Casting polypropylene film with controllable friction coefficient and preparation method thereof

A technology of cast polypropylene and friction coefficient, applied in the direction of flexible covering, packaging, wrapping paper, etc., can solve the problems of film heat sealing performance decline, film slippage, sealing failure, etc., to improve slip performance, The effect of stable slip performance and long-lasting mold release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

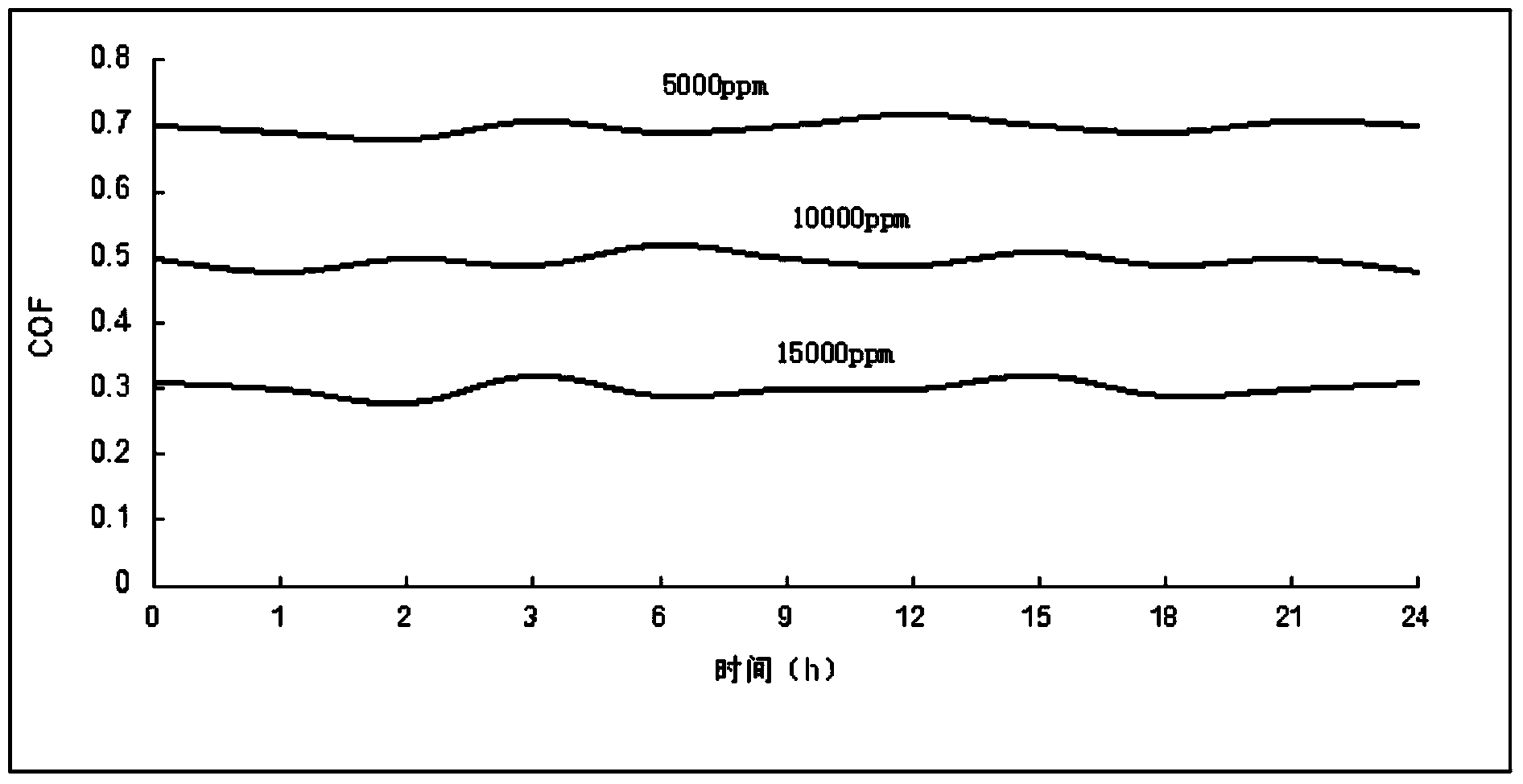

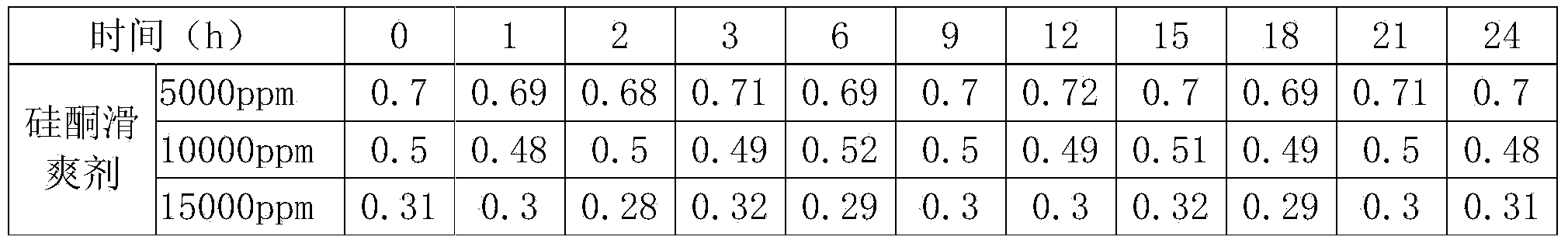

[0047] A cast polypropylene film with a controllable coefficient of friction is a three-layer co-extruded cast polypropylene film, which is divided into a heat-sealing layer, an intermediate layer, and a corona layer. The ratio between layers is 1:3:1, and the total thickness It is 30um. The heat-sealing layer is a preferred propylene-ethylene-butene terpolymer, with 97% propylene-ethylene-butene terpolymer as the main body, and simultaneously contains 1% silicone polymer slip agent (equivalent to slippery Agent concentration is 5000ppm), 2% anti-sticking agent.

[0048] The middle layer is isotactic homopolypropylene with high stiffness, and the corona layer is random copolymerized polypropylene.

[0049] The preparation method of the cast polypropylene film with controllable coefficient of friction of the present embodiment is:

[0050] (1) Mixing materials: Heat-sealing layer raw materials - 97% propylene-ethylene-butylene terpolymer raw material resin particles, 2% anti-...

Embodiment 2

