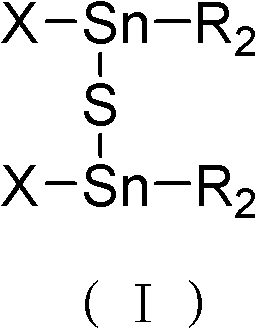

Sulfo-(combination) tin reverse-ester, preparation method and application

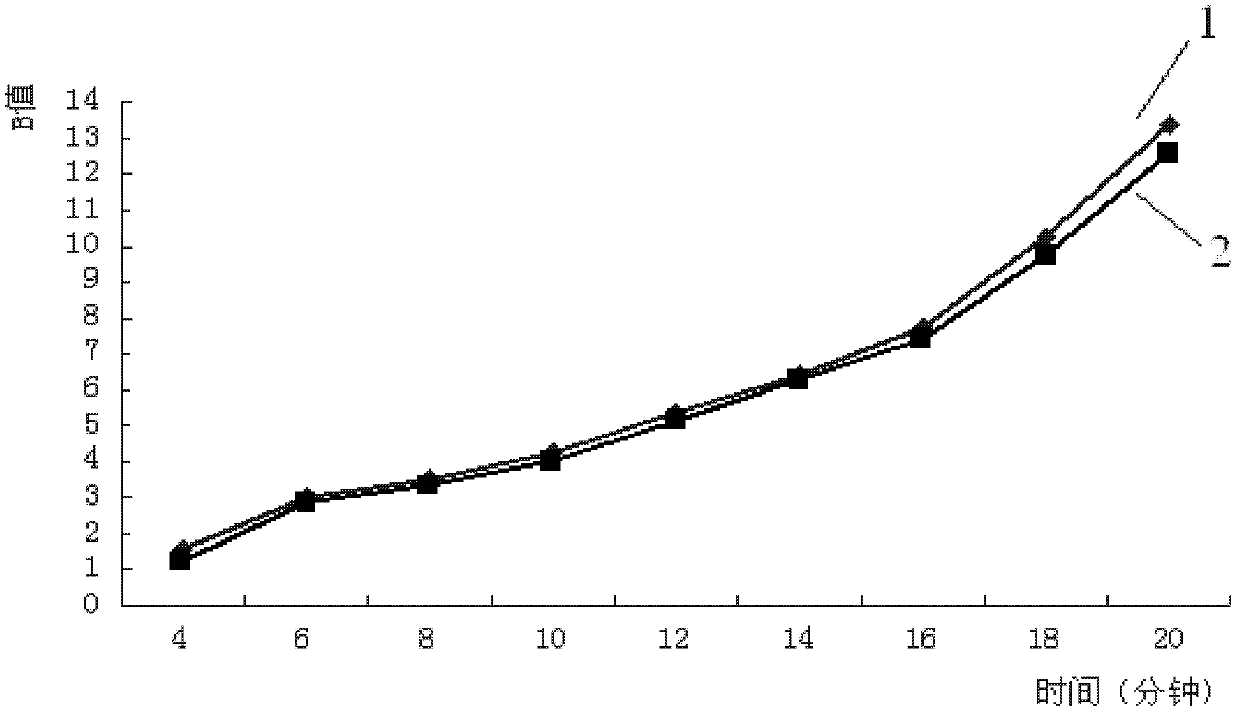

A technology of reverse ester tin and sulfuration, which is applied in the field of preparation of reverse ester tin thio, can solve the problem of high cost, and achieve the effects of simple operation, excellent lubricity, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 2.45mol of mercaptoethanol oleate, 1mol of monomethyl tin trichloride in the three-neck round bottom flask, add 150ml of pure water, stir well, then add 1 / 2 of the theoretical amount of ammonia (2.4mol) therein, and then Add 0.6 mol of ammonium sulfide, and finally add the remaining ammonia water, adjust the pH to 4.5-7, keep the reaction temperature at about 40°C, and the reaction time is 1.5 hours; then wash with water, and finally vacuumize and dehydrate to obtain the target product Thio (United) Reverse ester tin 807.0 grams, yield 97.0% based on monomethyl tin trichloride.

[0031] 1 H NMR (300MHz, CDCl 3 ) characterization results are: chemical shift δ=0.9(6), δ=0.95-0.98(12), δ=1.27-1.35(80), δ=1.68(8), δ=1.96(16), δ=2.23- 2.26(8), δ=2.83-2.86(8), δ=4.33-4.39(8), δ=5.41-5.48(8).

[0032] MS m / z: 1687 [M+Na].

[0033] Elemental analysis value (composition: C 82 h 154 o 8 S 5 sn 2 )(%): C: 58.96 (59.16), H: 9.30 (9.26), S: 9.55 (9.62), Sn: 14.42 (14.27...

Embodiment 2

[0035] Add 2.25mol of mercaptoethanol oleate and 1mol of monomethyl tin trichloride into a three-neck round bottom flask, add 200ml of pure water, stir, then add 2 / 3 of the theoretical amount of ammonia (2.3mol) to it, and then add Ammonium sulfide 0.7mol, and finally add the remaining ammonia water, adjust the pH to 4.5-7, keep the reaction temperature at 50°C, and the reaction time is 2 hours; then wash with water, and finally vacuum dehydrate to obtain the target product thio(joint) reverse ester tin 807.8 grams, with a yield of 97.1% based on monomethyl tin trichloride.

Embodiment 3

[0037] Add 2.30 mol of mercaptoethanol oleate and 1 mol of monomethyl tin trichloride into a three-neck round bottom flask, add 250 ml of pure water, stir, then add 2 / 3 of the theoretical amount of ammonia water (2.25 mol) to it, and then add Sodium sulfide 0.75mol, and finally add the remaining ammonia water, adjust the pH to 4.5-7, keep the reaction temperature at 60°C, and the reaction time is 2 hours; then wash with water, and finally vacuum dehydrate to obtain the target product thio(joint) reverse ester 802.9 grams of tin, with a yield of 96.5% based on monomethyl tin trichloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com