Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

280results about How to "Strong scratch resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

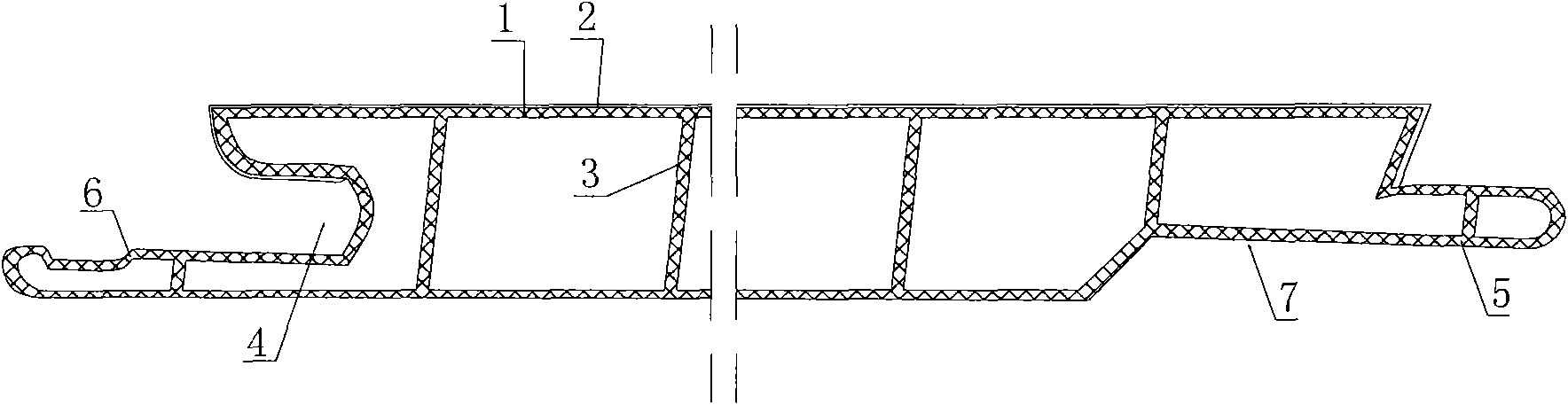

Environmental-friendly lead-free PVC ceiling sheet and manufacturing method and applications thereof

The invention relates to a ceiling sheet, in particular to an environmental-friendly lead-free PVC ceiling sheet and a manufacturing method and applications thereof. The environmental-friendly lead-free PVC ceiling sheet is obtained by blending the following components according to parts by weight and then extruding to mould: 50-100 parts of PVC resin SG-5, 15-50 parts of nano calcium carbonate, 3-10 parts of calcium zinc stabilizer, 1-3 parts of rutile titanium dioxide, 1-3 parts of CPE impact modifier, 1.5-5 parts of ACR enhancer, 0.2-0.8 part of stearic acid, 0.3-1.0 part of calcium stearate, and 0.2-0.4 part of PE wax. The PVC ceiling sheet is used as a novel environmental-friendly lead-free material of which the lead content is less than or equal to 200PPM, and is applicable to non-toxic places with high environmental requirements such as hospitals, operating rooms, baby rooms, food plants, and the like. The invention also discloses the manufacturing method of the ceiling sheet and ceiling gusset plates manufactured by the sheet.

Owner:HUAJUN PLASTIC BUILDING MATERIAL

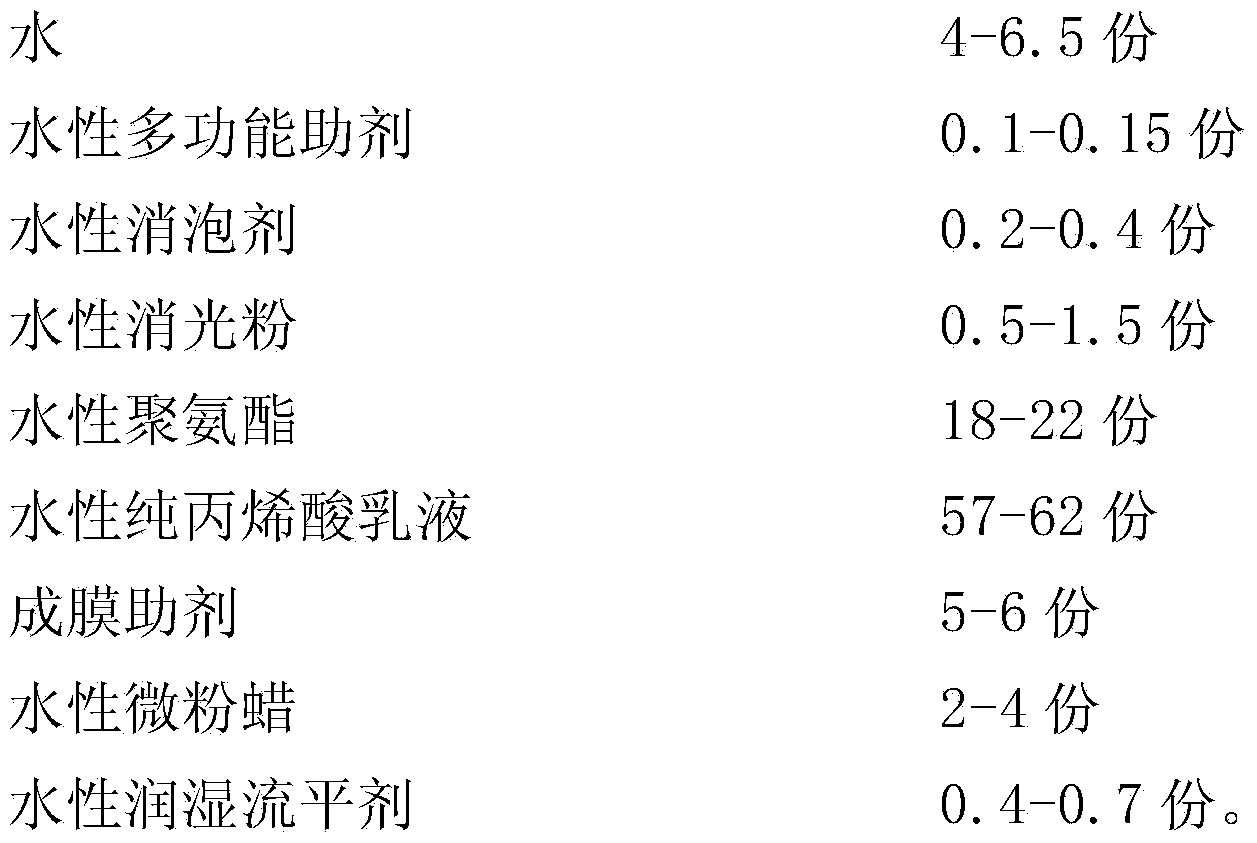

Aqueous woodenware matte clean finishing coat and its preparation method

The invention relates to a woodenware paint and a preparation method, and especially relates to an aqueous woodenware matte clean finishing coat and its preparation method, which belong to the paint field for building decoration. The provided aqueous woodenware matte clean finishing coat comprises the following raw materials by weight: 4-6.5 parts of water, 0.1-0.15 parts of aqueous multifunctional auxiliary agent, 0.2-0.4 parts of aqueous antifoaming agent, 0.5-1.5 parts of aqueous flatting silica, 18-22 parts of aqueous polyurethane, 57-62 parts of aqueous pure acrylic acid emulsion, 5-6 parts of film forming auxiliary agent, 2-4 parts of aqueous micro powder wax and 0.4-0.7 parts of aqueous wetting levelling agent. The prepared aqueous woodenware matte clean finishing coat has the advantages that the glossiness of a paint film is easily reduced, and the scratch resistance capability of the surface is strong.

Owner:SKSHU PAINT

Lead-free and cadmium-free bone china glaze and preparation process thereof

The invention discloses a lead-free and cadmium -free bone china glaze and a preparation process thereof. The lead-free and cadmium-free bone china glaze comprises the following compositions in percentage by weight: 50.0 to 62.0 percent of SiO2, 6.0 to 10.0 percent of Al2O3, 6.0 to 10.0 percent of CaO, 0.5 to 4 percent of MgO, 0.0 to 2.0 percent of BaO, 0.5 to 3.0 percent of SrO, 6.0 to 10.0 percent of ZnO, 2.0 to 6.5 percent of K2O, 1.0 to 5.0 percent of Na2O, 0.2 to 3.0 percent of Li2O, 1.0 to 3.0 percent of B2O3, 1.0 to 3.5 percent of ZrO2, 0.2 to 1.0 percent of La2O3, and 0.1 to 2.0 percent of P2O5. By optimizing the glaze formula, the glaze has no lead and cadmium, so the glaze is non-toxic and environment-friendly. The lead-free and cadmium-free bone china glaze and the preparation process thereof have the advantages of reducing the consumption of zinc oxide, overcoming the defects of soft glaze, easy scratching and color disadvantage caused by high zinc oxide content, and improving the hardness of the glaze by optimizing the chemical compositions of the glaze.

