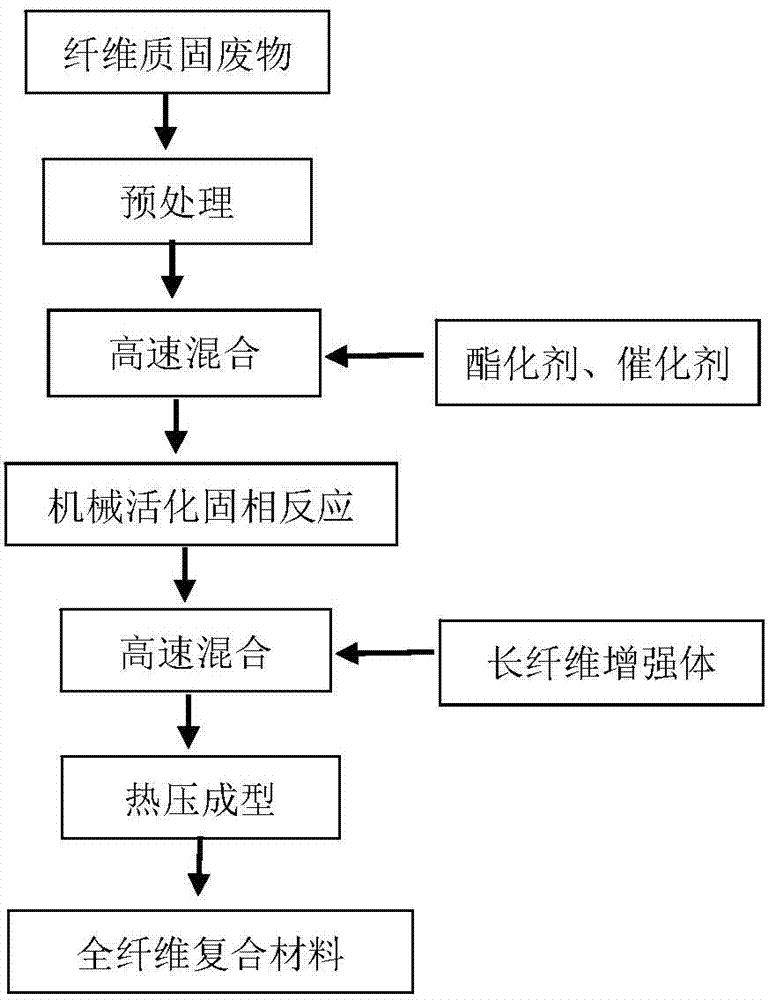

Preparation method of all-fiber degradable composite material

A composite material and full-fiber technology, applied in the field of preparation of degradable composite materials, can solve the problems of a large number of solvents, high cost, and large energy consumption, and achieve the effects of inhibiting heat-sensitive reactions, easy operation, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Select 10 kg of cassava distiller's grains, dry at 100 degrees Celsius to make the water content 5%, and pulverize to 80 mesh. The pulverized cassava distiller's grains, lauric acid and AlCl 3 According to the weight ratio of 100:40:5 into the high-speed mixer, stirring at a rotating speed of 1500rpm for 1min, to obtain cassava distiller's grains reaction mixture.

[0051] React the above-mentioned cassava distiller's grains reaction mixture and the ball milling medium in a ratio of 100g:600ml in a horizontal reinforced polysaccharide high polymer modified stirring ball mill reactor, and after stirring for 120min at a rotating speed of 250rpm and a temperature of 50 degrees Celsius, the ester Modified cassava distiller's grains.

[0052] The above-mentioned esterified modified cassava distiller's grains and sisal fiber were mixed in a high-speed mixer at a weight ratio of 100:10 at a speed of 1000 rpm for 2 minutes to obtain a mixed material.

[0053] Put the mixed mat...

Embodiment 2

[0055] Choose 10 kg of bagasse, dry it at 110 degrees Celsius, make the water content 5%, and pulverize it to 100 mesh, and add the pulverized bagasse, n-octanoic acid and KNO3 to the high-speed mixer according to the weight ratio of 100:30:12, Stir for 2 min at a rotational speed of 1000 rpm to obtain a cassava distiller's grains reaction mixture.

[0056] React the above-mentioned cassava distiller's grains reaction mixture and the ball milling medium in a ratio of 100g:200ml in a vertical reinforced polysaccharide high polymer modified stirring ball milling reactor. After stirring for 100 minutes at a speed of 300 rpm and a temperature of 60 degrees Celsius, the ester mixture is obtained. Modified bagasse.

[0057] The esterified modified bagasse and wood fiber obtained above were mixed in a high-speed mixer at a weight ratio of 100:20 at a speed of 500 rpm for 3 minutes to obtain a mixed material.

[0058] Put the mixed material obtained above into the mold, raise the tem...

Embodiment 3

[0060] Select 10 kg of cassava distiller's grains and bagasse mixture, dry it at 120 degrees Celsius to make the water content 5%, and crush it to 60 meshes. Add the crushed mixture, citric acid and KCl to the high-speed Mixer, stirring at 1200rpm for 80s to obtain a mixed reactant.

[0061] The above-mentioned mixed reactant and ball-milling medium were reacted in a horizontal reinforced polysaccharide high polymer modified stirring ball-milling reactor according to the ratio of 100g:500ml. After stirring for 90 minutes at a rotating speed of 400rpm and a temperature of 55 degrees Celsius, esterification was obtained. modified fiber.

[0062] The esterified modified fiber and wood fiber obtained above were mixed in a high-speed mixer at a weight ratio of 100:15 at a speed of 1500 rpm for 1 min to obtain a mixed material.

[0063] Put the mixed material obtained above into the mold, raise the temperature to 120 degrees Celsius in the flat vulcanizer, increase the pressure to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com