Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Good slippery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

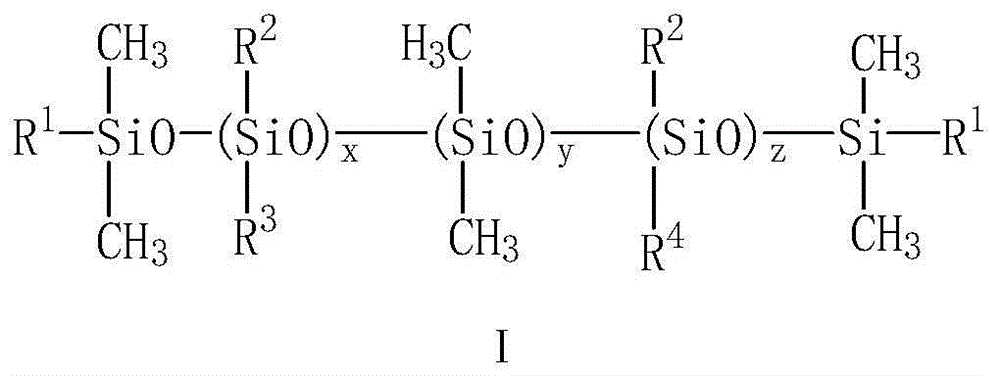

Environment-friendly ternary copolymerized segmented organic silicone finishing agent and preparation method thereof

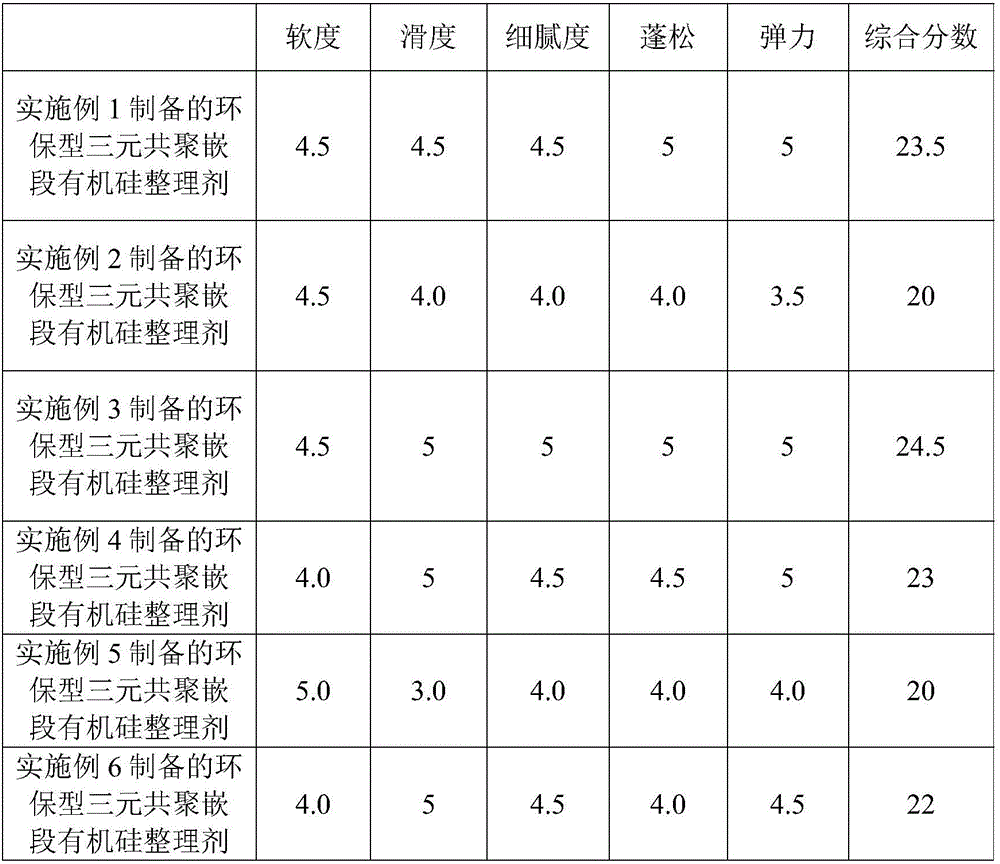

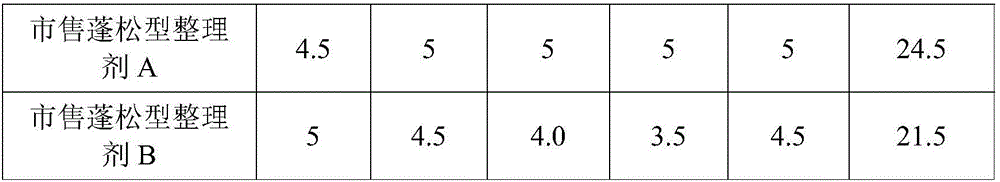

ActiveCN106592248ANo smellAvoiding the risk of gummingGrip property fibresVegetal fibresAcetic acidSolvent

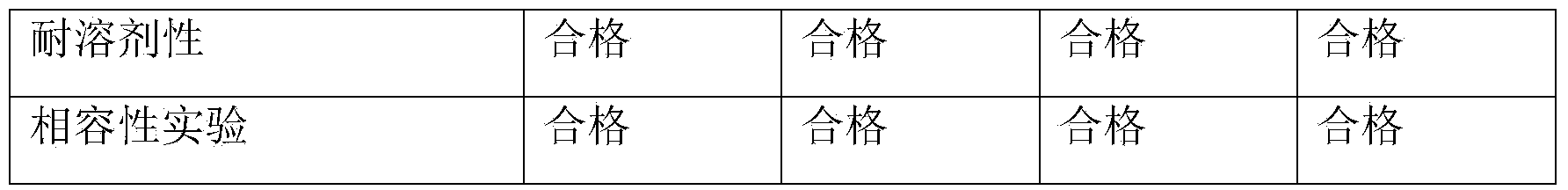

The invention discloses an environment-friendly ternary copolymerized segmented organic silicone finishing agent and a preparation method thereof. The environment-friendly ternary copolymerized segmented organic silicone finishing agent is prepared from the following components in percentage by weight: 20 to 40 percent of environment-friendly ternary copolymerized segmented silicon crude oil, 5 to 10 percent of emulsifier, 3 to 5 percent of cosolvent, 0.3 to 0.6 percent of glacial acetic acid and 50 to 70 percent of water. The environment-friendly ternary copolymerized segmented organic silicone finishing agent is prepared after the ternary copolymerized segmented silicon crude oil serving as a primary component is emulsified, so that the usage amount of a solvent is reduced, and the product cost can be lowered by 20 to 30 percent. The preparation method has the advantages of simple process, convenience in operation and control, stable quality and high production efficiency, and can be applied to large-scale industrial production.

Owner:肇庆市宏昊生物科技有限公司

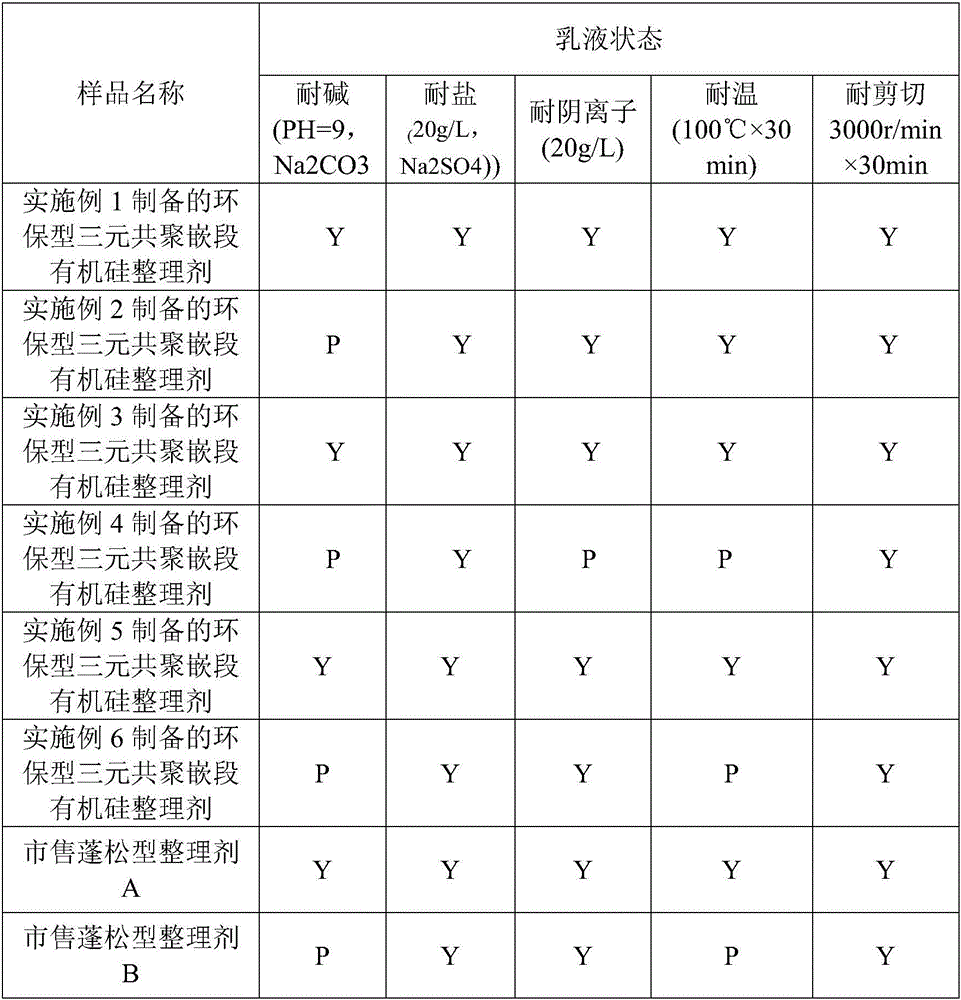

High-unwinding-tension spandex oil preparation

The invention discloses a high-unwinding-tension spandex oil preparation, which comprises the following components: 40-90% of mineral oil, 5-60% of dimethyl silicone oil, 1-10% of functional modified silicone oil and 3-15% of high-carbon isomerized fatty alcohol, and the sum of content percentages is 100% by total weight. The oil preparation disclosed by the invention is mainly applied to dry spinning, and has an outstanding characteristic that fibers both have a moderate astringent sliding degree so as to facilitate the forming of the fibers, and have an extremely good lasting barrier property so as to prevent inner-layer yarn bundles from being adhered, namely, the fibers are slidable but astringent, and astringent but non-stick, so that the astringent sliding degrees between fibers are kept, and the friction among fibers and metals is reduced, therefore, good astringent sliding property, permeability, antistatic property and unwinding property can be given to fibers, and then the perfect unification of forming and unwinding is achieved.

Owner:WACKER DYMATIC SILICONES SHUNDE CO LTD FOSHAN

Casting polypropylene film with controllable friction coefficient and preparation method thereof

InactiveCN104015448AHigh in active ingredientsGood compatibilityFlexible coversWrappersPolymer sciencePolypropylene

The invention discloses a casting polypropylene film with a controllable friction coefficient and a preparation method thereof, belonging to the technical field of packaging materials. The casting polypropylene film sequentially comprises a corona layer, a middle layer and a heat-seal layer with a thickness ratio of (20-30) to (50-65) to (15-20). The corona layer is made from homo-polypropylene or polypropylene random copolymer, the middle layer is made from isotactic homo-polypropylene, and the heat-seal layer comprises 90wt%-98wt% of propylene copolymer, 1wt%-3wt% of adhesion resisting agent and 1wt%-7wt% of macromolecule slip agent, namely silicone master batch. The preparation method sequentially comprises the following steps: mixing materials, extruding to form a film, cooling for shaping, measuring thickness, aureoling, trimming, reeling, performing aging treatment, and slitting. The heat-seal layer is uniformly dispersed in main body resin by the macromolecule slip agent, and the slip agent is well compatible with the main body resin due to high molecular weight, and thus a film surface friction coefficient is prevented from being changed by migration of the macromolecule slip agent due to temperature of a storage or usage environment.

