Carbon fiber flexible electric heating body and preparation method thereof

A carbon fiber heating and carbon fiber technology, applied in the direction of electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of low electrothermal conversion rate, increase safety hazards, poor waterproof effect, etc., and achieve good insulation and electrothermal conversion efficiency High, the effect of improving creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

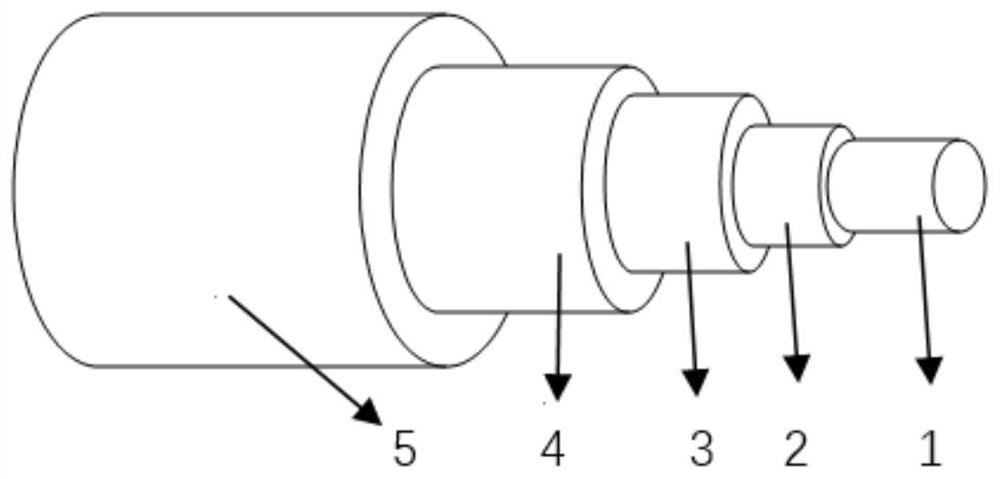

[0050] According to the resistance requirements of the heating body, 3K carbon fiber T700 filaments are used for rope braiding, the twist is 4 twists / cm, and the number of joints is 6 shares. The length of carbon fibers used in the electric heating body is calculated according to the following formula: carbon fiber filament length (unit: cm) = Rated voltage (unit: V)×rated voltage (unit: V) / rated power (unit: W) / resistance per unit length of carbon fiber (unit: Ω / cm), the length of the carbon fiber calculated in this embodiment is: 220×220 / 1000 / 1.7 = 28.47 cm. The surface of the prepared rope-like carbon fiber was subjected to instantaneous electrification to remove glue, the voltage was 85V, and the electrification time was 2s. After removing the glue, the carbon fiber rope is coated with surface radiation setting glue, the glue content is 25wt%, wherein the setting glue is made of phenolic resin as the base material, and the filler is nano-scale silicon carbide high-radiati...

Embodiment 2

[0052] According to the resistance requirements of the heating body, 3K carbon fiber T800 filaments are used for rope braiding, the twist is 3 twists / cm, and the number of joints is 4 shares. The length of carbon fibers used in the electric heating body is calculated according to the following formula: carbon fiber filament length (unit: cm) = Rated voltage (unit: V)×rated voltage (unit: V) / rated power (unit: W) / resistance per unit length of carbon fiber (unit: Ω / cm), the length of the carbon fiber calculated in this embodiment is: 220×220 / 1500 / 1.7=18.98cm The surface of the rope-shaped carbon fiber is subjected to instantaneous electrification and deglue treatment, the voltage is 80V, and the electrification time is 2s. After removing the glue, the carbon fiber rope is coated with surface radiation setting glue, the glue content is 20wt%, wherein the setting glue is made of unsaturated polyester resin as the base material, and the filler is nano-scale silicon carbide high-rad...

Embodiment 3

[0054] According to the resistance requirements of the heating body, 3K carbon fiber T300 filaments are used for ribbon braiding. The total number of single bundles of fibers in the braiding belt is 12 strands. The length of carbon fibers used in the electric heating body is calculated according to the following formula: carbon fiber length (unit: cm) = rated voltage ( Unit: V) × rated voltage (unit: V) / rated power (unit: W) / carbon fiber unit length resistance (unit: Ω / cm), the length of the carbon fiber calculated in this embodiment is: 220 × 220 / 1200 / 1.7 = 23.73 cm. The strip-shaped carbon fiber was subjected to instantaneous electrification to remove glue on the surface, the voltage was 80V, and the electrification time was 2s. After removing the glue, the carbon fiber rope is coated with surface radiation setting glue, the glue content is 30wt%, wherein the setting glue is made of thermosetting polyurethane as the base material, and the filler is nano-scale silicon car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com