Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44 results about "ISOCETYL STEARATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

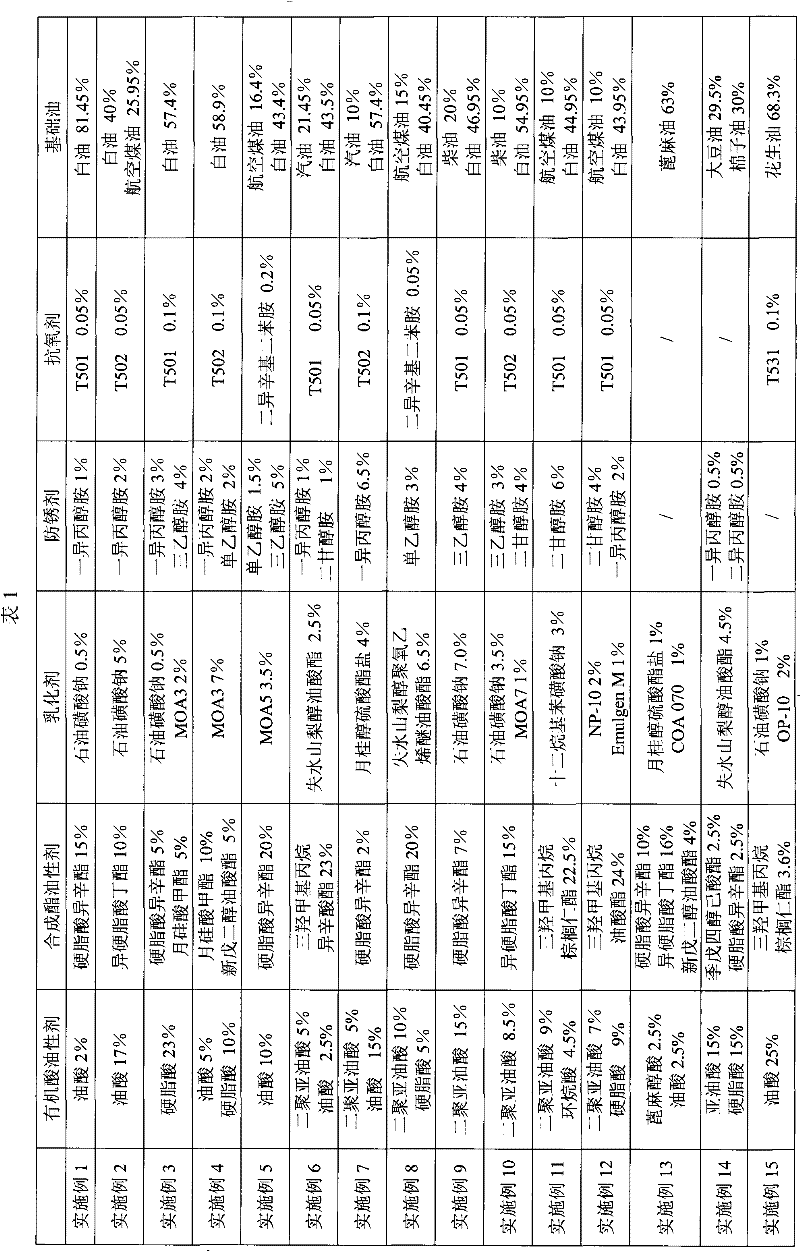

Drilling fluid lubricating agent

ActiveCN101486896AMeet the requirements of lubricating performanceImprove the lubrication effectDrilling compositionStearateTrimethylolpropane

The invention relates to a lubricant for drilling fluid, which essentially solves the problems of the prior art that the lubricant for drilling fluid has poor lubricating property in the high-density drilling fluid. The lubricant for drilling fluid comprises the following components calculating by weight percentage: a) 1 to 35 percent of long-chain organic acid oiliness agent; b) 1 to 35 percent of synthetic ester oiliness agent; c) 0.1 to 8 percent of emulsifier; and d) 25 to 90 percent of base oil; in which the synthetic ester oiliness agent is selected from at least one of isooctyl stearate, butyl isostearate, trimethylolpropane trioleate, trimethylolpropane palm kernel ester, trimethylolpropane ethylhexoate, neopentyl glycol oleate, methyl laurate or pentaerythritol caproate, therefore, the technical proposal solves the problem preferably, and can be used in the industrial production of lubricant for drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP

Finish for nylon FDY and preparation method

The invention relates to the technical field of auxiliary manufacturing in the fiber processing technology, in particular to finish for nylon FDY and a preparation method. The finish for nylon FDY comprises the following components: 55-60% of isooctyl stearate, 5-7% of scouring agents, 5-7% of oleic acid, 8-10% of coconut oil diethanolamine, 5-7% of hydrogenated castor oil polyoxyethylene ether, 5-7% of fatty alcohol polyoxyethylene ether 4, 1-2% of oleic acid sarcosine, 0.5-1% of hypophosphorous acid, 1-1.5% of potassium hydroxide and 5-7% of wetting agent. The preparation method comprises the process steps of mixing, stirring and testing. The finish for nylon FDY has good thermal stability, is less in volatilization and free of coking and has low coefficient of dynamic friction in the drawing stage and good cohesion.

Owner:JIAXING NEW & HIGH TECH FIBER

Rolling oil for stainless steel

ActiveCN102504919ALow viscosityExtended service lifeLubricant compositionWater sourceChlorinated paraffins

The invention relates to a rolling oil for a stainless steel, which is prepared by the following raw materials by weight: 64.5-79.9% of white oil, 5-15% of neopentyl polyol ester, 5-10% of pentaerythritol aliphatic ester, 2-5% of isooctyl stearate or butyl stearate, 0.5-1.2% of mixed-type high temperature antioxygen, 0.05-0.2% of phenol-type antioxygen, 0.05-0.1% of ethylenediaminetetraacetic acid (EDTA) dipotassium salt, 0.4-0.8% of antirust additive, 0.1-0.5% of metal passivator and 2-3% of antiwear agent. The invention uses synthetic ester to replace chlorinated paraffin, which prevents environmental pollution of chlorinated paraffin, meanwhile avoids using large quantity of water for cooling, saves massive water source and also converts the processing oil into recyclable oil, thereby prolonging the service life of the processing oil greatly. The invention has the features of excellent lubrication performance, cooling performance, rust resistance, cleanness, energy conservation andenvironmental friendliness. The waste liquid is less in volume and can be recycled. Therefore the rolling oil provided by the invention is the preferred processing oil for finishing rolling of stainless steel to obtain high-gloss surface.