Owner:SHENZHEN YONG FENG YUAN IND

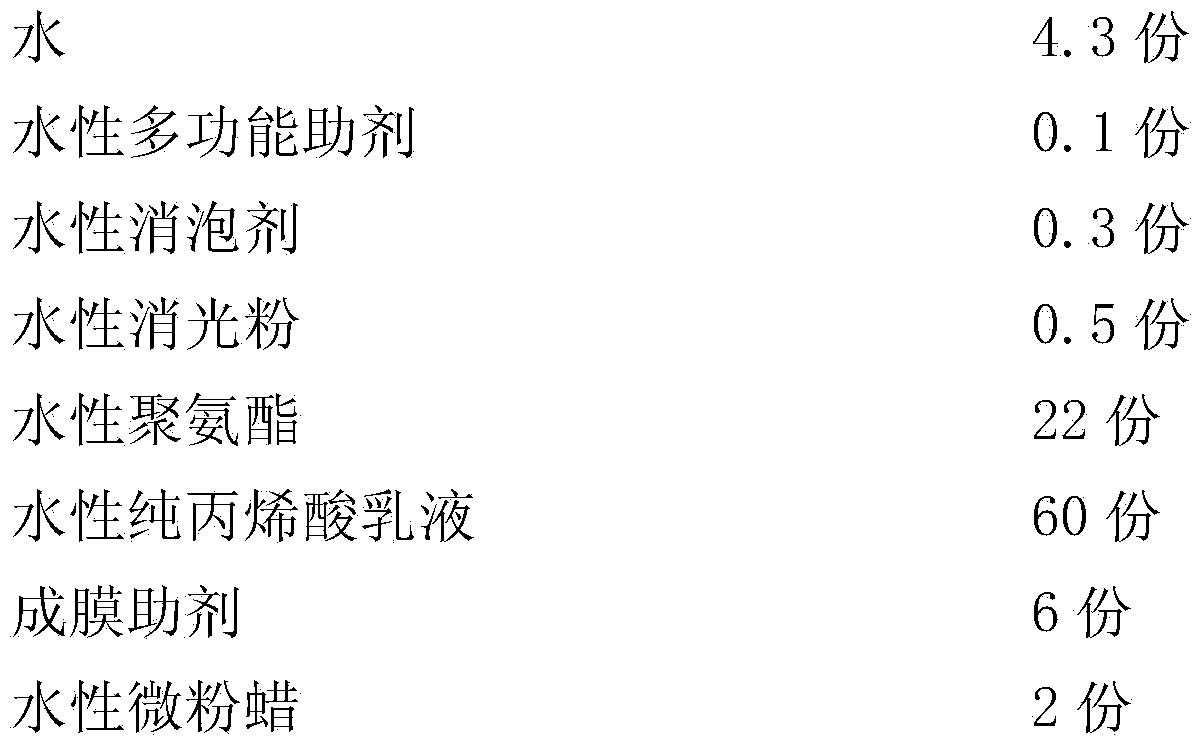

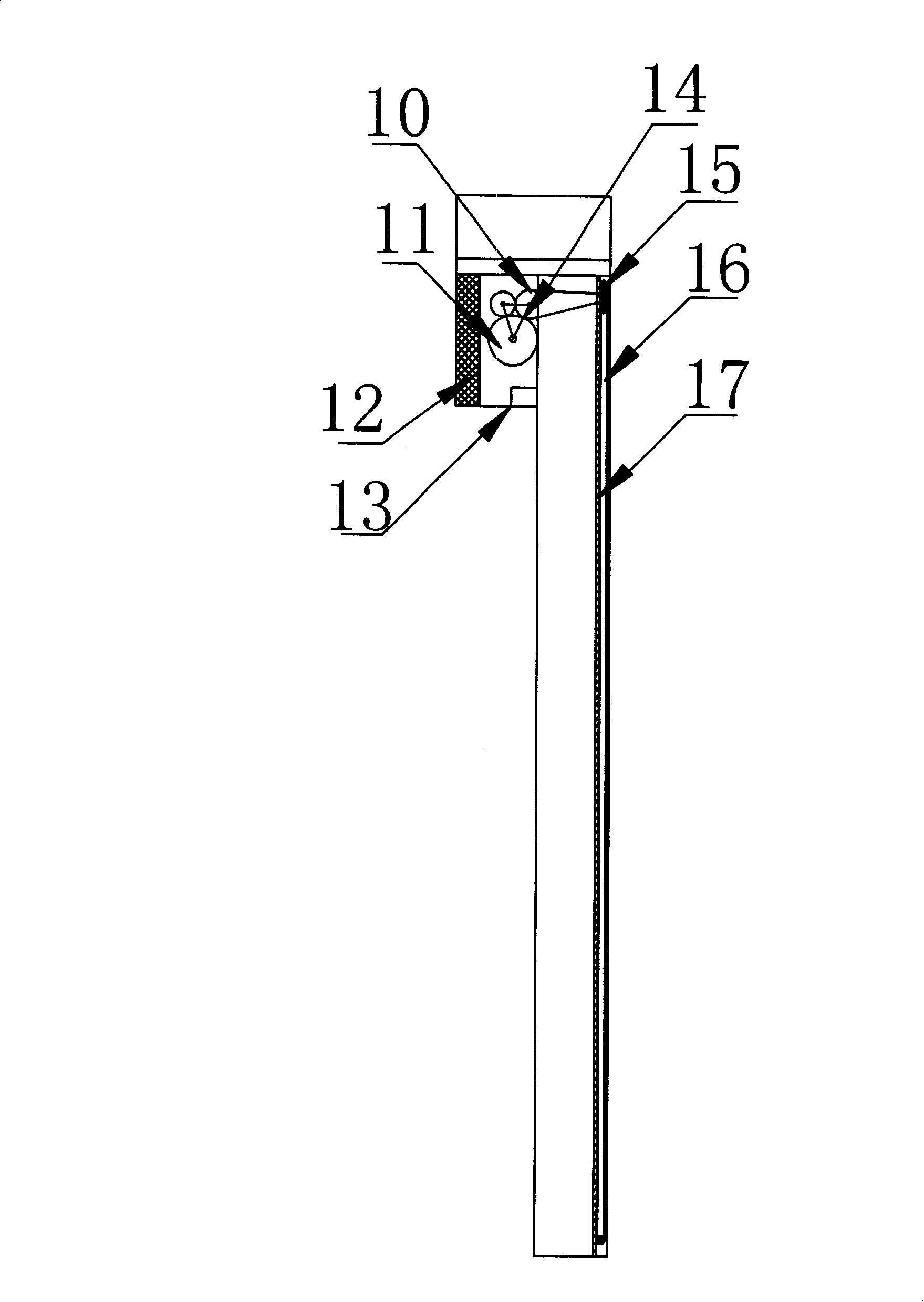

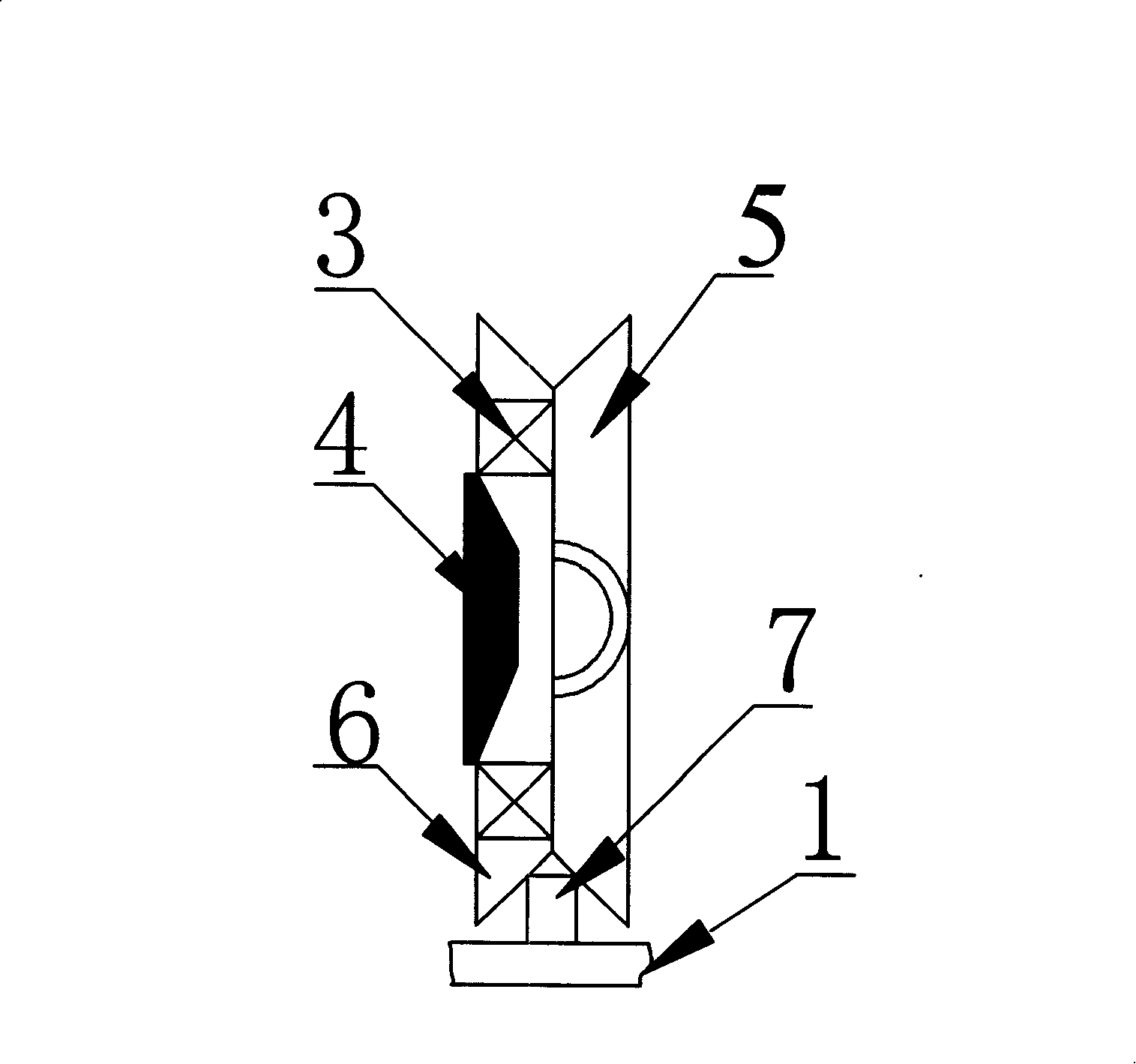

Dust abating protector of solar energy solar panel

InactiveCN101229545AReduce adhesionEvenly dispersedLayered productsCleaning using toolsLinear motionDrive wheel

The invention relates to a dust removal protection device for a solar battery board. The photographic surface of the battery board is provided with super white protection glass with high transmittance; the glass surface is coated with nanometer film; a drive motor is fixedly arranged in a protection shell on the battery board side through a bracket; an output shaft of the drive motor is connected with an input shaft of a transmission, the output shaft of the transmission is connected with a linkage mechanism; the rotating motion can be converted into linear motion by the linkage mechanism; one end of a brush-holder stud is actively connected with a drive wheel of the linkage mechanism; the other end of the brush-holder stud is arranged in a guide rail; a brush smear is fixedly arranged on the brush-holder stud; rubber strip of the brush smear presses to the surface of the protection glass; a trigger is arranged at the two ends of the battery board; the transmittance glass internal is provided with an optical sensor; an electric controller is electrically connected with a relay and the drive motor. The device of the invention can effectively wipe off sundries and dust on the battery board surface and improve absorption efficiency and transmission efficiency of the battery board to light energy, which is ideal matching equipment of the solar energy battery and has good application prospect.

Owner:JIANGSU HANDSON INTELLIGENT TECH CO LTD

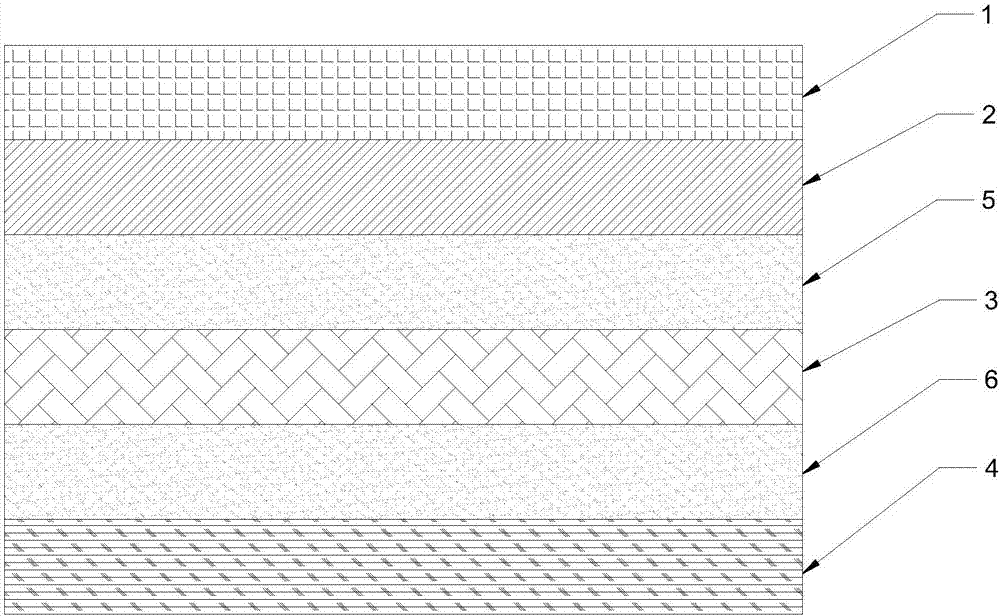

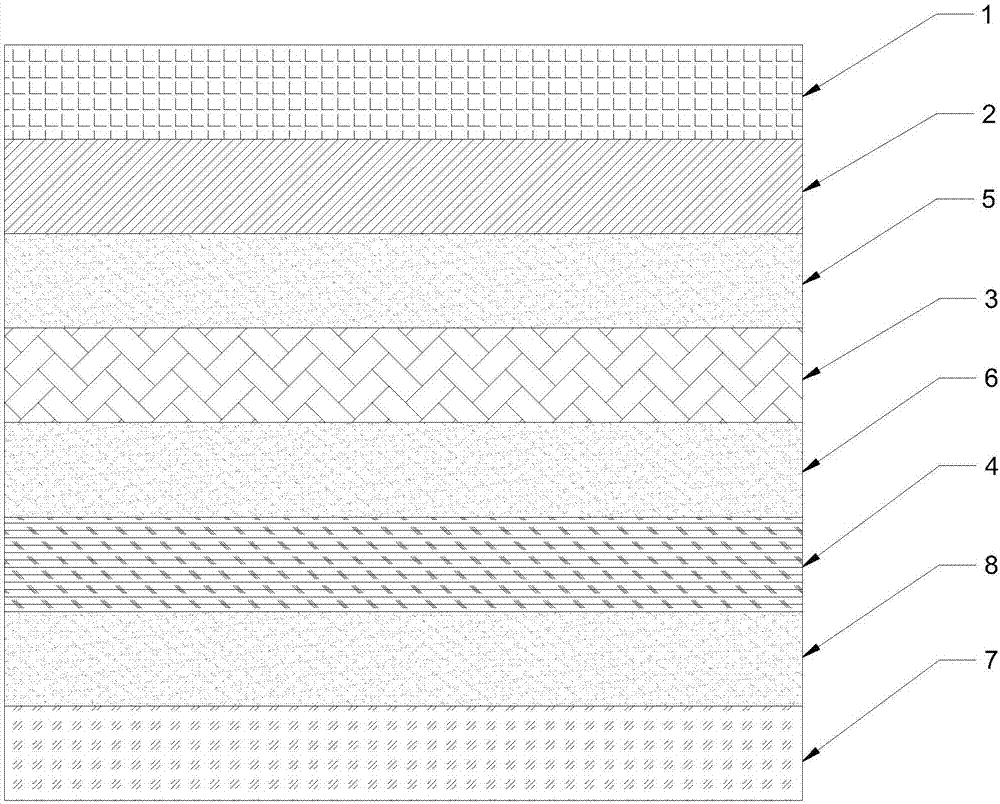

Super-wear-resisting and scratch-resistant and waterproof plastic floor and manufacturing method thereof

ActiveCN107165376AImprove wear resistanceStrong scratch resistanceSynthetic resin layered productsLaminationSingle plateEngineering

The invention discloses a super-wear-resisting and scratch-resistant and waterproof plastic floor and a manufacturing method thereof. The super-wear-resisting and scratch-resistant and waterproof plastic floor comprises a wear-resisting layer, a decorative layer, a matrix layer and a balancing layer which are sequentially arranged from top to bottom, and further comprises a first connection layer arranged between the decorative layer and the matrix layer and a second connection layer arranged between the matrix layer and the balancing layer. The wear-resisting layer is aluminum oxide wear-resisting paper, the decorative layer is a layer of paper impregnated by melamine resin, the matrix layer is a PVC sheet layer or a PVC hard-board layer or a multi-layer composite of the PVC sheet layer and the PVC hard-board layer or other high polymer materials, and the balancing layer is balancing paper or made after an veneer and the melamine resin are adopted to be subjected to impregnation and thermo-curing. According to the super-wear-resisting and scratch-resistant and waterproof plastic floor and the manufacturing method thereof, the aluminum oxide wear-resisting paper is adopted to serve as the wear-resisting layer, the matrix layer adopts PVC rolling or extrusion materials, and the bottom balancing layer is arranged, so that the floor has super high wear-resisting, scratch-resistant and waterproof performance.