[0057] A cast polypropylene film with a controllable coefficient of friction is a three-layer co-extruded cast polypropylene film, which is divided into a heat-sealing layer, an intermediate layer, and a corona layer. The ratio between layers is 1:3:1, and the total thickness It is 30um. The heat-sealing layer is a preferred propylene-ethylene-butene terpolymer, with 96% propylene-ethylene-butene terpolymer as the main body, while containing 2% silicone polymer slip agent (equivalent to slippery Agent concentration is 10000ppm), 2% anti-sticking agent.

[0058] The middle layer is isotactic homopolypropylene with high stiffness, and the corona layer is homopolypropylene.

[0059] The preparation method of the cast polypropylene film with controllable coefficient of friction of the present embodiment is:

[0060] (1) Mixing materials: Heat-sealing layer raw materials - 96% propylene-ethylene-butylene terpolymer raw material resin particles, 2% anti-sticking agent masterbatch ...

Embodiment 3

[0067] A cast polypropylene film with a controllable coefficient of friction is a three-layer co-extruded cast polypropylene film, which is divided into a heat-sealing layer, an intermediate layer, and a corona layer. The ratio between layers is 1:3:1, and the total thickness It is 30um. The heat-sealing layer is a preferred propylene-ethylene-butene terpolymer, with 95% propylene-ethylene-butene terpolymer as the main body, and simultaneously contains 3% silicone polymer slip agent (equivalent to slippery Agent concentration is 15000ppm), 2% anti-sticking agent.

[0068] The middle layer is isotactic homopolypropylene with high stiffness, and the corona layer is random copolymerized polypropylene.

[0069] The preparation method of the cast polypropylene film with controllable coefficient of friction of the present embodiment is:

[0070] (1) Mixing materials: Heat-sealing layer raw materials - 95% propylene-ethylene-butylene terpolymer raw material resin particles, 2% anti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com