Spandex dry spinning oil agent not containing organosilicone and preparation method thereof

A technology of dry spinning and silicone, applied in textiles and papermaking, fiber treatment, fiber types, etc., can solve the problems of difficult dyeing of spandex yarn, affecting the coloring rate of spandex yarn, insufficient lamination and compounding degree, etc.

- Summary

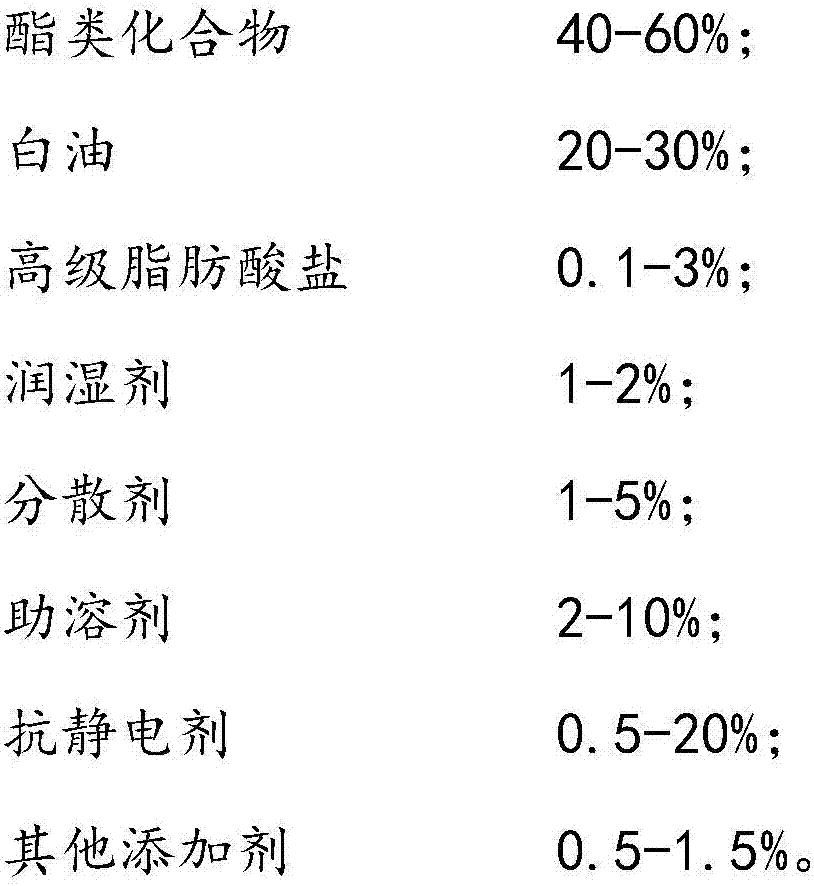

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

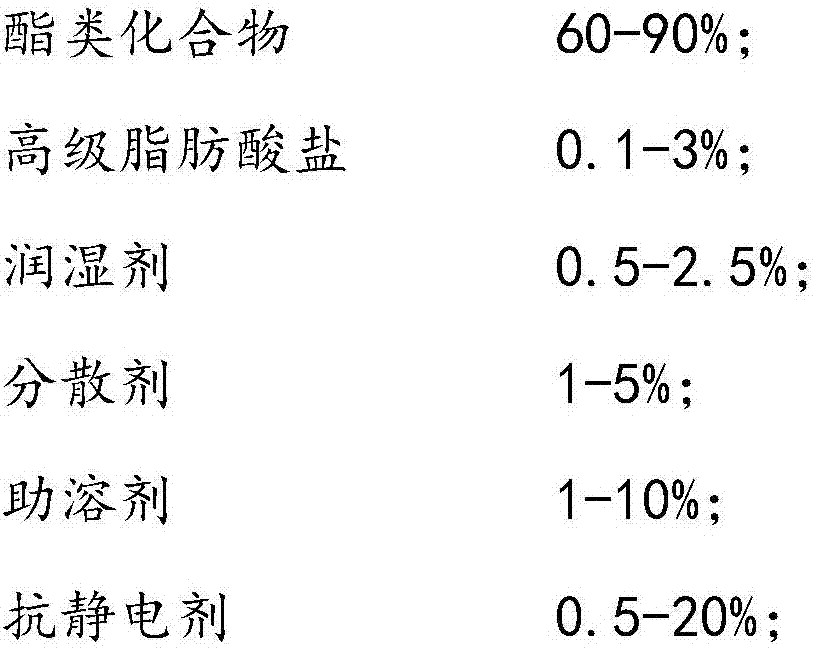

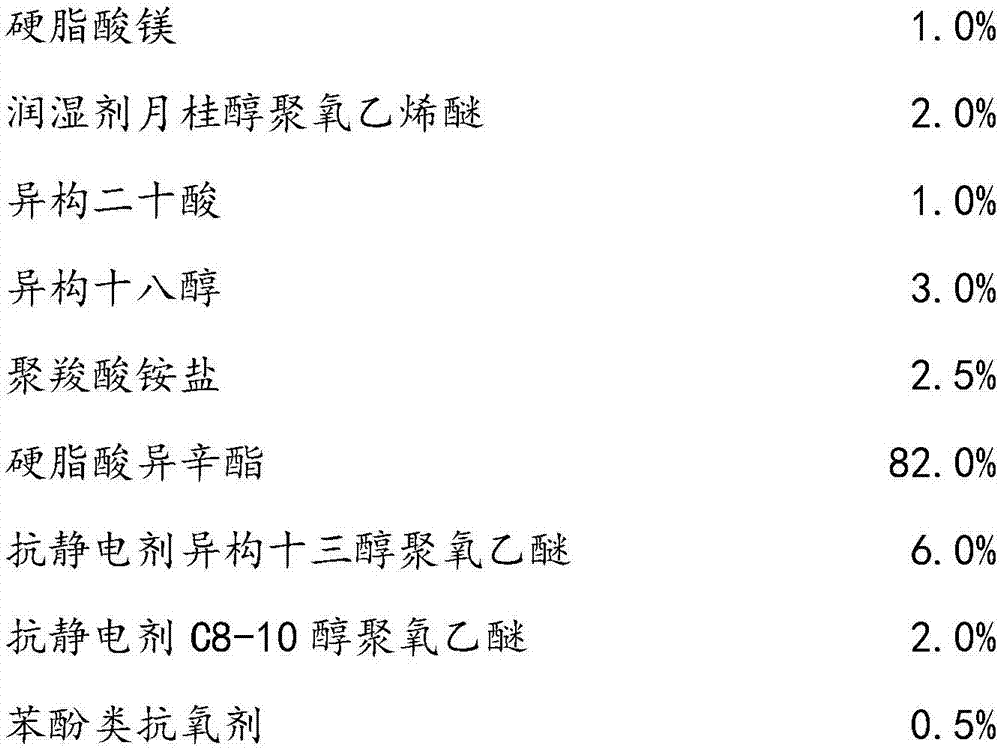

[0042] The formula components are as follows in the present embodiment:

[0043]

[0044] ①Add magnesium stearate and wetting agent lauryl alcohol polyoxyethylene ether first, disperse on a high-speed disperser for 20 minutes, then gradually add isosteric alcohol and isomeric eicosic acid, then add dispersant polycarboxylate ammonium salt, heat up After reaching 120°C, stir for 30 minutes, then lower the temperature to 80°C to obtain substance A;

[0045]②Raise the temperature of isooctyl stearate to 60°C, then add substance A, mix and cool down to 40°C, then add antistatic agent isotridecyl alcohol polyoxyethyl ether and C8-10 alcohol polyoxyethyl ether, add antioxidant Agent, mix evenly, that is.

[0046] In this example, a silicone-free spandex dry-spinning oil product was obtained as a nearly transparent liquid with a viscosity of 14.0 mPa.s at 25°C.

Embodiment 2

[0048] The formula components are as follows in the present embodiment:

[0049]