Owner:DARDE FLOORING DEV JIANGSU CO LTD

Production method of nano crystal-sand floor

ActiveCN101337366AStrong hardnessAnti-wear strengthPolishing machinesPretreated surfacesFloor slabWear resistant

The invention discloses a method for producing nanometer crystal sand surface floor slabs. The production method comprises the steps of slicing timber, selecting slabs and grooving according to conventional techniques, and further comprises the steps of conducting the polishing treatment for floor slab base materials, including seventeen-layer multiple permeation paint application technique, that is, applying two layers of water environmental protection primer, three layers of wear-resistant primer, nine layers of elastic primer, and three layers scraping-resistant finishing coat. The production method adopts the seventeen-layer multiple mutual-type permeation technique, that is, three plus two plus nine plus three, and utilizes the interactive permeation technique of nano-titanium paint molecules, so as to enable paint molecule layers to permeate into wood molecules. Through a plurality of layers of wear-resistant primer and hardening primer, and through leveling and a plurality of curing and sanding layers, the floor slab has high performance of super strong hardness, wear resistance, scraping resistance, oxidation and yellowing resistance. The paint surface adhesive force, the flexibility, and the scraping resistance of the floor slab greatly exceed those of the ordinary technical floor slab.

Owner:浙江永吉木业有限公司

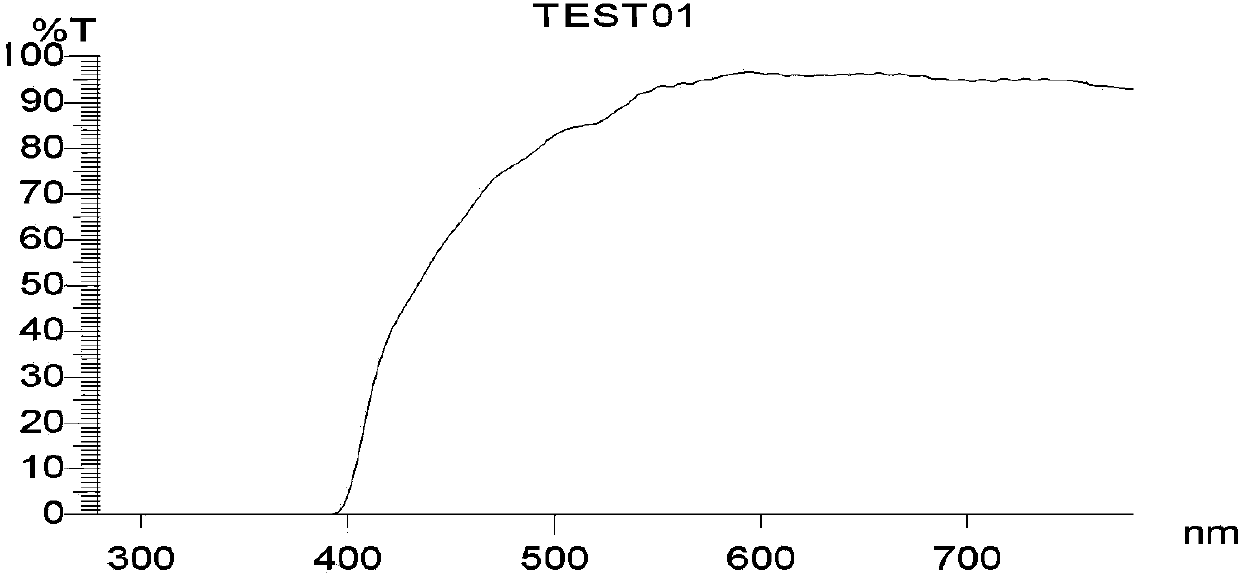

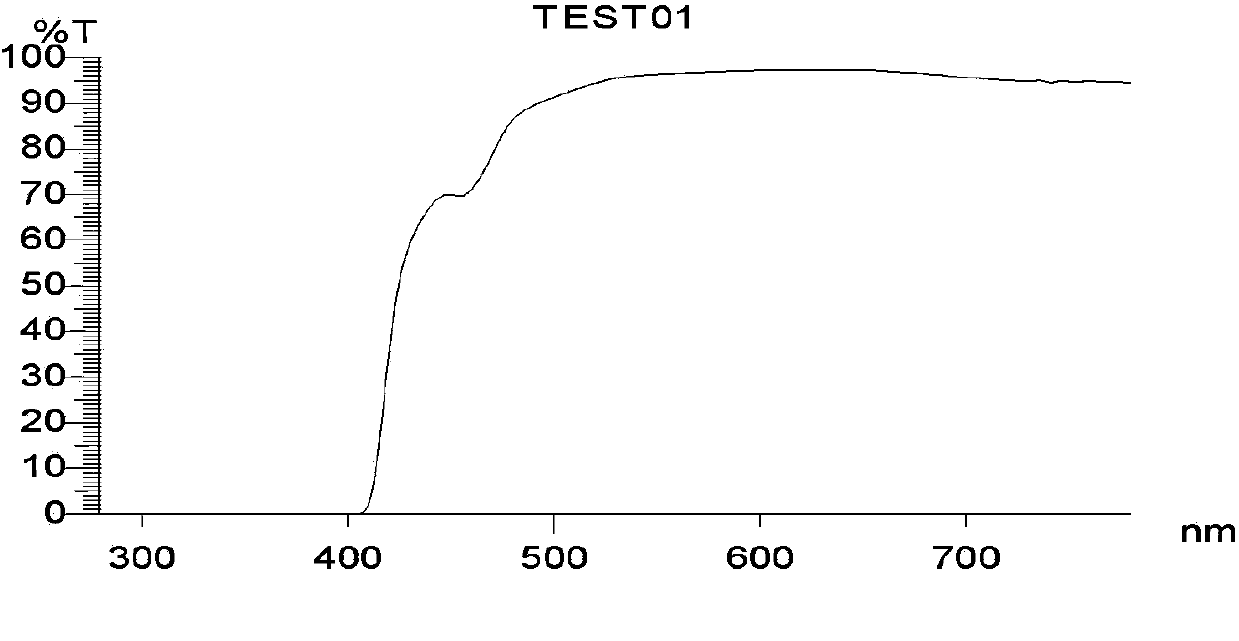

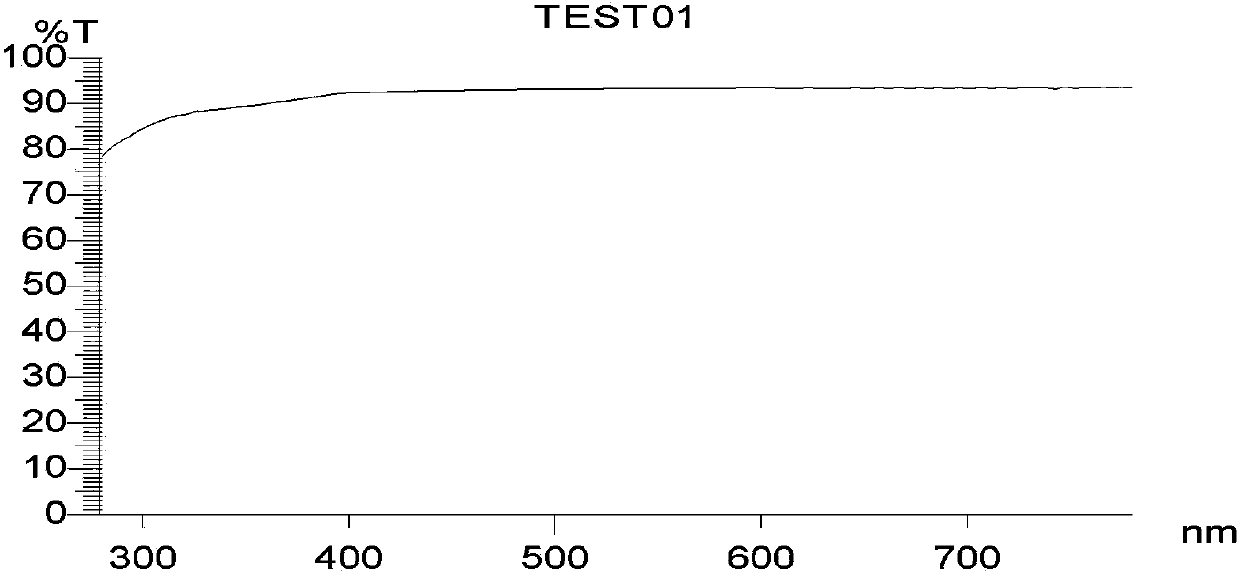

Anti-blue light film and manufacturing method thereof

ActiveCN103992672ANo damageStrong scratch resistanceFilm/foil adhesivesRadiation-absorbing paintsThermal energyLight energy

The invention discloses an anti-blue light film and a manufacturing method thereof, and particularly relates to an anti-blue light strengthening liquid, burdening of the anti-blue light strengthening liquid, a proportion of the anti-blue light strengthening liquid, a manufacturing method of the anti-blue light film and a product. The manufacturing method of the anti-blue light film comprises the following steps: preparing adsorbing type anti-blue light strengthening liquid; selecting a main base material; uniformly coating a layer of the prepared adsorbing type anti-blue light strengthening liquid on one surface of the main base material; preparing the anti-blue light film by thermal-energy curing and light-energy curing. The anti-blue light film manufactured by adopting the manufacturing method disclosed by the invention has the characteristics of being strong in scraping resistance and high in transmittance and micro-color bias, effectively protecting in a targeted manner, and being more free, convenient and simpler in product mixing.

