Low-oil-permeability high-strength addition-type silica gel and preparation method thereof

An addition-type, high-strength technology, applied in the field of silicone gel, can solve problems such as low elongation, easy oil leakage on the surface of the gel, and insufficient vulcanization degree, so as to improve strength and toughness, avoid brittle cracking, and improve tensile strength. The effect of elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In this embodiment, a low-permeability high-strength addition-type silicone gel has the following raw material composition, n Si-H / n Si-Vi =1.87:

[0044] 100 parts vinyl silicone oil

Vinyl content 0.2%

5 parts single-ended vinyl silicone oil

Vinyl content 0.2%

26 parts hydrogen silicone oil H1

Viscosity 1000mPa·s, hydrogen content 0.05%

10 parts hydrogen silicone oil H2

Hydrogen content 0.015%

0.1 Inhibitor

1-ethynyl-1-cyclohexanol

3ppm catalyst

Chloroplatinic acid-divinyltetramethyldisiloxane complex

[0045] The preparation method of the above-mentioned low oil-permeable high-strength addition type silicone gel is as follows:

[0046] a. Add the vinyl silicone oil, single-end vinyl silicone oil, hydrogen-containing silicone oil H1, hydrogen-containing silicone oil H2, and inhibitors into a planetary mixer or a high-speed dispersing mixer and mix for 20 minutes;

[0047] b. Add the catalyst, va...

Embodiment 2

[0049] In this embodiment, a low-permeability high-strength addition-type silicone gel has the following raw material composition, n Si-H / n Si-Vi =1.93:

[0050] 100 parts vinyl silicone oil

Vinyl content 0.3%

10 parts single-ended vinyl silicone oil

Vinyl content 0.1%

16.5 parts hydrogen silicone oil H1

Viscosity 3000mPa·s, hydrogen content 0.12%

22 parts hydrogen silicone oil H2

Hydrogen content 0.01%

0.5 Inhibitor

3,5-Dimethyl-1-hexynyl-3-ol

8ppm catalyst

Chloroplatinic acid-divinyltetramethyldisiloxane complex

[0051] The preparation method of the above-mentioned low oil-permeable high-strength addition type silicone gel is as follows:

[0052]a. Add the vinyl silicone oil, single-end vinyl silicone oil, hydrogen-containing silicone oil H1, hydrogen-containing silicone oil H2, and inhibitors into a planetary mixer or a high-speed dispersing mixer and mix for 20 minutes;

[0053] b. Add the catalyst...