Owner:永新股份(黄山)包装有限公司

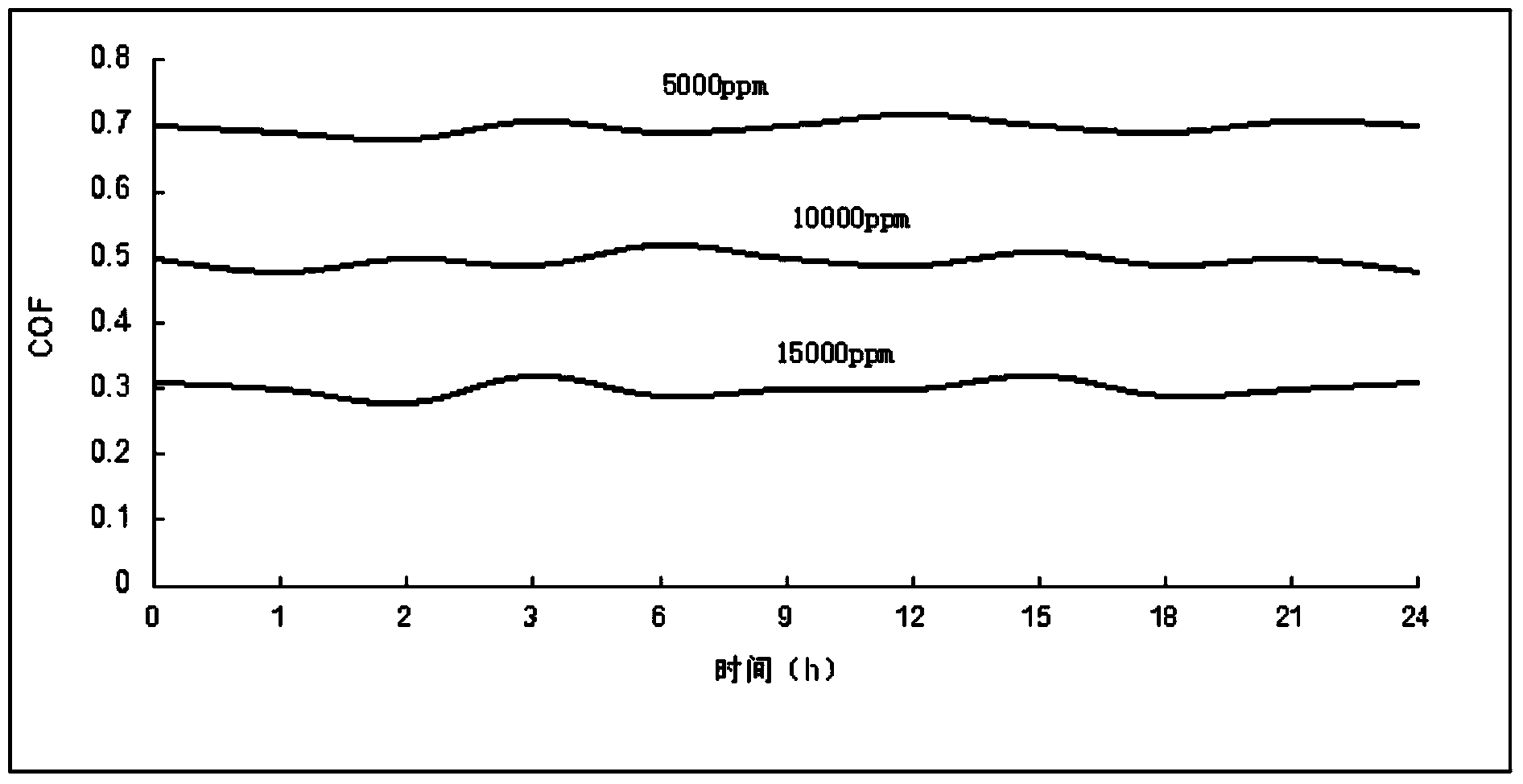

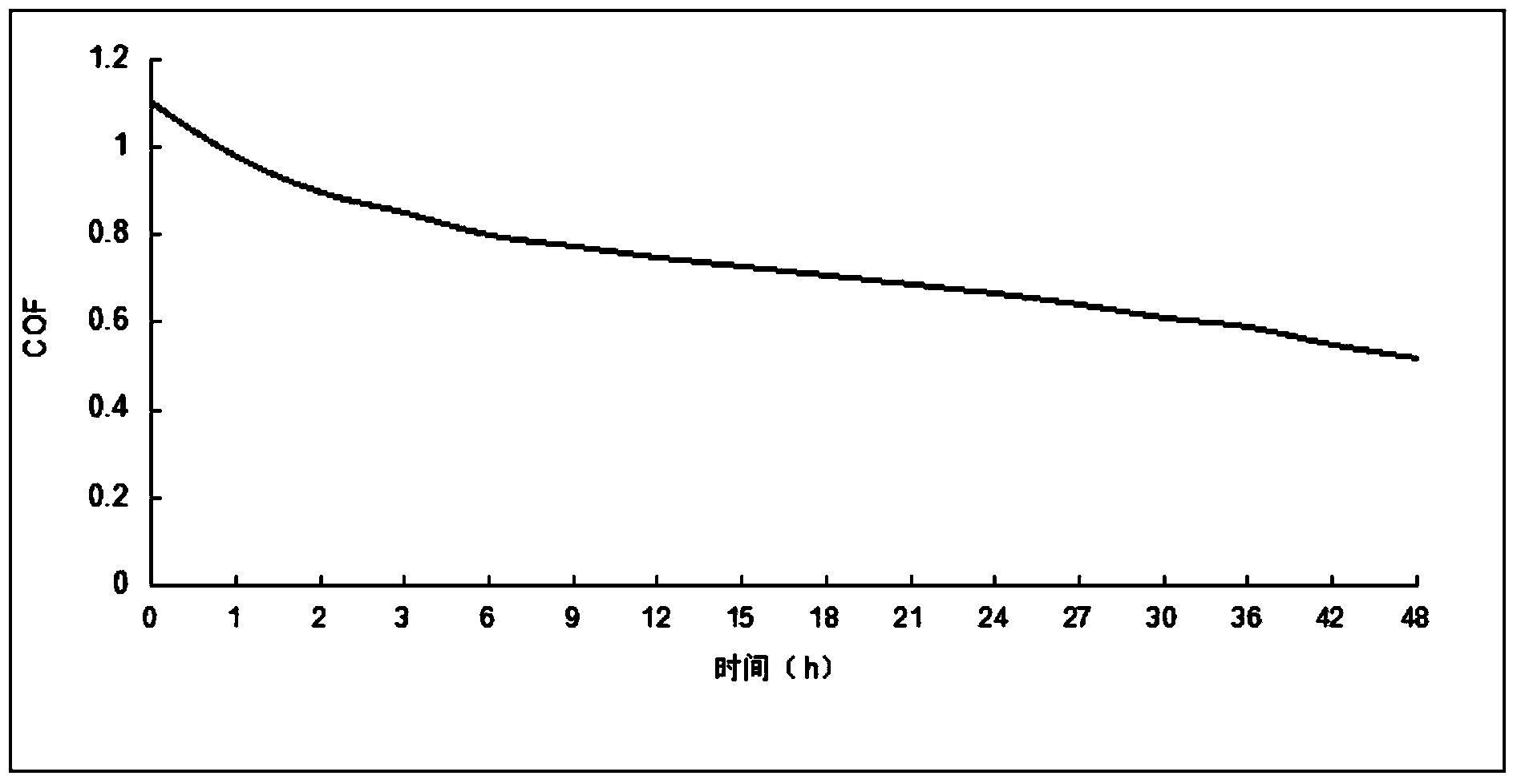

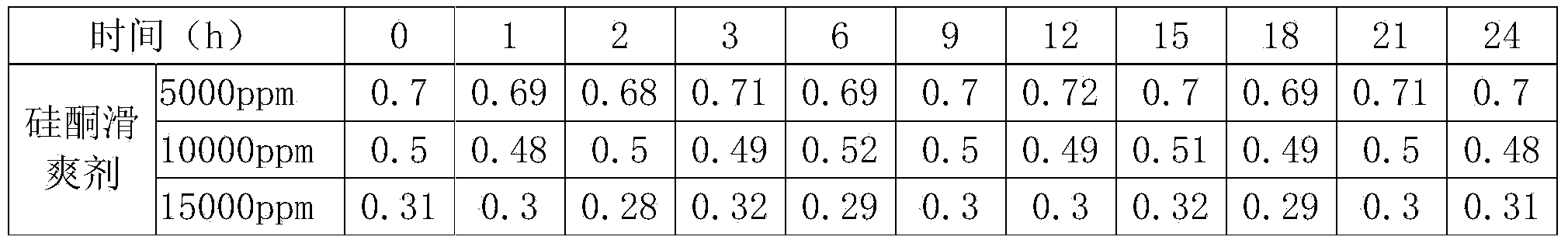

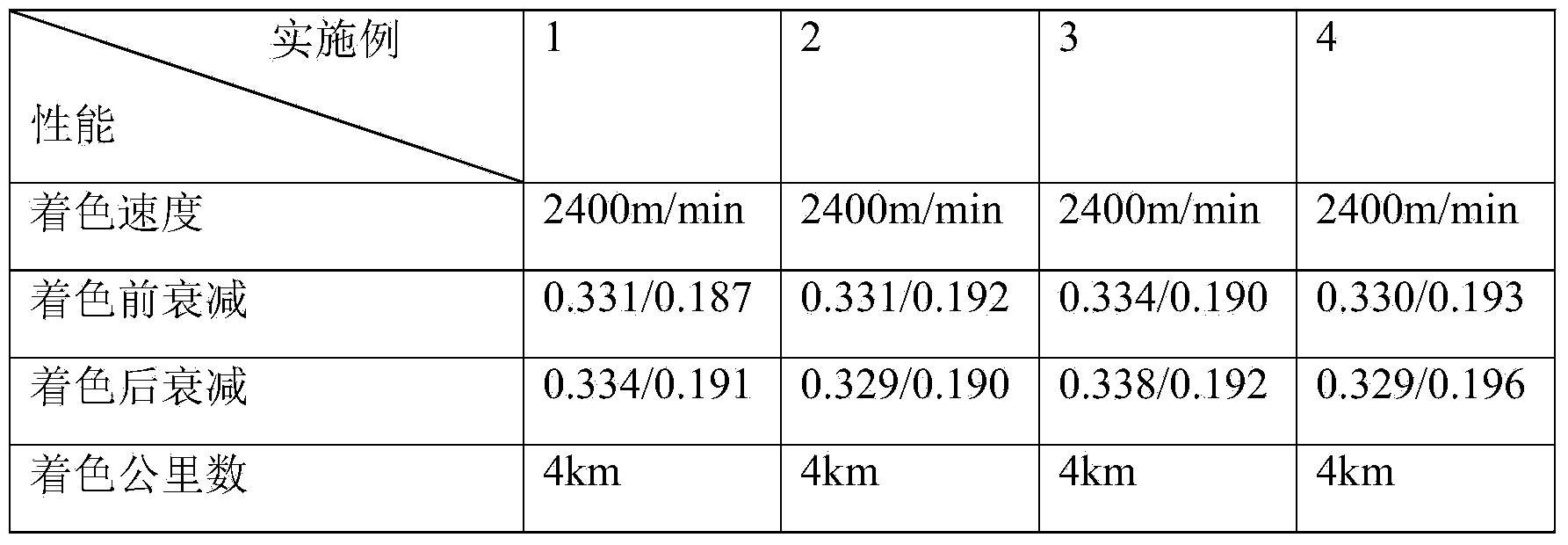

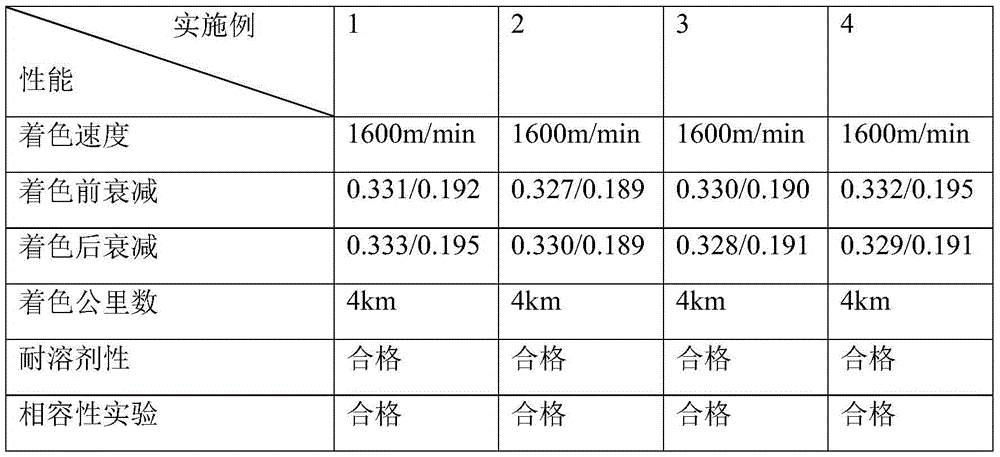

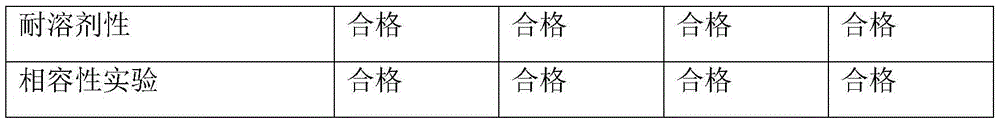

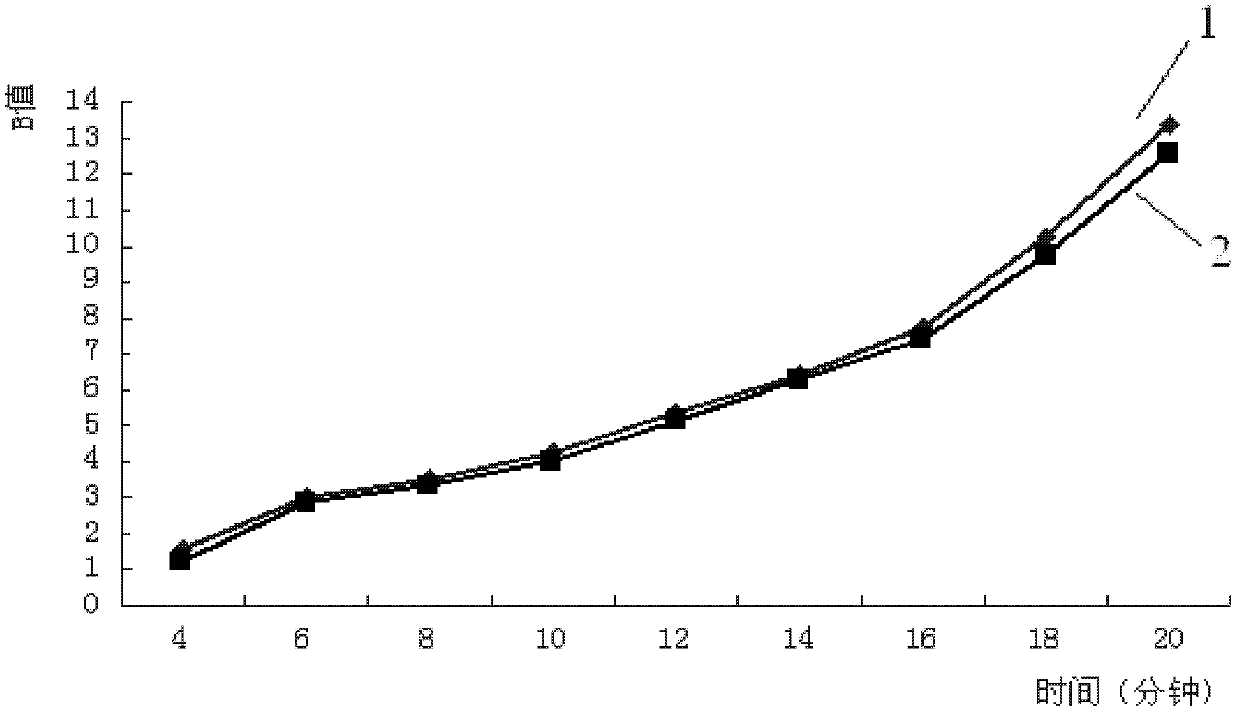

Optical fiber coloring ink with capacity of radiation curing

ActiveCN104263063ABright color does not fadeSmooth surface and good touchInksPhotoinitiatorOptical fiber cable

The invention relates to optical fiber coloring ink with capacity of radiation curing. The optical fiber coloring ink is characterized by comprising components in percentage by weight as follows: 1%-20% of color paste, 20%-40% of an activated diluent, 0.5%-4% of an auxiliary A, 40%-60% of UV resin and 3%-10% of a photoinitiator and an auxiliary initiator, and the percentage sum of the component is 100%. The optical fiber coloring ink with the capacity of radiation curing is high in curing speed and good in curing effect, an optical fiber colored by the ink has bright color and luster and smooth surface, is fadeless, touches good, and can be effectively distinguished in darker light.

Owner:武汉长盈鑫科技有限公司

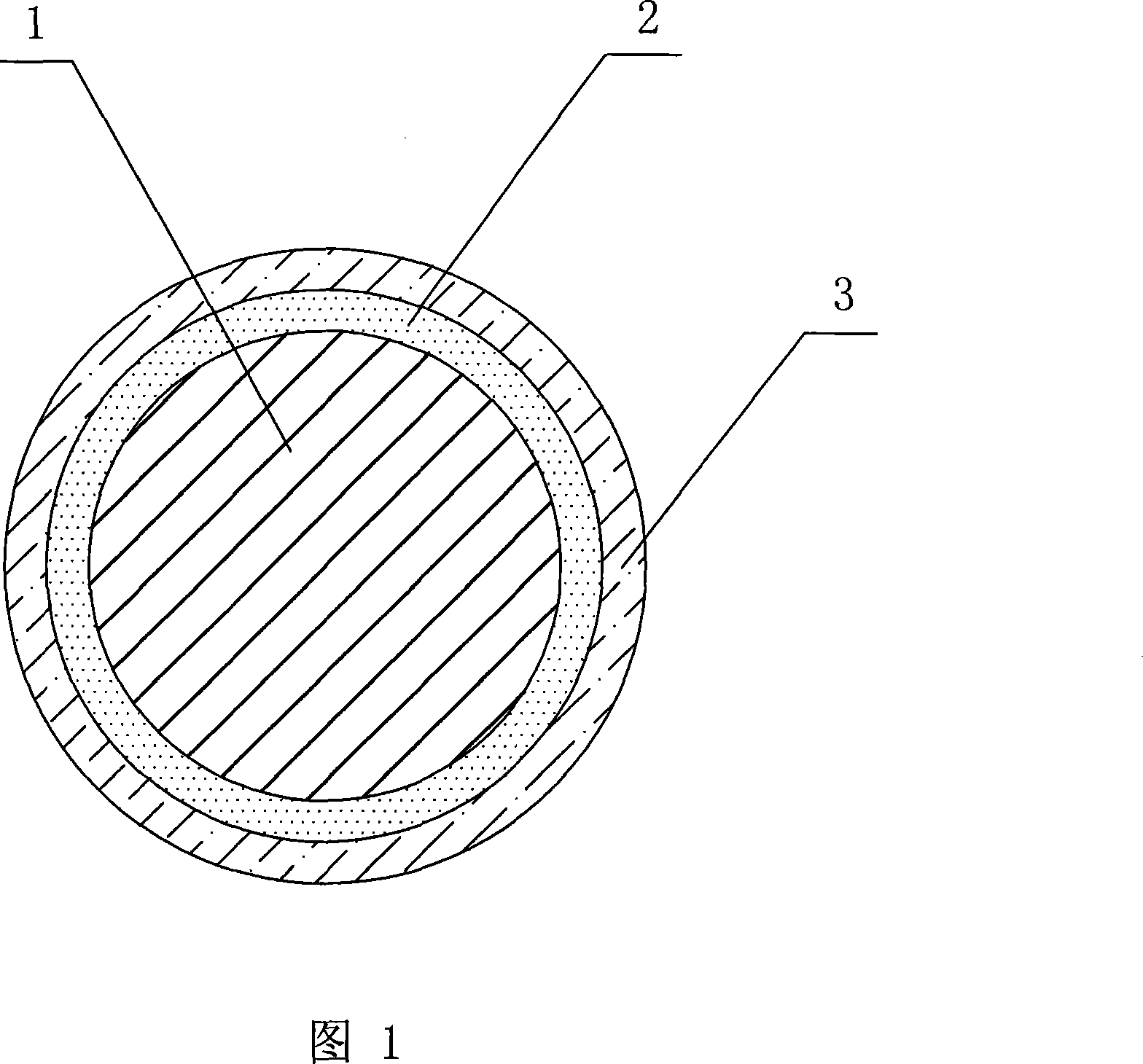

Self-adhesive enameled wire

InactiveCN101236800AStrong scratch resistanceGood slipperyInsulated cablesPolyamide coatingsCopper conductorLacquer

The invention relates to an electric material, in particular to a self-adhesive enameled wire, comprising a copper conductor and a polyurethane paint insulating layer which is coated on the outside of the copper conductor, wherein, a self-lubricating self-adhesive paint layer is also coated on the surface of the polyurethane paint insulating layer; chemical compositions and concentration percentage contents of various compositions of self-lubricating self-adhesive paint in the self-lubricating self-adhesive paint layer are as follows: amilan polyamide resins of 10 percent to 13 percent, cresols of 33 percent to 36 percent, phenols of 33 percent to 36 percent and xylene of 15 percent to 18 percent. Compared with the prior common self-adhesive enameled wire, the surface of the self-adhesive enameled wire has stronger scratch resistance and better gliding property, thereby the self-adhesive enameled wire is in accordance with high requirements provided by the modern electric machine industry to the enameled wire in the aspect of mechanical features.

