Bottom blue-developing thermosensitive label and preparation method thereof

A low-level, heat-sensitive technology, applied in the field of heat-sensitive labels, can solve problems affecting express transportation and delivery, monotonous visual effects, blurred writing, etc., and achieve the effect of not being easy to oxidize black spots, good dispersion, and easy to spray

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

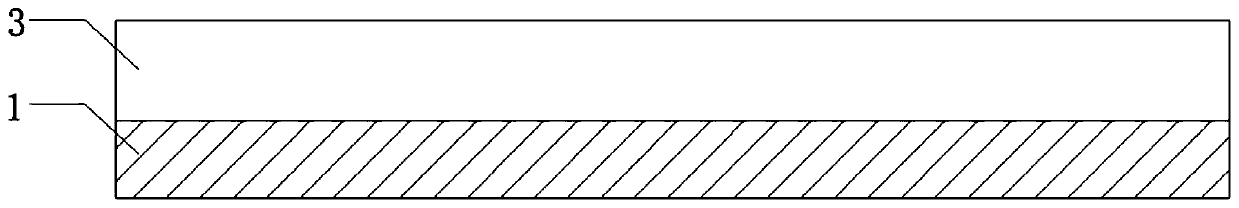

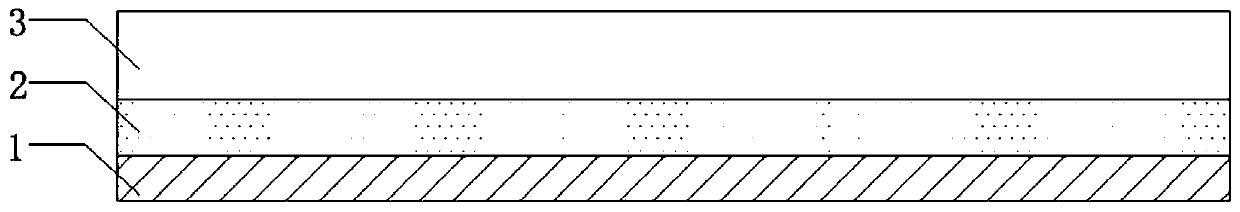

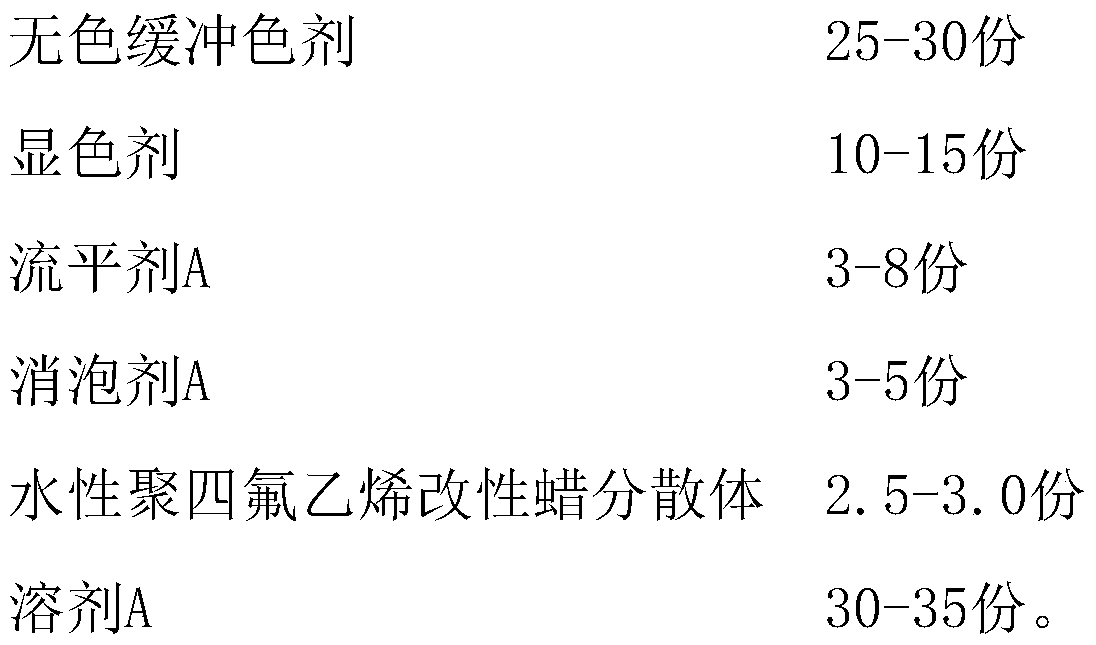

[0048] See figure 1 , a bottom layer 1 blue heat-sensitive label, comprising a bottom layer 1 and a dye layer 3 sequentially arranged from bottom to top, the bottom layer 1 is a carbon-free paper, and the dye layer 3 is made of a chromogenic dye; Color dye comprises the raw material of following weight portion:

[0049]

[0050] The colorless buffer color agent is γ-butyrolactone; the color developer is a blue color developer.

[0051] Described blue developing agent is dimethylaminobenzaldehyde.

[0052] The leveling agent A is a mixture of polydimethylsiloxane, isophorone and diacetone alcohol in a weight ratio of 2:2.5:1, and the defoamer A is made of polyoxyethylene polyoxygen A mixture of propylene pentaerythritol ether, polyoxyethylene polyoxypropanolamine ether and polyoxypropylene polyoxyethylene glyceryl ether in a weight ratio of 1:2:4, and the solvent A is ethanol.

[0053] The chromogenic dye is prepared by the following steps: adding various materials into s...

Embodiment 2

[0061] A blue-displaying thermosensitive label with a bottom layer 1, comprising a bottom layer 1 and a dye layer 3 sequentially arranged from bottom to top, the bottom layer 1 is carbon-free paper, and the dye layer 3 is made of a color-developing dye.

[0062] Described chromogenic dye comprises the raw material of following weight portion:

[0063]

[0064] The colorless buffer color agent is 2-carboxy-4'-diethylamino-2'-hydroxyl-benzophenone; the color developer is a blue color developer.

[0065] The blue developing agent is aniline phthalate.

[0066] The leveling agent A is a mixture of polydimethylsiloxane, isophorone and diacetone alcohol in a weight ratio of 3:2.5:1, and the defoamer A is made of polyoxyethylene polyoxygen A mixture of propylene pentaerythritol ether, polyoxyethylene polyoxypropanolamine ether and polyoxypropylene polyoxyethylene glyceryl ether in a weight ratio of 1:1.5:4, and the solvent A is acetone.

[0067] The chromogenic dye is prepared b...

Embodiment 3

[0075] A blue-displaying thermosensitive label with a bottom layer 1, comprising a bottom layer 1 and a dye layer 3 sequentially arranged from bottom to top, the bottom layer 1 is carbon-free paper, and the dye layer 3 is made of a color-developing dye.

[0076] Described chromogenic dye comprises the raw material of following weight portion:

[0077]

[0078]

[0079] The colorless buffer color agent is 2-hydroxyl-4-(N-ethyl-N-isobutyl)amino-2'-carboxybenzophenone; the color developer is a black developer.

[0080] The black developing agent is 4-hydroxyl-4'-isopropoxydiphenyl sulfone.

[0081] The leveling agent A is a mixture of polydimethylsiloxane, isophorone and diacetone alcohol in a weight ratio of 4:2.5:1, and the defoamer A is made of polyoxyethylene polyoxygen A mixture of propylene pentaerythritol ether, polyoxyethylene polyoxypropanolamine ether and polyoxypropylene polyoxyethylene glyceryl ether in a weight ratio of 1:1:4, and the solvent A is benzene.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com