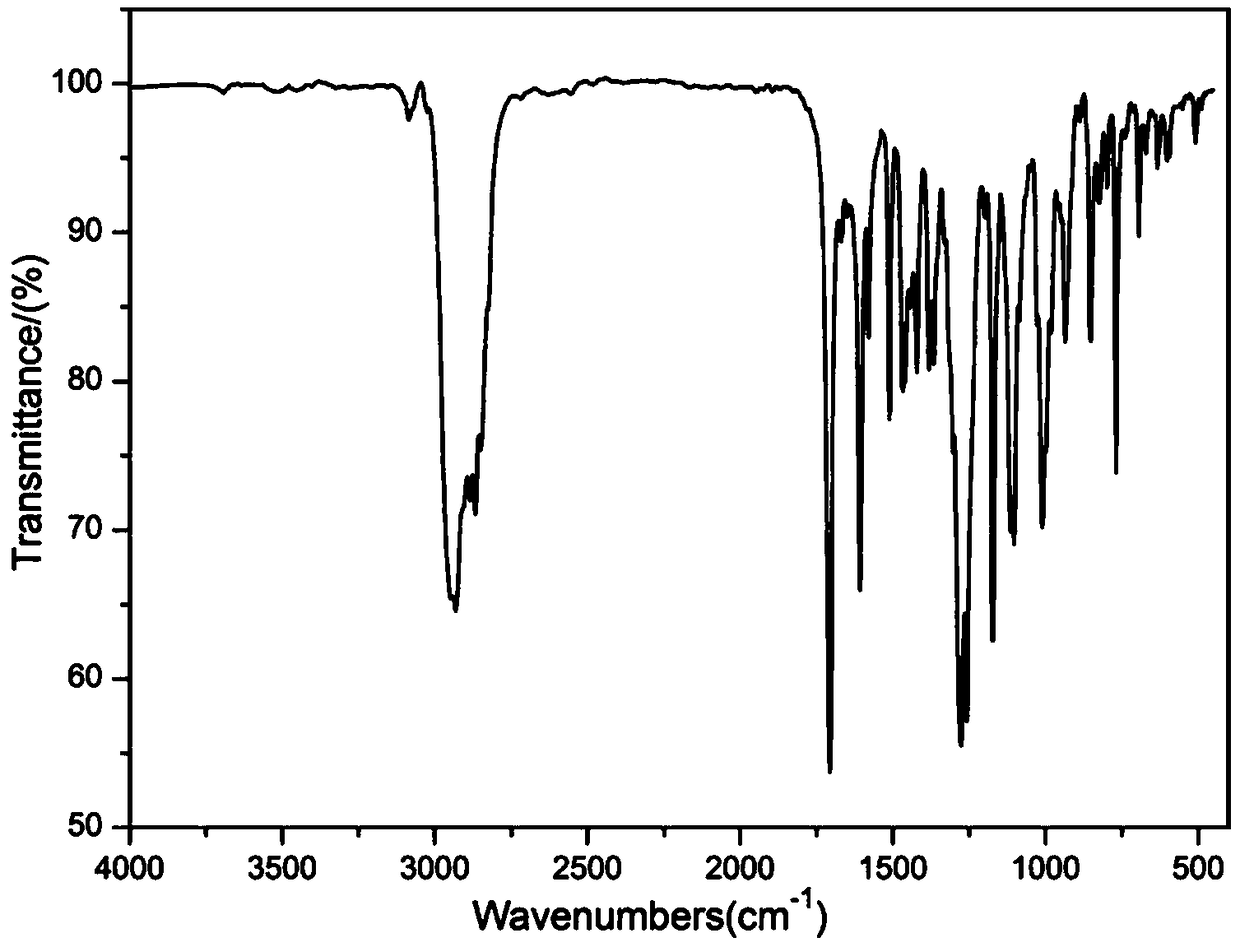

Hydrophobic palladium/metal organic framework material, preparation method thereof and application of hydrophobic palladium/metal organic framework material to synthesis of 2,5-dimethylfuran

ActiveCN108654693AImprove hydrophobicityEasy to prepareOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsAlcoholHydrogen

The invention discloses a hydrophobic palladium / metal organic framework material which is a solid catalytic material prepared by taking a porous metal organic framework as a carrier, introducing elemental palladium by using an impregnation-reduction method, and then, carrying out polydimethylsiloxane coating treatment. The invention further discloses a method for preparing 2,5-dimethylfuran by selectively catalyzing hexose by using the hydrophobic palladium / metal organic framework material. The method comprises the steps: dissolving hexose into alcohol, and carrying out a reaction at 70-130 DEG C for 0.25-12 h under the action of an acidic additive by taking the hydrophobic palladium / metal organic framework material as a catalyst and polymethylhydrosiloxane as a hydrogen donor, wherein theconcentration of hexose in alcohol is 0.2-10wt%, and the total quantity of Pd contained in the used hydrophobic palladium / metal organic framework material is 0.1-5mol% relative to hexose. The hydrophobic palladium / metal organic framework material disclosed by the invention is stable in structure, and the catalytic efficiency is obviously higher than that of a commercially available palladium carbon and common palladium / metal organic framework material under the same condition.

Owner:NANJING AGRICULTURAL UNIVERSITY

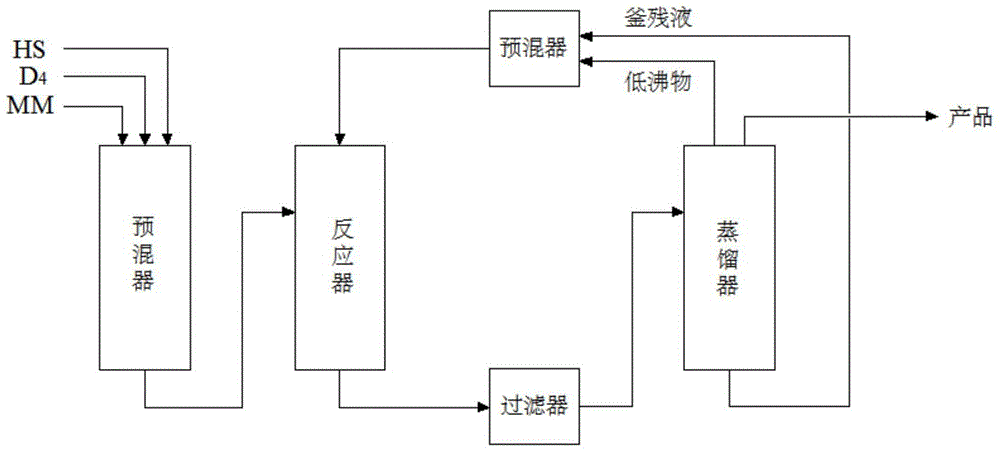

Method for continuous preparation of polysiloxane by fixed-bed reactor

The invention belongs to the technical field of organic silicon materials and relates to a method for continuous preparation of polysiloxane by a fixed-bed reactor. The method includes: taking B2O3-MoO3 / ZrO2 solid super acid as a catalyst and taking polymethylhydrosiloxane (HS), octamethylcyclotetrasiloxane (D4) and hexamethyldisiloxane (MM) as raw materials, well mixing the raw materials in a premixer and heating to a certain temperature, continuously feeding raw material mixed liquor through the upper end of the fixed-bed reactor to realize reaction, delivering filtered products into a distiller, removing low-boiling-point substances, evaporating a target product out, and feeding mixed liquid of the low-boiling-point substances and kettle residual liquor into the reactor to prepare the target product. The method is low in reaction temperature, raw material utilization rate and target product yield are high, operation process is simple and easy to realize continuous production, the solid acid is low in corrosion effect on equipment and destructive effect on environment, and energy saving and environment friendliness are realized.

