Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Excellent unwinding property" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyurethane fiber dry spinning oil agent and preparation method thereof

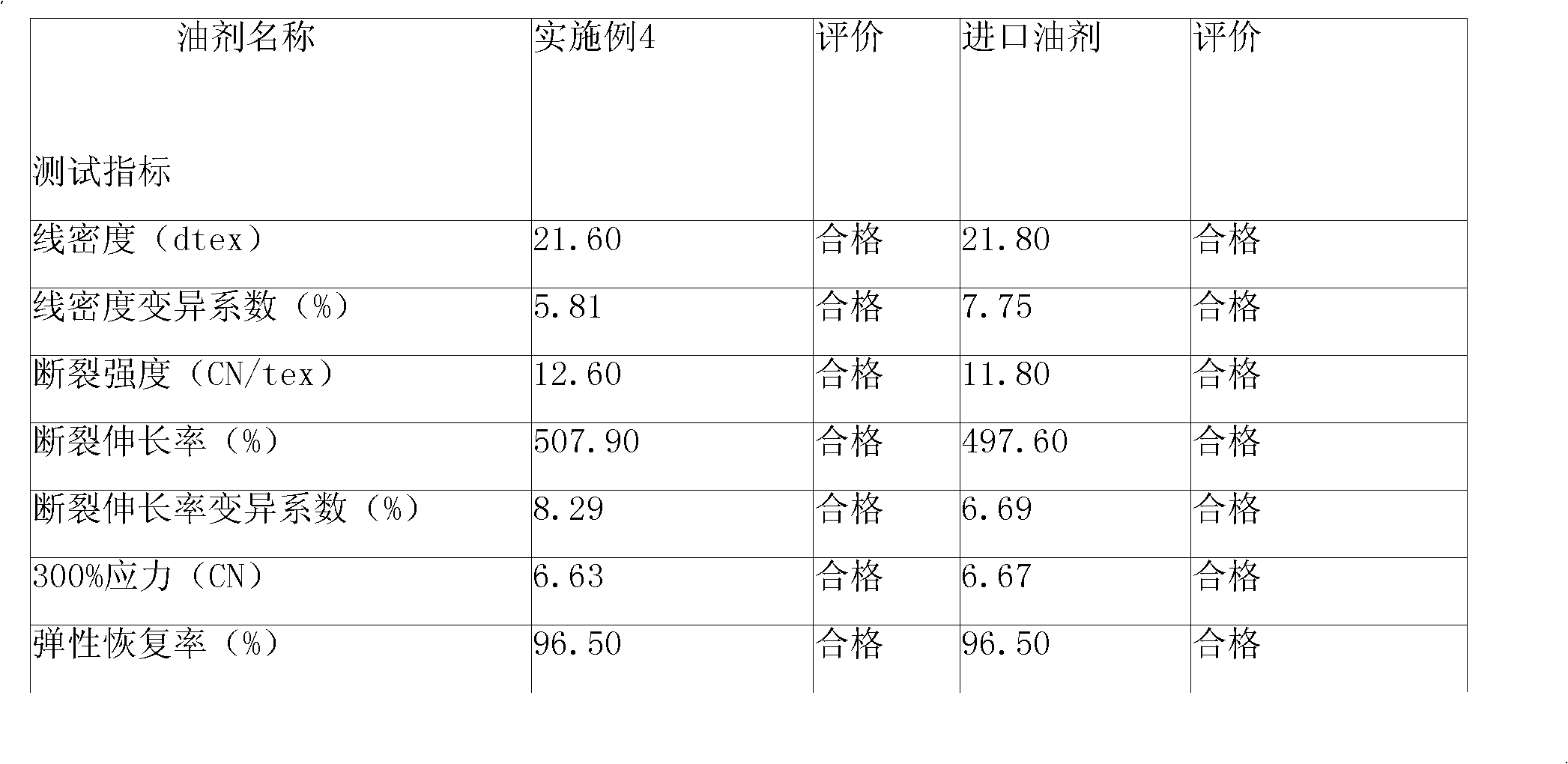

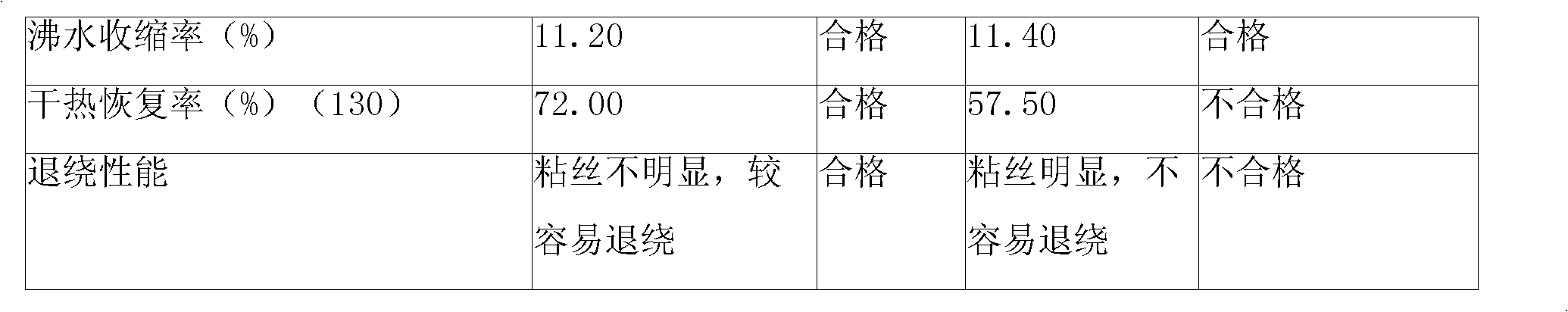

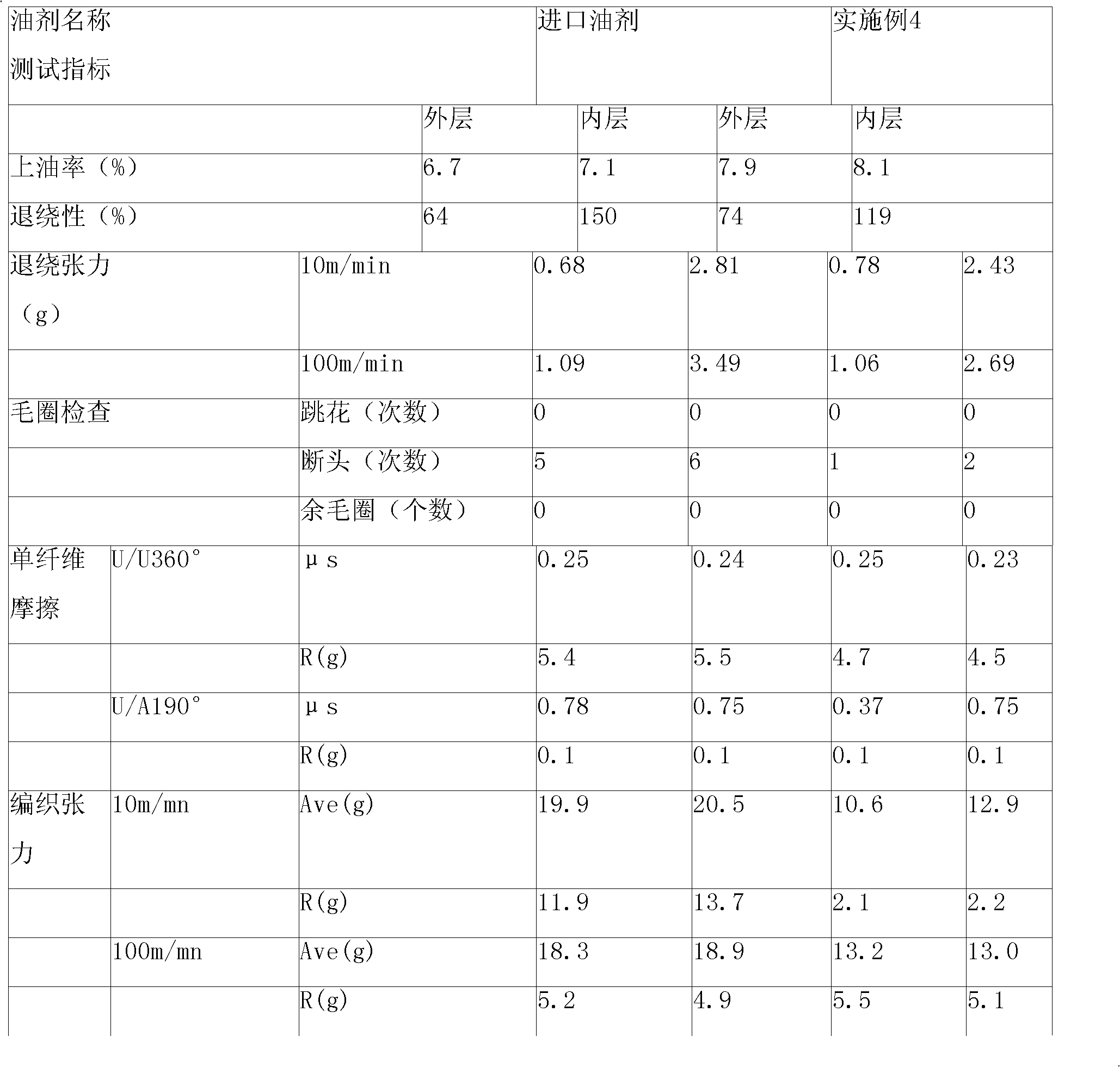

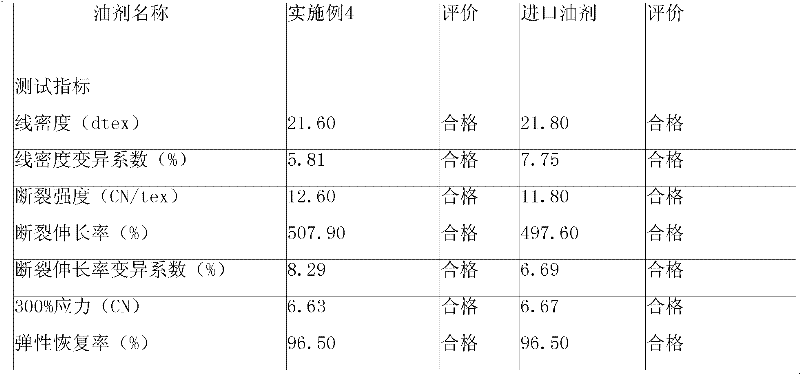

The invention discloses a polyurethane fiber dry spinning oil agent, which comprises 30 to 80 weight percent of dimethyl silicon oil, 10 to 50 weight percent of mineral oil, 1 to 7.5 weight percent of high-carbon isomeric fatty alcohol or acid, 1 to 5 weight percent of dispersed component, 0.1 to 1.5 weight percent of stearate and 2 to 20 weight percent of antistatic component. The dispersed component is a mixture of an organic silicon surfactant and acrylic acid-maleic acid copolymer, and the weight ratio of the organic silicon surfactant to the crylic acid-maleic acid copolymer is 1:0.5-2; and the antistatic component is a mixture of polyether silicon oil and nonionic isomeric alcohol polyethenoxy ether, and the weight ratio of the polyether silicon oil to the nonionic isomeric alcohol polyethenoxy ether is 1:0.5-2. The polyurethane fiber dry spinning oil agent has excellent smoothness, softness, antistatic property, stable performance and excellent anti-adherent performance; polyurethane fiber treated by the oil agent has good unreeling property and forming property; and in the subsequent processing flow, polyurethane filaments are easy to unreel, not drop edge and has few broken filaments.

Owner:BEIJING GUANGHUA TEXTILE GRP +2

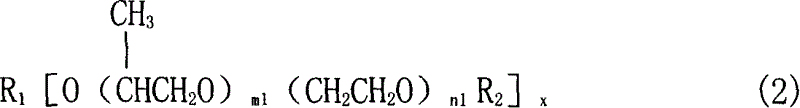

Environment-friendly polypropylene filament yarn oil agent and production method thereof

The invention discloses a preparation method of an environment-friendly polypropylene filament yarn oil agent, comprising the following steps of: weighing 40 to 60 parts by weight of fatty alcohol ether phosphate potassium salt, 2 to 8 parts by weight of polysiloxane polyether copolymer, 3 to 12 parts by weight of pentaerythritol oleate, 4 to 10 parts by weight of fatty alcohol polyoxyethylene ether, 2 to 12 parts by weight of ethylene oxide-epoxypropane block polyether, 20 to 45 parts by weight of polyethylene glycol laurate, 10 to 20 parts by weight of butter alcohol amine phosphate salt and 5 to 10 parts by weight of high-carbon heterogeneous alcohol phosphate potassium salt, heating to 40 to 80 DEG C, reacting under the stirring condition, then adding 20 to 40 parts of emulsifying agent EL-40, 1 to 5 parts of methyl-1-hydroxyethyl-2-stearyl imidazoline ammonium methosulfate, 5 to 15 parts of dimethyl silicon oil, 2 to 40 parts of deionized water and 0.001 to 0.02 part of preservative, reacting under the stirring condition at 50 to 70 DEG C, and separating to obtain the environment-friendly polypropylene filament yarn oil agent.

Owner:青岛荣达新材料研究所

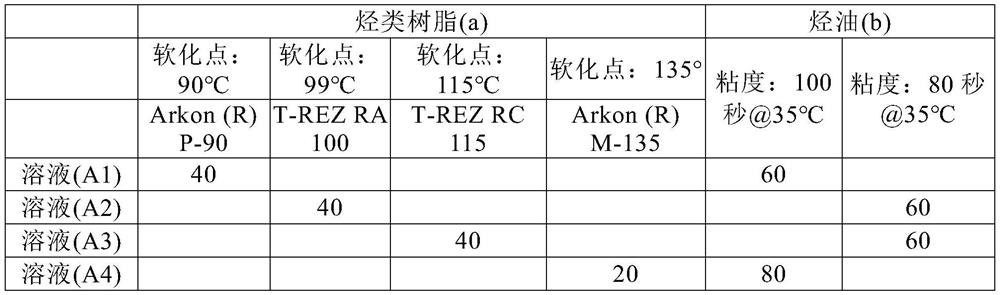

Surface protection sheet

InactiveCN101617013AExcellent unwinding propertyGood adhesivenessFilm/foil adhesivesAdhesive articlesRough surfaceElastomer

A surface protection sheet including a base layer and a pressure-sensitive adhesive layer which have been formed by coextrusion. The surface protection sheet has satisfactory suitability for unwinding from a roll, etc., and the pressure-sensitive adhesive layer has a smooth surface and satisfactory adhesion to rough surfaces, is free from release ingredient transfer thereto, and hence poses no problem concerning contamination. The surface protection sheet comprises: a base layer comprising a thermoplastic resin; a pressure-sensitive adhesive layer formed on one side of the base layer; and a back treatment layer formed on the other side and comprising a polyethylene resin. The surface protection sheet is characterized in that the base layer, pressure-sensitive adhesive layer, and back treatment layer have been integrally formed by coextrusion molding and the pressure-sensitive adhesive layer contains a noncrystalline polyolefin elastomer in an amount of 50 wt.% or larger.