Owner:常州华成电工有限公司

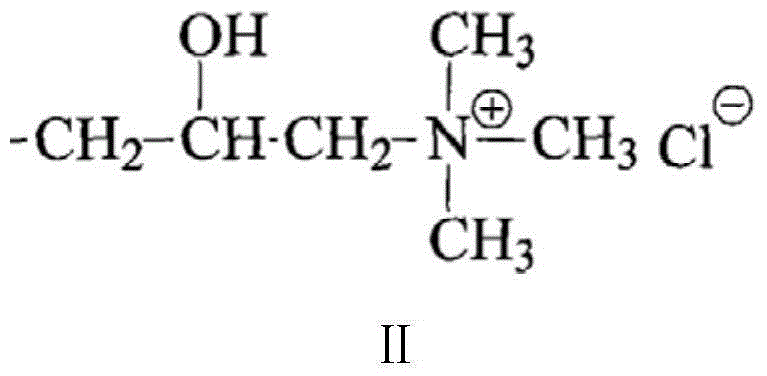

Softening agent for rayon embroidery thread

The invention relates to a softening agent for a rayon embroidery thread, which belongs to the field of softening agents for fabrics. The softening agent comprises, by mass, 10 to 30% of modified amino siloxane, 1 to 8% of quaternary ammonium salt, 5 to 15% of a nonionic emulsifier, 0.1 to 0.5% of organic acid and 46.5 to 83.9% of deionized water. A preparation method for the softening agent comprises the following steps: adding the above-mentioned percentages of the modified amino siloxane and the nonionic emulsifier into a variable-speed mixer and carrying out uniform mixing under stirring; then adding the quaternary ammonium salt and carrying out stirring; slowing adding the organic acid and deionized water in proportion and carrying out an emulsification reaction; and then successively carrying out uniform mixing under stirring and split charging. The softening agent for the rayon embroidery thread has good stability, can endow the thread with excellent slippery and reduce static electricity of the thread, lowers a thread breakage rate in the process of high-speed embroidering and improves the luster of the thread.

Owner:上海氟聚化学产品股份有限公司

Production process of environment-friendly cattle hide mattress

InactiveCN105316437AFeel comfortableGood elasticityTanning treatmentPre-tanning chemical treatmentContinuous useEnzyme

The invention discloses a production process of environment-friendly cattle hide mattress. The production process includes the following steps: primary tanning, finely cutting, shaping and drying, mill-softening, spray-scalding, cutting, splicing, quality inspection, and storage in storerooms to obtain a real leather mattress finish product. Compared with the prior art, the production process is safe and environment-friendly and is free of pollution. The prepared leather is free of heavy metal and formaldehyde and satisfies environment requirement. By means of a bio-enzyme preparation for degrading and dissolving materials, an aqueous solution for dissolving the materials can be recycled without water resource waste. The prepared leather has a good hand feel, is excellent in elasticity, smoothness and extensibility. The mattress is safe to use and is free of damage on human body.

Owner:YIBIN HAOYU LEATHER CO LTD

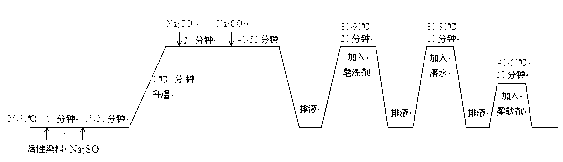

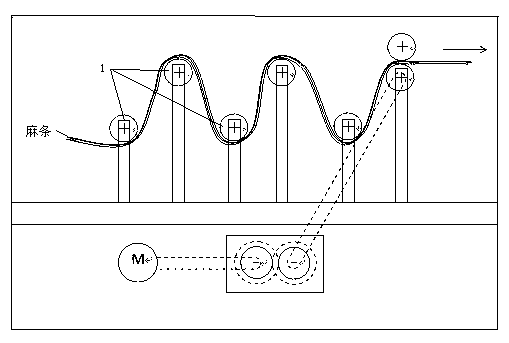

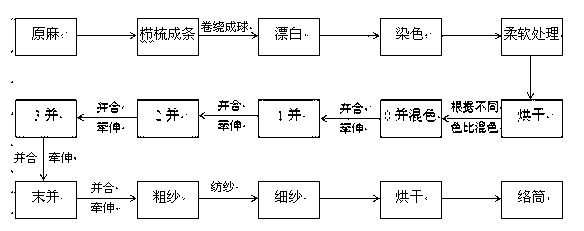

Production method of bastose wet spinning yarn

ActiveCN103215713APromote degradationSolve the problem that the production cannot be openedFabric breaking/softeningSucessive textile treatmentsYarnPulp and paper industry

The invention relates to a production method of a bastose wet spinning yarn. The production method of the bastose wet spinning yarn comprises the steps of heckling, degumming, scouring and bleaching, dyeing, drying and softening, then color mixture is carried out on two kinds or more than two kinds of ramie strips of different colors according to different color ratios, the ramie strips are mixed and drafted after 4-6 drawing working procedures, roving and wet spinning thinning working procedures are carried out on the ramie strips, and finally the ramie strips are dried, spooled and packaged to form a finished product. The production method of the bastose wet spinning yarn is characterized in that the heckling working procedure comprises a process of strip manufacturing and a process of ball formation, the process of strip manufacturing means that short fibers are removed and then long bastose fibers are manufactured into the ramie strips; and the process of ball formation means that the continuous ramie strips are wound layer by layer from inside to outside to form a hollow cylindrical bastose ball. The produced bastose wet spinning yarn is uniform in dyeing, bright in color, rich in level, and good in color fastness.