Owner:鹰潭来奇科技有限公司

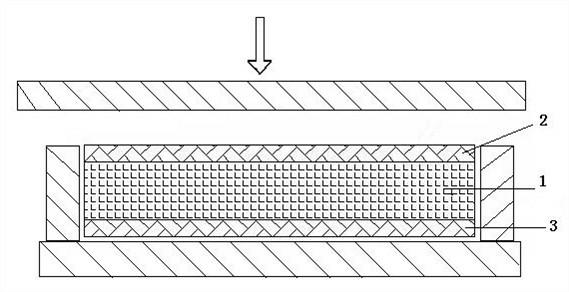

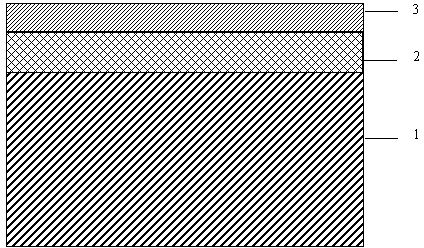

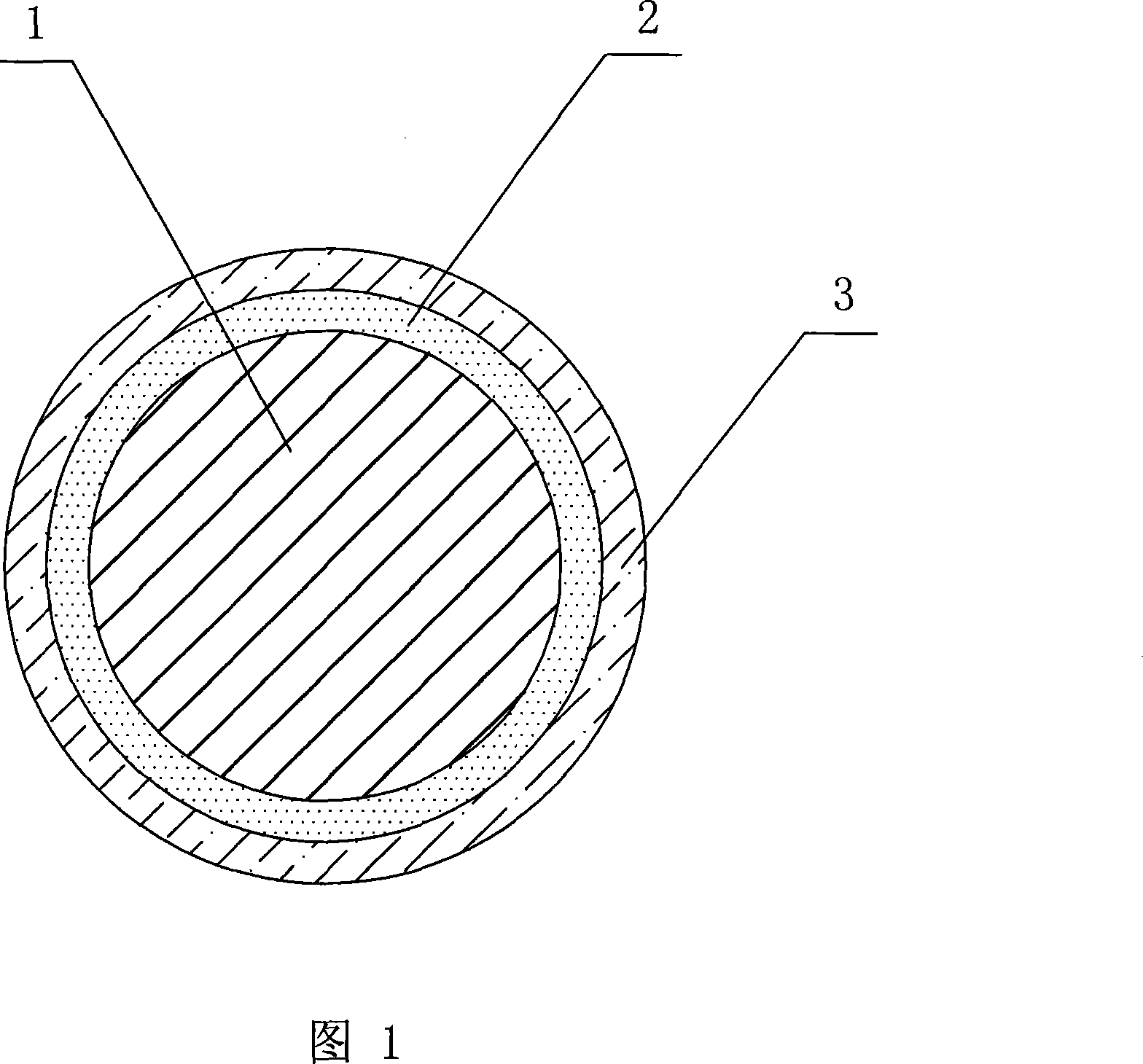

Composite fiber material product, preparation method thereof and application thereof

InactiveCN102166857AHigh hardnessStrong impact resistanceSynthetic resin layered productsLaminationFiberCorrosion resistant

The invention discloses a composite fiber material product, a preparation method thereof and an application thereof. The composite fiber material product comprises a piece of middle fiber material cloth (1), an upper surface film (2) arranged above the fiber material cloth (1) and a lower surface film (3) arranged under the fiber material cloth (1), wherein the outer surfaces of the upper surface film (2) and the lower surface film (3) are further provided with a layer of glass fiber cloth (4). The upper surface film and the lower surface film of the composite fiber material product can be respectively and internally printed with characters or patterns, the surfaces can be respectively formed to be a mirror surface or matting, and the composite fiber material product is attractive in appearance, free of air vents and needle eyes, good in rigidity, strong in impact resistance and mar resistance, and strong in heat resistance and corrosion resistance, so that the composite fiber material product can be widely used for manufacturing shells of various electronic products, electrical equipment, aviation and spaceflight equipment, and the like. The preparation method of the composite fiber material product is low in mould requirement, can be used for preparing the composite fiber material product with a surface which has the mirror surface or is matting. The follow-up treatment to the surface of the product can be avoided, such as polishing and the like, so that the invention is convenient to operate, and high in yield and production efficiency.

Owner:宜兴市中碳科技有限公司

Environment-friendly water-based nano varnish and preparation method

InactiveCN104178013AGood weather resistanceGood compatibilityPolyurea/polyurethane coatingsWater basedState of art

The invention relates to environment-friendly water-based nano varnish and a preparation method thereof. The preparation method comprises the following steps: putting 10-30 parts by weight of water-based nano activation base material in a reaction kettle, slowly adding 1-5 parts by weight of coupling agents and 1-5 parts by weight of aids in sequence, standing for 8-48 hours for curing, and putting the obtained cured material, 50-70 parts by weight of emulsion and 10-30 parts by weight of water in an activation kettle to undergo group activating, crosslinking and grafting, thus obtaining a product under the conditions of nitrogen or argon protection, pressure of 0.1-3Mpa and activation time of 8-48 hours, wherein the temperature range of the activation kettle is controlled to be 30-80 DEG C. Compared with the prior art, the environment-friendly water-based nano varnish has the advantages of complete water-based environment-friendly system, no environmental pollution, complete water-based low-temperature self-drying system, no safety hazards such as burning and explosion, high adhesion to metal materials, good hardness, strong scratch resistance and the like.

Owner:JIANGSU MEIYICHEN NEW MATERIAL TECH

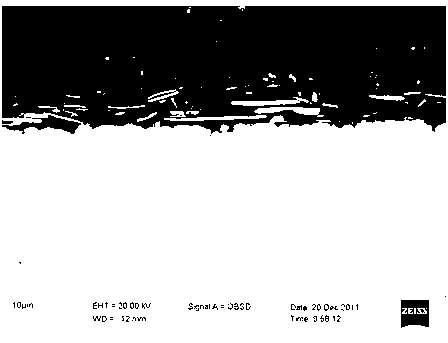

Neodymium iron boron rare earth permanent magnet surface anti-corrosion coating and preparation method thereof

ActiveCN102936455AControl thicknessImprove protectionPretreated surfacesAnti-corrosive paintsAcrylic resinRare earth

The invention belongs to the technical field of surface treatment and particularly relates to a neodymium iron boron rare earth permanent magnet surface anti-corrosion coating and a preparation method thereof. The neodymium iron boron rare earth permanent magnet surface anti-corrosion coating is composed of a bottom coating and a top coating, the thickness of the bottom coating is in a range from 10mum to 25mum, the chemical components of the bottom coating comprise 55% to 65% of one or two types of metals of zinc and aluminum, 0% to 5% of one or a plurality of types of metals of nickel, chromium, molybdenum, neodymium, praseodymium, cobalt and titanium and 34% to 40% of neutral resins, the thickness of the top coating is in a range from 5mum to 15mum, and the chemical components of the top coating comprise 55% to 65% of one or a plurality of types of metals of zinc, aluminum, titanium, molybdenum, nickel, cobalt and chromium and 35% to 45% of phenolic resins or acrylic resins. The preparation method includes that firstly the surface of a permanent magnet is preprocessed, a centrifugal immersion tossing is utilized to prepare the bottom coating, and a rolling spraying process is utilized to prepare the top coating. The neodymium iron boron rare earth permanent magnet surface anti-corrosion coating and the preparation method thereof have the advantages that by means of double layers of coatings, the corrosion resistance is high, the surface binding force is high, the usage temperature is higher than 200 DEG C, the magnetic property of the neodymium iron boron rare earth permanent magnet is improved, the service life is prolonged, and the service environment is widened.

Owner:SHENYANG GENERAL MAGNETIC

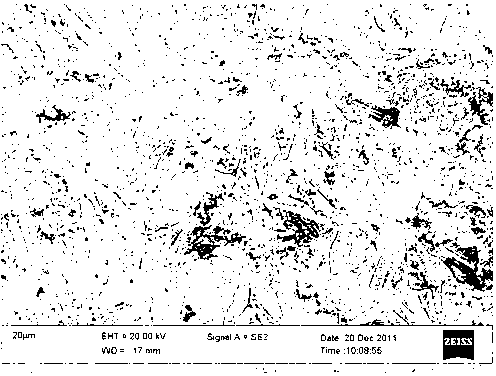

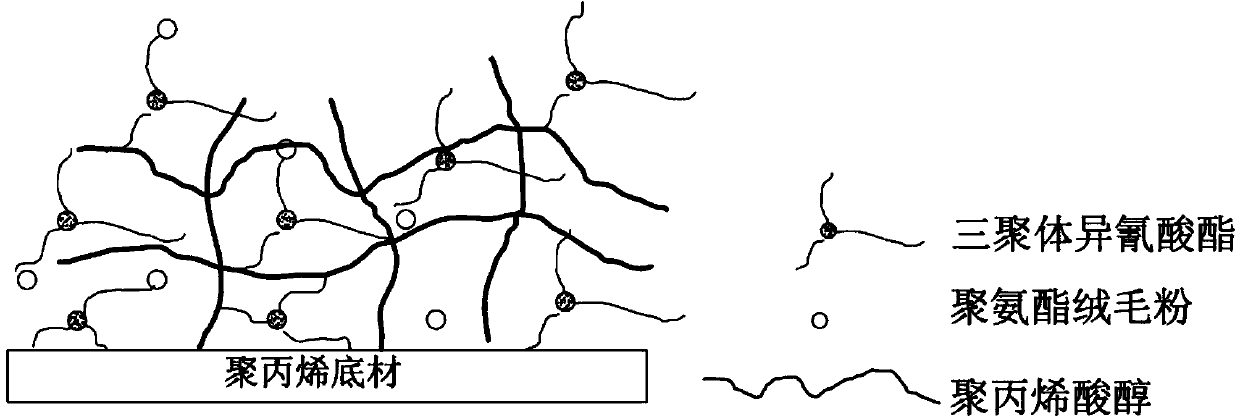

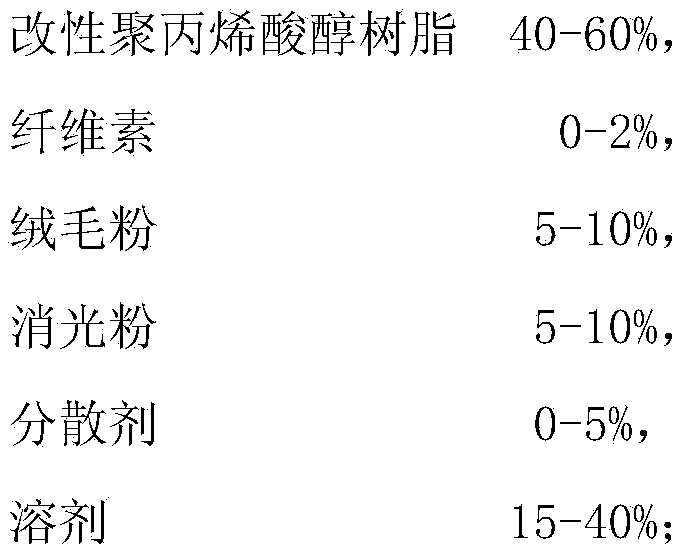

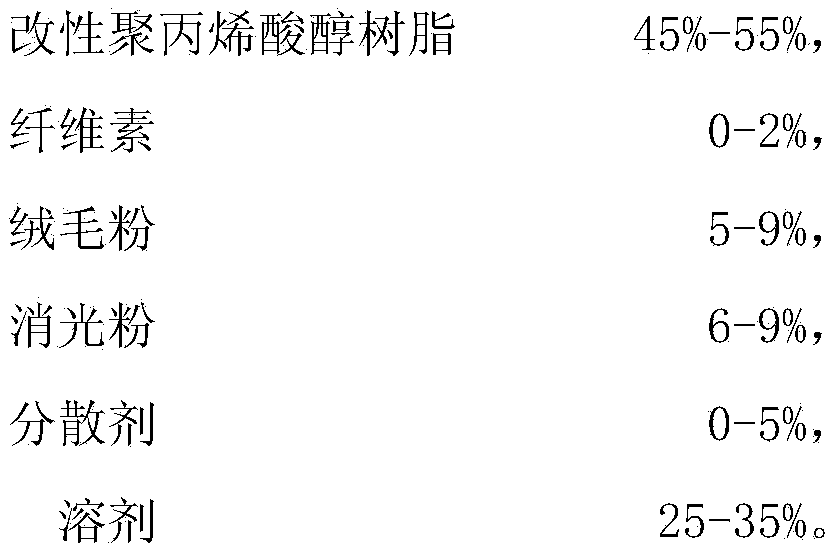

Mist surface hand feeling scratch-resistant coating paint and preparation method thereof

The invention discloses a mist surface hand feeling scratch-resistant coating paint and a preparation method thereof. The mist surface hand feeling scratch-resistant coating paint is composed of a component A and a component B, wherein the part ratio of the component A to the component B is equal to 100: (1-5); the component A comprises the following components in mass percentage: 40-60 percent of modified poly-acrylic acid alcohol resin, 0-2 percent of cellulose, 5-10 percent of tomentum powder, 5-10 percent of extinction powder, 0-5 percent of dispersing agent and 15-40 percent of solvent; the component B is a hardening agent. Due to the adoption of the manner, the mist surface hand feeling scratch-resistant coating paint can meet scratch-resistant property, improves the coating texture and the decoration effect, has a special hand feeling and meets different decoration requirements.