Embodiment 3

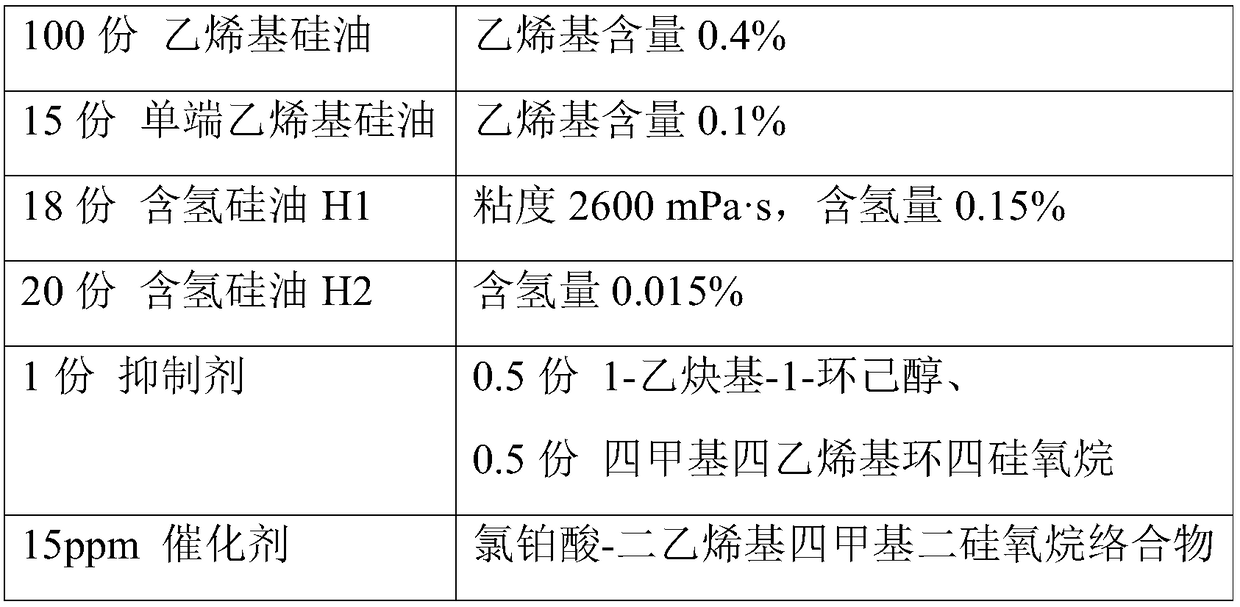

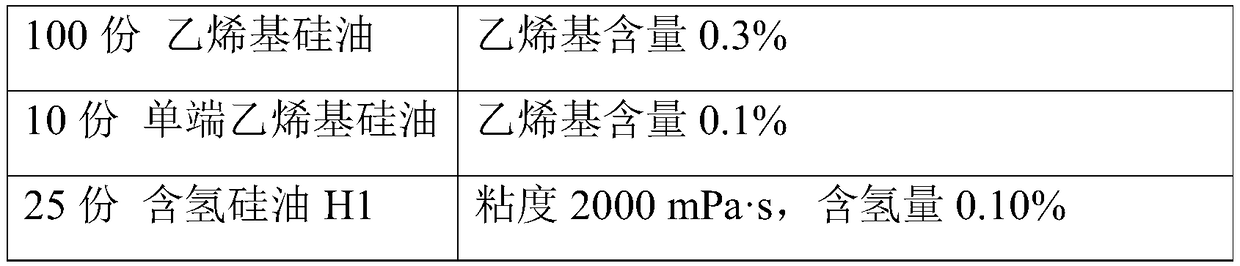

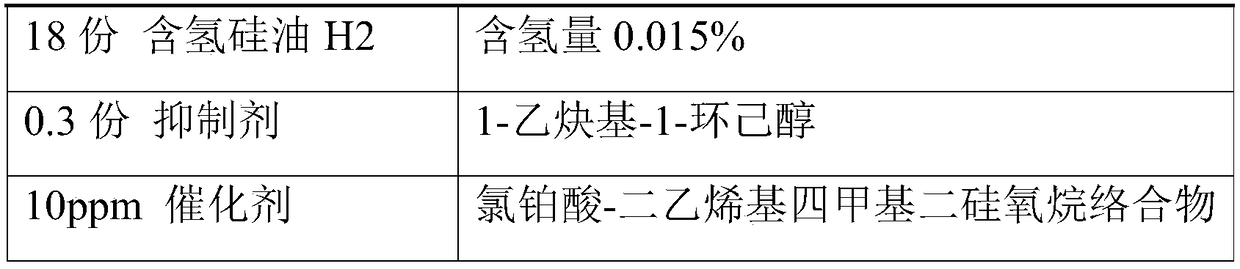

[0055] In this embodiment, a low-permeability high-strength addition-type silicone gel has the following raw material composition, n Si-H / n Si-Vi =1.76:

[0056]

[0057] The preparation method of the above-mentioned low oil-permeable high-strength addition type silicone gel is as follows:

[0058] a. Add the vinyl silicone oil, single-end vinyl silicone oil, hydrogen-containing silicone oil H1, hydrogen-containing silicone oil H2, and inhibitors into a planetary mixer or a high-speed dispersing mixer and mix for 20 minutes;

[0059] b. Add the catalyst, vacuumize and stir for 10 minutes to obtain the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com