Owner:NITTO DENKO CORP

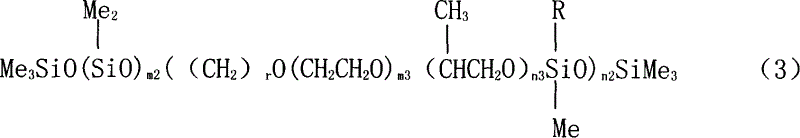

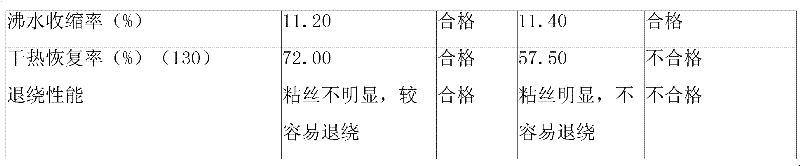

Oil solution for spandex spinning by dry method, and preparation and use thereof

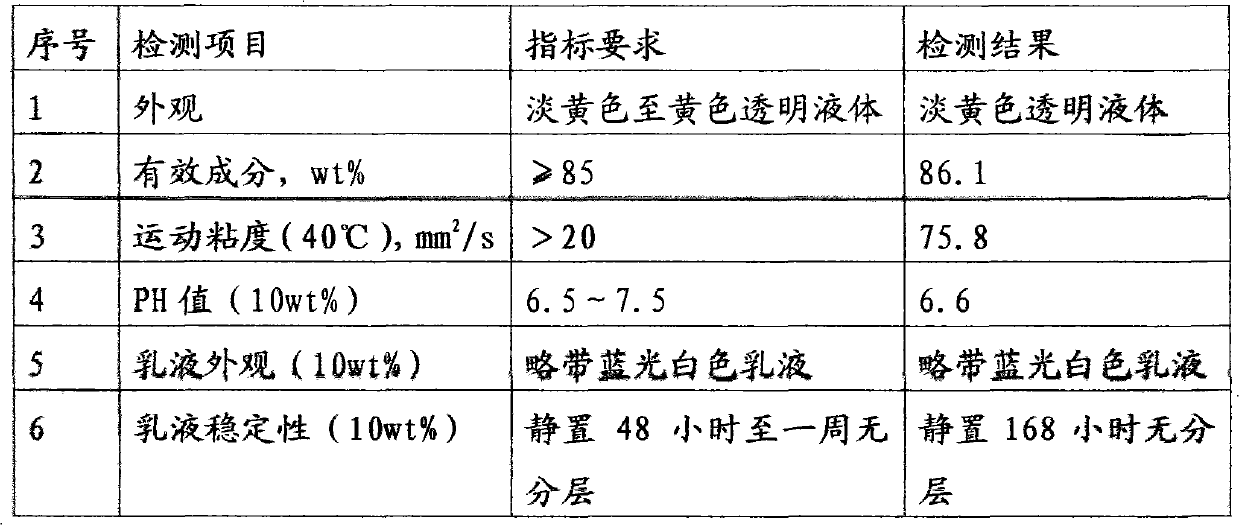

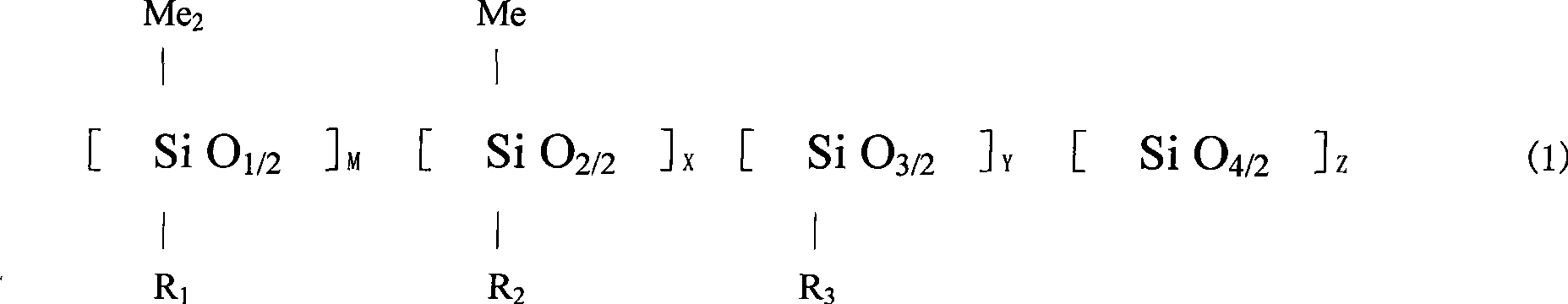

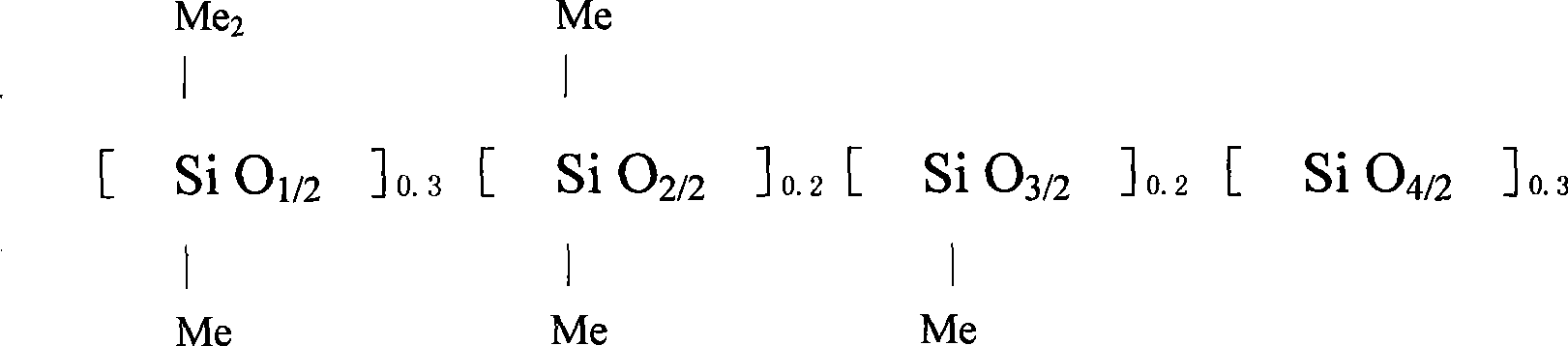

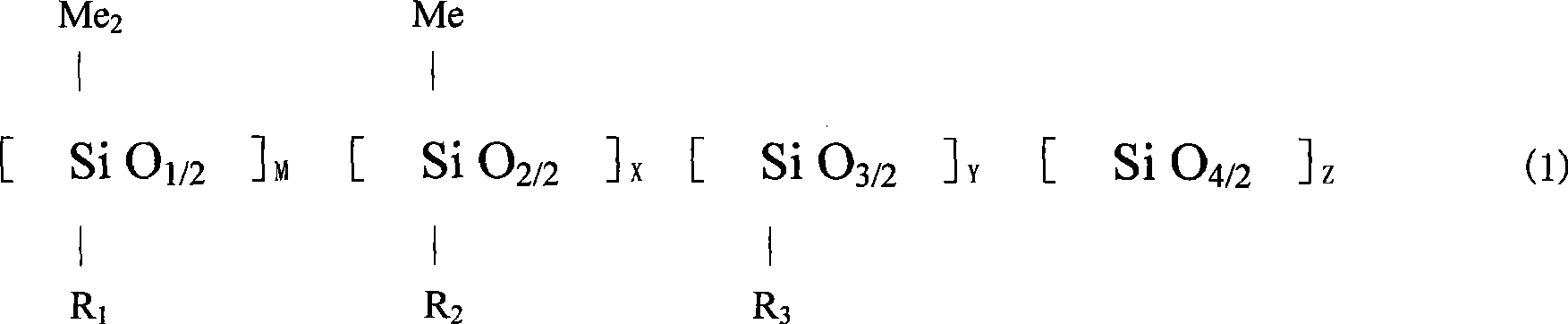

The invention relates to a preparation agent for dry method urethane elastic fiber spinning. The preparation agent comprises the following components: silicone resin, methyl silicone oil, modification silicone oil, mineral oil and antistatic agent. The preparation method comprises the following steps: 1, silicane chain links(M, X, Y and Z) are mixed and evenly stirred, started, added with acid water at a temperature of 25 DEG C and reacted for 1 hour at the temperature of between 60 and 70 DEG C, stirring stops, after layering, the resin on the lower layer is separated out, the pH value of the resin is neutral by washing, and the resin is subjected to vacuum pumping, temperature rise and dewatering to prepare the silicone resin; and 2, the silicone resin, the methyl silicone oil, the polyether modification silicone oil, the mineral oil and the antistatic agent are placed in a stirring kettle, and evenly mixed at the temperature of between 10 and 50 DEG to obtain. The application of the preparation agent is as follows: the preparation agent is put in a storage tank and transferred to an oil nozzle or roller by an oil pump, and the urethane elastic fiber is directly contacted and oiled. The preparation agent for dry method urethane elastic fiber spinning is transparent liquid, does not contain solid particle components such as hard ester acid magnesium and the like, does not plug pipes and equipment in the oiling process, and does not need power-off cleaning, thereby improving production efficiency.

Owner:NINGBO ECONOMIC & TECHN DEV ZONE SICO NEW MATERIAL

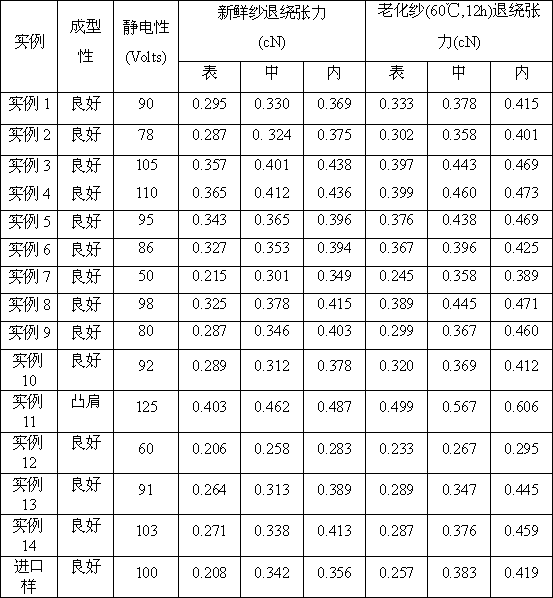

High-unwinding-tension spandex oil preparation

The invention discloses a high-unwinding-tension spandex oil preparation, which comprises the following components: 40-90% of mineral oil, 5-60% of dimethyl silicone oil, 1-10% of functional modified silicone oil and 3-15% of high-carbon isomerized fatty alcohol, and the sum of content percentages is 100% by total weight. The oil preparation disclosed by the invention is mainly applied to dry spinning, and has an outstanding characteristic that fibers both have a moderate astringent sliding degree so as to facilitate the forming of the fibers, and have an extremely good lasting barrier property so as to prevent inner-layer yarn bundles from being adhered, namely, the fibers are slidable but astringent, and astringent but non-stick, so that the astringent sliding degrees between fibers are kept, and the friction among fibers and metals is reduced, therefore, good astringent sliding property, permeability, antistatic property and unwinding property can be given to fibers, and then the perfect unification of forming and unwinding is achieved.

Owner:WACKER DYMATIC SILICONES SHUNDE CO LTD FOSHAN

Oil preparation agent in use for spinning in urethane elastic fiber

The invention discloses a polyurethane fibre spinning oil. Its composition includes (by wt%) 5-80% of mineral oil, 10-75% of silicone oil, 0.5%-30% of epoxyethane and epoxypropane copolyether, 0.5%-50% of polyether silicone oil, 0.5-15% of antistatic agent and 0.1-10% of anti-sticking property improving agent.

Owner:CHINA PETROCHEMICAL CORP +1

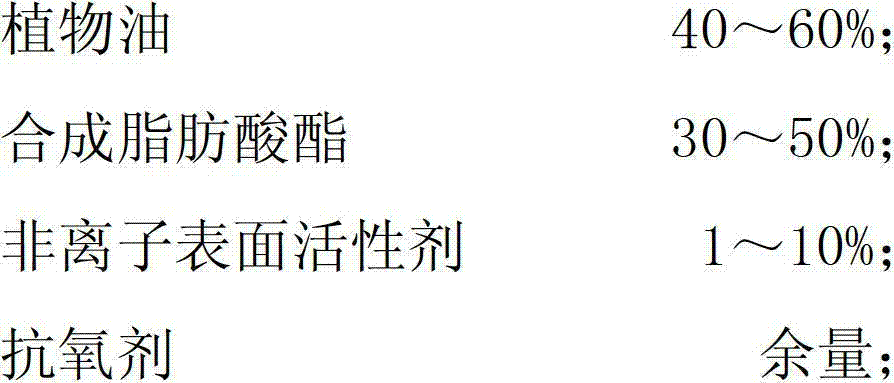

Cord thread spinning oil

InactiveCN103161068AImprove spinnabilityHigh spinnability, uniform fiber draft, high breaking strengthFibre typesSynthetic polymer filament chemical after-treatmentRapeseedEngineering

The invention discloses cord thread spinning oil. The cord thread spinning oil comprises, by mass, 40-60% of plant oil, 30-50% of compound fatty acid ester, 1-10% of non-ion surfactant, and the balance antioxidant. The plant oil is selected from at least one of peanut oil, soya-bean oil, linseed oil, castor oil, health oil, and rapeseed oil, refined processing is carried out on the plant oil, iodine value is higher than 70, the compound fatty acid ester is pentaerythritol ester or trimethylolpropane ester, and the non-ion surfactant is fatty alcohol-polyoxyethylene ether, fatty alcohol polyurethane propylene ether or fatty alcohol polyoxyethylene polyoxypropylene.