Owner:ZHEJIANG JINYUAN FLAX

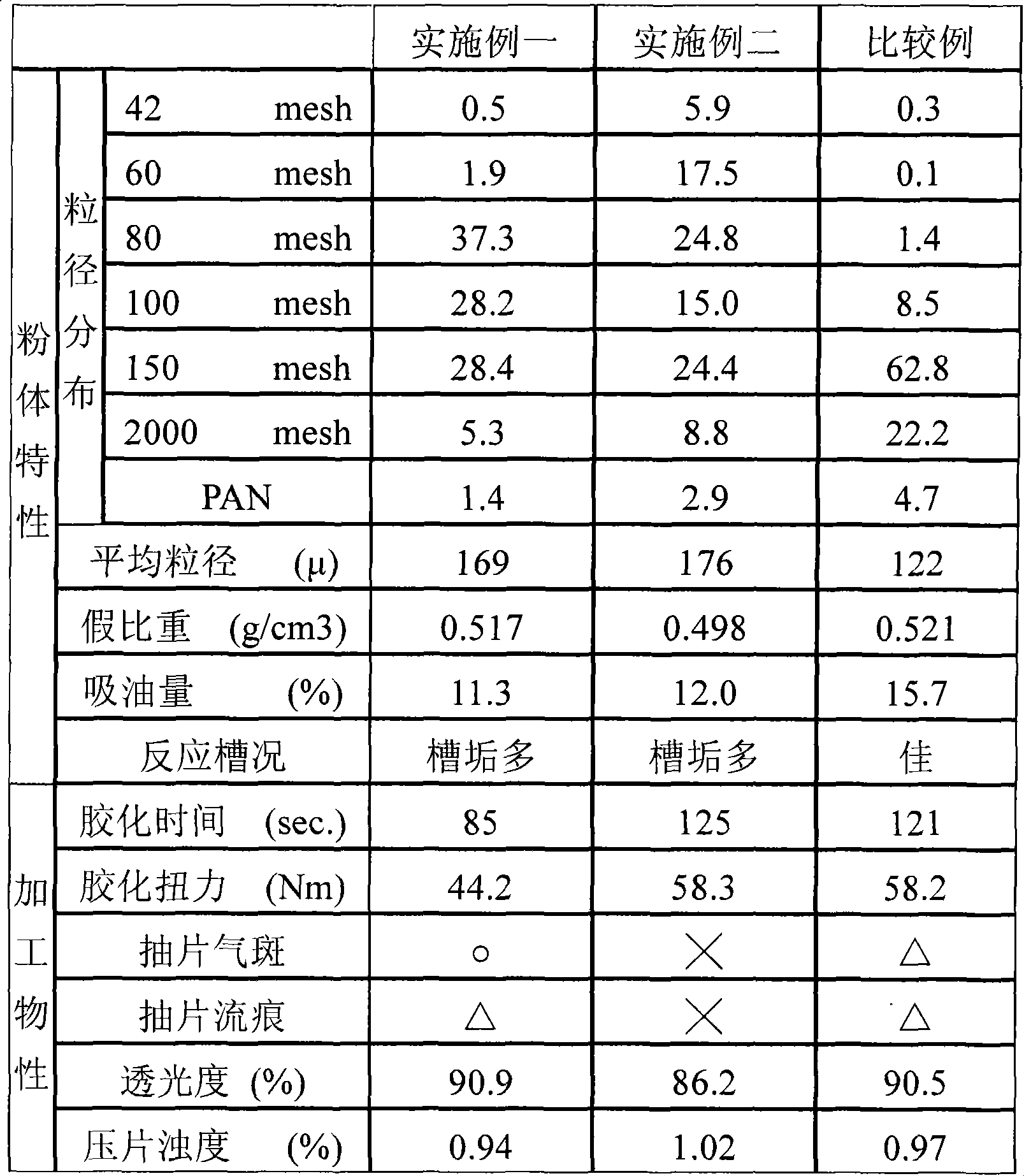

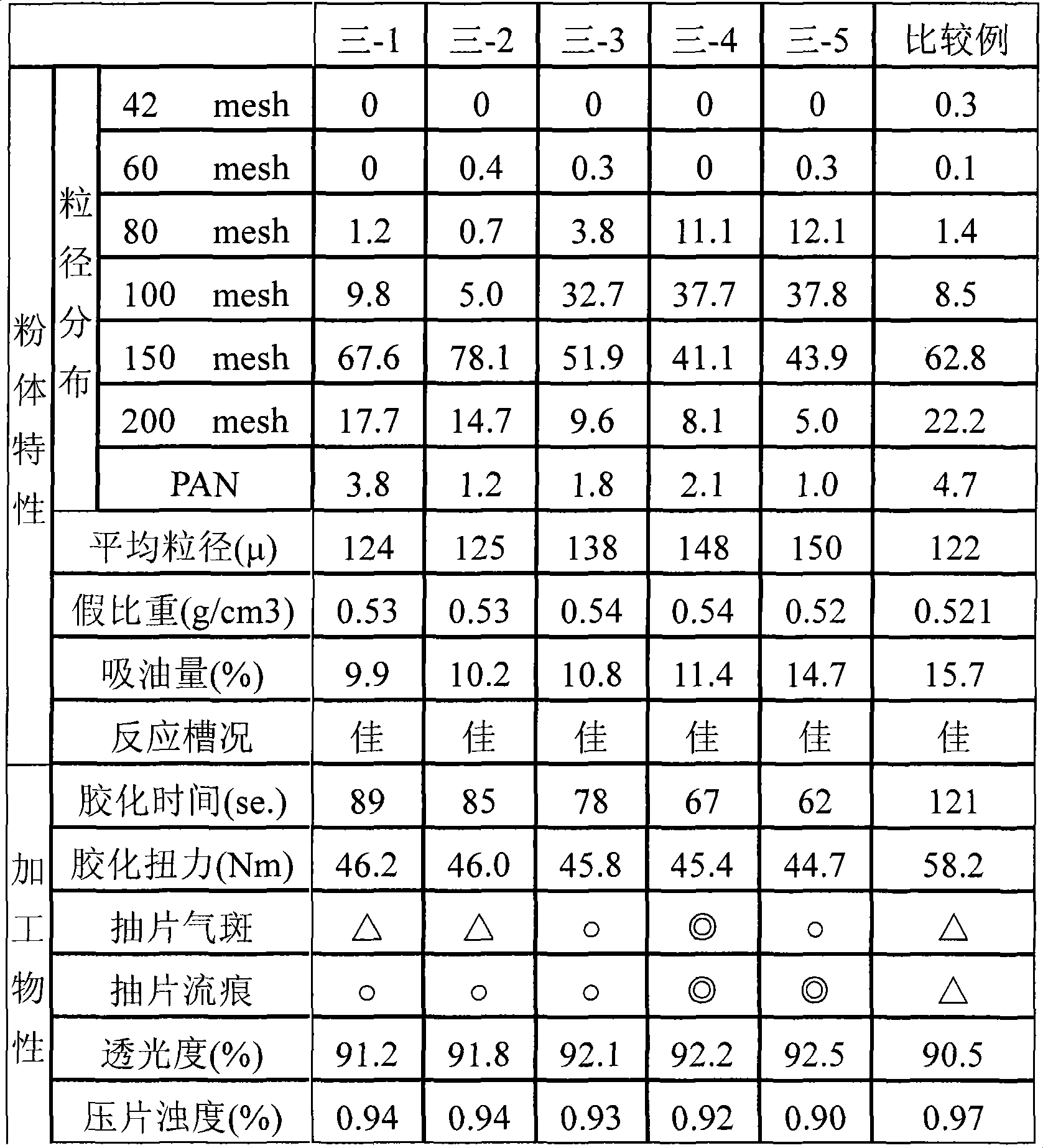

Preparation of functional composite material polyvinylhalogenides resin

The invention provides a functional composite material poly ethylene halide resin, which is prepared by the solution method, the block polymerization method or the suspension polymerization method. The poly ethylene halide resin is prepared through the following steps: (1) providing ethylene halide monomer or multiple polymerization monomers mainly including ethylene halide monomer 90.0 to 99.9 wt% of total composition; and (2) sectionally adding or adding at a time multiple alkyl acrylate monomer or alkyl acrylate / acrylic polymer emulsion / dried substance 10.0 to 0.1 wt% of total composition, and carrying out copolymerization or graft polymerization reaction, wherein the polymerization monomer (ethylene halide monomer or multiple polymerization monomers mainly including ethylene halide monomer) is added in bath or sectionally continuous added, and the multiple alkyl acrylate monomer or alkyl acrylate / acrylic polymer emulsion / dried substance is continuously added during reaction process or is placed into a coincidence tank before reaction.

Owner:FORMOSA PLASTICS CORP

Environment-friendly fur tanning method

InactiveCN103320551AFeel comfortableIncrease elasticityTanning treatmentPre-tanning chemical treatmentFood gradeWater resources

The invention belongs to the field of processing of fur, and discloses an environment-friendly fur tanning method. The method comprises the following steps of: soaking the fur, degreasing, pickling, tanning, neutralizing, drying, kicking oil and softening. The materials adopted by the method are in food grade, safe and environment-friendly, and free of pollution; and the prepared fur does not contain heavy metals and formaldehyde, and accords with the environment-friendly requirements. A chemical material is degraded by a biological enzyme preparation, so that the solution of the chemical material and water is continuously used; water resource is not wasted; and the fur prepared by the method is thin and soft, and comfortable in hand handle, and has good elasticity, smoothness and extensibility.

Owner:GUCHENG DAHUA HAOYE FUR TANNAGE

Super-smooth silky silicone oil for fabric after-treatment and after-treatment process

The invention provides super-smooth silky silicone oil for fabric after-treatment. The oil comprises comprises, in parts by weight, 2-20 parts of ethoxylated stearamide, 4 to 30 parts of hydroxyl silicone oil, 2 to 20 parts of amino polyether silicone oil, 1 to 15 parts of carboxyl modified silicone oil, 1 to 15 parts of polyurethane modified silicone oil, 5 to 15 parts of alcohol ether carboxylate, 0.1 to 5 parts of non-ionic emulsifier, 1 to 10 parts of glacial acetic acid, 0.1 to 5 parts of glycerol and 40 to 80 parts of water. The treated product is good in smoothness, strong in moisteningfeeling, full and saturated, and has a silk-like feeling, so that the grade of the product is greatly improved, and the economic benefit is greatly increased. The oil can be used in a same bath withanionic substance finishing agents such as a coating, a brightening agent and a soaping agent, so that conventional multifunctional finishing split-bath use is changed into the one-bath use, the multifunctional finishing of the fabric becomes easy, the energy loss is reduced, and the treatment efficiency is improved. The invention further provides an after-finishing process.

Owner:广东宏昊化工有限公司

Preparation method and application of novel modified organic silicon softening agent

The invention discloses a preparation method and application of a novel modified organic silicon softening agent, and belongs to the technical field of textile chemical industry. The preparation method comprises the catalyst preparing process and the softening agent preparing process, wherein zinc sulfate and D-sodium gluconate solids are added into 100 ml of water to be mixed to prepare a catalyst solution, polysiloxane, butyl methacrylate and n-butyl acrylate are mixed and stirred, the catalyst solution is added after the temperature is increased, and a temperature increasing reaction is performed to obtain the modified organic silicon softening agent. The invention further discloses application of the organic silicon softening agent in a flax fabric finishing technology. The preparation method is simple, convenient, easy to operate, low in cost and suitable for the large-scale industrialized production requirement; after the novel modified organic silicon softening agent is applied to flax fabric finishing, the good flexibility and wrinkle resistance are given to flax fabric fiber, the smoothness and brightness are also excellent, and the extremely high market promotion value is achieved.

Owner:SUZHOU INSILK CO LTD

Energy-saving and environment-friendly protecting material for slab continuous casting mold

The invention discloses an energy-saving and environment-friendly protecting material for a slab continuous casting mold, which comprises raw materials by weight percent: 2-5% of carbon black, 1-3% of carburant, 11-15% of fluorite, 1-4% of sodium fluoride, 1-3% of cryolite, 2-5% of manganese carbonate, 2-5% of barium carbonate, 10-12% of white alkali, 7-15% of grain slag, 2-7% of calcite, 40-50% of wollastonite and 1.5-2.5% of yellow dextrin. When being used, the protecting material can show good spreadability, heat preservation performance and melting performance in a crystallizer; heat transmission amount at the periphery in the crystallizer is stable and uniform, and high casting speed requirements can be met; and testing slag strip is small, non-uniformity of inflow is improved, and the protecting material has good lubricity so as to prevent caking steel leakage. No slag inclusion or caking slag phenomena exist on the surface of a casting blank, so that the surface quality of the casting blank is good.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

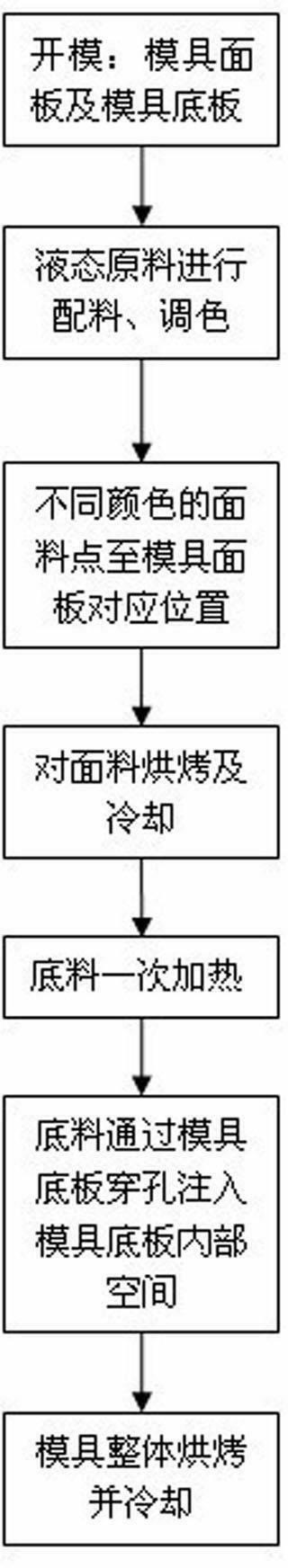

Polyvinyl chloride (PVC) trade mark producing process

InactiveCN102658623AImprove stabilityEasy to processOther domestic articlesSurface patternSurface layer

The invention provides a polyvinyl chloride (PVC) trade mark producing process. The process comprises the following steps of: performing die sinking according to the shape of a trade mark, wherein a producing mold comprises a mold surface plate and a mold bottom plate which are mutually folded to each other; dividing a prepared ingredient into surface layer liquid materials and bottom layer liquid materials, and adding various colorants to match colors of various surface layer liquid materials and bottom layer liquid materials respectively; dispensing the surface layer liquid materials in various corresponding colors to corresponding positions of the mold surface plate on which trade mark surface patterns are formed by using dispensing equipment; baking the mold on which the surface layer liquid materials are dispensed, and cooling after shell fabrics are baked; heating a backing material at a time; folding the mold bottom plate and the mold surface plate, and injecting the heated bottom layer liquid materials into the mold bottom plate through a perforated hole of the mold bottom plate; and baking the integral mold subjected to injection molding, and cooling. By the process, the liquid materials are utilized; the conventional step in which aids are required to be added and the conventional granulation step are eliminated; and simultaneously, the color stability and the secondary processing performance of products are improved.

Owner:GUANGDONG LIXIN INTELLIGENT TECH CO LTD

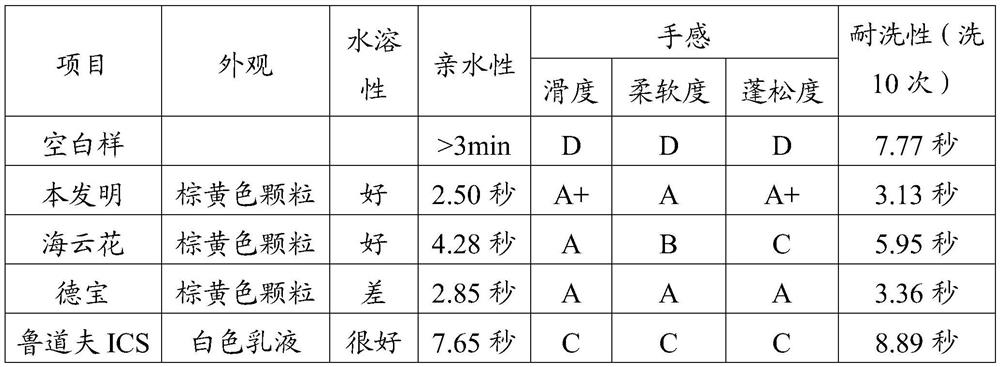

Multifunctional moisture absorption and sweat releasing finishing agent and preparation method therefor

ActiveCN111705511AStrong water absorptionGood moisture permeabilityGrip property fibresPolymer sciencePolyethylene terephthalate glycol

Owner:湖南金全立生物科技股份有限公司

Process for preparing high-dispersibility ultrafine mica powder

ActiveCN102732069BIncrease concentrationModerate oil absorptionInorganic pigment treatmentSuspended matterSilicon dioxide

The invention relates to a process for preparing high-dispersibility ultrafine mica powder, comprising the following steps: preparing a silicon precursor ethanol mixed solution from anhydrous ethanol and one or more of the tetramethoxysilane, the tetraethoxysilane with the mass parts of silica of 28, the ethyl silicate with the mass parts of silica of 32 and the ethyl silicate with the mass parts of silica of 40; adding natural muscovite or synthetic mica into a reactor, adding deionized water to prepare a suspension; stirring and heating the suspension, and adjusting the pH value of the suspension by aqueous alkali; pumping the silicon precursor ethanol mixed solution into the suspension, and continuously subjecting the silicon precursor ethanol mixed solution and the suspension for reaction of 1 hour to obtain a mother solution; removing suspended matters in the mother solution by filtering, washing by deionized water, and washing a filtrated in a baking oven to obtain the high-dispersibility ultrafine mica powder. The process can fully exert the advantages of the ultrafine mica powder, is simple and has the advantages of high production efficiency, low equipment cost and low energy consumption.