Owner:彭美东

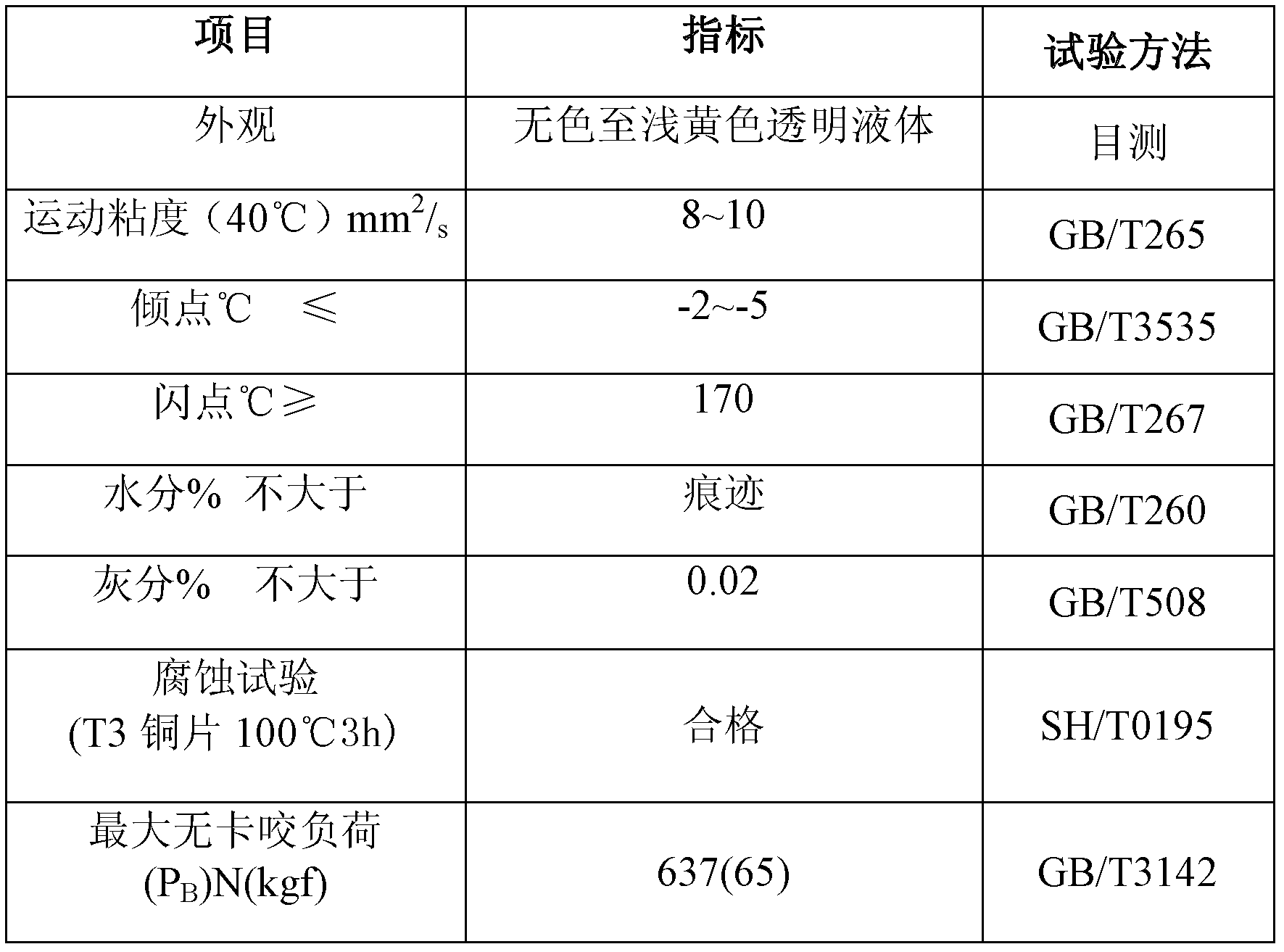

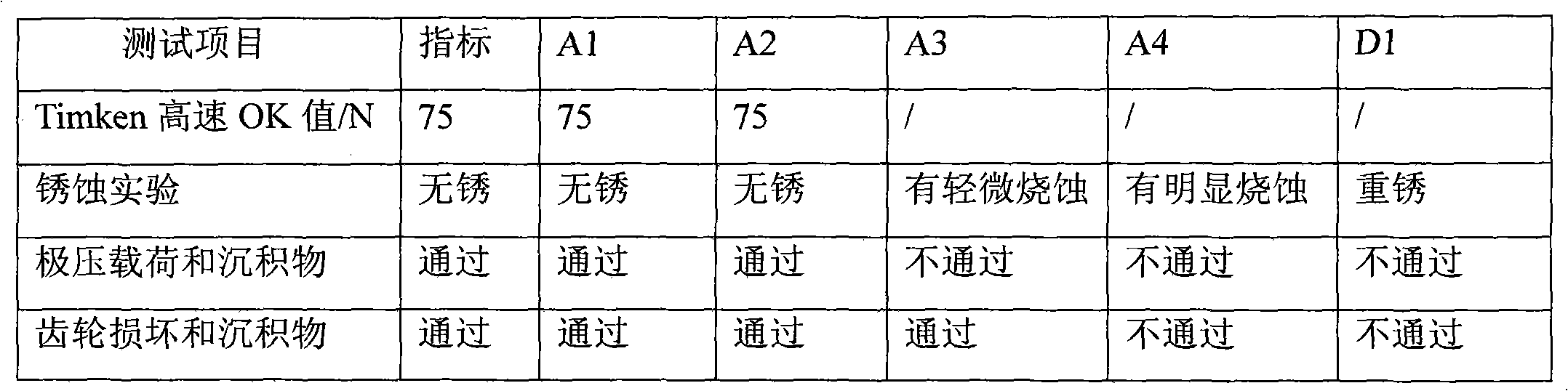

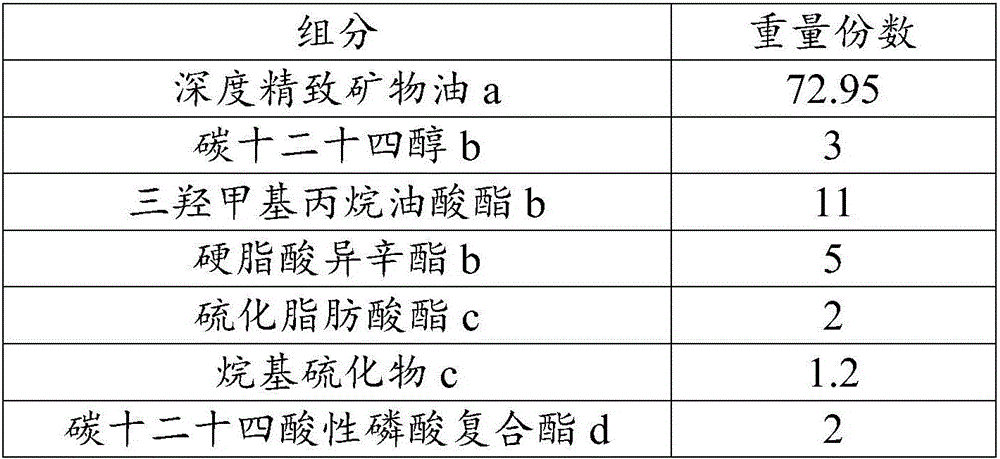

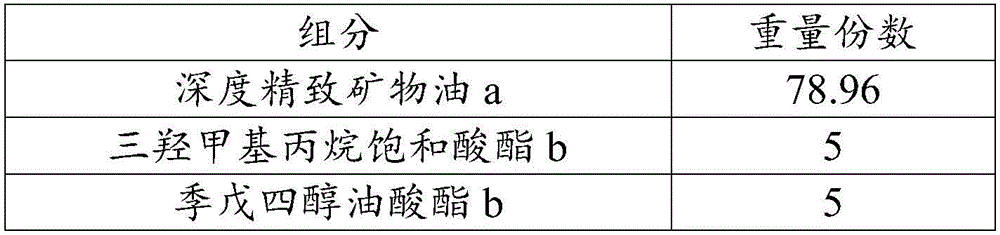

Gear oil composition for automobile

InactiveCN101993763AImprove antioxidant capacityExtend your lifeAdditivesPolymer scienceWear resistant

The invention discloses a gear oil composition for an automobile. The gear oil composition for the automobile comprises viscosity blend base oil, a sulfur-containing extreme pressure additive, a phosphorus-containing wear-resistant additive, an antirust additive, a metal passivator and a synthetic ester oiliness additive, wherein the synthetic ester oiliness additive may be one or more of trimethylolpropane trioleate, octyl stearate, butyl stearate, isooctyl stearate and isooctyl palmitate; and the synthetic ester oiliness additive accounts for 2 to 10 percent of the total weight of the gear oil composition. The gear oil has the advantages of high wear resistance, high maximum non-seizure load, high load-bearing capacity, high viscosity index, high low-temperature flowability, high lubricating property and the like, is suitable for the lubrication of an automobile manual gearbox and a rear drive axle gear and is also suitable for an automobile automatic gearbox.