Owner:TIANJIN POLYTECHNIC UNIV

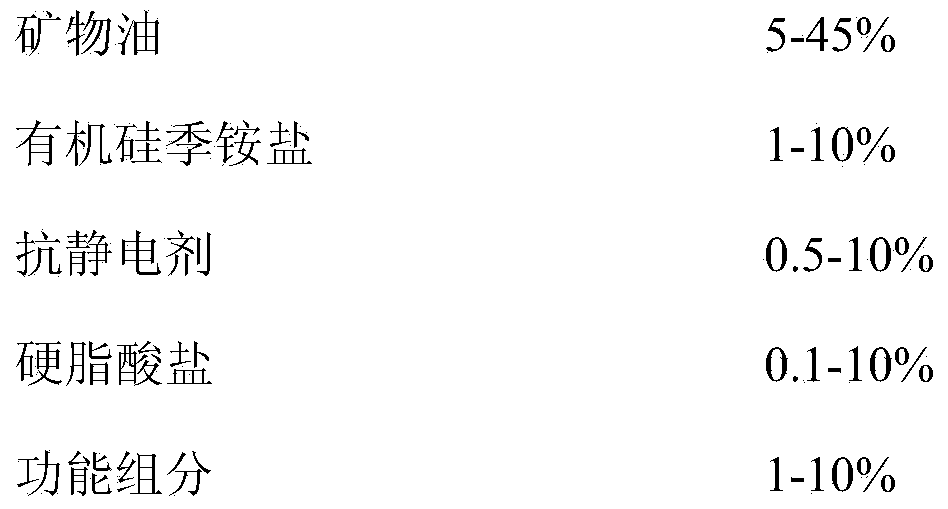

Dry-process spandex spinning oil agent

InactiveCN104372446AExcellent unwinding propertyImprove antistatic performanceMonocomponent synthetic polymer artificial filamentSynthetic polymer filament chemical after-treatmentFiberPelargonium x hortorum

The invention discloses a dry-process spandex spinning oil agent. The dry-process spandex spinning oil agent comprises the following components in percentage by weight: 20%-80% of dimethyl silicone oil, 5%-45% of mineral oil, 1%-10% of organic silicon quaternary ammonium salt, 0.5%-10% of an antistatic agent, 0.1%-10% of stearate and 1%-10% of a functional component. The functional component is natural extract of one or more of folium artemisiae argyi, mint, mozzie buster, lavender, pelargonium hortorum, cordate telosma and murraya paniculata, and also can be natural essence oil of roses, jasmines, citrus bergamia, sandalwood and the like. The oil agent has good smoothness and stability; and a spandex fiber treated by the oil agent has good unwinding performance, is antistatic, and has one or more effects of resisting bacteria, repelling mosquitoes, having aroma and the like.

Owner:ZHEJIANG HUAFENG SPANDEX

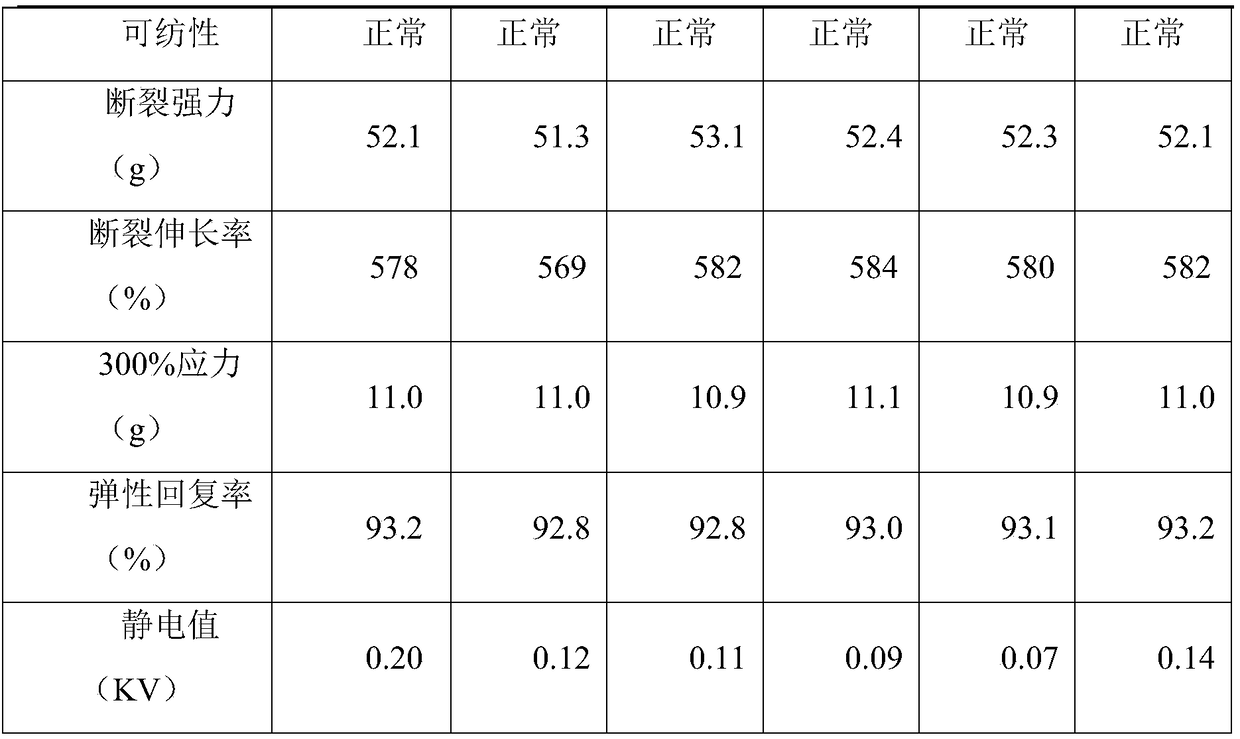

Ultra-strong antistatic spandex spinning oil and preparation method thereof

ActiveCN106521965AExcellent unwinding propertyImprove dispersion stabilityFibre typesGrapheneStearic acid

The invention discloses ultra-strong antistatic spandex spinning oil and a preparation method thereof. The ultra-strong antistatic spandex spinning oil is prepared from 40 to 80% mass of polydimethylsiloxane, 5 to 30% mass of white oil, 1 to 10% mass of organosilicon quaternary ammonium salt, 0.1 to 10% mass of metallic stearate and 0.1 to 10% mass of graphene, wherein the percentage content is the mass percentage of the component content to the total oil mass. The novel material ultra-strong antistatic graphene is mixed into the spandex spinning oil, and the prepared spandex spinning cake has good formation, is easy to unwind and has strong antistatic property.

Owner:华峰重庆氨纶有限公司

Spandex dry spinning oil agent not containing organosilicone and preparation method thereof

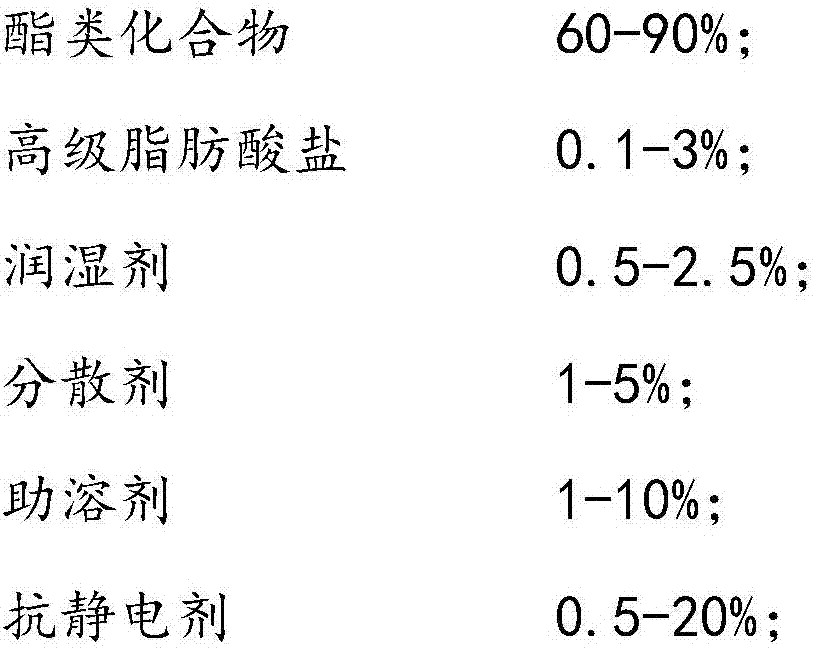

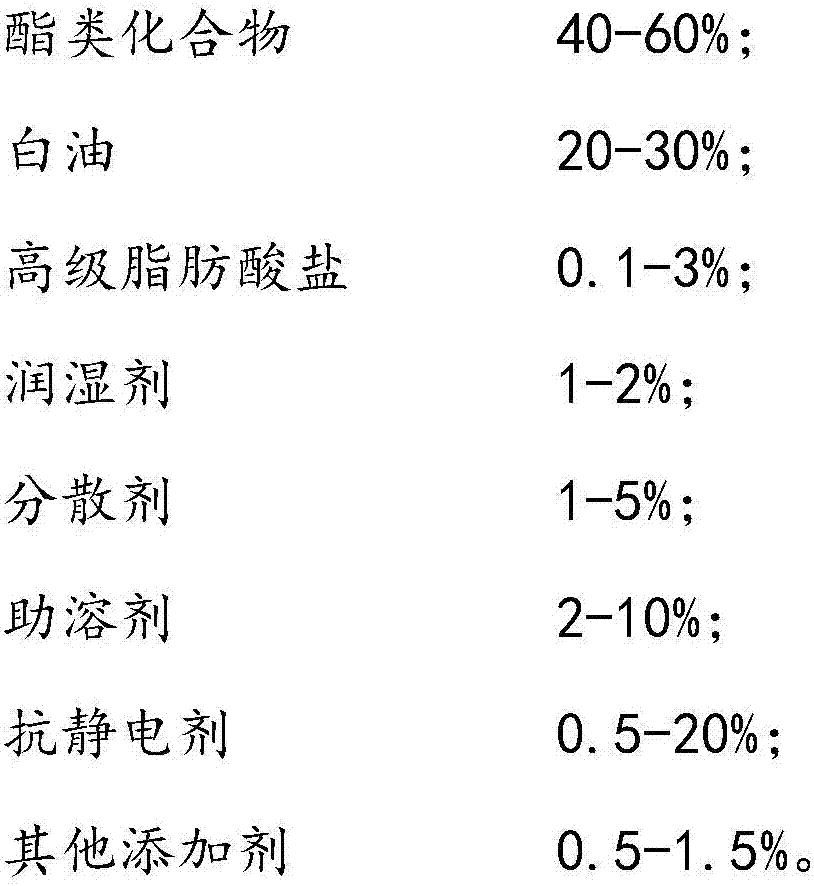

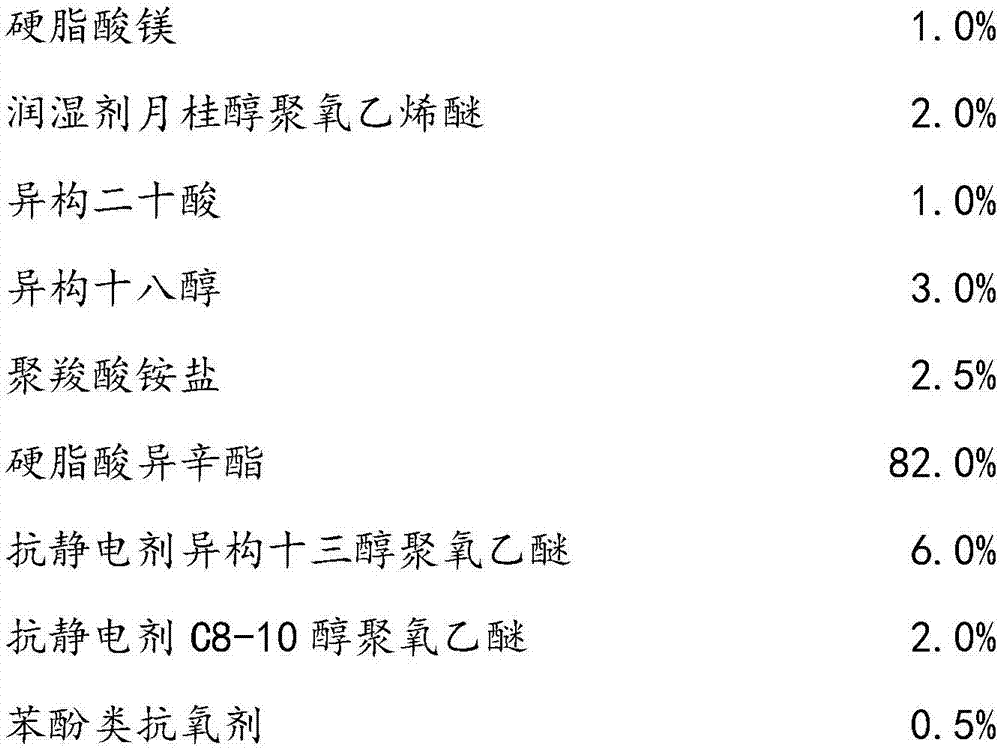

The invention relates to a spandex dry spinning oil agent not containing organosilicone and a preparation method thereof. The spandex dry spinning oil agent comprises 60 to 90% of ester type compound, 0.1 to 3% of higher fatty acid salt, 0.5 to 2.5% of wetting agent, 1 to 5% of dispersant, 1 to 10% of dissolving additive, and 0.5 to 20% of anti-static agent. The spandex dry spinning oil agent has the advantages that (1) the oil agent adhered onto fiber can be easily removed, and the oil-applied spandex yarn can be laminated, compounded and adhered, and be easily and uniformly dyed; (2) by adopting the formula compounding and technology optimizing, the dispersion of metal magnesium is small, and the nanometer level can be reached; the spandex fiber has good anti-adhering and isolation properties, the anti-adhering and adhering-preventing effects are good, and the unwinding property of inner layer and outer layer is excellent; the smoothness is proper.