Owner:杭州弗沃德精细化工有限公司

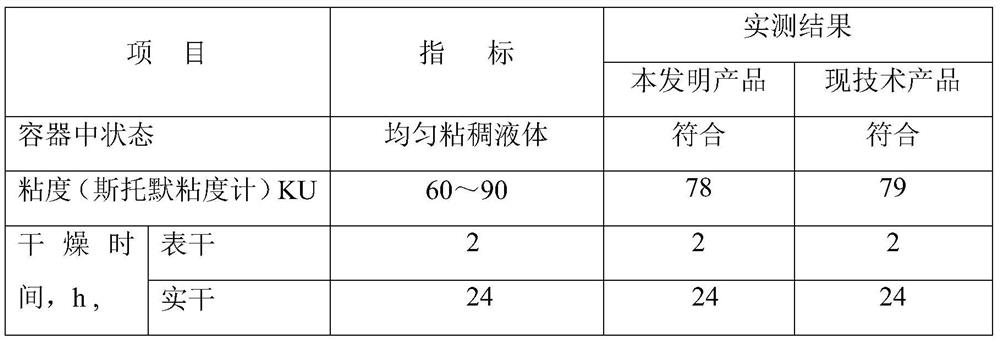

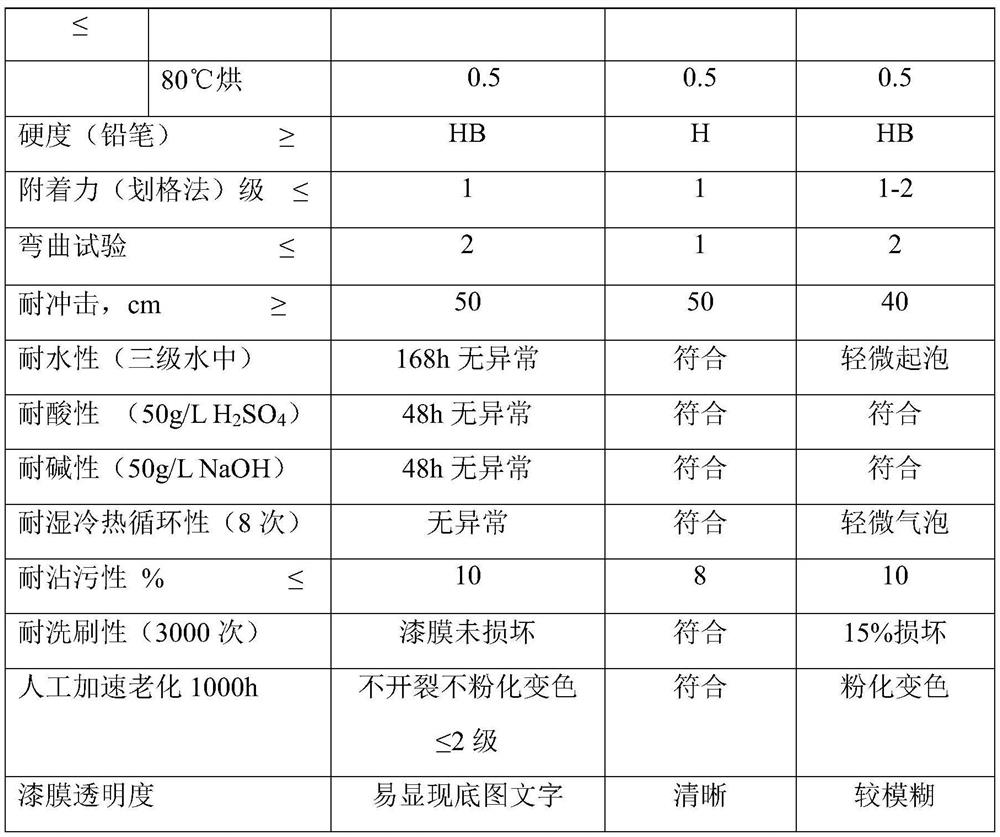

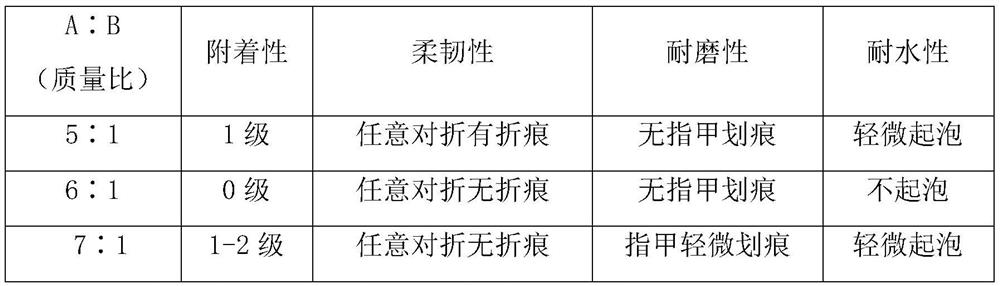

Waterborne coating of self-adhesive decorative cloth and preparation method thereof

The invention discloses a waterborne coating of a self-adhesive decorative cloth and a preparation method thereof, and relates to the technical field of waterborne coatings. The coating is mainly prepared from the following raw materials in parts by weight: 60-65 parts of waterborne organosilicone modified hydroxy acrylic resin, 5-6 parts of polyether modified polydimethylsiloxane, 0.1-0.2 part ofa preservative, 0.2-0.4 part of a defoamer, 0.5-0.7 part of a base material wetting agent, 0.2-0.4 part of a flatting agent, 2-4 parts of an adhesion promoter, 0.6-0.8 part of a thickening agent, 0.3-0.5 part of a pH regulating agent, 8-10 parts of transparent siboner, and 18-22 parts of deionized water. The invention further provides a preparation method of the coating. The coating and the method have the beneficial effects that, the waterborne coating of the self-adhesive decorative cloth has good adhesion and can be easily applied on the self-adhesive decorative cloth; the coating has goodcoating layer elasticity and can be flexibly bent together with the self-adhesive decorative cloth; the coating is good in transparency and original patterns on the self-adhesive cloth is naturally shown; and the functional effect is good.

Owner:ANQING LINGHU PAINT

High-strength easily-erased resin pencil lead and preparation method thereof

The invention relates to a high-strength easily-erased resin pencil lead and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing, by mass, 92-99 partsof thermoplastic resin, 1-8 parts of inorganic nanoparticles and 0.5-2.5 parts of a processing aid in a mixer, and extruding and granulating the obtained mixture by a parallel twin-screw extruder to prepare reinforced thermoplastic resin particles; and uniformly mixing 15-50 parts of the reinforced thermoplastic resin particles, 40-80 parts of graphite, 5-18 parts of a lubricant and 1-5 parts of asurfactant, drying and dehydrating the obtained mixture, kneading and mixing the dried mixture by an internal mixer, granulating the kneaded mixture in a single-screw extruder, molding obtained granules by an extrusion molding machine, and cutting the molded granules to prepare the pencil lead with a suitable length. The resin pencil lead prepared in the invention has the advantages of high strength, easiness in being erased, good slippery and good coloring property, and the preparation method has the advantages of simple process, low cost, and realization of continuous large-scale production. The pencil lead can be widely used in pencils for writing, drawing and painting.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI +1

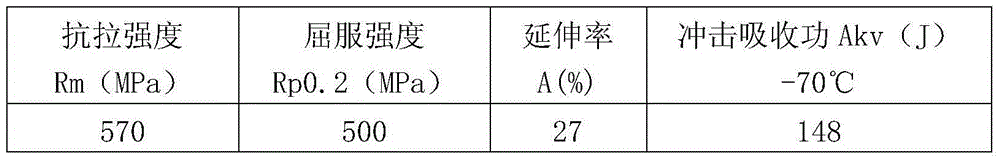

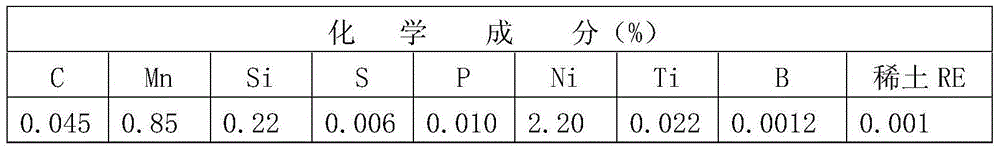

-70 degrees centigrade low-temperature steel welding bar

ActiveCN104551455AReduce segregationDecreased low temperature toughnessWelding/cutting media/materialsSoldering mediaSlagMolten bath

The invention discloses a -70 degrees centigrade low-temperature steel welding bar. The -70 degrees centigrade low-temperature steel welding bar comprises a welding core and a coating, the coating of the welding bar is composed of 44-54% of marble, 15-24% of fluorite, 3-6% of barium carbonate, 2-5% of quartz, 2-5% of dehydration potassium titanate, 0.5-1.5% of borax, 1-3% of manganese metal, 3-6% of atomized ferrosilicon, 1-3% of rare earth ferrosilicon, 3-6% of ferrotitanium, 0.5-1.0% of silicon calcium alloy, 6.0-8.0% of nickel powder and 0.2-1.0% of Teflon. The -70 degrees centigrade low-temperature steel welding bar is featured with low nickel content, less splashing, good molten bath fluidity, uniform slag cover, soft electric arc sound, beautiful weld joint appearance, easiness in sediment separation and good welding technique, the content of diffusible hydrogen in the weld joint metal is within 5ml / 100 g (mercury process), and this meets the standard super-low-hydrogen welding bar requirement.

Owner:JIANGSU JIUZHOU NEW MATERIAL TECH CO LTD

Fabric softener

The invention discloses a fabric softener. The fabric softener comprises the following components in parts by mass: 3-15 parts of ester quaternary ammonium salt, 1-5 parts of water-soluble polyether silicone oil, 2-10 parts of amino silicone oil, 0.2-0.8 parts of EDC, 0.06 ~ 0.18 parts of N-hydroxy thiosuccinimide, and 70-80 parts of deionized water. The fabric softener of the invention can effectively reduce the color change when the amino silicone oil with a high ammonia value has the advantages of good softness and smoothness, and has no damage to the fabric after use, and increases the softness and the gas permeability of the fabric, after washing, the fabric has good rewetting property, antistatic performance, no yellowing, light fragrance, and long fragrance stay.

Owner:湖北健客日化有限公司

High-molecular polymer PVP

The invention discloses a green and environment-friendly high-molecular polymer PVP. Deionized water, polyvinyl pyrrolidone (PVP) powder, stearic acid, glycerin, sodium benzoate, and ethyl p-hydroxybenzoate are taken as the main raw materials, and made into a high-molecular polymer material through a scientific condensation technology; wherein the high-molecular polymer material is harmless to human body, is green and environment-friendly, and has a wide application range and low price. The provided high-molecular polymer PVP has the advantages of long service life, high viscosity, good slip performance, low smearing resistance, low production cost, and high cyclic utilization value.

