Component packaging method for warped flexible solar cells for stratospheric aircraft

A flexible solar cell and packaging method technology, applied in electrical components, semiconductor devices, circuits, etc., can solve the problems of short circuit of components, easy residual air bubbles on the back of the support substrate and the battery, unfavorable for the application of stratospheric aircraft, etc., to improve the working characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

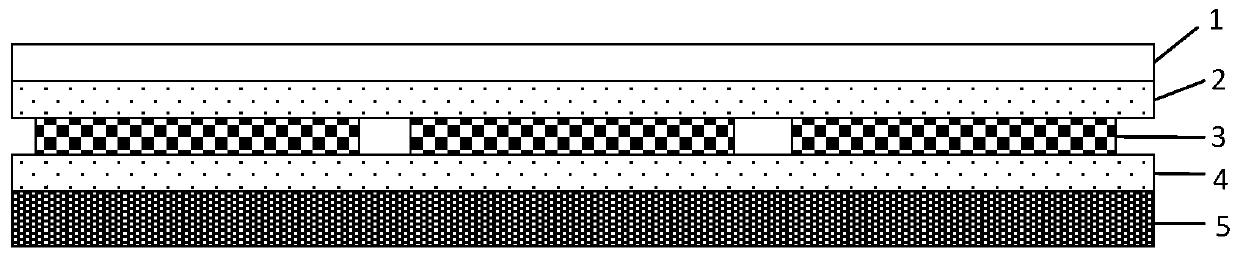

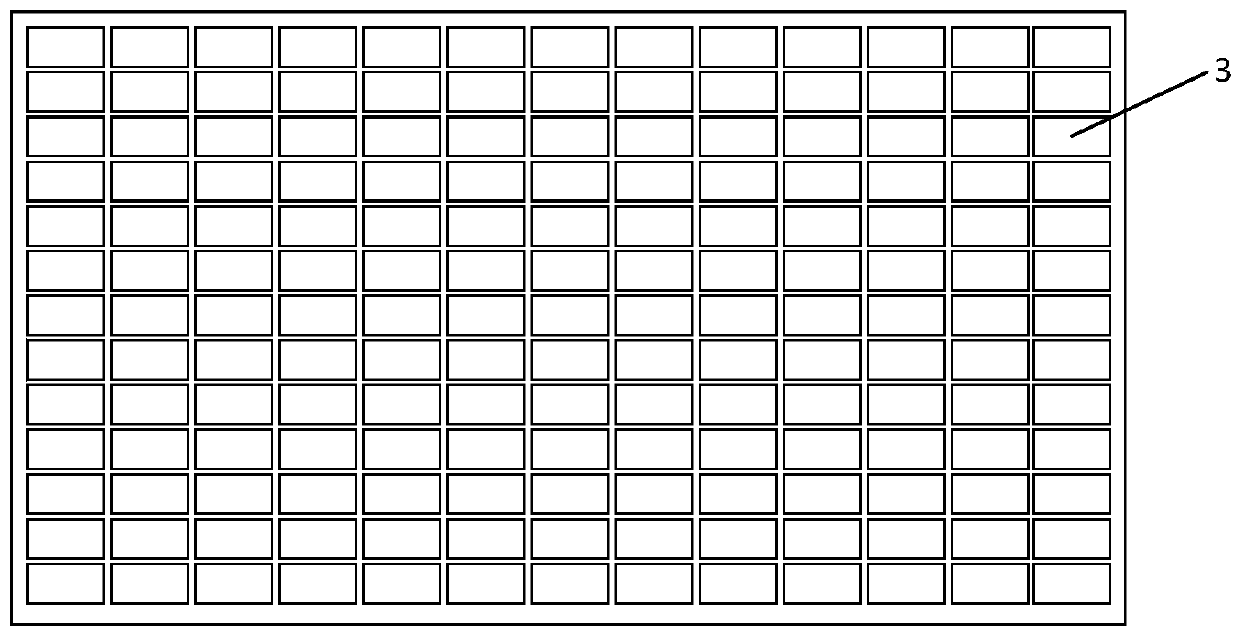

[0026] figure 1 It is a schematic diagram of the encapsulation structure of a typical flexible thin-film solar cell module for stratospheric aircraft. From top to bottom, there are upper surface encapsulation film 1, transparent hot-melt adhesive film 2, flexible thin-film solar cell 3, white hot-melt adhesive film 4 and The lower surface encapsulation film 5 .

[0027] In this example, the upper surface packaging film 1 adopts ethylene-tetrafluoroethylene copolymer (abbreviated as ETFE) film, which has good weather resistance and optical transmittance. In this example, the thickness is 25 μm and the average optical transmittance is 92%. The ETFE film is made of high-quality ETFE film, and at the same time, corona treatment is performed on the side that is bonded to the polyolefin film, so that it has high surface activity and improves the adhesion to the polyolefin film.

[0028] In this example, the transparent hot-melt adhesive film 2 is a transparent polyolefin (POE) film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com