Owner:烟台锐泽化学品有限公司

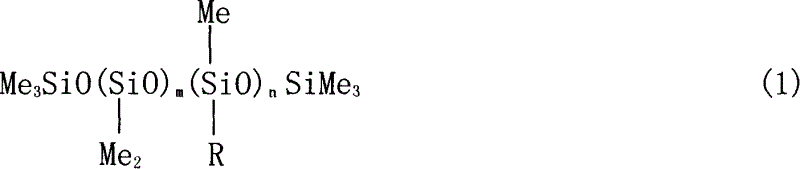

Spandex spinning oil with function of enabling exterior-interior unwinding to be uniform, and preparation method of spandex spinning oil

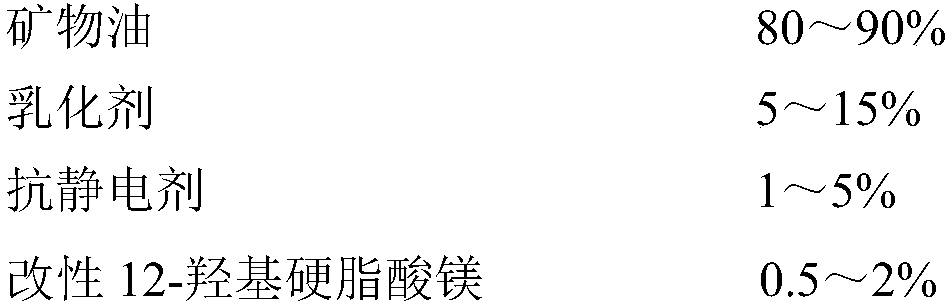

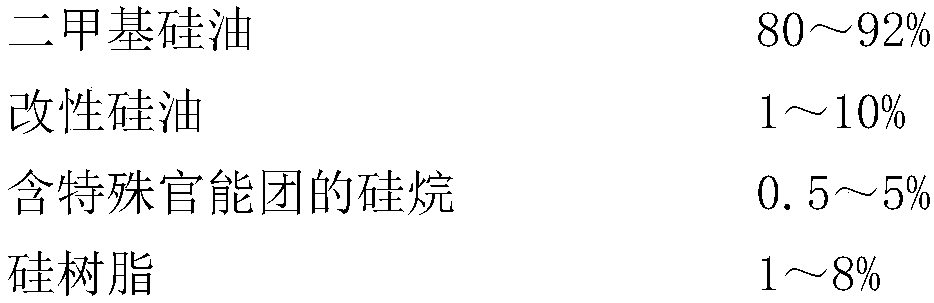

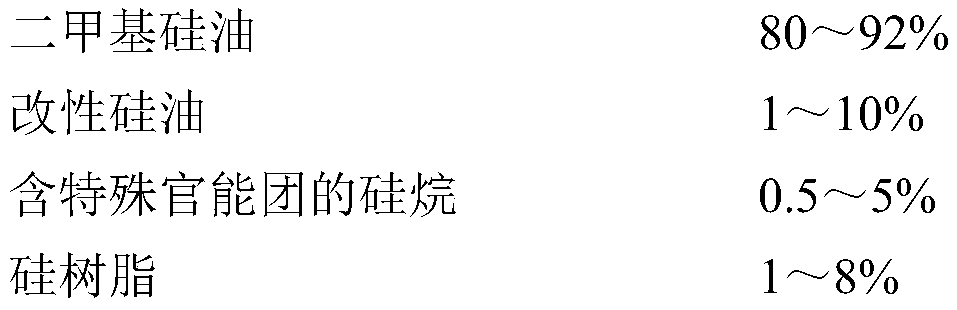

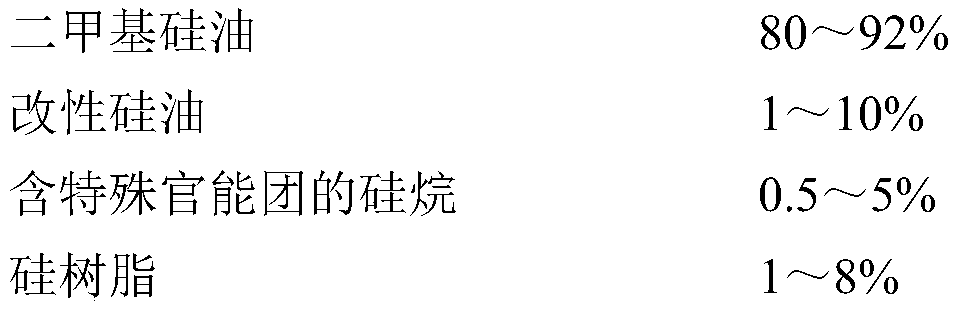

The invention relates to spandex spinning oil with a function of enabling exterior-interior unwinding to be uniform, and a preparation method of the spandex spinning oil. The spandex spinning oil is prepared by mixing a component A and a component B, wherein the component A is prepared from the following components by weight: 80-92% of dimethyl silicone oil, 1-10% of modified silicone oil, 0.5-5%of silane containing special functional groups and 1-8% of silicon resin; the component B is prepared from the following components by weight: 80-90% of mineral oil, 5-15% of a W / O type emulsifying agent, 1-5% of an antistatic agent and 0.5-2% of modified magnesium stearate; the mixing ratio of the component A to the component B is equal to (1.5 to 1)-(1 to 1.2). The oil which is prepared by the method and is used for polyurethane elastic fibers is yellowish transparent liquid, and not only can enable spandex fibers to have excellent formability in a winding process, but also has higher surface energy and has stronger adsorption to polyurethane so as to enable the polyurethane not to easily migrate to the surfaces of the fibers from the inner layers of the fibers, thus endowing the spandexfibers with more uniform exterior-interior unwinding and further enabling the spandex fibers to be smoothly unwound and not to be broken in the subsequent application.

Owner:ZHEJIANG HUAFENG SPANDEX

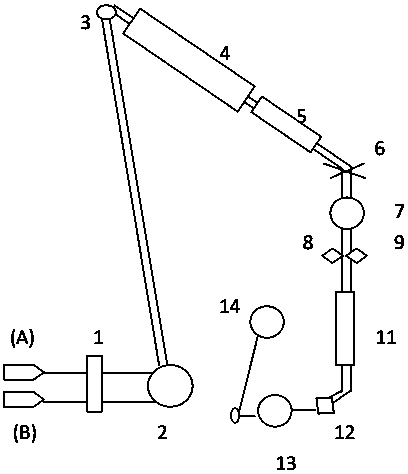

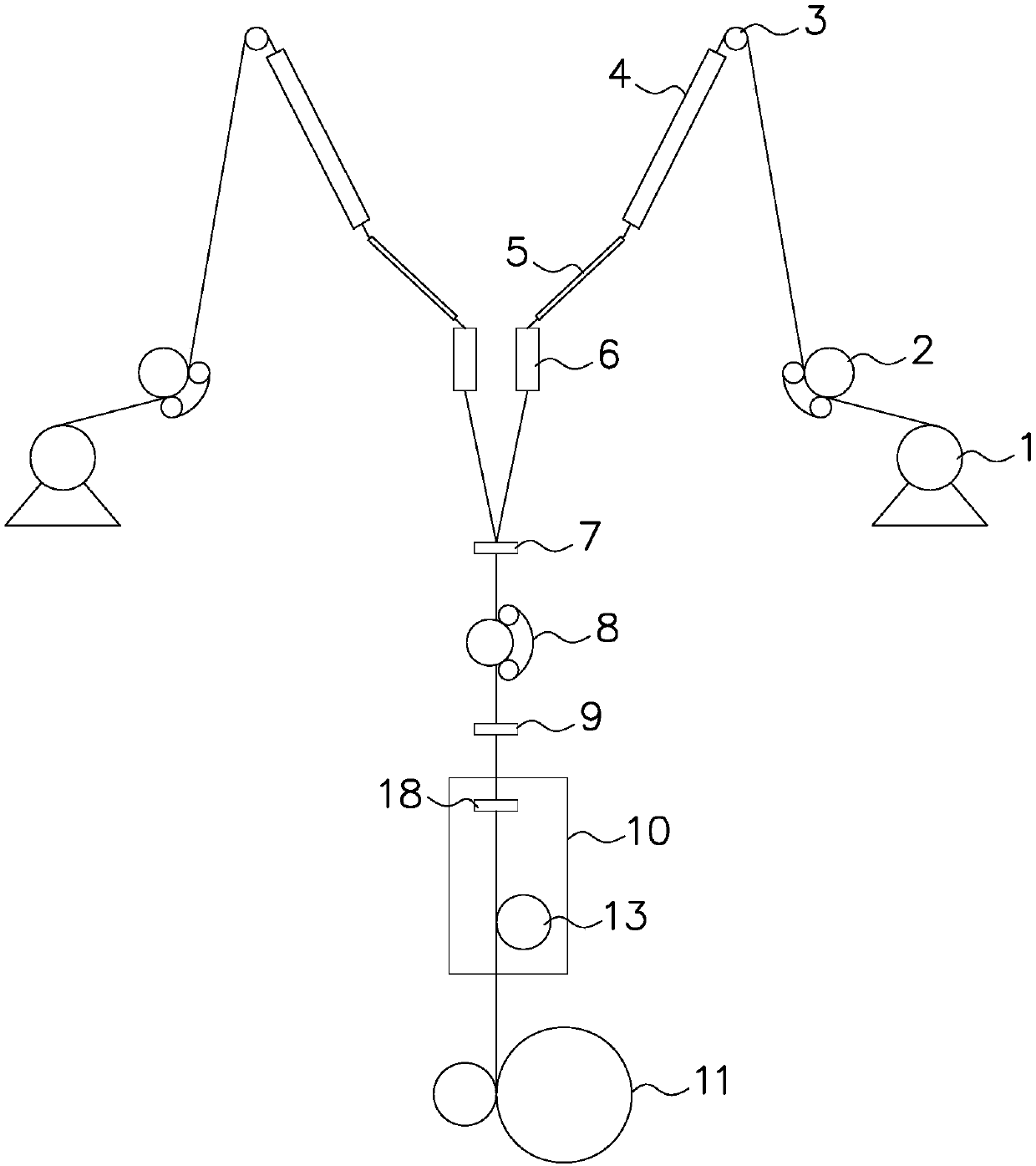

Production method for high-definition dual-color DTY complex fiber

The invention relates to the technical field of spinning, and provides a production method for a high-definition dual-color DTY complex fiber. The problem that a high-definition complex fiber cloth cover on the market is turbid in design and color and not good enough in definition is solved. Polyester pre-oriented yarn (A) and (B) can run a normal yarn path on an elasticizer S+Z machine till emphasis network air pressure at a middle roller, and then, polyester pre-oriented yarn (A) and (B) at a lower roller can pass through a nozzle emphasis network air pressure at the same time to compound two filaments. The technology is simple, and the fabric cloth cover is high in definition of design and color.