Owner:LUOHE LOUFOR STATIONERY MFG

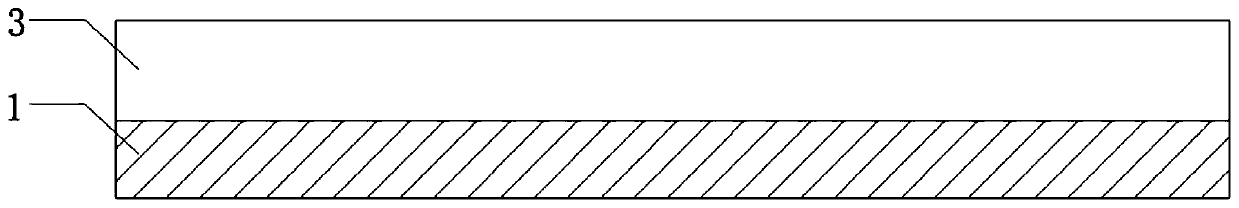

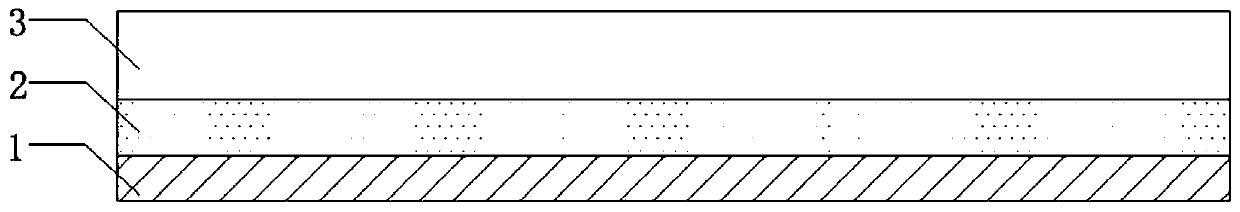

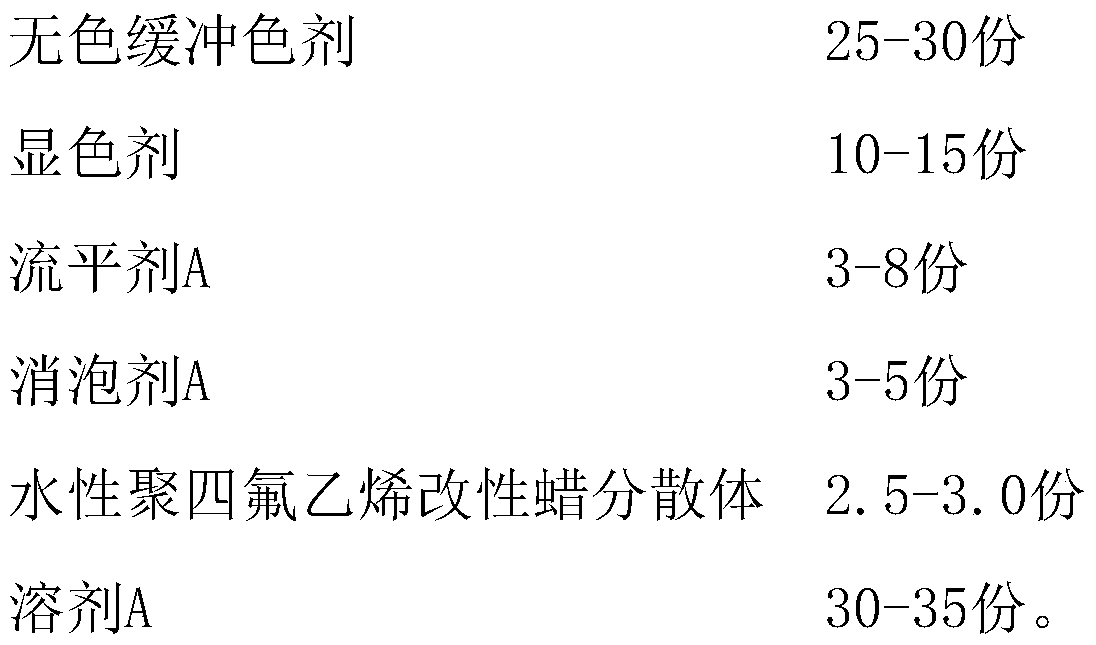

Bottom blue-developing thermosensitive label and preparation method thereof

ActiveCN110379293AGood dispersionBroaden applicationStampsPaper/cardboard articlesHigh volume manufacturingSolvent

The invention relates to the technical field of thermosensitive labels, in particular to a bottom blue-developing thermosensitive label and a preparation method thereof. The bottom blue-developing thermosensitive label comprises a bottom layer and a dye layer which are sequentially arranged from bottom to top, wherein the bottom layer is carbon-source-free paper, and the dye layer is made of developing dye; the color development dye comprises the following raw materials in parts by weight: 25-30 parts of a colorless buffer toner, 10-15 parts of a color developing agent, 3-8 parts of a flattingagent A, 3-5 parts of a defoamer A, 2.5-3.0 parts of an aqueous polytetrafluoroethylene modified wax dispersion, and 30-35 parts of a solvent A. The dye layer of the bottom blue-developing thermosensitive label can change the color developing of the printed characters in a printing state of a thermosensitive printer, can improve the withered monotonous sense of only single black characters at present and can improve the color development effect. The preparation method of the bottom blue-developing thermosensitive label has the advantages of the simple operation, the easy control, the high production efficiency and the stable quality, and can be used for mass production.

Owner:GUANGDONG TENGEN IND GRP CO LTD

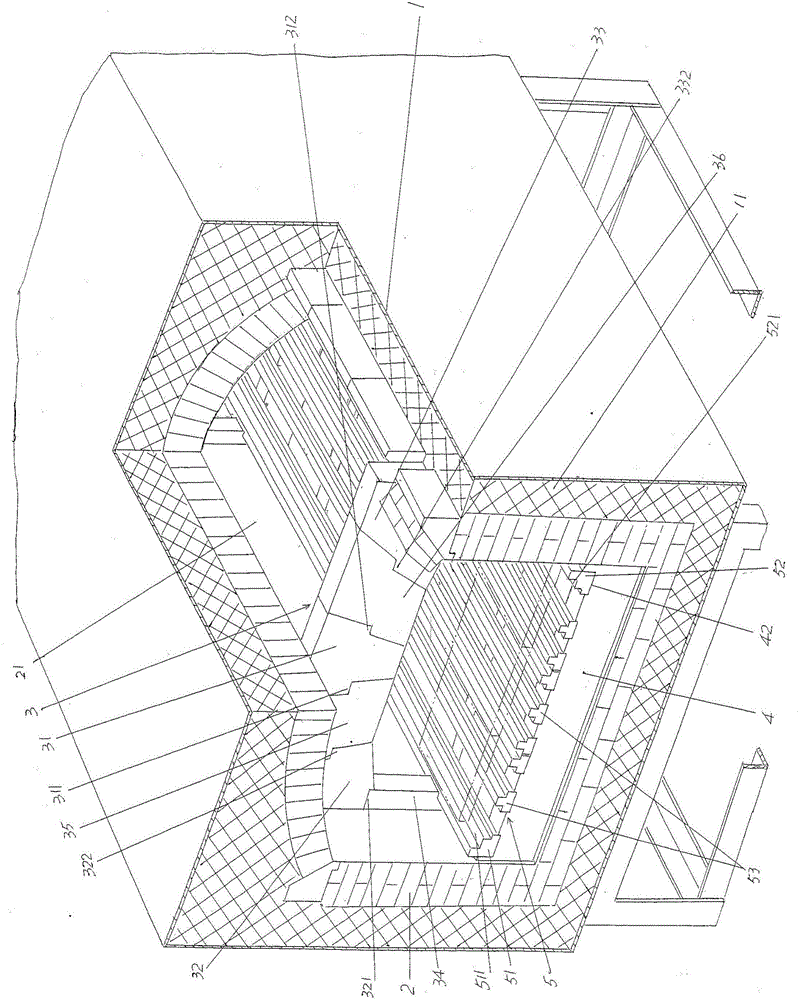

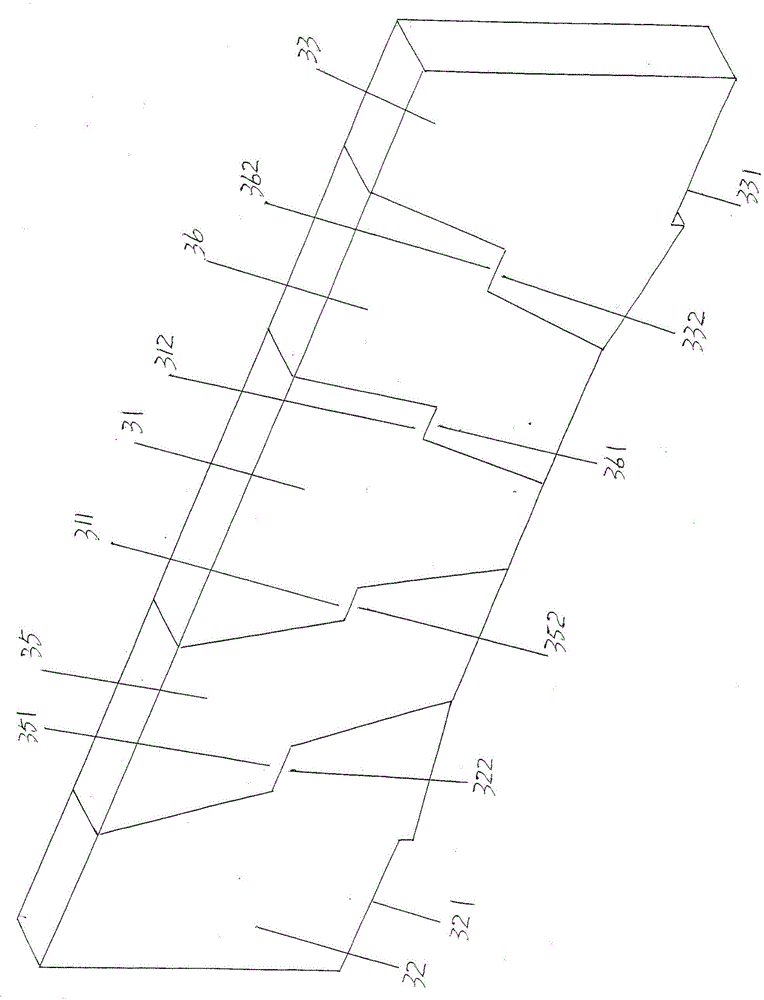

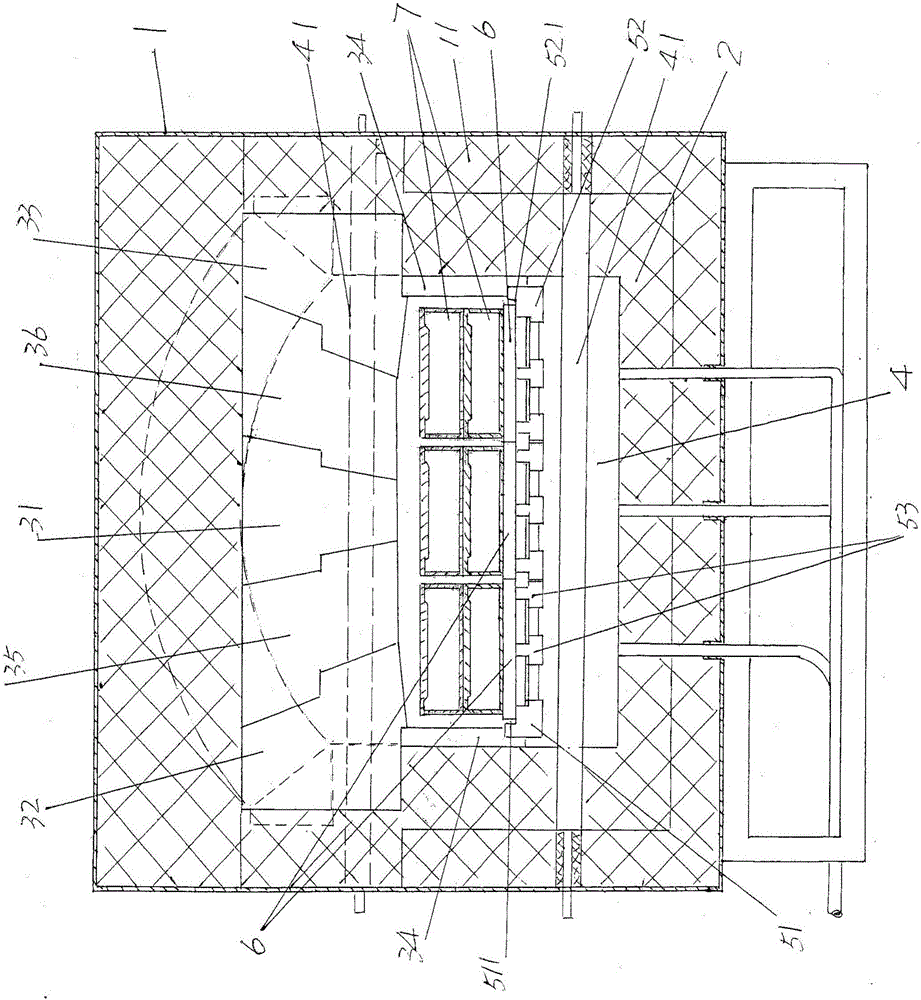

Efficient battery material sintering furnace with push plate guide sliding function