Owner:昆山大世界油墨涂料有限公司

Environment-friendly PVC (Polyvinyl Chloride) foaming ceiling panel and preparation method thereof

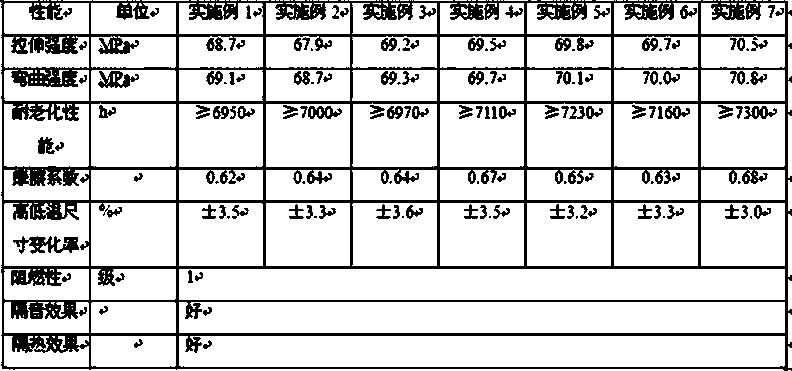

The invention provides an environment-friendly PVC (Polyvinyl Chloride) foaming ceiling panel and a preparation method thereof. The environment-friendly PVC foaming ceiling panel comprises the following components in parts by weight: 90-110 parts of PVC resin, 5-10 parts of polylactic acid, 7-12 parts of polycaprolactone, 10-20 parts of polyester fiber, 50-70 parts of barium sulfate, 3-7 parts of plasticizer, 5-11 parts of stabilizer, 1.7-5 parts of titanium dioxide, 0.6-2 parts of PE (Poly Ethylene) wax, 2-5.5 of processing modifier, 1.4-3.2 parts of anti-impact modifier, 0.7-1.5 parts of composite foaming agent and 20-30 parts of sepiolite. The environment-friendly PVC foaming ceiling panel provided by the invention has the characteristics of environmental friendliness, good weather fastness, high fire resistance, strong scratch resistance, sound insulation, thermal insulation, dust prevention, noise absorption, insect prevention and light reflection and is very suitable for serving as an indoor ceiling.

Owner:安徽济峰节能材料有限公司

Photo-degradable formaldehyde membrane based on modified titanium dioxide

InactiveCN106947339AGood catalytic degradation effectExtend your lifeFilm/foil adhesivesPolyureas/polyurethane adhesivesDioxide titaniumFormaldehyde

The invention discloses a photo-degradable formaldehyde membrane based on modified titanium dioxide, belonging to the technical field of membranes. According to the photo-degradable formaldehyde membrane, when a hardening liquid coating layer is configured, modified titanium dioxide is prepared and is well dispersed into hard coating layers of products of automobile membranes, building membranes and household membranes, so that the process is simplified, the cost is saved, and furthermore, the obtained photo-degradable formaldehyde membrane is capable of degrading formaldehyde without influencing the original properties of the automobile membranes, the building membranes and the household membranes.

Owner:JIANGYIN TONGLI OPTOELECTRONICS TECH

Normal temperature curing fluorocarbon resin coating and preparation method thereof

The invention discloses a normal temperature curing fluorocarbon resin coating. The coating comprises the following components in percentage by weight: 38 to 60 percent of chlorotrifluoroethylene-vinyl ester polymer, 5 to 10 percent of coupling agent, 1 to 6 percent of pigment, 1 to 5 percent of nanoparticles, 0.05 to 2 percent of aid, 20 to 45 percent of solvent, 5 to 15 percent of curing agent and 0.003 to 0.05 percent of drier, wherein the coupling agent is fluorosilane with -CF3 and -CF2 groups; the aid is a defoamer or a surfactant; the solvent is xylene and methyl isobutyl ketone or butyl acetate and the methyl isobutyl ketone; and the drier is dibutyltin dilaurate. By adopting a specific coating formula, the solubility of fluorocarbon resin in the solvent is improved, the added aid, pigment and the like are soluble, various components are easy to disperse in various dispersion modes, the coating is convenient to operate on site, the adhesion of the coating can reach level 0 and the coating has high scratch resistance and high acid, alkali and salt resistance.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

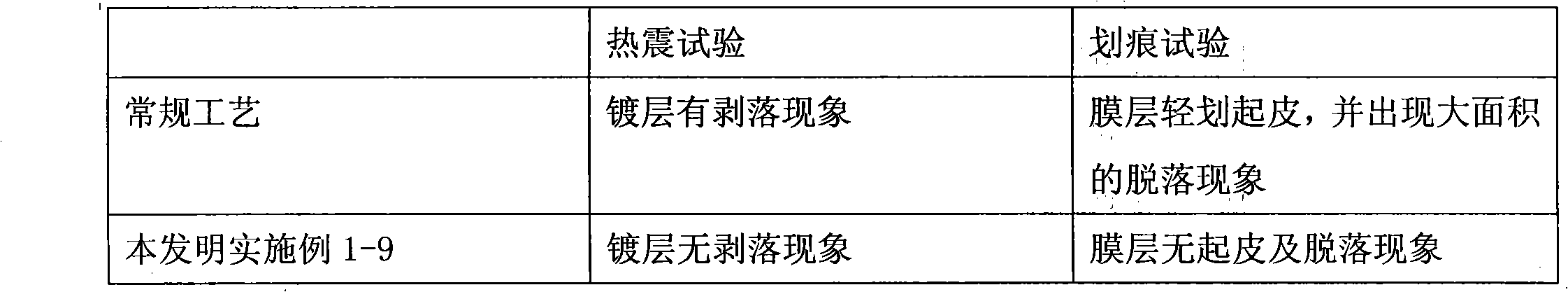

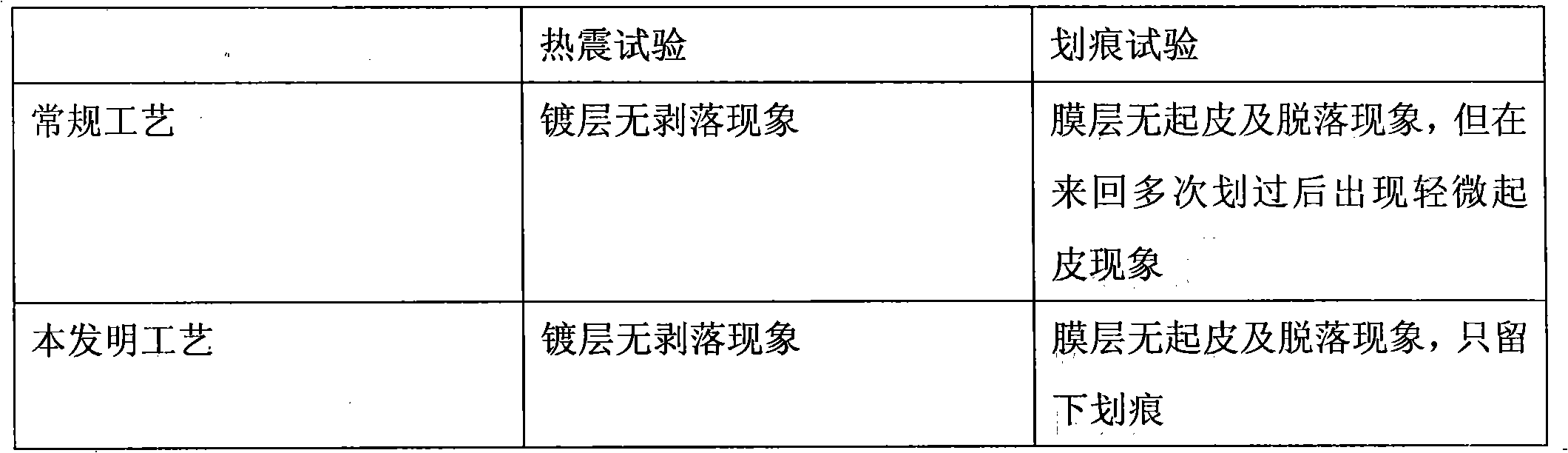

Metal surface treatment process

InactiveCN102392246AIncreasing the thicknessHigh hardnessVacuum evaporation coatingSputtering coatingSurface cleaningSprayer

The invention belongs to the technical field of metal surface treatment, and especially relates to a metal surface treatment process which comprises the following process steps of: (a) surface cleaning, that is, performing surface cleaning of a metal substrate to be treated, removing attachments on the surface of the metal substrate; (b) glaze layer spraying, that is, performing atomization spraying of glaze onto the surface of the metal substrate by a spray gun or a sprayer to form a glaze layer; (c) baking and curing, that is, baking the metal substrate with the sprayed glaze layer in a baking oven so as to cure the glaze layer; (d) secondary cleaning, that is, performing secondary cleaning of the metal substrate with the sprayed glaze layer; (e) PVD coating, that is, performing PVD coating of the metal substrate with the sprayed glaze layer to form a film layer on the surface of the glaze layer so as to obtain the metal substrate finished product. The metal substrate finished product of the invention has high thickness and hardness, and thus has strong wear resistance and scratching resistance; the PVD coating provides the metal substrate finished product with good temperature change resistance and corrosion resistance, and good metal luster.

Owner:东莞市泉硕五金加工有限公司

Folding screen, manufacturing method thereof, and mobile terminal

InactiveCN110211499AStrong scratch resistanceGood elastic cushioning effectIdentification meansElastic modulusEngineering

The invention relates to a folding screen, a manufacturing method thereof, and a mobile terminal. The folding screen comprises a flexible display panel and a flexible protective film; the flexible display panel is provided with a display face, and the flexible protective film comprises flexible glass and a protective layer; the flexible glass covers the side, where the display face is located, ofthe flexible display panel, and the elastic modulus of the flexible glass is smaller than or equal to 72 Gpa; and the protective layer covers the side, back on to the display face, of the flexible glass, and the elastic modulus of the protective layer is smaller than or equal to 10 Gpa. According to the folding screen, the manufacturing method thereof, and the mobile terminal, the flexible glass provides good scratch-resisting performance, and thus when the flexible glass covers the display face of the flexible display panel of the folding screen, the side, where the display face is located, of the flexible display panel can be effectively prevented from being scratched; and the flexible glass is protected through the protective layer, and thus the flexible glass is not prone to being broken so as to guarantee that the flexible glass stably protects the flexible display panel.

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

Wear-resistant hydrophobic nano composite film and preparation method thereof

InactiveCN104694877AImprove mechanical propertiesImprove hydrophobicityVacuum evaporation coatingSputtering coatingComposite filmWear resistant

The invention relates to a wear-resistant hydrophobic nano composite film and a preparation method thereof, belonging to the technical field of metal surface treatment and modification. The composite film is based on high-speed steel, or titanium alloy, or hard alloy, or pure metal, and a pure metal film and a microstructure nano composite film are sequentially prepared on the base surface. The preparation method comprises the following steps: depositing a nano composite hard film with excellent mechanical properties on the base material surface by arc ion plating, and generating a micro / nano dual structure on the film surface by an ultra-fast laser processing technique to obtain the surface film with favorable mechanical properties and certain hydrophobicity. The film maintains excellent mechanical properties of the nano composite hard film: high surface hardness, high toughness, high wearability and high scratch resistance; and the microstructure on the film surface is constructed, so that the film has certain hydrophobicity. The preparation method has the advantages of simpler equipment, low cost, low energy consumption and no pollution, and can implement efficient green manufacturing.