Owner:ZHEJIANG HENGYI HIGH TECH MATERIAL

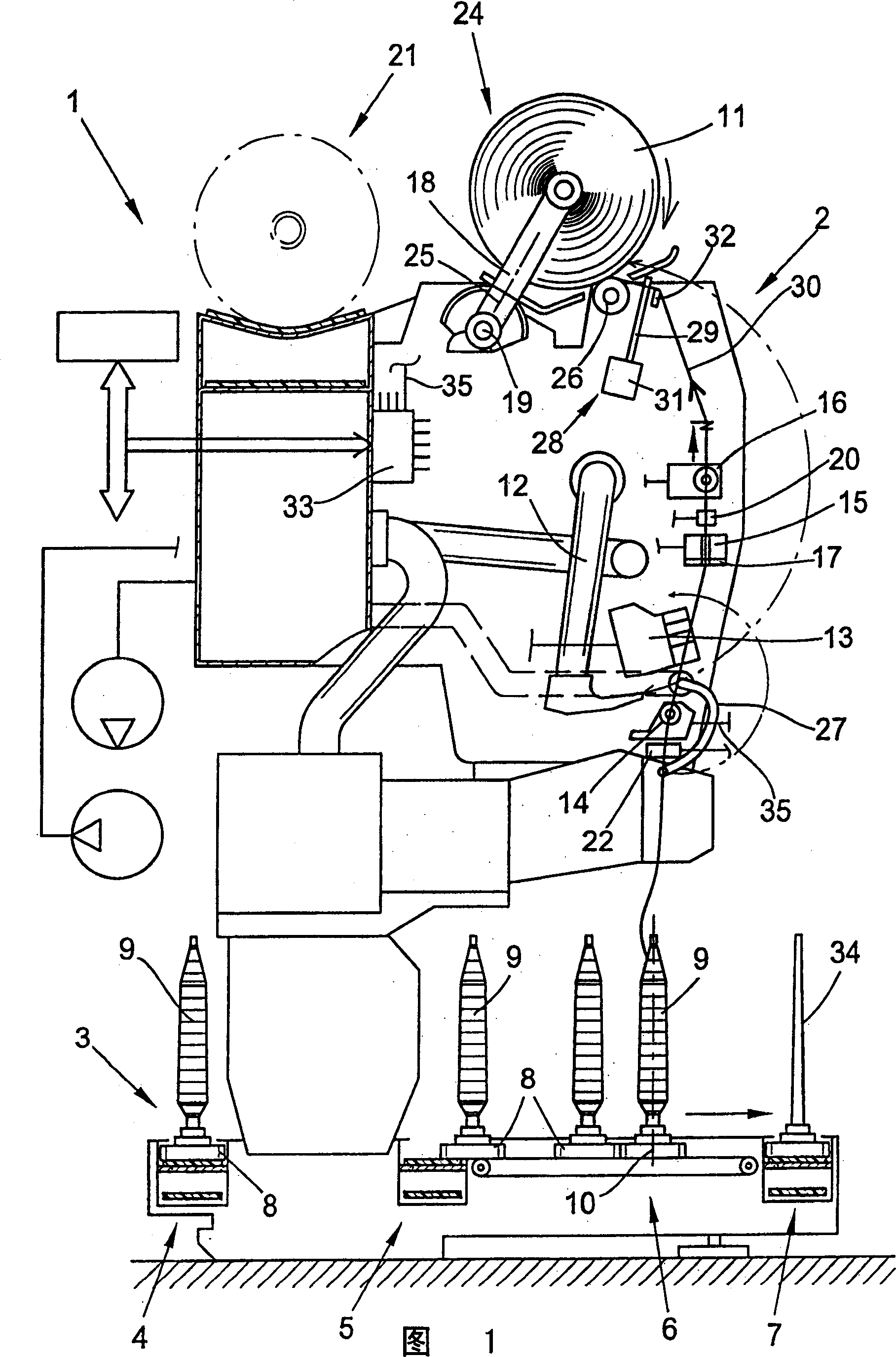

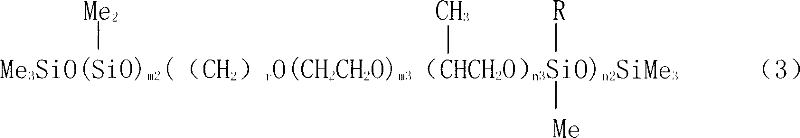

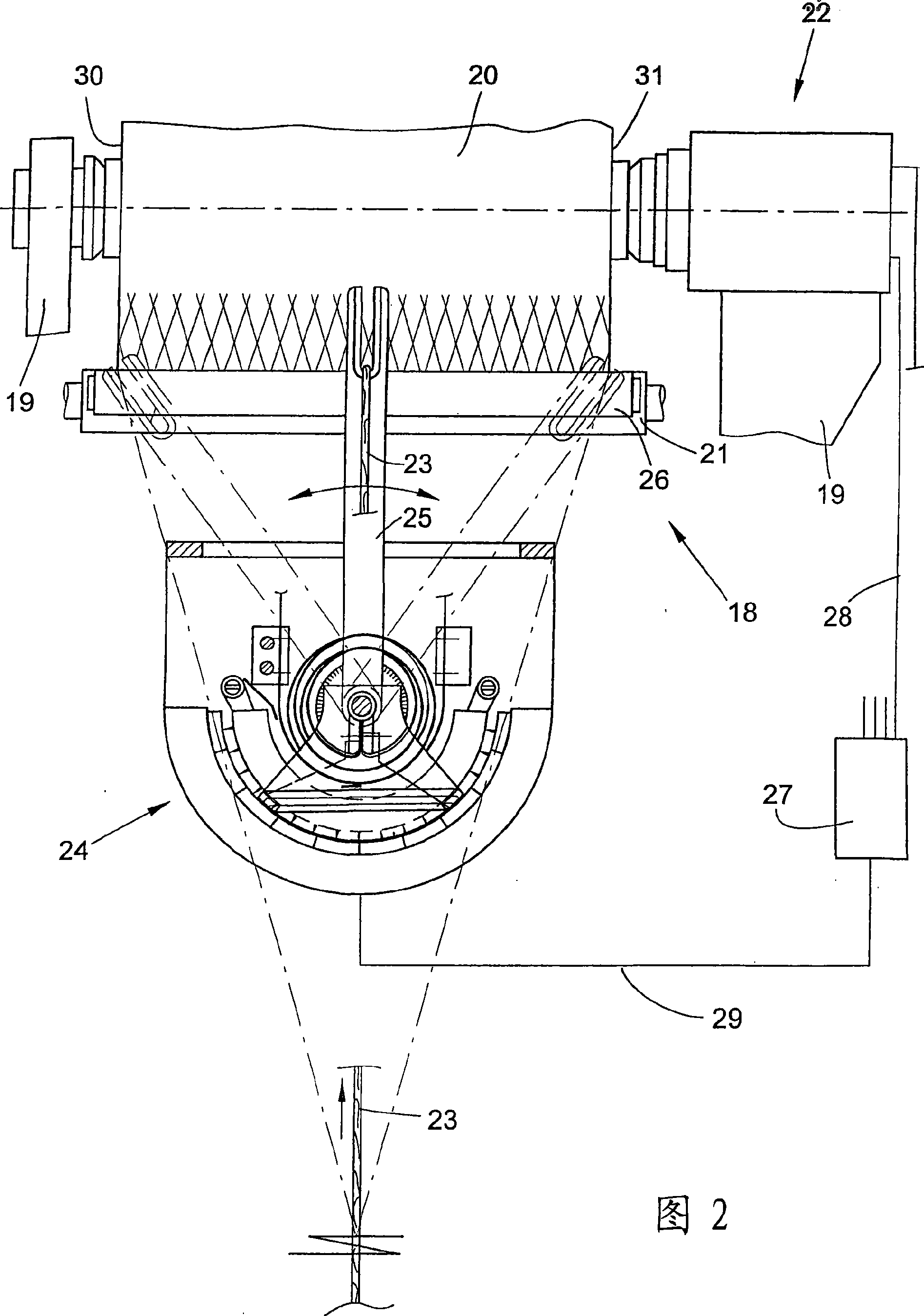

Method for manufacturing cross winding bobbin

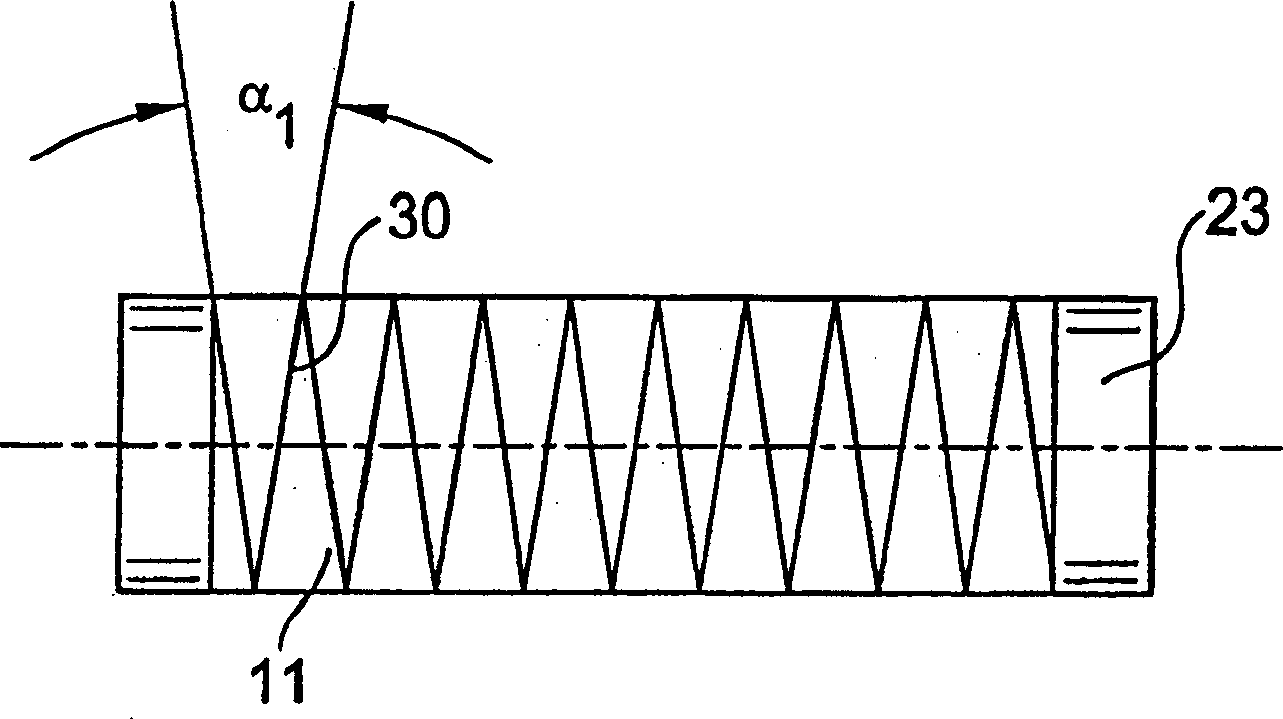

To produce a cross wound bobbin (11), at the workstation (2) of a bobbin winder (1), the yarn (30) is wound at the start of a winding cycle at a crossing angle to increase the density of the bobbin core. The crossing angle is increased significantly during the winding cycle, so that the density of the wound bobbin is reduced progressively outwards. The increased crossing angle acts against the yarn laying width, and the stroke movement of the reciprocating yarn guide (29) has a defined increase.

Owner:SAURER GERMANY GMBH & CO KG

Preparation method of easy-unwinding spandex

ActiveCN110923844AExcellent yield and unwinding performanceSimple stepsTextile/flexible product manufactureMonocomponent synthetic polymer artificial filamentPolyesterPolymer science

The invention relates to easy-unwinding spandex and a preparation method thereof. The preparation method comprises the following concrete steps of Step 1, prepolymerization: mixing MDI (Methylenediphenyl Diisocyanate) and PTMG (Polytetramethylene Etherglycol) for reaction to generate an NCO (Isocyanate Group) terminated PP (Prepolymer); Step 2, chain extension: dissolving the PP in DMAC (N,N-dimethyl acetamide) by a high-speed rotator, passing a solution through a rotary reactor, and adding chain-extended amine and terminated amine into the reactor to obtain a POL raw solution; Step 3, curing:adding function additives (an antioxidant, a dyeing additive, a lubricant, an anti-yellowing agent and the like) into the POL raw solution, after curing for a certain time, adding alkali-soluble polyester, and performing uniform stirring and dispersing to obtain a DOPE raw solution; and Step 4, spinning forming: after impurities are removed from the DOPE by a filter, conveying the DOPE to a spinneret plate through a pump; performing drying through a channel to remove the DMAC; then, performing soaking by a high-temperature alkali solution tank; performing drying by hot air; and after coolingand shaping, performing oiling to obtain the spandex. Meanwhile, in the production process, a spinning raw solution has good spinnability.

Owner:ZHEJIANG HUAFENG SPANDEX

A kind of super antistatic spandex spinning oil agent and preparation method thereof

ActiveCN106521965BExcellent unwinding propertyImprove dispersion stabilityFibre typesGrapheneStearic acid

The invention discloses ultra-strong antistatic spandex spinning oil and a preparation method thereof. The ultra-strong antistatic spandex spinning oil is prepared from 40 to 80% mass of polydimethylsiloxane, 5 to 30% mass of white oil, 1 to 10% mass of organosilicon quaternary ammonium salt, 0.1 to 10% mass of metallic stearate and 0.1 to 10% mass of graphene, wherein the percentage content is the mass percentage of the component content to the total oil mass. The novel material ultra-strong antistatic graphene is mixed into the spandex spinning oil, and the prepared spandex spinning cake has good formation, is easy to unwind and has strong antistatic property.

