Self-emulsifying acrylic acid organic silicon wax protection material as well as preparation method and application thereof

A silicone wax, self-emulsifying technology, used in coatings, textiles and papermaking, fiber processing, etc., can solve the problems of high price and limited application, and achieve the effect of high softening point, high dosage and remarkable lotus leaf effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1~6

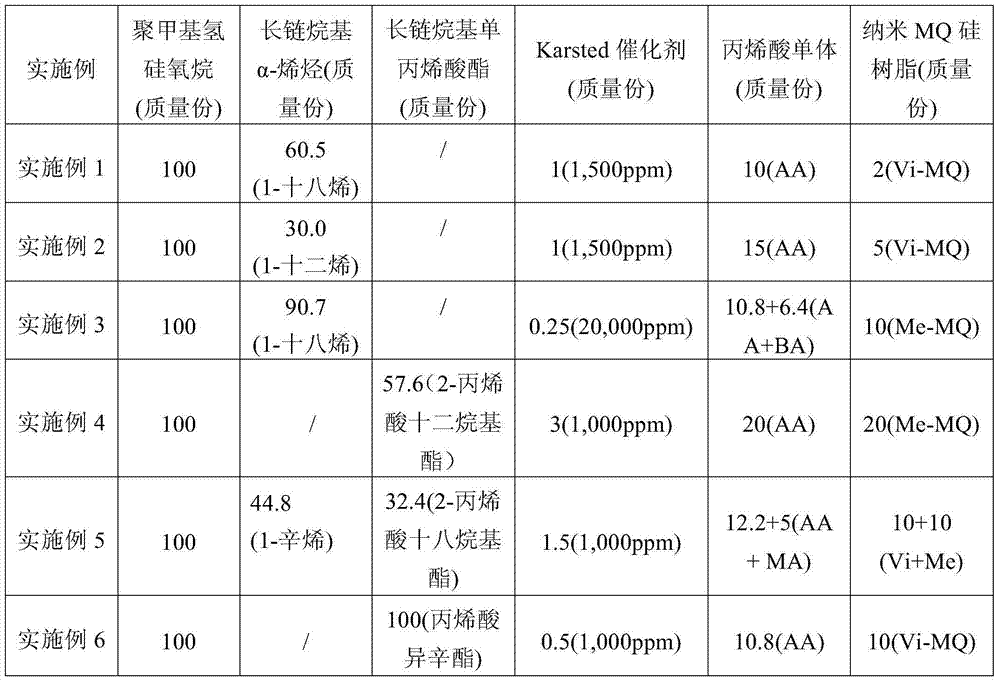

[0042] Examples 1-6: Preparation of self-emulsifying acrylic silicone wax protective material

[0043] The materials corresponding to Examples 1-6 were prepared according to the formula in Table 1.

Embodiment 1

[0047] In a 500mL three-necked flask equipped with a reflux device, 100g of low-hydrogen-containing polymethylhydrogensiloxane (also known as low-hydrogen silicone oil, with an active hydrogen content of 0.38wt%) and 60.5g of 1-18 ene, stirred, and added 1 g of platinum divinyltetramethyldisiloxane double-head complex solution (Karsted catalyst) (the concentration of platinum is 1,500 ppm, and the amount of platinum is low-hydrogen-containing polymethylhydrogen silicon 15ppm of oxane mass), heated to 120°C for 3 hours, cooled to 70°C, added 10g of acrylic acid (AA) and 2g of vinyl MQ silicone resin (Vi-MQ, the mass content of vinyl is 1.2wt%), 70 ℃ heat preservation reaction for 3 hours. Then it was cooled to room temperature to obtain the acrylic silicone wax polymer SAQ1. Take 100g of it, and slowly add 25g of ammonia water (the ammonia concentration is 5.6wt%) (a mixture of 10wt% ammonia water 14g and water 11g) under stirring to prepare a self-emulsifying acrylic silicone...

Embodiment 2

[0049] Into a 500mL three-necked flask equipped with a reflux device, 100g of low-hydrogen silicone oil (active hydrogen content of 0.38wt%) and 30.0g of 1-dodecene were sequentially added, stirred, and 1g of Karsted catalyst was added (the concentration of platinum was 1,000ppm, the amount of platinum used is 10ppm of the mass of low-hydrogen polymethylhydrosiloxane), heated to 100°C for 3 hours, cooled to 80°C, and then added 15g of acrylic acid (AA) and vinyl MQ silicone resin (Vi -MQ, vinyl mass content is 1.2wt%) 5g, heat preservation reaction at 80°C for 4 hours. Then cooled to room temperature to obtain acrylic silicone wax polymer SAQ2. Take 100g of it, and slowly add 25g of ammonia water (ammonia concentration is 10wt%) under stirring to prepare a self-emulsifying acrylic silicone wax protective material WSAQ2 with an effective concentration of 80%, and observe the stability of the self-emulsifying protective material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com