Owner:常州翊迈新材料科技有限公司

Graphene-containing Cr-free dacromet water-based paint as well as preparation method and use method thereof

InactiveCN107325610AHigh hardnessImprove corrosion resistanceAnti-corrosive paintsWater basedPhosphoric acid

The invention discloses graphene-containing Cr-free dacromet water-based paint as well as a preparation method and a use method thereof. The graphene-containing Cr-free dacromet water-based paint is prepared from a component A, a component B, a component C and graphene aqueous slurry, wherein the component A contains Zn, Al, water and a dispersant; the component B contains phosphoric acid, a PH regulator and cerium ammonium nitrate; the component C contains a thickener, a film-forming aid and a film-forming agent, and graphene accounts for 0.5%-1% of the total mass of the paint. The graphene-containing Cr-free dacromet has the advantages that corrosion resistance is greatly improved, the coating thickness is reduced from 20 mu m to 6 mu m, and salt-fog resistance time is prolonged from 80 hours to 120 hours.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

Surface antiseptic treating agent for cable bridge frame

InactiveCN101085889ARaise the ratioOvercome the problem of poor scratch resistanceCellulose coatingsAnti-corrosive paintsWear resistantRare earth

The invention relates to a kind of corrosion-resistant and erosion resistant coating material, which in detail is a corrosion-resistant material for cable bridge surface. The invention adds flaky zinc powder concentration for traditional dacromet coating formulation, adds penetrating agent, surface active agent, hardening agent and rare earth material. The coating layer on the surface is characterized by high adhesion power, good wearing resistant performance, good antiweatherability and stable chemically-resistant property, and suitability for wild environment utilization for a long time, which as long as 30 years.

Owner:孔繁明

Self-adhesive enameled wire

InactiveCN101236800AStrong scratch resistanceGood slipperyInsulated cablesPolyamide coatingsCopper conductorLacquer

The invention relates to an electric material, in particular to a self-adhesive enameled wire, comprising a copper conductor and a polyurethane paint insulating layer which is coated on the outside of the copper conductor, wherein, a self-lubricating self-adhesive paint layer is also coated on the surface of the polyurethane paint insulating layer; chemical compositions and concentration percentage contents of various compositions of self-lubricating self-adhesive paint in the self-lubricating self-adhesive paint layer are as follows: amilan polyamide resins of 10 percent to 13 percent, cresols of 33 percent to 36 percent, phenols of 33 percent to 36 percent and xylene of 15 percent to 18 percent. Compared with the prior common self-adhesive enameled wire, the surface of the self-adhesive enameled wire has stronger scratch resistance and better gliding property, thereby the self-adhesive enameled wire is in accordance with high requirements provided by the modern electric machine industry to the enameled wire in the aspect of mechanical features.

Owner:常州华成电工有限公司

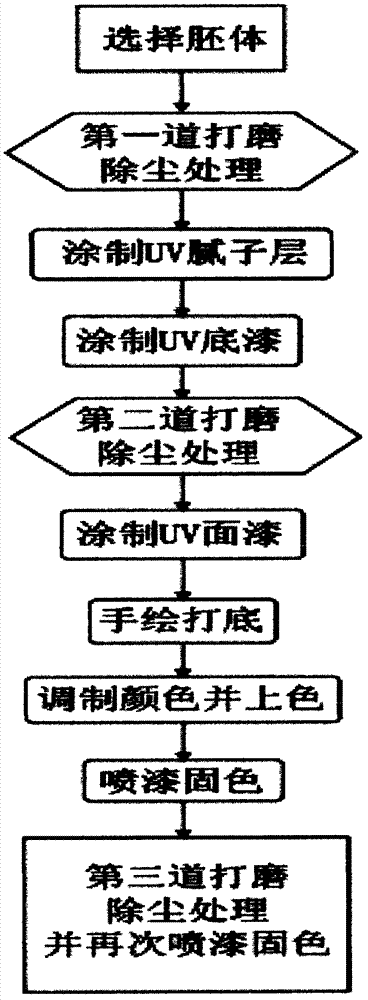

Method for manufacturing blue and white porcelain staircase

InactiveCN103085146AStrong paint adhesionHigh film hardnessPretreated surfacesWood working apparatusHandrailFiber layer

A method for manufacturing a blue and white porcelain staircase comprises the following steps: step a, selecting the blue and white porcelain process to manufacture a blank body, and performing first grinding and dust removal treatment on the blank body; manufacturing a tread plate, a vertical plate, a stand column, a handrail, a crossbeam and a samson post, wherein at least the vertical plate and the stand column are selected to manufacture the blank body through the blue and white porcelain process; and performing mechanical or manual sanding and dust removal on the blank body. The method for manufacturing the blue and white porcelain staircase has the advantages that a paint film gradually enters into wood fibers layer by layer and is performed with high-temperature ultraviolet light polymerization, the paint surface is strong in adhesive force, the paint film is high in hardness and has strong abrasion resistance and scraping resistance, a layer of porcelain glaze paint surface which is solid in texture and clear in color is formed on the paint surface, the paint film is full and smooth and enough in light sensation, presents blue and white porcelain like natural innervation and texture, and the blue and white porcelain staircase is strong in porcelain texture, obvious in three-dimensional color, rich in layering, capable of resisting ultraviolet radiation and not apt to fade.

Owner:上海捷步实业有限公司

Chrome vanadizing process of automotive chain pin shaft

ActiveCN104404445AImprove wear resistanceStrong scratch resistanceSolid state diffusion coatingBoronWear resistance

The invention relates to a chrome vanadizing process of an automotive chain pin shaft with the advantages of larger load, wear resistance, corrosion resistance, oxidation resistance, good fatigue property and long service life. The finely-ground pin shaft is arranged in a converter, 60-70 percent of anhydrous borax, 10-15 percent of Cr2O3, 8-15 percent of V2O5 as a penetrating agent and a certain amount of reducing agent are simultaneously added into the converter, the converter is kept to be in a rotating state and is subjected to heat preservation for 10 hours at a temperature of 1000 plus or minus 2 DEG C, chrome vanadizing is performed, the pin shaft subjected to chrome vanadizing is poured into quenching oil to be quenched, and residual waste salt on the surface is boiled by using boiled water; after the reducing agent is added into salt bath, vanadium is reduced firstly, chrome is likely to be simultaneously reduced only when the reducing agent is excessive, and active vanadium, chrome alum and chrome vanadium boron atoms can be respectively obtained according to different consumptions of the reducing agent so as to realize vanadinizing, chrome vanadizing and chrome vanadium boronizing of steel.

Owner:HANGZHOU CHIZHENG TECH

UV photocureable coating for explosion-proof membrane hardening coating of vehicle-mounted touch screen and preparation

InactiveCN106497170AIncrease crosslink densityReduce brittlenessAntifouling/underwater paintsPaints with biocidesPhotoinitiatorAcrylate

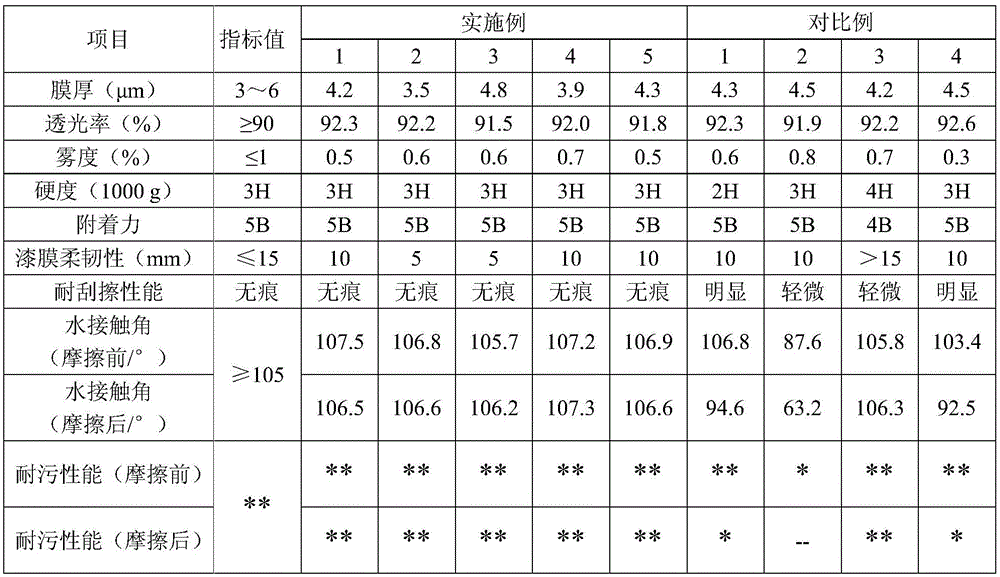

The invention belongs to the field of UV photocureable coatings, and discloses a UV photocureable coating which is extremely high in scratching resistance and hydrophobic and oleophobic anti-pollution property and is used for an explosion-proof membrane hardening coating of a vehicle-mounted touch screen, a preparation method and application of the UV photocureable coating and a hardening membrane based on the UV photocureable coating. The coating is prepared from the following components in parts by mass: 20 to 50 parts of a mulfunctional acrylate monomer, 1 to 5 parts of a sulfur alcohol monomer, 0.1 to 1 part of a fouling resistant additive, 1 to 5 parts of nano particles, 1 to 3 parts of a photoinitiator and 40 to 80 parts of an organic solvent, wherein the mulfunctional acrylate monomer is an acrylate active diluent with the mulfunctional level of 4 to 6. The invention further provides the hardening membrane obtained on the basis of the UV photocureable coating. The hardening membrane is extremely high in steel wool starching resistance (with water contact angle greater than or equal to 105 degrees) and stable in hydrophobic and oleophobic anti-pollution property and flexibility. Compared with the conventional PET hardening membrane, the hardening membrane based on the UV photocureable coating can realize comprehensive upgrading of the performance; and by the coating production mode and UV photocuring, the production efficiency is improved, and the production cost is reduced.

Owner:GUANGZHOU HUMAN ENG MATERIAL

Alloy nodular cast iron for railway vehicle brake disks

The invention relates to an alloy nodular cast iron which comprises the following components in percentage by weight: 2.0-5.0% of carbon, 1.0-4.0% of silicon, 0.2-1.0% of manganese, 0.1-0.6% of nickel, 0.1-0.80% of molybdenum, 0.01-0.08% of copper, 0.01-0.08% of magnesium, 0.01-0.06% of rare-earth Re, and the balance of iron and inevitable impurities.

Owner:BEIJING ZONGHENG ELECTROMECHANICAL TECH DEV +1

Plastic tube sign belt

ActiveCN101318422ANot easy to fall offStrong scratch resistanceInk ribbonsThermographySolventPOLYETHYLENE WAX