Owner:华峰重庆氨纶有限公司

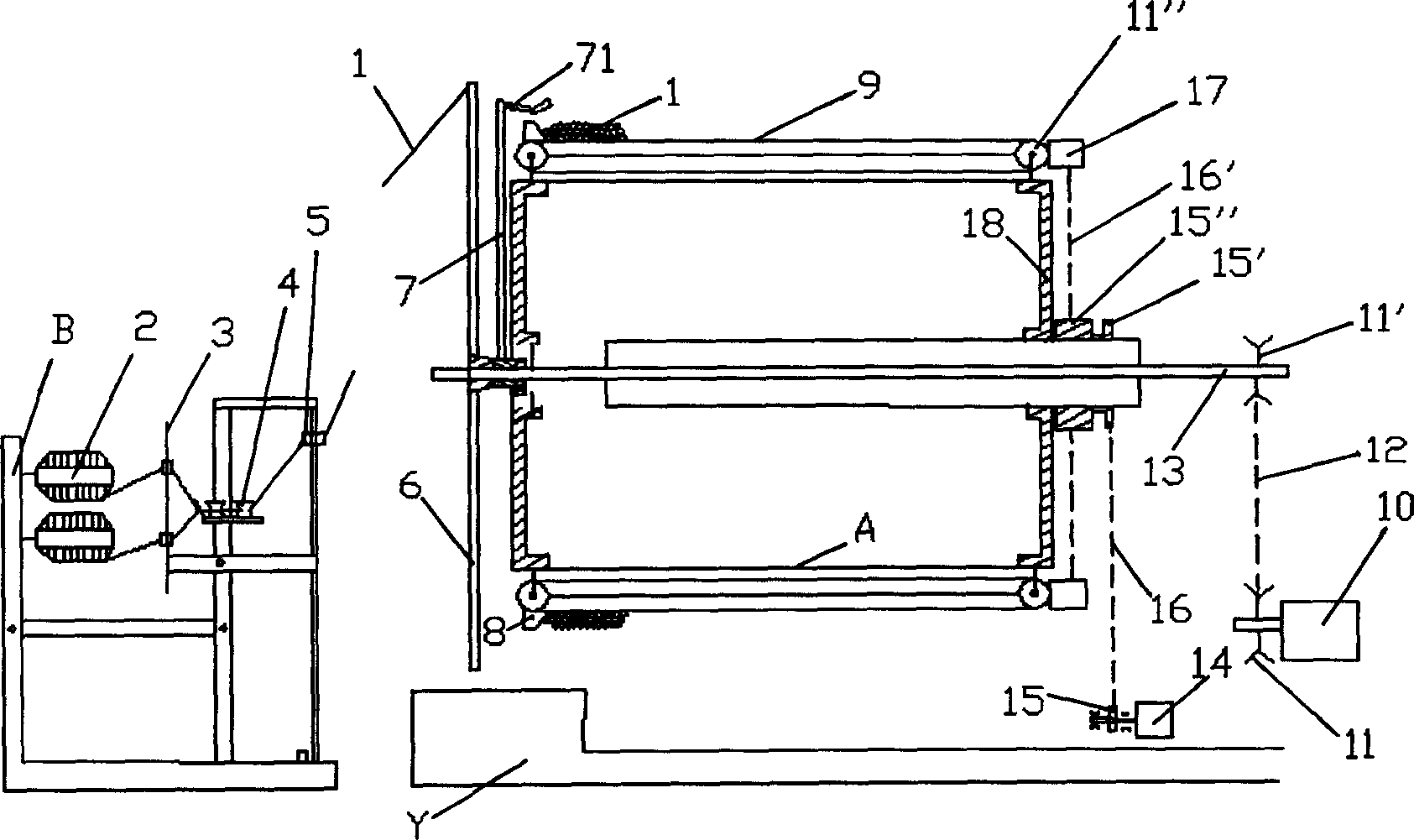

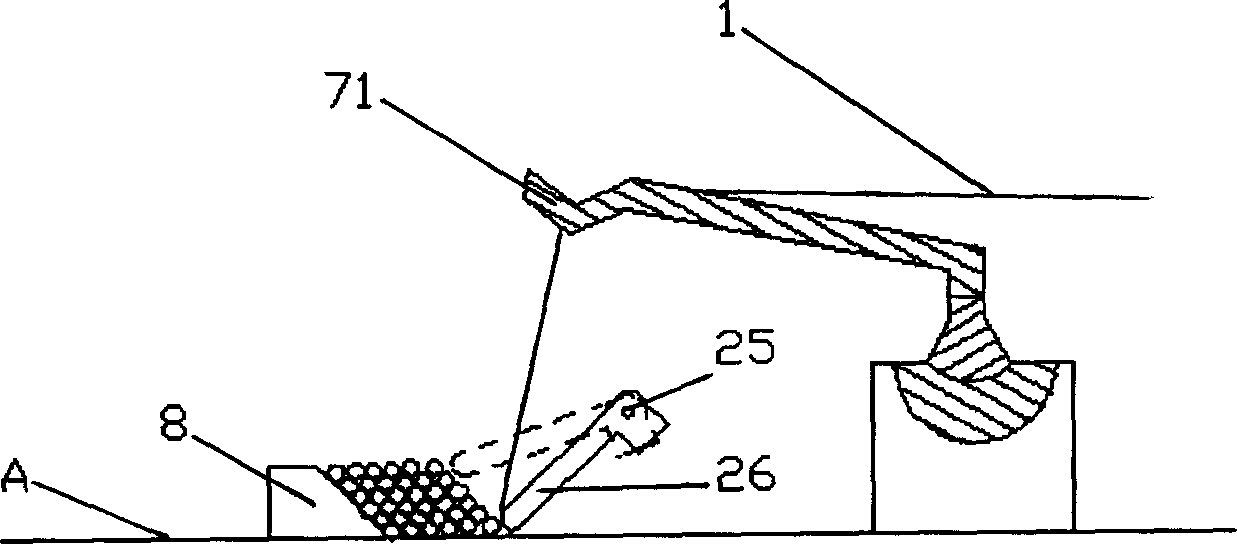

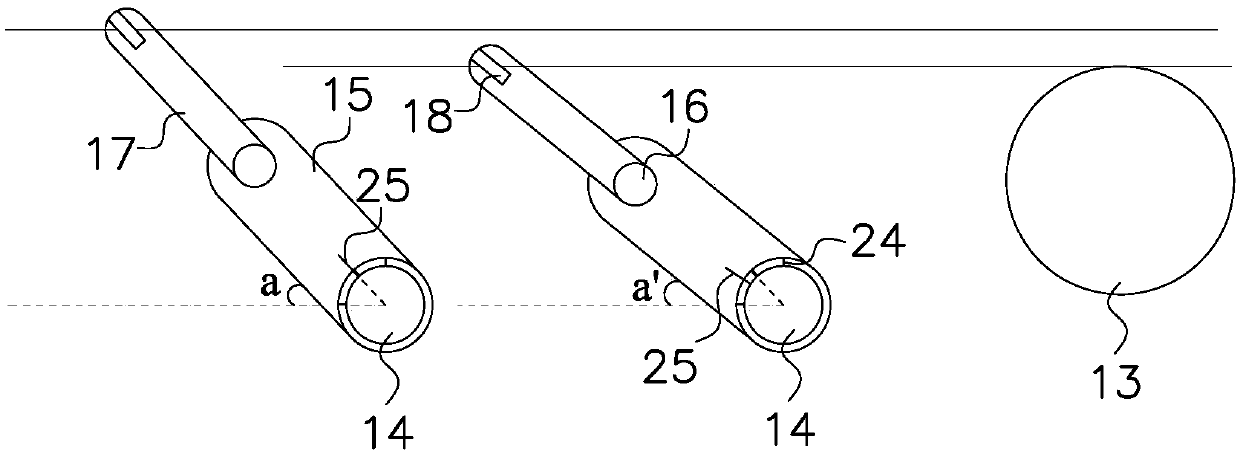

Yarn layer breadth-determining spinning mechanism of warper

InactiveCN1482295AStacks are neat and orderlyStable formWarping machinesTextiles and paperYarnComputer engineering

The present invention discloses a constant size profiling winding device for the yarn layer of sample piece beaming machine features that it also includes a guide rod frame on the inner wall of whichare guide rods in uniform distribution, three rack bars are extended on the left bottom of its outer ring, and three toothed gears and three stepping motors are arranged on the left bottom position. The invention accomplishes constant size profiling yarn discharging method by simple structure.

Owner:DONGHUA UNIV

Polyurethane fiber dry spinning oil agent and preparation method thereof

Owner:BEIJING GUANGHUA TEXTILE GRP +2

Oil preparation agent in use for spinning in urethane elastic fiber

The invention discloses a polyurethane fibre spinning oil. Its composition includes (by wt%) 5-80% of mineral oil, 10-75% of silicone oil, 0.5%-30% of epoxyethane and epoxypropane copolyether, 0.5%-50% of polyether silicone oil, 0.5-15% of antistatic agent and 0.1-10% of anti-sticking property improving agent.

Owner:CHINA PETROCHEMICAL CORP +1

Crosswound bobbin and method for producing such a bobbin

During the production of cross-wound bobbins, the yarn wound onto the cross-wound bobbins is reciprocated by means of a yarn guide, which can be controlled independently of the drive of the cross-wound bobbins and determines the laying width. Here, the laying width is variable. A portion of the cheese layer has a different width than the rest. The rhombus of the cheese layer is all closed. The invention can be installed in the winding position of spinning machines producing cross-wound bobbins and improves package density, uniformity and unwinding performance of cross-wound bobbins.

Owner:RIETER AUTOMATIC WINDER GMBH

Plied oilless nylon 6 DTY (draw textured yarn), production technique thereof and draw-texturing machine to implement production technique

The invention discloses a plied oilless nylon 6 DTY (draw textured yarn), a production technique thereof and a draw-texturing machine to implement the production technique. The production technique comprises (1) heating and drawing two raw yarns; (2) after heating and drawing, cooling, and carrying out false twisting; (3) plying the two false-twisted tows, and winding to obtain a plied oilless nylon 6 DTY, wherein winding tension is 0.05-0.06 times fineness of a finished yarn, and winding overfeed is 3.5-6.5%. The production technique includes no oiling step; since no oiling is performed, towseasily produce static electricity during unwinding, which causes mutual adhesion of strands and end breakage, and also causes poor unwinding performance. In order to overcome such defect of the oilless yarn, the winding tension is set to be 0.05-0.06 times the fineness of the finished yarn, the winding overfeed is set to 3.5-6.5%, and therefore, unwinding performance of the plied oilless nylon 6DTY is improved effectively.

Owner:浙江鼎艺新材料科技有限公司

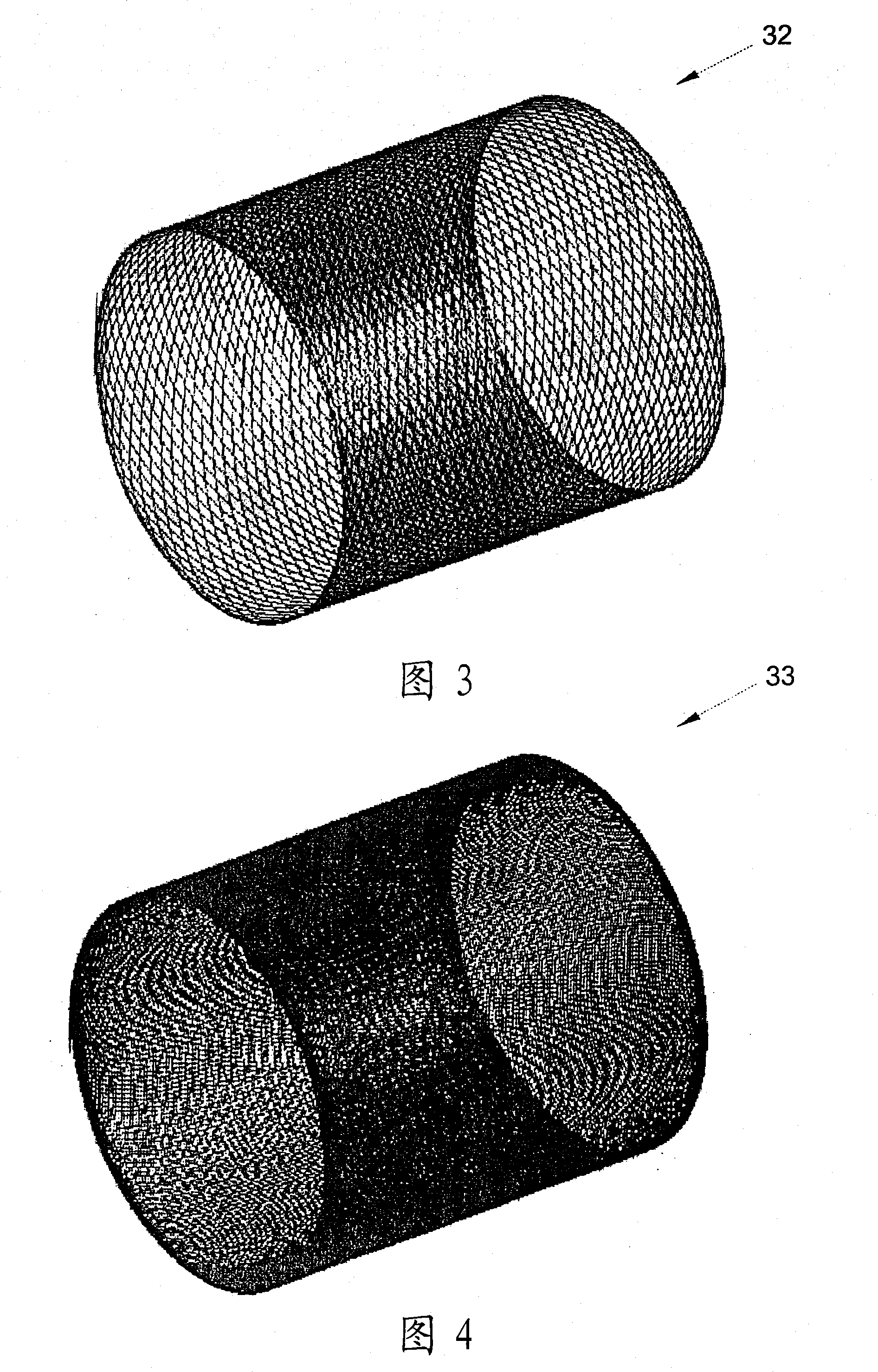

Conic tube and rolling method thereof

InactiveCN1269711CCrossing angle decreasesExcellent unwinding propertyFilament handlingContinuous wound-up machinesYarnBobbin