InactiveCN105783502AGood slipperyReduce distanceMuffle furnacesRetort furnacesTemperature controlElectrical battery

An efficient battery material sintering furnace with a push plate guide sliding function comprises a furnace shell, a furnace lining, an upper partitioning beam and a lower partitioning beam, and is characterized by further comprising a push plate guide sliding mechanism, wherein the push plate guide sliding mechanism consists of a left limiting guide track, a right limiting guide track and a group of middle guide tracks; cross sections of the left limiting guide track and the right limiting guide track are L-shaped; cross sections of the group of middle guide tracks are inverted-T-shaped; a left limiting guide track groove is formed in one side, which faces the right limiting guide track, of the left limiting guide track; a right limiting guide track groove is formed in one side, which faces the left limiting guide track, of the right limiting guide track; a position, which corresponds to the left end of the lower partitioning beam, of the left limiting guide track is fixed with the lower partitioning beam; a position, which corresponds to the right end of the lower partitioning beam, of the right limiting guide track is fixed with the lower partitioning beam; the group of middle guide tracks are positioned between the left limiting guide track and the right limiting guide track and are fixed with the lower partitioning beam; the upper partitioning beam comprises a central insert block, a left insert block, a right insert block and a pair of insert block support columns. Collapse can be avoided; temperature control and atmosphere uniformized effects of adjacent sintering temperature regions are ensured; energy is saved; and a push plate and side walls of a furnace chamber are protected.

Owner:SUZHOU HUIKE EQUIP CO LTD

Preparation method of regenerated cellulose/inorganic nano-material composite film

The invention discloses a preparation method of a regenerated cellulose / inorganic nano-material composite film. The preparation method comprises the steps of firstly, preparing water mixed suspensionof an inorganic nano-material, mixing the prepared water mixed suspension with an ionic liquid aqueous solution, and carrying out dewatering concentration treatment on the obtained mixture; then, mixing the concentrated ionic liquid mixed suspension of the inorganic nano-material with a cellulose raw material, and carrying out dewatering and defoaming treatment to obtain a uniform and transparentcellulose / inorganic nano-material solution; finally, regenerating the cellulose / inorganic nano-material solution for forming a film so as to obtain the regenerated cellulose / inorganic nano-material composite film. The preparation method provided by the invention overcomes the defects that the traditional regenerated cellulose film is low in slippery degree, poorer in softness, poor in service performance under the conditions of low temperature and high humidity, and the like, and improves the quality of the cellulose film; furthermore, the preparation method solves the problems that the traditional regenerated cellulose film is high in energy consumption and pollution during preparation.

Owner:山东中科恒联生物基材料有限公司 +1

Aqueous surface coating solution composition and polyester film structure

InactiveCN113337190AHigh transparencyLow hazeLayered productsPolyurea/polyurethane coatingsPolymer scienceInorganic particle

Owner:NANYA PLASTICS CORP

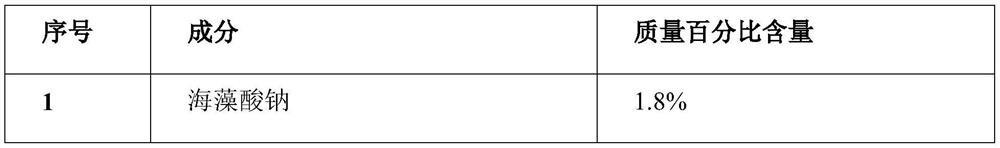

Mild and effective carbonic acid gel facial mask and preparation method thereof

InactiveCN111773116AFully absorbedGentle bubble responseCosmetic preparationsToilet preparationsEthylene glycol bisPolyethylene glycol

The present invention provides a mild and effective carbonic acid gel facial mask. The mild and effective carbonic acid gel facial mask is prepared from the following raw material components in percentages by mass: 0.5%-3% of sodium alginate, 0.5%-2.0% of carbomer, 0.5%-1.5% of sodium carbonate, 2%-5% of calcium sulfate, 10%-25% of glucono lactone, 0.1%-0.3% of a thickener, 10%-20% of an additiveand the balance of deionized water, wherein the additive is a mixture of glycerin, polyethylene glycol, dipropylene glycol, 1,3-butanediol, flavor, and phenoxyethanol. Meanwhile, the invention furtherprovides a preparation method of the facial mask. The raw materials are weighed according to the proportions to separately prepare liquid 1 and liquid 2 of the facial mask, and then equal-weight mixing is carried out for use. The mild and effective carbonic acid gel facial mask has the advantages of a mild and durable foaming reaction, large foaming volume and good application effect.

Owner:南京紫鸿生物科技有限公司

Radiation Curable Optical Fiber Coloring Inks

ActiveCN104263063BBright color does not fadeSmooth surface and good touchInksOptical radiationDiluent

The invention relates to optical fiber coloring ink with capacity of radiation curing. The optical fiber coloring ink is characterized by comprising components in percentage by weight as follows: 1%-20% of color paste, 20%-40% of an activated diluent, 0.5%-4% of an auxiliary A, 40%-60% of UV resin and 3%-10% of a photoinitiator and an auxiliary initiator, and the percentage sum of the component is 100%. The optical fiber coloring ink with the capacity of radiation curing is high in curing speed and good in curing effect, an optical fiber colored by the ink has bright color and luster and smooth surface, is fadeless, touches good, and can be effectively distinguished in darker light.

Owner:武汉长盈鑫科技有限公司

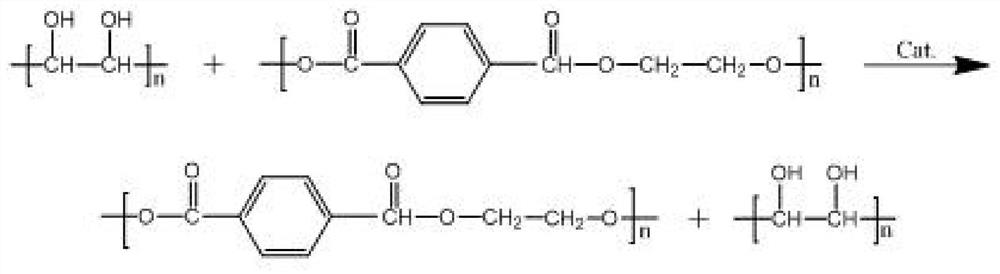

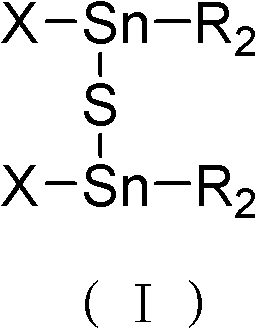

Sulfo-(combination) tin reverse-ester, preparation method and application

The invention relates to sulfo-(combination) tin reverse-ester which adopts the structure shown in a formula (I). The invention further provides a preparation method of the sulfo-(combination) tin reverse-ester and the application of the sulfo-(combination) tin reverse-ester in PVC heat stabilizer. The sulfo-(combination) tin reverse-ester creates sulfur bridges, increases sulfur tin bonds, and increases molecular weight; all the performances of the sulfo-(combination) tin reverse-ester are superior to those of the conventional tin reverse-ester heat stabilizer; and the sulfo-(combination) tin reverse-ester can be used as the novel PVC heat stabilizer with a better effect. In the preparation method, raw materials has low prices and are easy to get, a synthetic method adopts mild conditions and is simple and convenient to operate, and a favorable application prospect can be achieved.

Owner:湖北犇星新材料股份有限公司

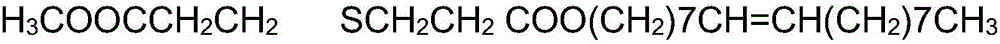

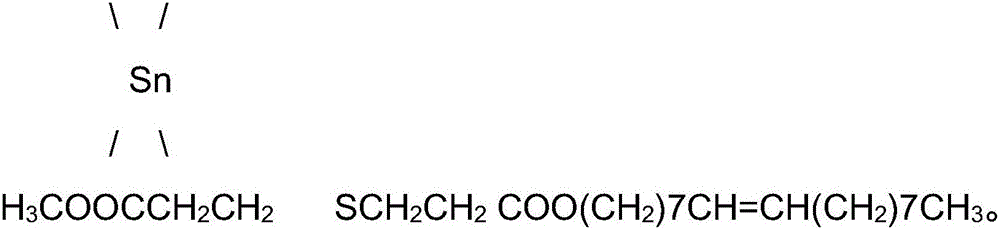

Mercaptoethyl dioleate dimethoxycarbonylethyl tin compound and preparation method thereof

The invention discloses a mercaptoethyl dioleate dimethoxycarbonylethyl tin compound. The molecular formula of the compound is shown in the description. Oleic acid is used to synthesize a (reverse) ester tin compound, the change of the (reverse) ester group increases the activity of the (reverse) ester group and realizes good early-stage stability when the (reverse) ester tin compound is used as a stabilizer, and high-molecular-weight oleic acid in the ester makes the compound have excellent lubricity and have the effects not possessed by traditional organic tin. A unique device and a unique technology are adopted, so the reaction effect is good, the efficiency is high, and the application prospect is good.

Owner:邹平县星宇塑料助剂有限公司

Energy-saving and environment-friendly protecting material for slab continuous casting mold

The invention discloses an energy-saving and environment-friendly protecting material for a slab continuous casting mold, which comprises raw materials by weight percent: 2-5% of carbon black, 1-3% of carburant, 11-15% of fluorite, 1-4% of sodium fluoride, 1-3% of cryolite, 2-5% of manganese carbonate, 2-5% of barium carbonate, 10-12% of white alkali, 7-15% of grain slag, 2-7% of calcite, 40-50% of wollastonite and 1.5-2.5% of yellow dextrin. When being used, the protecting material can show good spreadability, heat preservation performance and melting performance in a crystallizer; heat transmission amount at the periphery in the crystallizer is stable and uniform, and high casting speed requirements can be met; and testing slag strip is small, non-uniformity of inflow is improved, and the protecting material has good lubricity so as to prevent caking steel leakage. No slag inclusion or caking slag phenomena exist on the surface of a casting blank, so that the surface quality of the casting blank is good.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com