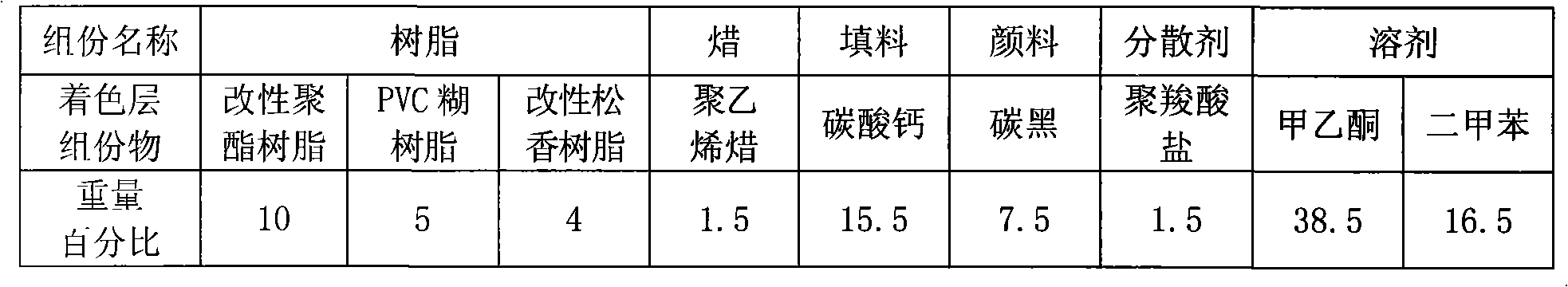

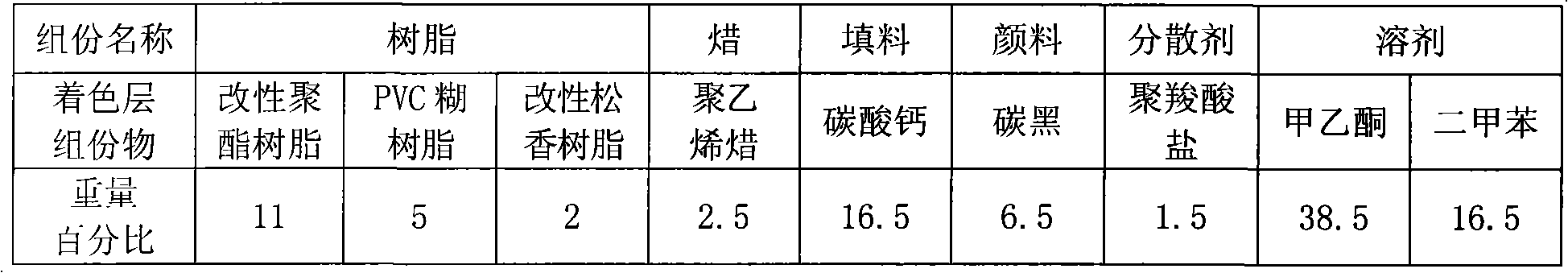

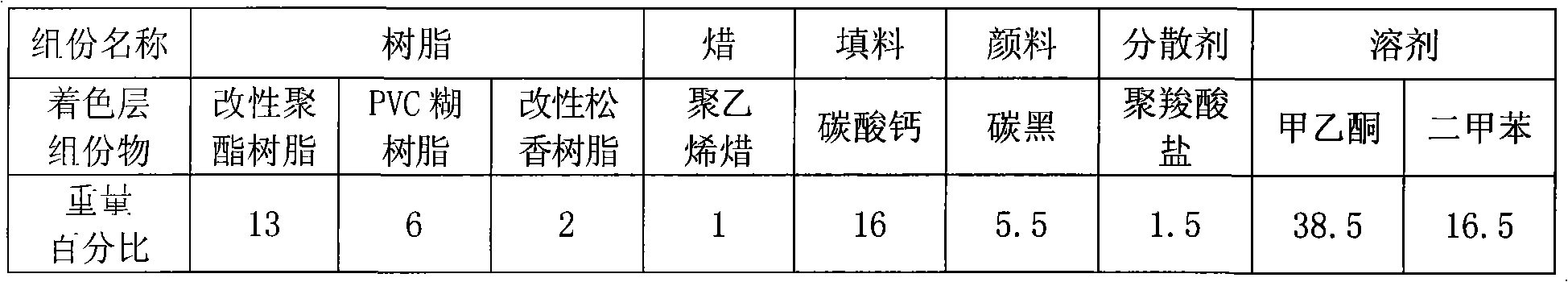

The invention discloses a plastic tube mark band which consists of a substrate and a coloring layer on the substrate; the coloring layer includes the following components of 17 to 24 percent of resin, 1 to 2.5 percent of polyethylene wax, 15 to 17.5 percent of filler, 5 to 7.5 percent of dye, 0.5 to 1.5 percent of dispersant and 48 to 55 percent of solvent according to the weight percentage. The plastic tube mark band manufactured by the technical scheme of the invention is characterized in that the coloring layer not only has a coloring function, but also has excellent sticking function; the coloring layer can be better stuck on the printing substrate, is hard to fall off, has high scraping-resistance property, overcomes a complex structure of a sticking layer on the coloring layer adopted by a plurality of technical literatures, simplifies the product structure and the production technique as well as reduces the production cost; but the property of the product is not reduced.

Owner:JIAOZUO ZHUOLI STAMPING MATERIAL CO., LTD.

Surface processing agent for neodymium-iron-boron permanent magnet as well as preparation method and processing method thereof

ActiveCN102031511AImprove stabilityFast film formationInductances/transformers/magnets manufactureMagnetic materialsMolybdateHigh surface

The invention discloses a surface processing agent for a neodymium-iron-boron permanent magnet as well as a preparation method and a processing method thereof. The surface processing agent for the neodymium-iron-boron permanent magnet of the invention comprises the following raw materials in proportion by weight (calculated by 1 liter in volume): 10-12g / L of molybdate, 7-9g / L of hypermanganate, 3-4g / L of sodium fluoride, 1-2g / L of auxiliary film-forming agent, 0.2-.04g / L of cerate, 0.1-0.3g / L of additive, a trace amount of pH regulator and the balance of water. The surface processing agent of the invention can be used for surface processing at normal temperature, the processing time is short, the permanent magnet obtained after processing has high surface corrosion-resisting property, good passivation-layer adhesive force and high scratch-resisting capability, and the invention is simple in processing process and convenient for practical operation.

Owner:合肥华清高科表面技术股份有限公司

Liquid resin composition, cured film and laminate

ActiveCN1791635ASimplify the manufacturing processExcellent adhesionSynthetic resin layered productsCellulosic plastic layered productsRefractive indexSolvent

A liquid resin composition comprising (A) a fluoropolymer, (B) a curable compound, (C) metal oxide particles having a number average particle diameter of 100 nm or less, and (D) a solvent. Once this composition is cured, metal oxide particles (C) can be segregated, the refractive index can be changed by 0.05 to 0.8 in the film thickness direction, and the cured material has a substantially two-layer structure of a low refractive index layer and a high refractive index layer. membrane.

Owner:JSR CORPORATIOON

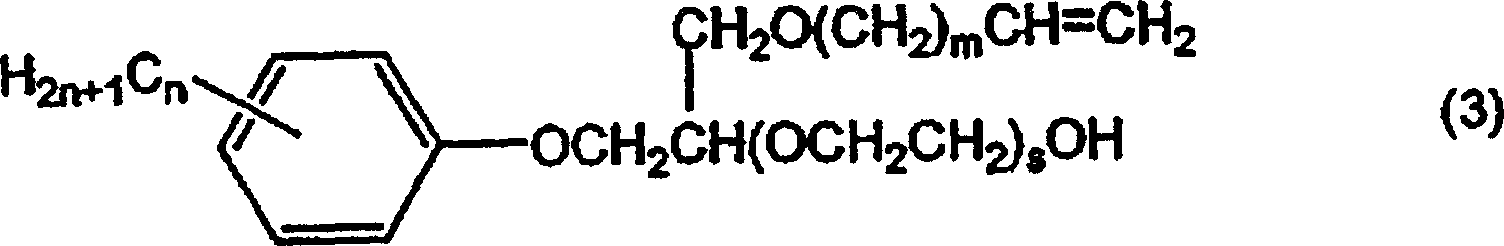

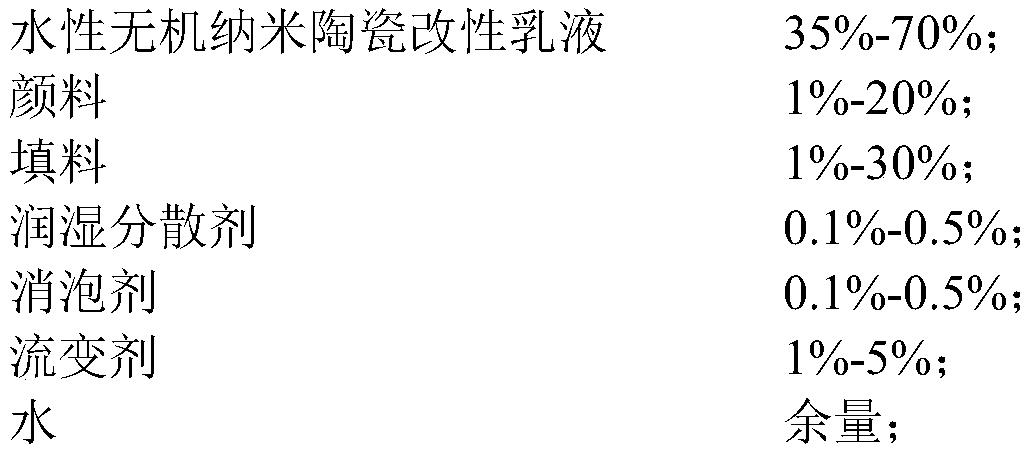

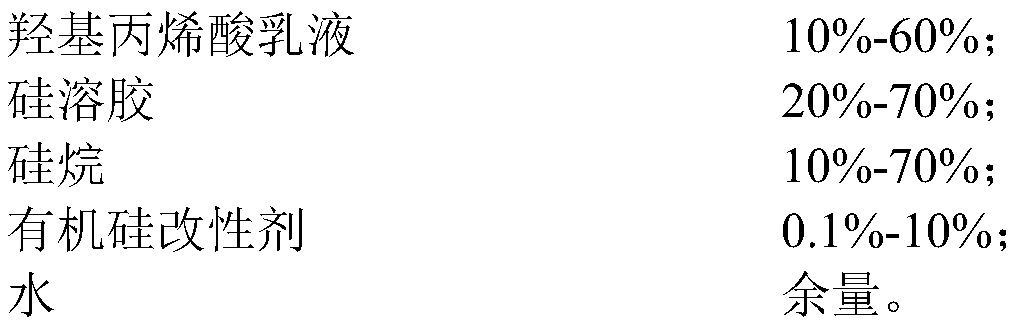

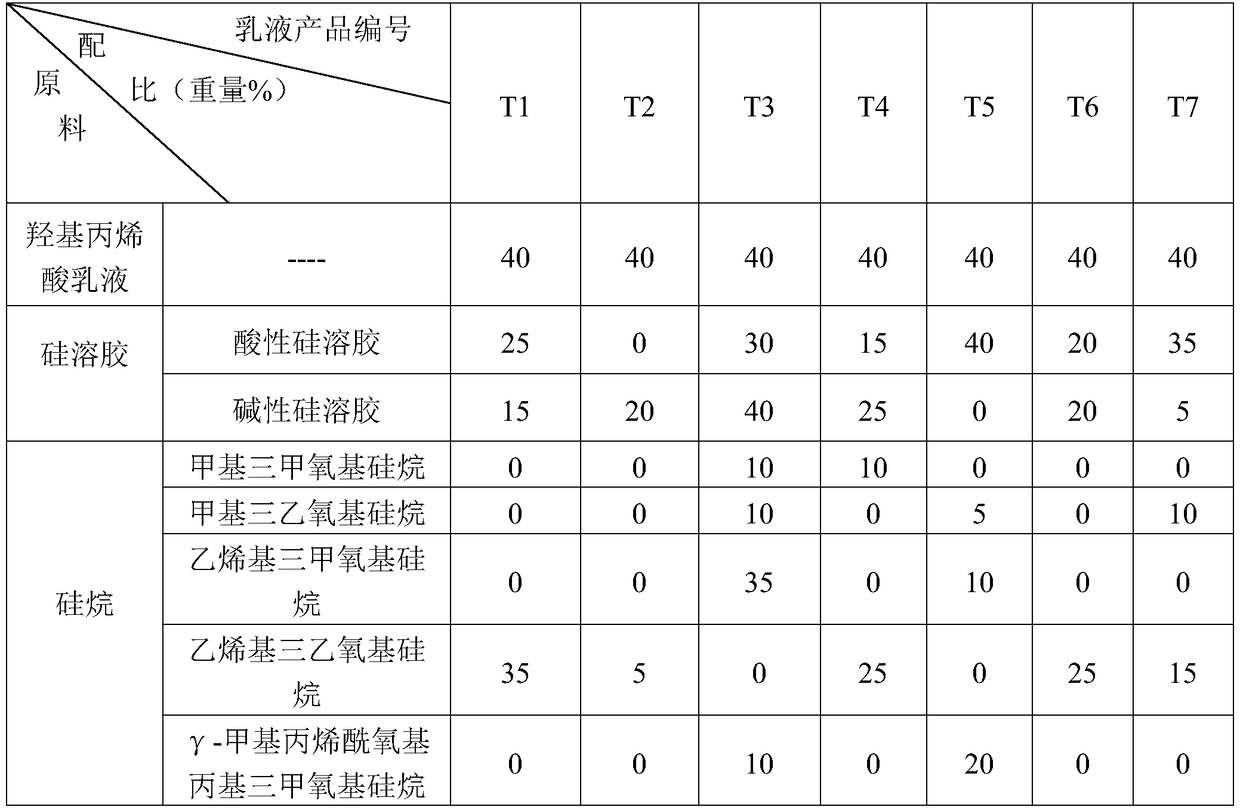

Waterborne anti-doodling and self-cleaning coating and preparation method thereof

ActiveCN109266153AImprove hydrophobicityImprove self-cleaning abilityAntifouling/underwater paintsPaints with biocidesMaterials scienceDefoamer

The invention belongs to the technical field of coating and in particular relates to waterborne anti-doodling and self-cleaning coating and a preparation method thereof. The coating is prepared from the following components: 35 to 70 percent of waterborne inorganic nano-ceramic modified emulsion, 1 to 20 percent of a pigment, 1 to 30 percent of filling, 0.1 to 0.5 percent of a wetting dispersant,0.1 to 0.5 percent of a de-foaming agent, 1 to 5 percent of a rheological agent and the balance of water, wherein the waterborne inorganic nano-ceramic modified emulsion is prepared from 10 to 70 percent of hydroxyl acrylic emulsion, 20 to 70 percent of silica sol, 10 to 70 percent of silane, 0.1 to 10 percent of an organic silicon modifying agent and the balance of water. According to the waterborne anti-doodling and self-cleaning coating, a sol-gel technology is adopted, and inorganic nano modification and organic silicon modification are carried out at the same time, so that the rigidity and wear resistance of the coating can be remarkably improved; a final coating product has good weather resistance and hydrophobic property and is obviously better than that of traditional self-cleaningcoating.