Owner:SUZHOU SHIHAO BUILDING MATERIAL NEW TECH ENG

High-lubricating rolling oil composition and application thereof

ActiveCN106318568AImprove the lubrication effectMeet lubrication needsLubricant compositionPhosphateButylated hydroxytoluene

The invention relates to a high-lubricating rolling oil composition and application thereof. The composition is prepared from 40-90 parts of highly refined mineral oil, 10-30 parts of carbon dodecanol tetradecyl alcohol, isotridecyl alcohol, n-octanol, pentaerythritol oleate, trimethylolpropane trioleate, diisooctyl phthalate, 2-ethylhexyl palmitate, isooctyl stearate, methyl palmitate or butyl stearate, 1-5 parts of ZDTP, octadecyl zinc dithiophosphate, sulfurized olefin, sulfide aliphatic acid ester, sulfurized animal oil, alkyl sulfide or sulfur phosphorus molybdenum, 0.5-5 parts of amine thiophosphate, isooctyl acidic phosphate octadecylamine, tricresyl phosphate, tributyl phosphate, dibutyl phosphate and carbon-12 to carbon-14 acid phosphate compound ester, 0.1-5 parts of 2,6-butylated hydroxytoluene, N-phenyl naphthylamine, thioether phenol or alkyl diphenylamine and 0.01-2 parts of 1H-benzotriazole, thiadiazole derivative and benzotriazole.

Owner:CHINA PETROLEUM & CHEM CORP

Novel desizing agent and preparation method thereof

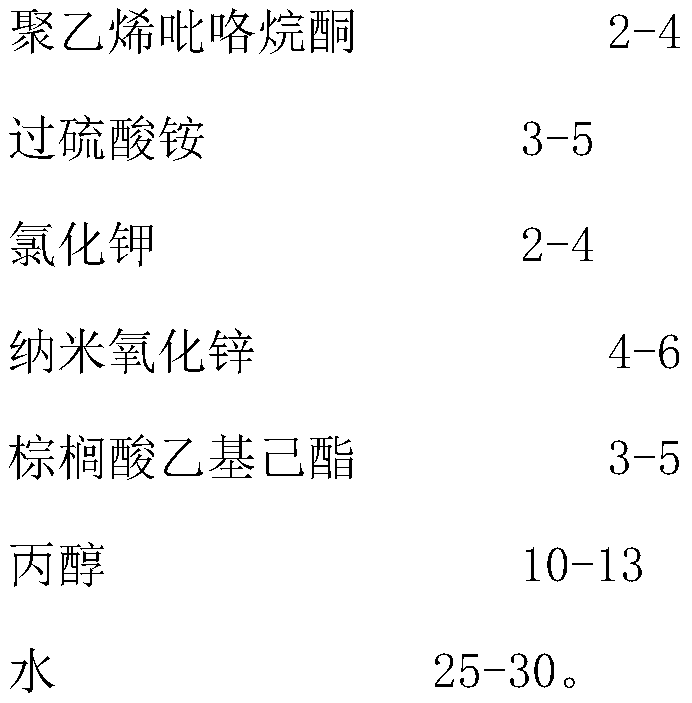

ActiveCN108505318AWith desizing effectImprove desizing effectDry-cleaning apparatus for textilesGrip property fibresEthylhexyl palmitatePotassium