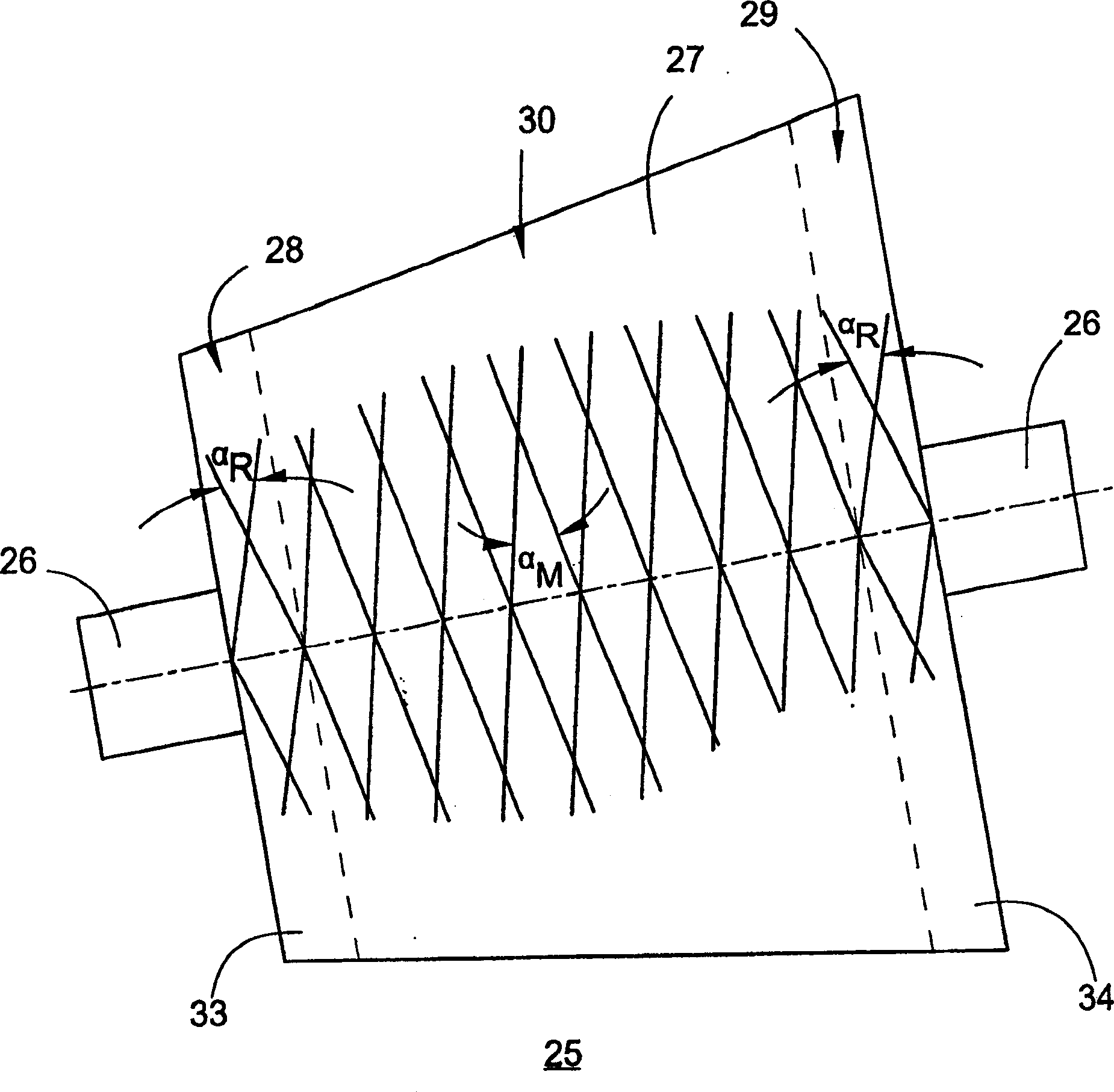

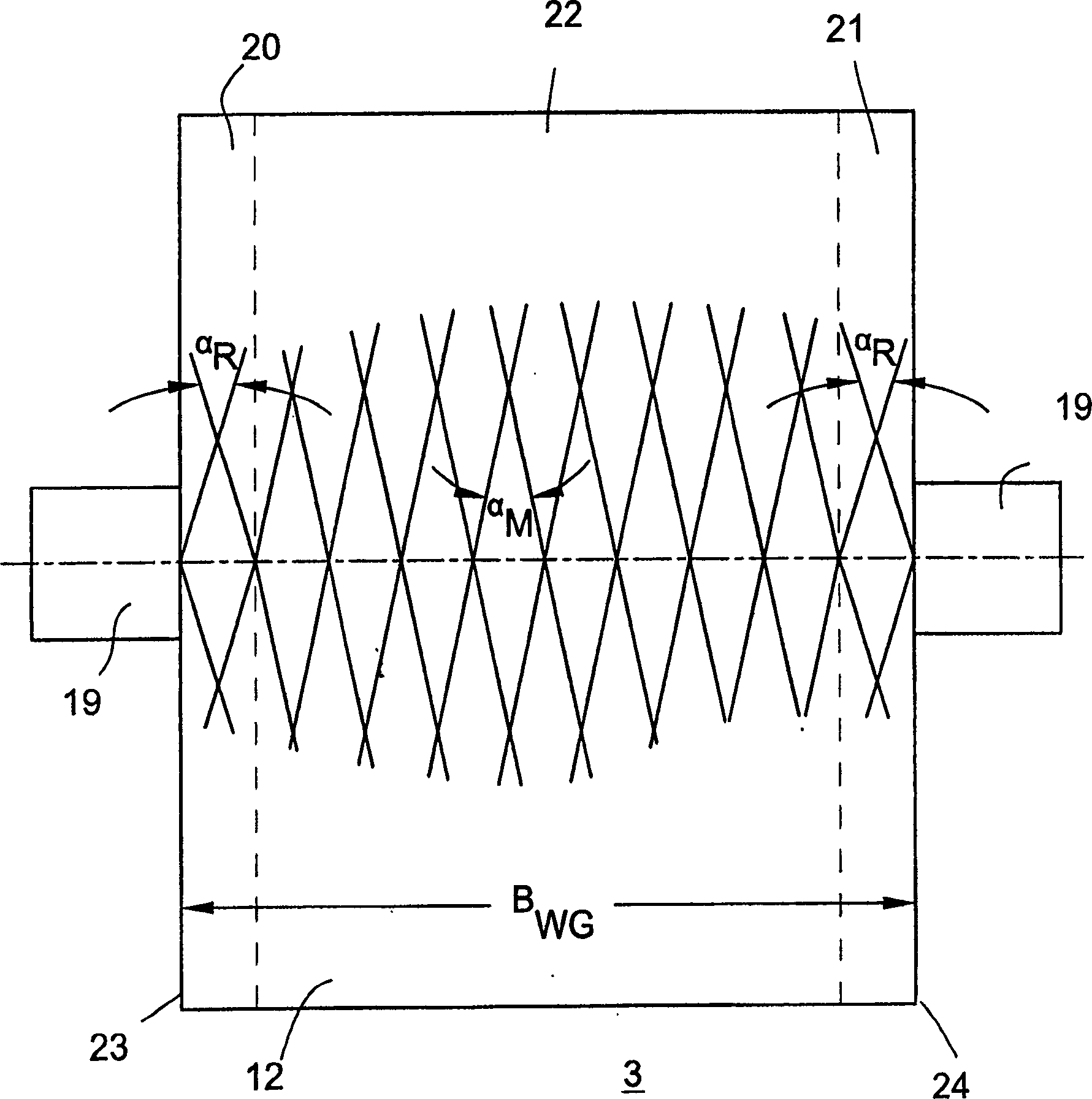

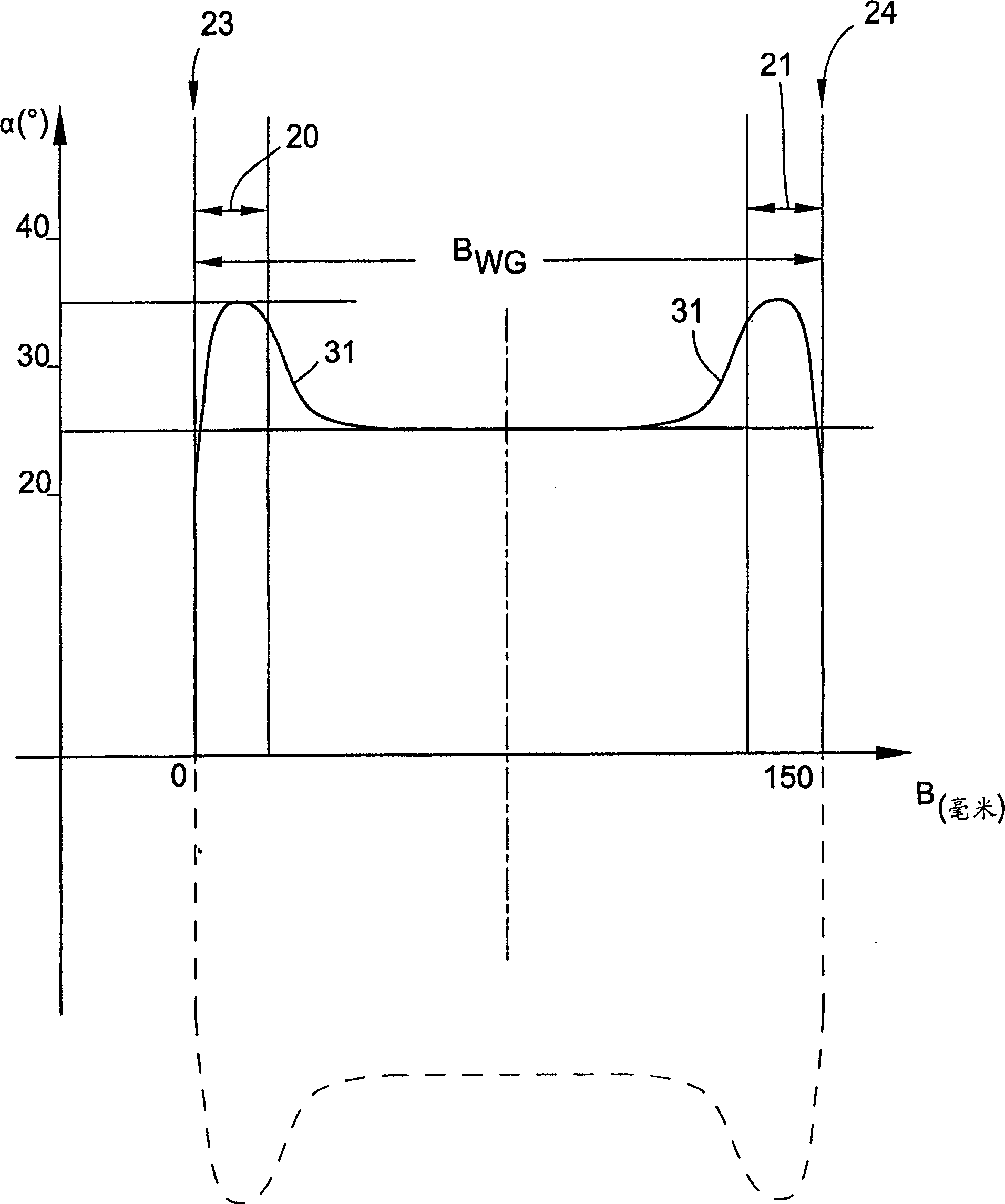

A method for forming a conical cross-wound bobbin by rotor spinning yarn by the following winding the yarn package, that is in a winding process, a crossing angle alpha in the middle section is smaller than that of the other parts of the winding process, and an across alpha M is created between 15-28 degrees in the middle zone, which is produced with this angle across alpha M more than 50% of the total winding width B WG.

Owner:SAURER GERMANY GMBH & CO KG

Oil solution for spandex spinning by dry method, and preparation and use thereof

The invention relates to a preparation agent for dry method urethane elastic fiber spinning. The preparation agent comprises the following components: silicone resin, methyl silicone oil, modification silicone oil, mineral oil and antistatic agent. The preparation method comprises the following steps: 1, silicane chain links(M, X, Y and Z) are mixed and evenly stirred, started, added with acid water at a temperature of 25 DEG C and reacted for 1 hour at the temperature of between 60 and 70 DEG C, stirring stops, after layering, the resin on the lower layer is separated out, the pH value of the resin is neutral by washing, and the resin is subjected to vacuum pumping, temperature rise and dewatering to prepare the silicone resin; and 2, the silicone resin, the methyl silicone oil, the polyether modification silicone oil, the mineral oil and the antistatic agent are placed in a stirring kettle, and evenly mixed at the temperature of between 10 and 50 DEG to obtain. The application of the preparation agent is as follows: the preparation agent is put in a storage tank and transferred to an oil nozzle or roller by an oil pump, and the urethane elastic fiber is directly contacted and oiled. The preparation agent for dry method urethane elastic fiber spinning is transparent liquid, does not contain solid particle components such as hard ester acid magnesium and the like, does not plug pipes and equipment in the oiling process, and does not need power-off cleaning, thereby improving production efficiency.

Owner:NINGBO ECONOMIC & TECHN DEV ZONE SICO NEW MATERIAL

High-strength polyester POY oily agent and preparation method thereof

InactiveCN108642880AHigh strengthIncrease coefficient of frictionAbrasion resistant fibresPolyesterPhosphate

The invention discloses a high-strength polyester POY oily agent. The high-strength polyester POY oily agent is prepared from, by mass, 40-60 parts of smoothing agent, 10-30 parts of emulsifier, 1-5 parts of antistatic agent, 20-40 parts of stabilizer and 10-20 parts of deionized water; the smoothing agent is prepared by compounding, by mass, 60-80 parts of polyether, 5-20 parts of mineral oil and0-10 parts of fatty alcohol ester or polyol ester; the emulsifier is a diphenylmethane dimeric surfactant, the antistatic agent is C8-C16 monoalkyl fatty alcohol polyoxyethylene ether phosphate, andthe stabilizer is tallowseed oil modified alkyd resin. The wear resistance and heat resistance of the oily agent are improved, the strength of an oil membrane is enhanced, friction coefficients of theoil membrane are increased, the fluctuation is small, and requirements for high speed spinning are met. The compatibility of polyether of the smoothing agent and the antistatic agent is improved, andthe strength of the oil membrane and the bundling performance of silk strips are improved. Emulsification is stable, good interfacial properties are achieved, the production process is environment-friendly and clean, and the high-strength polyester POY oily agent is suitable for certain-scale industrial production.

Owner:杭州华春化纤染织有限公司

Columnar tube and rolling method thereof

InactiveCN1426948ACrossing angle decreasesExcellent unwinding propertyFilament handlingContinuous wound-up machinesYarnBobbin

A winding method for forming a cylindrical shape bobbin is provided, whereby, an intersection angle (alpha) is varying while the yarn is winded. To guide yarn, a yarn intersection angle (alpha M) at the center zone in the bobbin winding process is between 15-28 degrees and the yarn intersection angle (alpha R) towards the edge zones of two ends of the winding package is larger than that of the center zone.

Owner:SAURER GERMANY GMBH & CO KG

Fully drawn yarn (FDY) paper tube capable of improving unwinding effect and paper tube performance and preparation method

ActiveCN110228731AHigh compressive strengthHigh hardnessMonocarboxylic acid ester polymer adhesivesMechanical working/deformationYarnFiber

The invention provides a fully drawn yarn (FDY) paper tube. A paper tube body comprises a paper tube base cylinder layer and an outer coating layer coating the external surface of the base cylinder layer. One end of the paper tube body is a straight edge end, and the other end of the paper tube body is a turned edge end. The base cylinder layer is formed by mixedly winding bobbin fiber paper and recycled base paper with a weight ratio of no less than 10%, the outer coating layer is made of facial tissues selected from parchments or glass paper, and the weight ratio of the recycled base paper is not less than 20%. The paper tube has good physical properties and mechanical properties and is simple and reasonable in structure. The end face friction of the paper tube can be effectively reduced, the retention rate of tail fibers is reduced, yarn breaking or fuzzy yarn during paper tube unwinding is avoided, and thus the unwinding success rate of a yarn cake is increased, and the graded product rate of chemical fiber products is promoted.

Owner:福建省三丰纺织器材有限公司

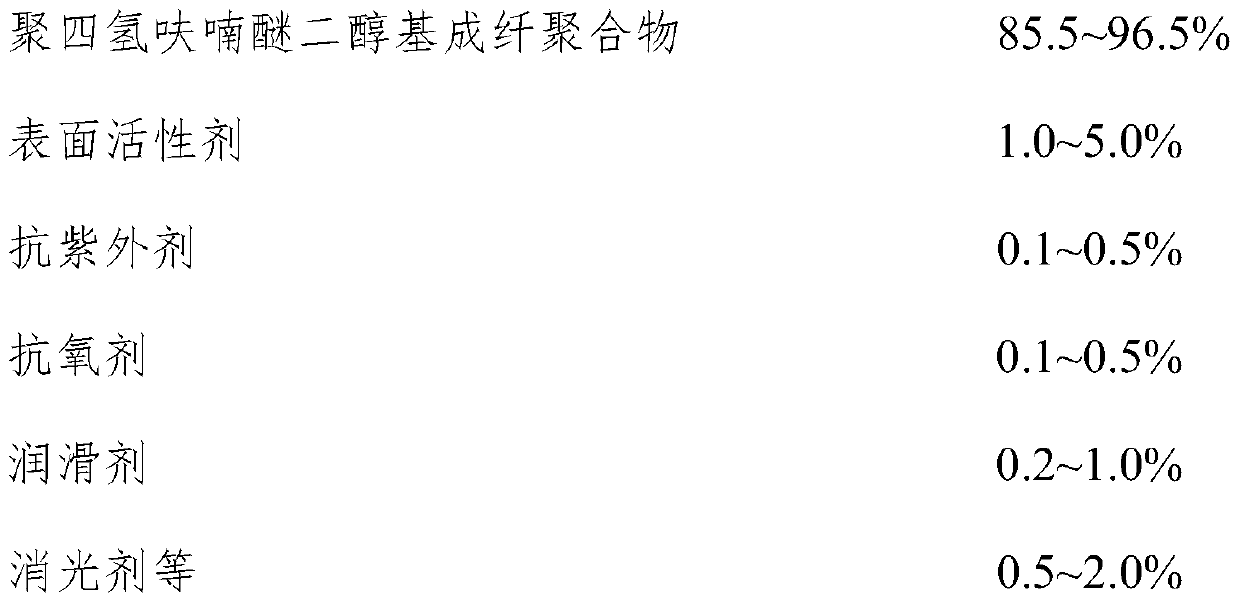

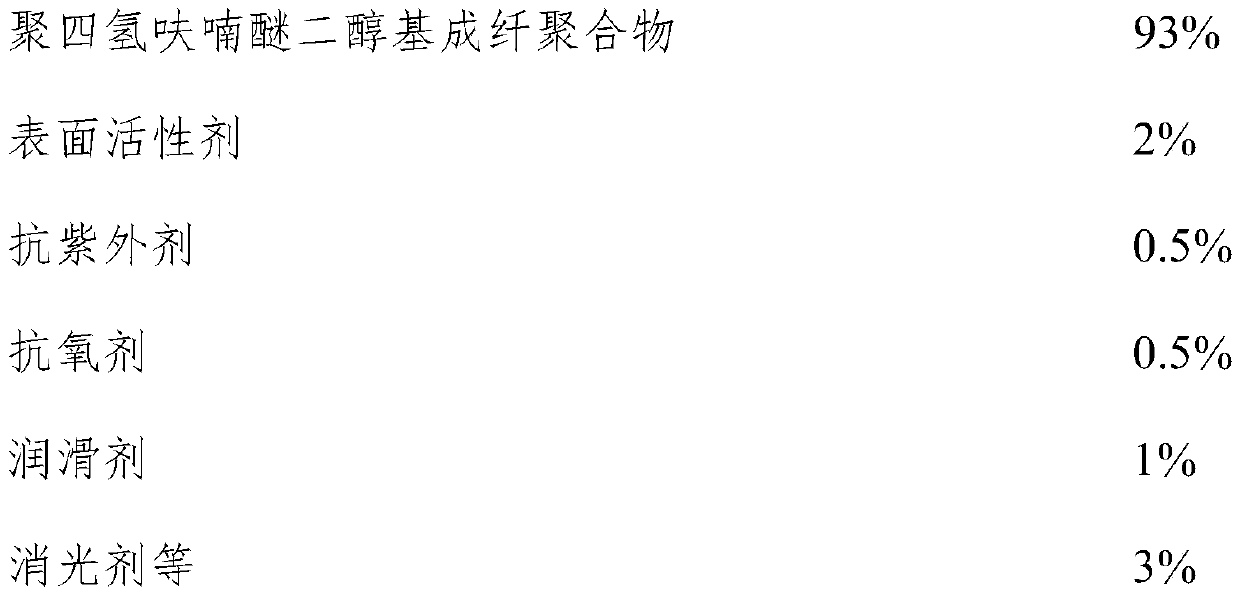

Easy-backing-off anti-adhesion polyurethane fiber and preparation method thereof

InactiveCN110318114AGood unwinding effectExcellent mechanical and physical propertiesMonocomponent synthetic polymer artificial filamentArtifical filament manufacturePrepolymerDiamine