Owner:JIANGSU MAYSTA CHEM

Multienzyme cleaning agent for medical appliances

ActiveCN108949381AInhibition of activityAvoid damageOrganic detergent compounding agentsAmpholytes/electroneutral surface-active compoundsSodium chloroacetateCleansing Agents

The invention discloses a multienzyme cleaning agent for medical appliances, and belongs to the technical field of medical treatment. According to the multienzyme cleaning agent, 4-formylbenzeneboronic acid is added to effectively inhibit the protease activity during storage, and protease activity is prevented from being reduced; beta cyclodextrin and nonionic surfactant Pluronic-F88 in an aqueoussolution are subjected to host-guest recognition, a hydrogen bond is formed from adjacent beta-cyclodextrins through cavity peripheral cyclodextrin, and functions of other cleaning activators cannotbe influenced; polymethylhydrosiloxane, hexamethyldisiloxane and like are used as raw materials, tert-amino in intermediate and sodium chloroacetate perform a quaternization reaction, the appliance surface is protected from secondary pollution; and baicalin and bacterium prodigiosum polysaccharides are added to reduce rejection and pyrogen reaction caused by over-high load of microorganisms, and the use safety of medical appliances can be improved. The multienzyme cleaning agent can solve the problems of low bioenzyme activity and poor cleaning effect in an enzyme cleaning agent since proteasein current multi-enzyme cleaning agent can decompose other bioenzyme in a solution.