Owner:CHANGSHA HUANGMEI PAINT

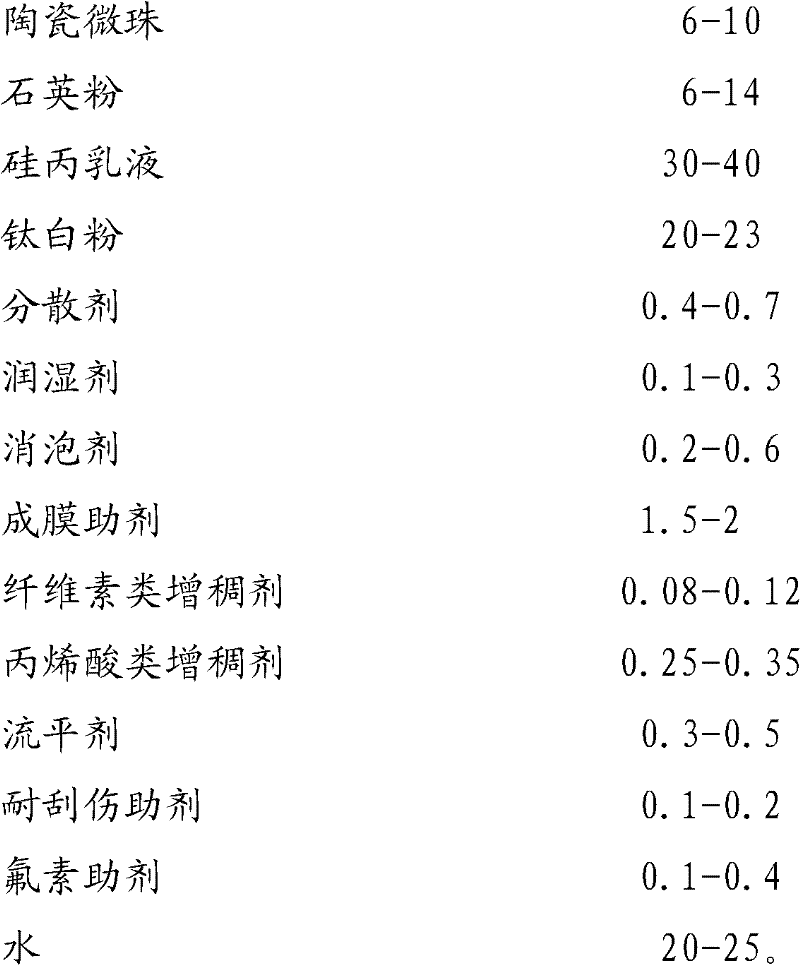

Waterborne scratch-resistant coating and preparation method thereof

The invention discloses a waterborne scratch-resistant coating, which is prepared from the following raw materials in part by weight: 6 to 10 parts of ceramic mirobeads, 6 to 14 parts of quartz powder, 30 to 40 parts of silicone acrylic emulsion, 0.4 to 0.7 part of dispersing agent, 0.1 to 0.3 part of wetting agent, 0.2 to 0.6 part of defoaming agent, 1.5 to 2 parts of film forming aid, 0.1 to 0.4 part of thickening agent, 0.3 to 0.5 part of levelling agent, 0.1 to 0.2 part of scratch-resistant aid, 0.1 to 0.4 part of fluorine aid, 20 to 23 parts of titanium white and 20 to 25 parts of water.The ceramic mirobeads, the quartz powder and the scratch-resistant aid are added, so that the compactness of a film is improved, the hardness and surface smoothness of the film are improved, and the film has high scratch resistance, wear resistance and resistance to soiling, and has a smooth handfeel like a glass surface.

Owner:HEBEI CARPOLY PAINT CO LTD

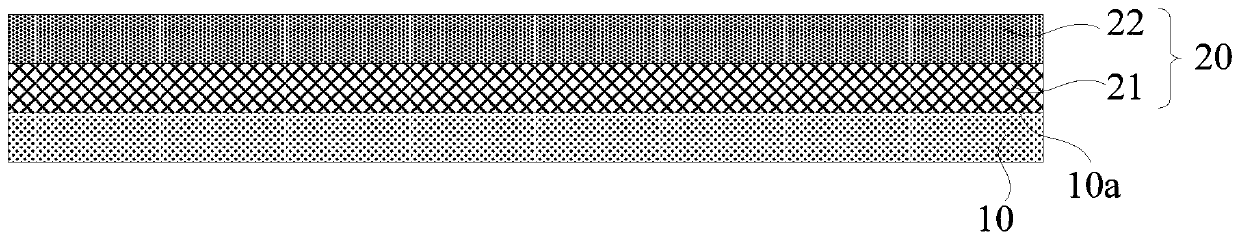

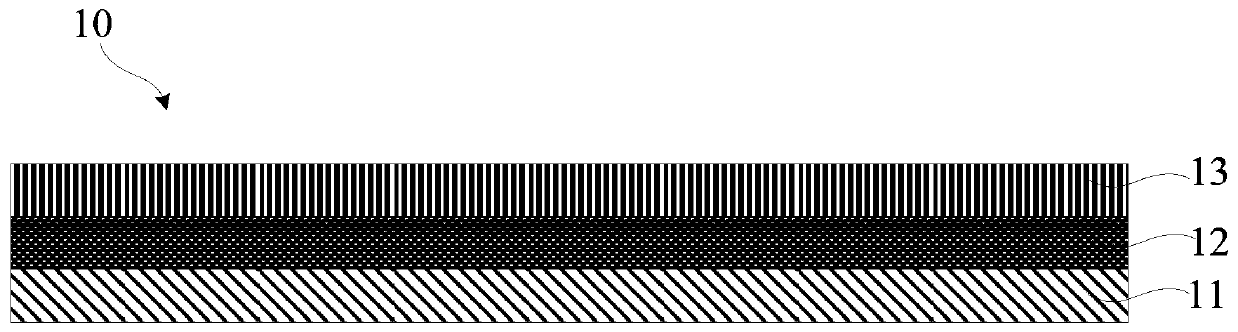

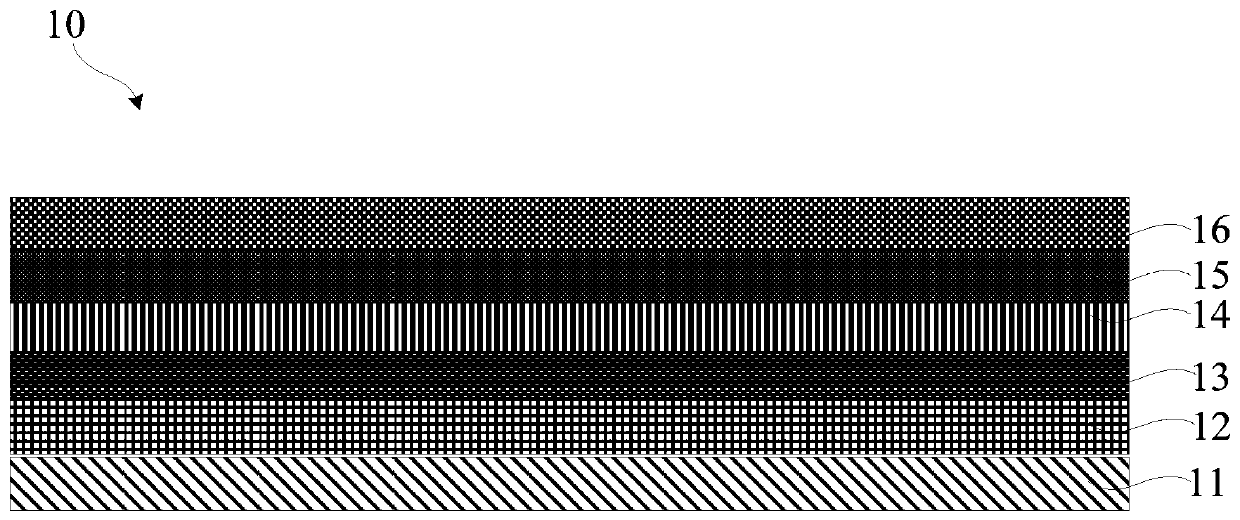

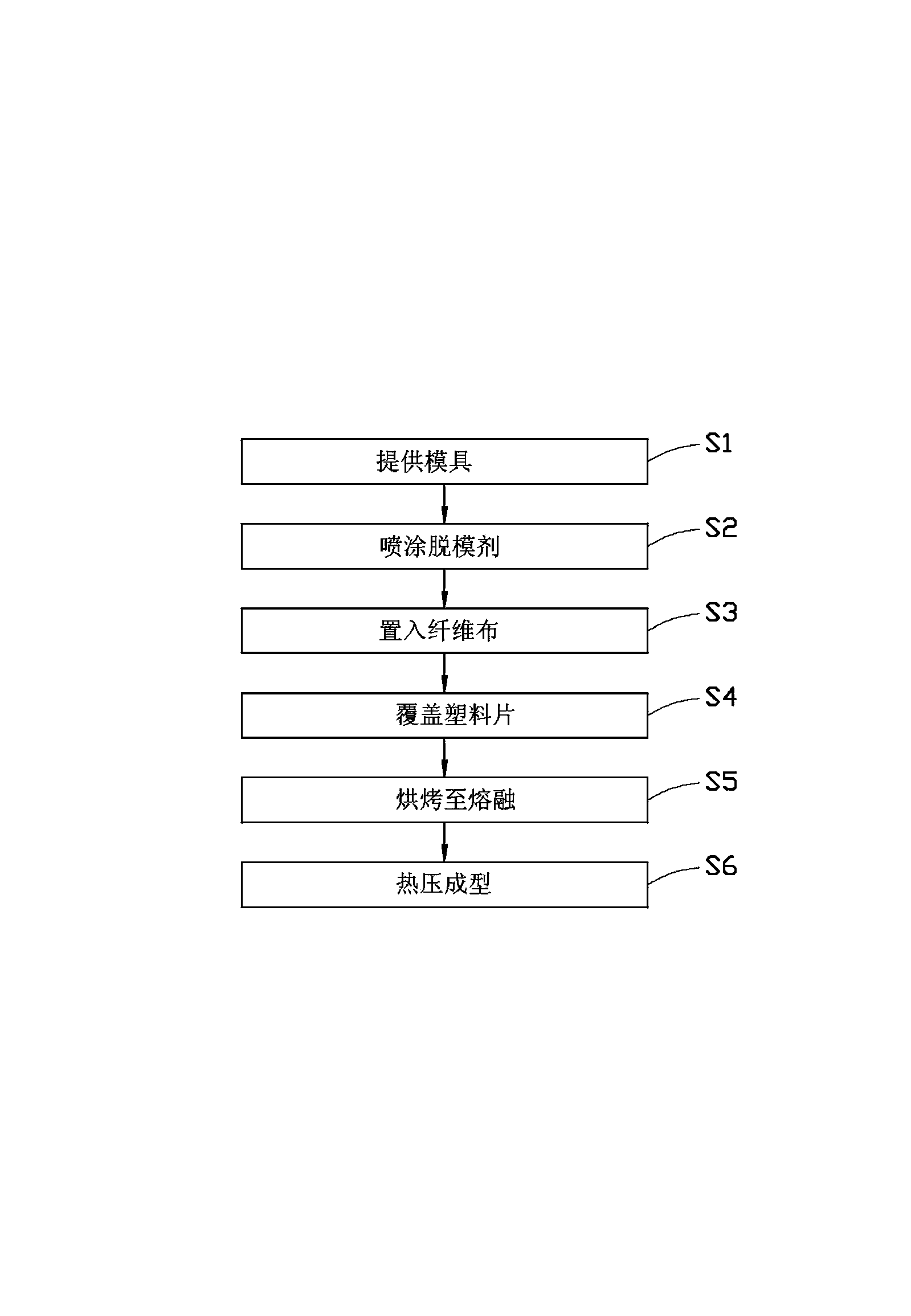

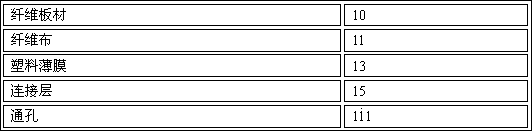

Production method of fiber sheet material and fiber sheet material produced by adopting method

ActiveCN104228293AEasy to operateFlat surfaceLayered product treatmentSynthetic resin layered productsMolten stateFiber

The invention provides a production method of a fiber sheet material. The production method comprises the following steps: putting fiber cloth into a mould; putting a plastic sheet on the surface of the fiber cloth; carrying out baking treatment on the plastic sheet so that the plastic sheet is molten and the molten plastic part penetrates into the fiber cloth; and carrying out hot pressing treatment on the fiber cloth, the fused fiber cloth in the molten state and plastic penetrating into the fiber cloth to form a plastic thin film on the surface of the fiber cloth. The invention further provides the fiber sheet material produced by the production method of the fiber sheet material.

Owner:泰州市海通资产管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com