Low release quantity additive halogen-free flame-retardant heat-conduction organic silicon pouring sealant and preparation method thereof

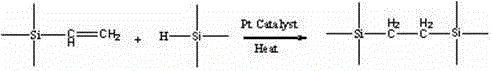

A technology of silicone potting and addition molding, which is used in the fields of low outgassing, thermal conductive addition silicone liquid potting, and halogen-free flame retardant. It can solve the problem of high outgassing and achieve good fluidity and excellent thermal conductivity. and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Preparation of base rubber: at room temperature (25°C), 120 parts of α,ω divinylpolydimethylsiloxane with a volatile content of 0.3% and a viscosity of 500mPa.s, and its ethylene base content of 0.5%; 100 parts of amorphous alumina with a volatile content of 0.21% and an average particle size of 5 μm; 140 parts of aluminum hydroxide with a volatile content of 0.18% and an average particle size of 3 μm; a volatile content of 0.28 %, 60 parts of heavy calcium carbonate with an average particle size of 30 μm are added to the kneader, heated up to 120 ° C and mixed for 1 h, then ground twice by a three-roller machine and cooled to obtain a base compound.

[0041] (2) Preparation of component A: Take 100 parts of the base rubber, add 3.5 parts of polymethylhydrogensiloxane (Si-H :Si-Vi~1.65), 0.2 parts of 1,3-diethyl-1,1,3,3-tetramethyldisiloxane, stirred for 2h, mixed evenly and removed under vacuum condition of 0.08-0.09MPa After bubbling, make up component A.

[004...

Embodiment 2

[0049] Other contents are as in the examples, and the preparation steps are as follows:

[0050] (1) Preparation of base rubber: at room temperature (25°C), 100 parts of α,ω divinylpolydimethylsiloxane with a volatile content of 0.25% and a viscosity of 100mPa.s, and its ethylene base content of 0.8%; 50 parts of zinc oxide with a volatile content of 0.24% and a particle size of 40-50 μm; 50 parts of magnesium hydroxide with a volatile content of 0.15% and a particle size of 20-30 μm; a volatile content of 0.28 %, 100 parts of glass beads with an average particle size of 100 μm were added to the kneader, heated to 150 ° C and mixed for 2 hours, then ground by a three-roll machine twice and then cooled to obtain the base rubber.

[0051] (2) Preparation of component A: Take 100 parts of base rubber, add 3.7 parts of polymethylhydrogensiloxane (Si-H :Si-Vi~1.85), 0.1 parts of 1,3,5,7 tetravinyl-1,3,5,7 tetramethylcyclotetrasiloxane, stirred for 3 hours and mixed evenly, under t...

Embodiment 3

[0055] (1) Preparation of base rubber: at room temperature (25°C), 110 parts of α,ω divinylpolydimethylsiloxane with a volatile content of 0.3% and a viscosity of 1000mPa.s, and its ethylene Base content of 0.4%; 100 parts of boron nitride with a volatile content of 0.25% and a particle size of 3-10 μm; 200 parts of zinc borate with a volatile content of 0.18% and a particle size of 20-30 μm; a volatile content of 0.28 %, 150 parts of silicic acid powder with a particle size of 80-100 μm was added to the kneader, heated to 100°C and mixed for 3 hours, then ground by a three-roll machine for 3 times and then cooled to obtain the base rubber.

[0056] (2) Preparation of component A: Take 100 parts of base rubber, add 2.5 parts of polymethylhydrogensiloxane (Si-H :Si-Vi~1), 0.01 part of 1-ethynyl-1-cyclohexanol, stirred for 0.5h and mixed evenly, then removed the air bubbles under the vacuum condition of 0.08-0.09MPa, and prepared into component A.

[0057] (3) Preparation of co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com