Owner:JIANGXI KEXING BIOLOGICAL ENG CO LTD

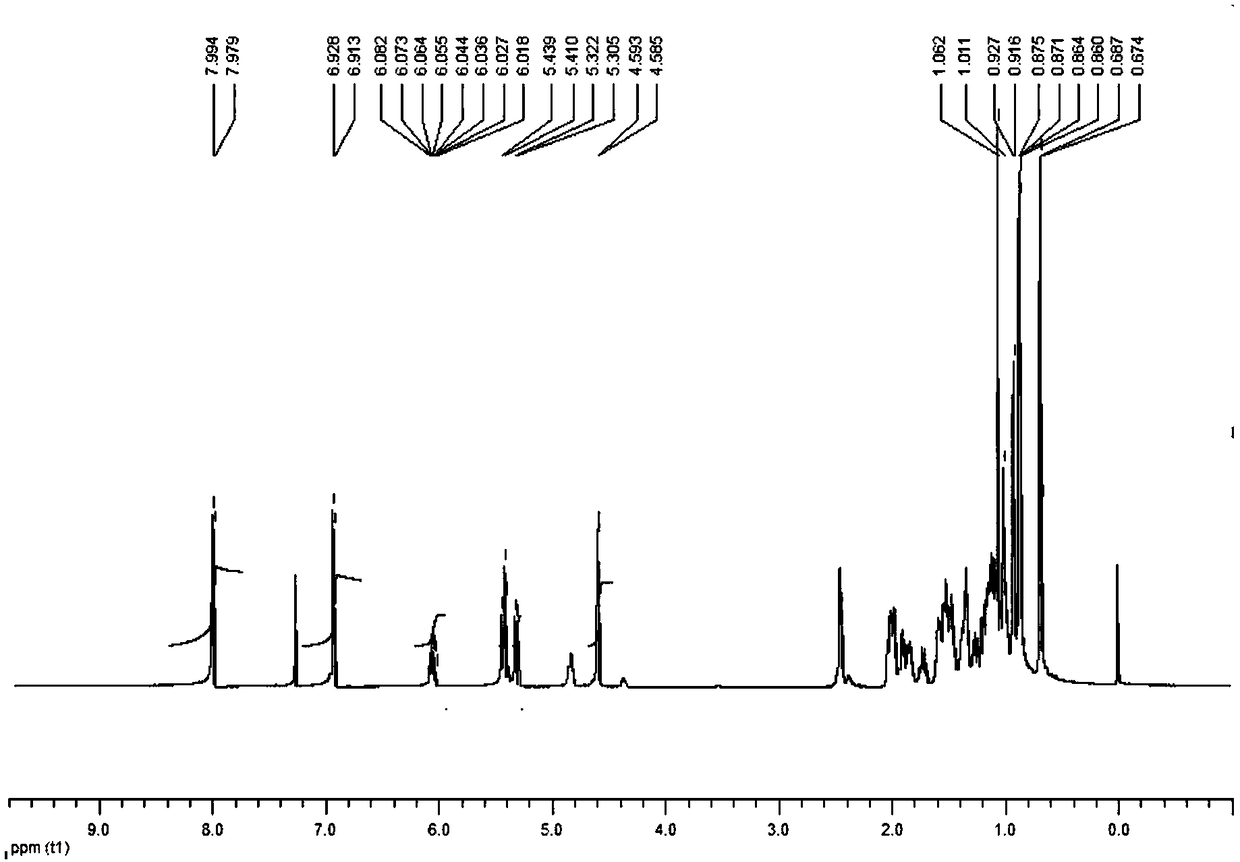

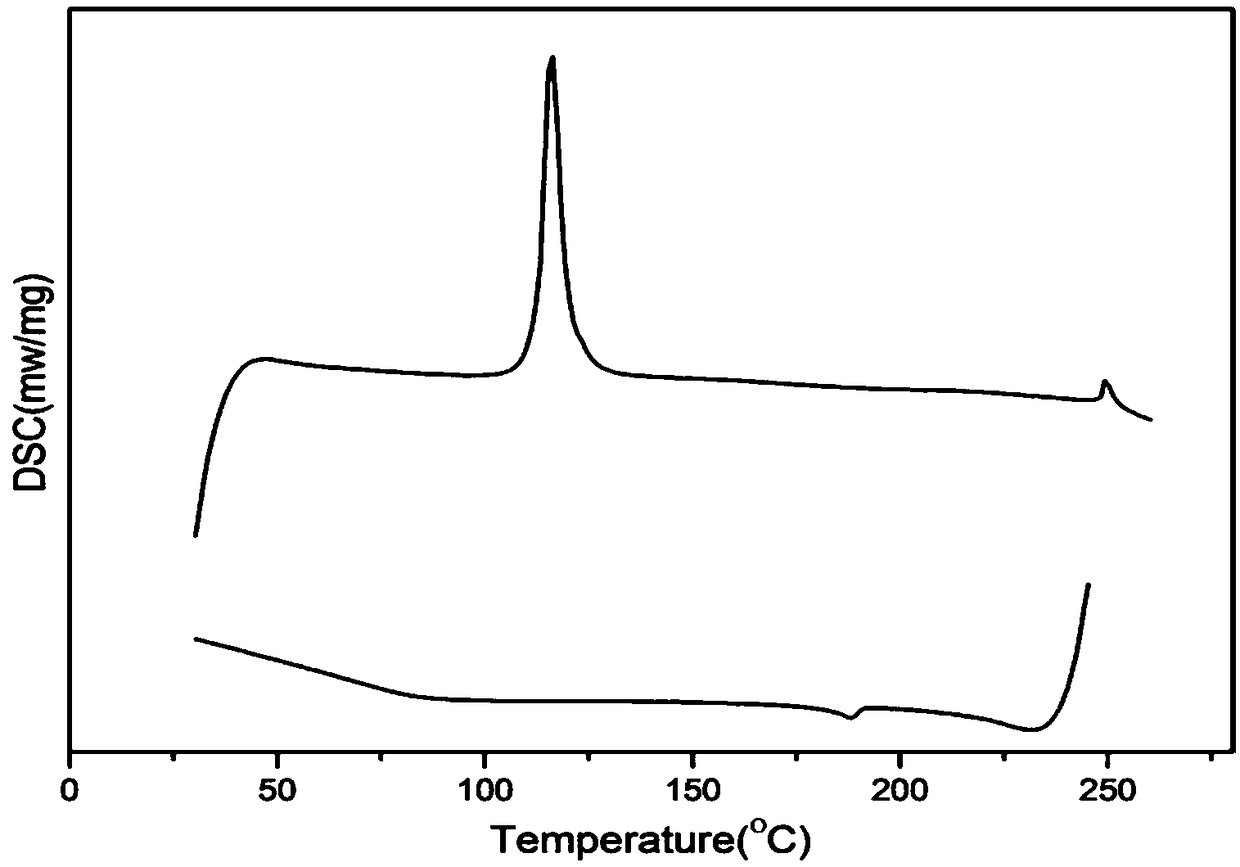

Bonded fluorescent rare earth liquid crystal ionomer and preparation method thereof

ActiveCN109021981ALiquid crystalWide range of liquid crystalLiquid crystal compositionsLuminescent compositionsCholesterolFluorescence

The invention discloses a bonded fluorescent rare earth liquid crystal ionomer and a preparation method thereof, and belongs to the technical field of polymer materials. The bonded fluorescent rare earth liquid crystal ionomer is prepared by graft copolymerization of a liquid crystal monomer 4-cholesterol allyloxy benzoate M1, acrylic acid M2, a rare earth complex M3 and polymethylhydrosiloxane PMHS. Compared with liquid crystal polymers, strong fluorescence appears at specific wavelength. Compared with common rare earth complexes, the prepared rare earth liquid crystal ionomer has liquid crystallinity and wide liquid crystal range, and has the liquid crystal range reaching 199 DEG C. In addition, through thermogravimetric analysis, the prepared rare earth liquid crystal ionomer has good heat stability, and can have wide application prospect in optics, machinery, electronics, display and other fields. The preparation method is simple, easy to operate, high in yield and prone to industrialized production.