The invention provides a polyurethane fiber which can keep easy-backing-off and anti-adhesion performance for a long time and a preparation method of the polyurethane fiber. The method comprises the steps that (1) raw materials polytetramethylene glycol and 4,4,-methylenediphenyl diisocyanate are subjected to a mixing reaction to obtain a prepolymer, and a proper amount of solvent is added for preparing a prepolymer solution; (2) the prepolymer solution and a mixed diamine chain extender react to form a polymer solution; (3) a special additive, namely a sizing agent is added to the polymer solution, and through stirring and curing, a spinning stock solution is prepared; (4) through spinning of spinning equipment, the easy-backing-off anti-adhesion polyurethane fiber is prepared. At least six months after the easy-backing-off anti-adhesion polyurethane fiber is taken down from a winding head, the adhesion and yarn breaking phenomena do not occur in the backing-off process of the polyurethane fiber, the storage life of the polyurethane fiber is prolonged, the service life of the polyurethane fiber is prolonged, the loss of the polyurethane fiber is greatly reduced, and the industrialproduction cost is reduced.

Owner:ZHENGZHOU ZHONGYUAN SPANDEX ENG TECH

A kind of spandex spinning finish with uniform unwinding inside and outside and its preparation method

The invention relates to spandex spinning oil with a function of enabling exterior-interior unwinding to be uniform, and a preparation method of the spandex spinning oil. The spandex spinning oil is prepared by mixing a component A and a component B, wherein the component A is prepared from the following components by weight: 80-92% of dimethyl silicone oil, 1-10% of modified silicone oil, 0.5-5%of silane containing special functional groups and 1-8% of silicon resin; the component B is prepared from the following components by weight: 80-90% of mineral oil, 5-15% of a W / O type emulsifying agent, 1-5% of an antistatic agent and 0.5-2% of modified magnesium stearate; the mixing ratio of the component A to the component B is equal to (1.5 to 1)-(1 to 1.2). The oil which is prepared by the method and is used for polyurethane elastic fibers is yellowish transparent liquid, and not only can enable spandex fibers to have excellent formability in a winding process, but also has higher surface energy and has stronger adsorption to polyurethane so as to enable the polyurethane not to easily migrate to the surfaces of the fibers from the inner layers of the fibers, thus endowing the spandexfibers with more uniform exterior-interior unwinding and further enabling the spandex fibers to be smoothly unwound and not to be broken in the subsequent application.

Owner:ZHEJIANG HUAFENG SPANDEX

Polyurethane elastic yarn and manufacturing method thereof

PendingCN113874561AImprove adhesionImprove comfortMonocomponent polyurethanes artificial filamentAbsorbent padsYarnPolymer science

To provide a polyurethane elastic yarn that is superior in unwinding properties and adhesive properties in respect to a hot melt adhesive agent, and to provide a manufacturing method thereof. A polyurethane elastic yarn wherein the main structural component of the polyurethane is a polymer diol or diisocyanate; and includes a polymer that includes, as the main structural unit, a structural unit that uses an aromatic olefin and / or an aliphatic diolefin as a monomer, and is partially hydrogenated or completely hydrogenated.

Owner:东丽奥培隆特士股份有限公司

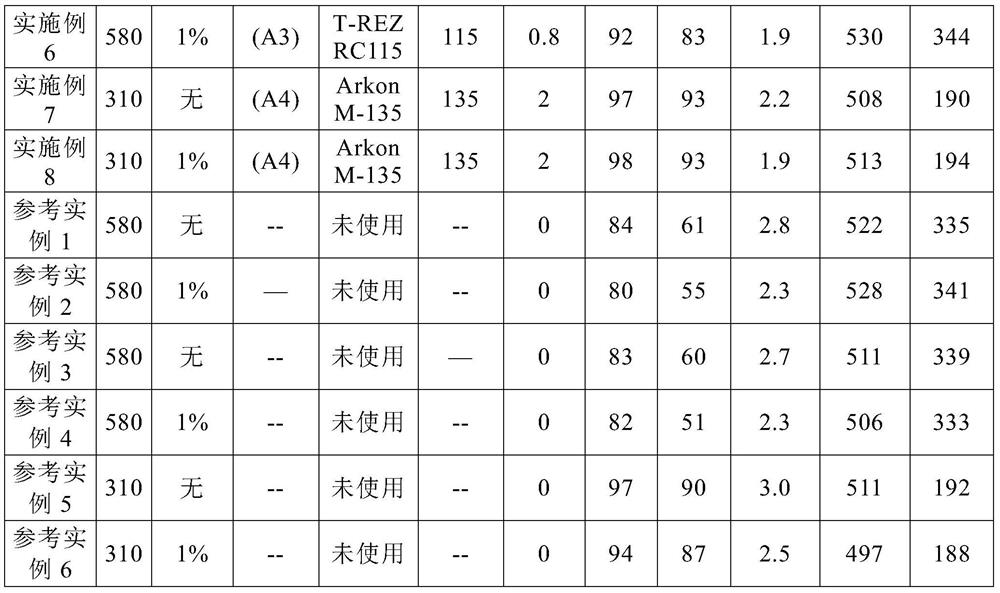

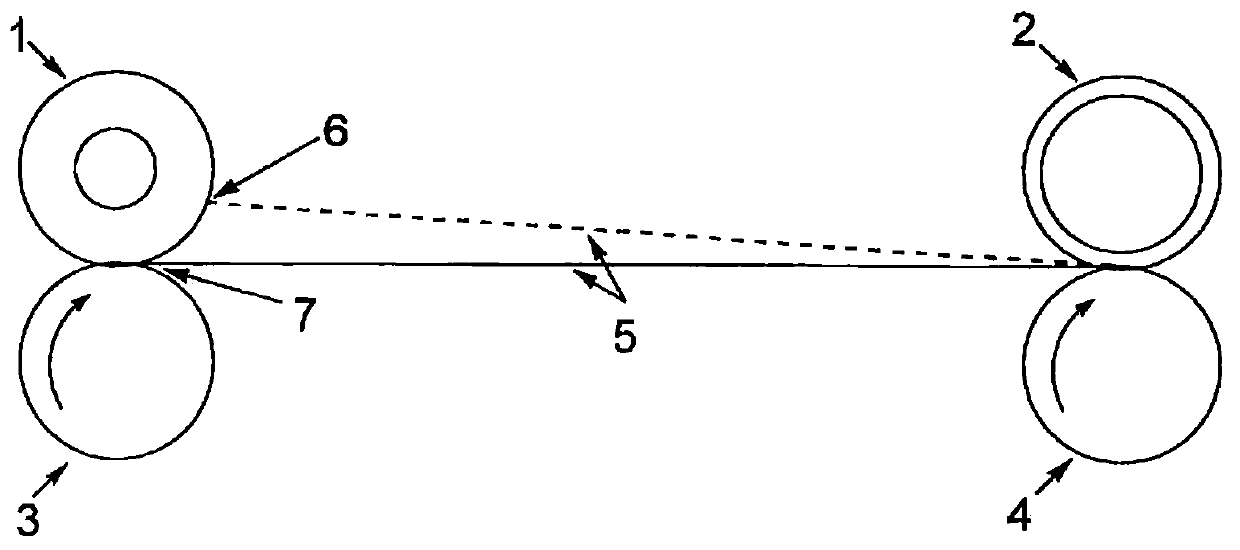

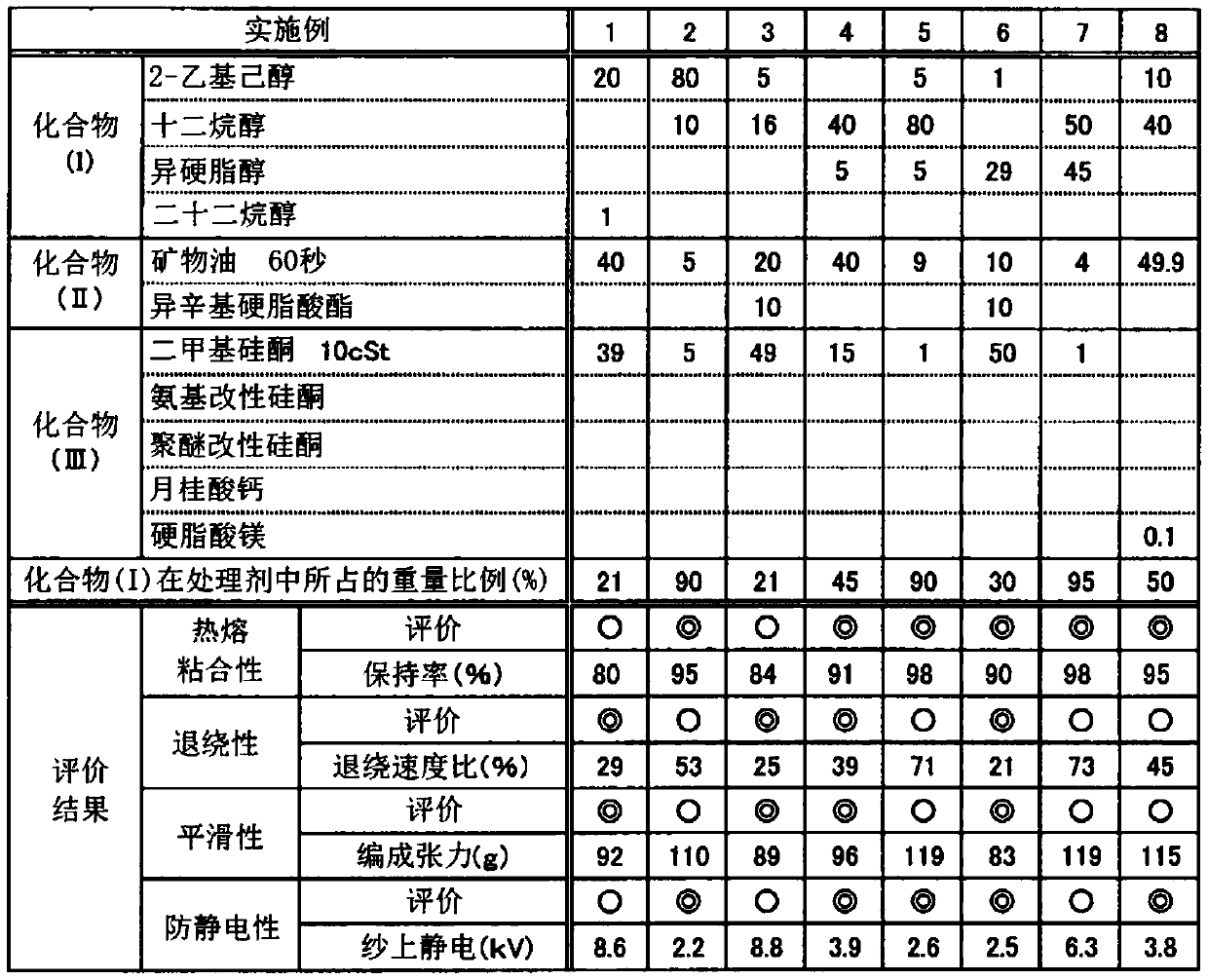

Treatment Agent for Elastic Fiber and Its Utilization

Provided are: a treating agent for elastic fibers that are excellent in terms of adhesion to hot-melt adhesives, unwindability, and smoothness; and elastic fibers that are excellent in terms of adhesion to hot-melt adhesives, unwindability, and smoothness. The treating agent for elastic fibers comprises a component (I) which is at least one compound selected from among higher alcohols, polyhydric alcohols having a valence of 3-6, alkylene oxide adducts of higher alcohols, and alkylene oxide adducts of polyhydric alcohols having a valence of 3-6 and a component (II) which is at least one oil selected from among mineral oils and ester oils, the weight proportion of the component (I) in the treating agent being 21-90 wt%.

Owner:MATSUMOTO YUSHI SEIYAKU

A kind of preparation method of easy unwinding spandex

ActiveCN110923844BExcellent yield and unwinding performanceSimple stepsTextile/flexible product manufactureMonocomponent synthetic polymer artificial filamentPolyesterPolymer science

The invention relates to an easy-unwinding spandex and a preparation method thereof. The specific preparation method is as follows: Step 1. Prepolymerization: mixing and reacting diphenylmethane diisocyanate MDI and polytetramethylene ether glycol PTMG to generate isocyanate group NCO End-capped prepolymer PP; Step 2. Chain extension: Dissolve PP in N,N-dimethylacetamide DMAC using a high-speed rotator and pass the solution through a rotating reactor where chain-extending amine is added , end-capped amine to obtain the POL stock solution; step 3. ripening: add functional additives (antioxidant, dyeing auxiliaries, lubricants, anti-yellowing agents, etc.) in the POL stock solution, mature for a certain period of time, add alkali-soluble polyester, After stirring and dispersing evenly, the DOPE stock solution is obtained; Step 4. Spinning and forming: the above-mentioned DOPE is pumped to the spinneret after removing impurities through the filter, and then dried in the tunnel to remove DMAC, then soaked in a high-temperature lye pool, and dried with hot air After drying, cooling and shaping, oiling is done to obtain spandex. At the same time, in the production process, the spinnability of the spinning dope is good.

Owner:ZHEJIANG HUAFENG SPANDEX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com