Method for continuous preparation of polysiloxane by fixed-bed reactor

A fixed bed reactor and polysiloxane technology, applied in the field of organic silicon materials, can solve the problems of reduced catalytic performance, damage of ion exchange resin, etc., and achieve the effects of low reaction temperature, high mechanical strength, and avoidance of residual impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

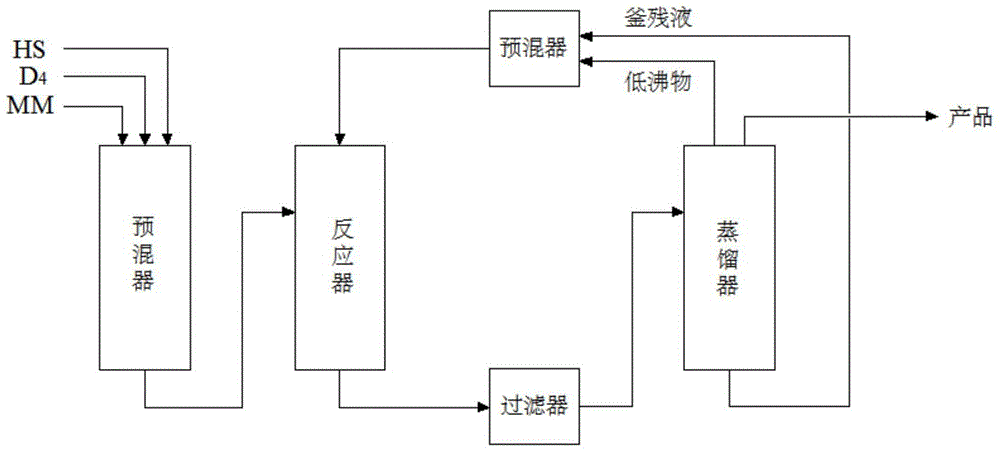

Image

Examples

Embodiment 1

[0025] Add 50.0 grams of zirconium hydroxide and 77.6 grams of ammonium paramolybdate into 200 ml of distilled water and mix evenly, stir at 80°C for 12 hours, dry at 105°C, press into tablets at 10MPa, and sieve 40-60 mesh particles , baked at 800°C for 3 hours. Take 50.0 grams of particles and immerse in 40 milliliters of boric acid aqueous solution with a concentration of 5.0 mg boron / ml for 12 hours, dry at 105°C, and roast at 400°C for 3 hours to obtain boron-modified B 2 o 3 -MoO 3 / ZrO 2 A solid acid catalyst, wherein the molar ratio of elements is B:Mo:Zr=0.28:1:5.

[0026] The reactor used is a tubular fixed bed with a length of 40 cm and an inner diameter of 20 mm. Put 50 grams of the above-mentioned solid acid catalyst into the middle section of the reaction tube, according to the mass ratio HS:D 4 : MM=0.41:6.56:1 Put the raw materials into the pre-mixer and mix them evenly, and preheat to 40°C. The mass space velocity is 40h -1 , after the product flows thr...

Embodiment 2

[0029] Add 100.0 grams of zirconium hydroxide and 77.6 grams of ammonium paramolybdate into 200 ml of distilled water and mix evenly, stir at 80°C for 12 hours, dry at 105°C, press into tablets at 10MPa, and sieve 40-60 mesh particles , Baked at 800°C for 3 hours, cooled and taken out. Get 50.0 grams of granules and soak in 40 milliliters of boric acid aqueous solution with a concentration of 5.0 mg boron / ml for 12 hours, dry at 105°C, and roast at 400°C for 3 hours to obtain B 2 o 3 -MoO 3 / ZrO 2 The catalyst, wherein the molar ratio of elements is B:Mo:Zr=0.51:1:10.

[0030] The preparation conditions of polysiloxane were the same as in Example 1. Target product MD for one-way reaction 7 D, 3 M yield was 38%.

[0031] Pass the mixture of low boiling matter and bottom liquor into the reactor again to prepare the target product MD 7 D, 3 M, calculate the target product MD after reaction 7 D, 3 M overall yield was 81%.

Embodiment 3

[0033] Add 100.0 grams of zirconium hydroxide and 51.7 grams of ammonium paramolybdate into 200 ml of distilled water and mix evenly, stir at 80°C for 12 hours, dry at 105°C, press into tablets at 10MPa, and sieve 40-60 mesh particles , Baked at 800°C for 3 hours, cooled and taken out. Get 50.0 grams of granules and soak in 40 milliliters of boric acid aqueous solution with a concentration of 5.0 mg boron / ml for 12 hours, dry at 105°C, and roast at 400°C for 3 hours to obtain B 2 o 3 -MoO 3 / ZrO 2 The catalyst, wherein the molar ratio of elements is B:Mo:Zr=0.74:1:15.

[0034]The preparation conditions of polysiloxane were the same as in Example 1. The target product yield for a single pass reaction was 36%.

[0035] Pass the mixture of low boiling matter and bottom liquor into the reactor again to prepare the target product MD 7 D, 3 M, calculate the target product MD after reaction 7 D, 3 M overall yield was 76%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com