Owner:XUZHOU UNIV OF TECH

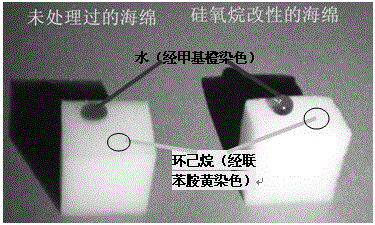

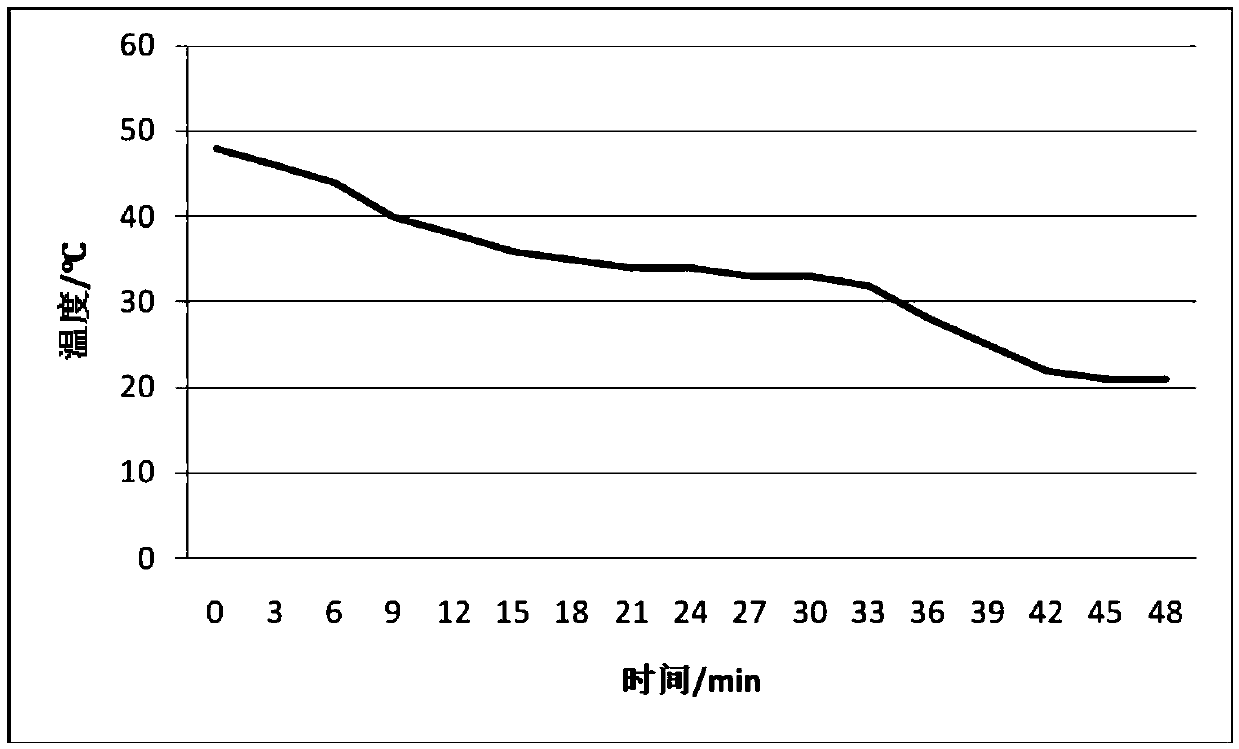

Method for preparing efficient oil-water separation sponge

ActiveCN105688846AEfficient separationAutomatic separationFatty/oily/floating substances removal devicesOther chemical processesSuperhydrophobeEcological environment