[0050] ① First add calcium stearate and wetting agent C10-12 fatty acid polyoxyethylene ester, disperse on a high-speed disperser for 20 minutes, then gradually add isomeric cetyl alcohol and isomeric eicosic acid, then add polycarboxylate sodium salt, heat up After reaching 120°C, stir for 40 minutes, then lower the temperature to 70°C to obtain substance A;

[0051] ②Raise the temperature of isotridecanyl stearate to 60°C, then add substance A, mix and cool down to 40°C, then add antistatic agent and nano silicon dioxide, and mix well to get ready.

[0052] In this example, a silicone-free spandex dry spinning oil product was prepared. The product was a clear and transparent liquid with a viscosity of 13.0 mpa.s at 25° C.

Embodiment 3

[0054] The formula components are as follows in the present embodiment:

[0055]

[0056]

[0057] ① First add zinc stearate and wetting agent polyoxypropylene lauryl ether, disperse on a high-speed disperser for 20 minutes, then gradually add isomeric cetyl alcohol and isomeric tetracosanoic acid, and then add dispersant lauryl polyethylene glycol Glycol ether sodium sulfate, heat up to 120°C, stir for 30 minutes, then cool down to 70°C to obtain substance A;

[0058] ②Raise the temperature of isocetyl stearate to 60°C, then add substance A, mix and cool down to 40°C, then add antistatic agent isotridecyl alcohol polyoxyethylene ether and C10-12 alcohol polyoxyethylene ether Phosphate ester, defoamer, after mixing evenly.

[0059] In this example, a silicone-free spandex dry spinning oil product was prepared, which was a nearly transparent liquid with a viscosity of 13.5 mpa.s at 25°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com