The invention discloses a method for preparing efficient oil-water separation sponge. Porous sponge sold on the market is adopted as a base body, an addition reaction of polymethylhydrosiloxane (PHMS) and tetravinyl tetramethylcyclotetrasiloxane (Vid4) is adopted, an organosiloxane coating is established on the surface of the sponge, that is, an organic silicone hydrophobic material is obtained, and thus the efficient oil-water separation sponge with a high superhydrophobicity characteristic and a super-oleophilicity characteristic is prepared. The method is simple in operation, raw materials are cheap and easy to obtain, the prepared efficient oil-water separation sponge can separate oil / water mixtures in a layered mode efficiently and automatically and can be recycled, and a new thought is provided for developing an intelligent oil-water separation material and relieving huge pressure of the ecological environment.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Silica gel composition and preparation method thereof

The invention provides a silica gel composition. The silica gel composition comprises a silica gel body consisting of components A and B in a mass ratio of 1 to 5, wherein the component A comprises, by mass, 34-83% of dimethyl polysiloxane, 12-65% of polymethylhydrosiloxane and 1-5% of catalysts; the component B is prepared from, by mass, 34-83% of dimethyl polysiloxane, 12-65% of polymethylhydrosiloxane and 1-5% of cross-linking agent; the silica gel composition further contains, based on the total mass of the silica gel body, 0.4-1% of fumed silica, 3.3-4% of prefoamed polymer microspheres and 20-30% of phase change paraffin or 40-50% of solid-state phase change microcapsules; wherein, the prefoamed polymer microspheres are prefoamed polystyrene microspheres, and shells of the prefoamed polystyrene microspheres are made of polystyrene. The silica gel composition is low in specific gravity and weight, has high thixotropy and a good phase change function and is particularly suitable for preparing silica gel prosthesis products. The invention further provides a preparation method of the silica gel composition. According to the preparation method, steps are few, the process is short, operation is easy and convenient, and preparation cost is low.

Owner:SUZHOU MEISHANZI GARMENTS CO LTD

Stable and efficacious soft solid product

A low residue antiperspirant and / or deodorant composition in the form of an anhydrous, surfactant-free and antiseptic alcohol-free suspension exhibiting a syneresis of less than 8% is disclosed which comprises: (a) a dimethicone / vinyldimethicone crosspolymer composition made by reacting a polymethylhydrogensiloxane with an alpha, omega-divinylpolydimethyl siloxane for which the dimethicone / vinyldimethicone crosspolymer composition is used at a concentration of 0.5-10% in cyclomethicone; (b) polyethylene beads having a density in the range of 0.91-0.98 grams / cm3 and a particle size in the range of 5-40 microns, wherein the polyethylene beads are used in an amount of at least 2% by weight based on the total weight of the composition; (c) a volatile silicone; (d) an emollient or mixture of two or more emollients; and (e) an effective amount of an antiperspirant active material.

Owner:COLGATE PALMOLIVE CO

Heatproof impact-resistant nylon pipe dedicated for automobile

The invention discloses a heatproof impact-resistant nylon pipe dedicated for automobile. The nylon pipe is prepared by extruding a modified nylon composite material, which comprises the following raw materials in parts by weight: 100 parts of nylon, 20 to 35 parts of low density polyethylene, 3 to 10 parts of maleic anhydride grafted polyethylene, 3 to 8 parts of polymethylhydrosiloxane, 5 to 15 parts of epoxy resin, 3 to 10 parts of nano calcium carbonate, 2 to 10 parts of aminated carbon nanotube, 3 to 10 parts of nano silicon dioxide, 5 to 12 parts of melamine cyanurate, 1 to 5 parts of organic nano montmorillonite, 2 to 10 parts of polytetrafluoroethylene, 5 to 15 parts of ethylene propylene diene monomer, 2 to 5 parts of ethylene bisstearamide, 0.5 to 2 parts of calcium stearate, 1 to 3 parts of coupling agent, 15 to 35 parts of diethyl aluminum phosphinate, and 1 to 2.5 parts of lanthanum stearate. The provided heatproof impact-resistant nylon pipe dedicated for automobile has the advantages of excellent heatproof, flame retardant, and impact resistant properties and long service life.

Owner:安徽都邦电器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com