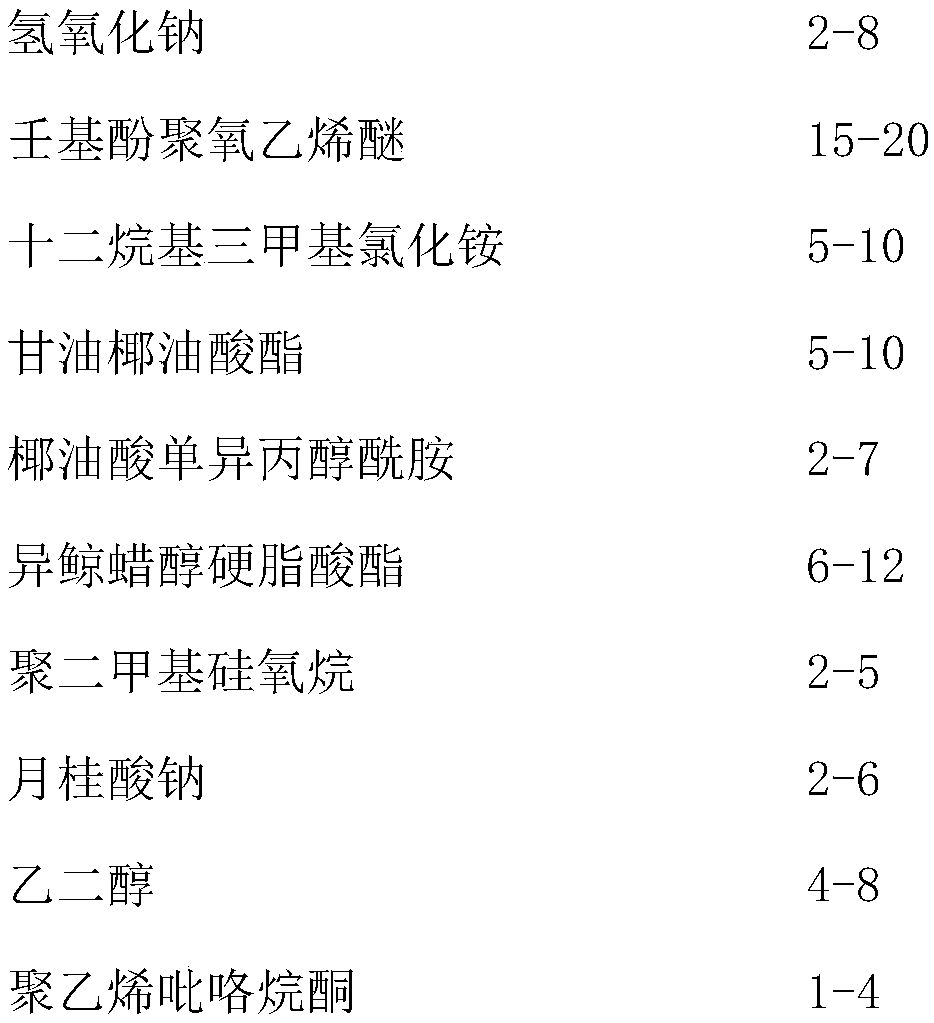

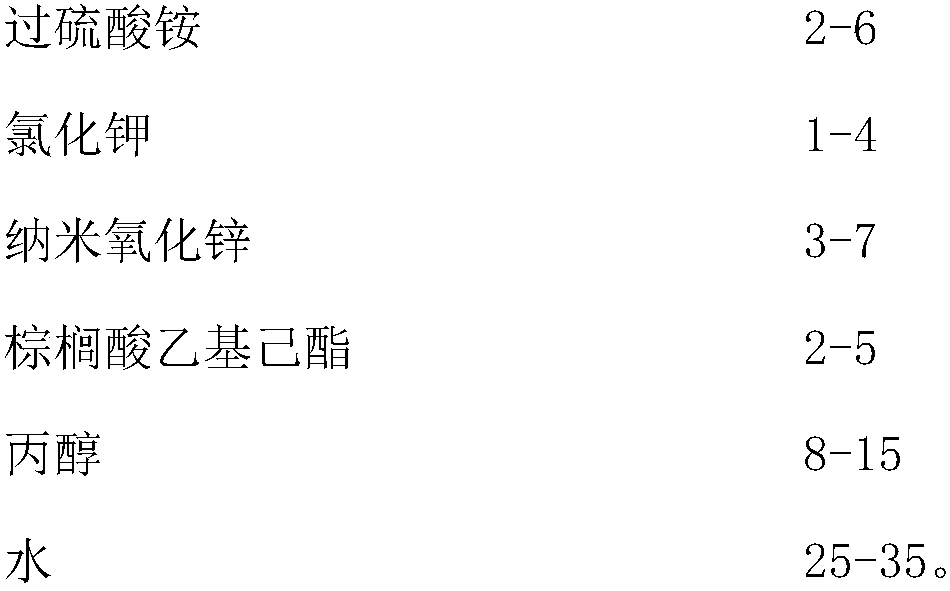

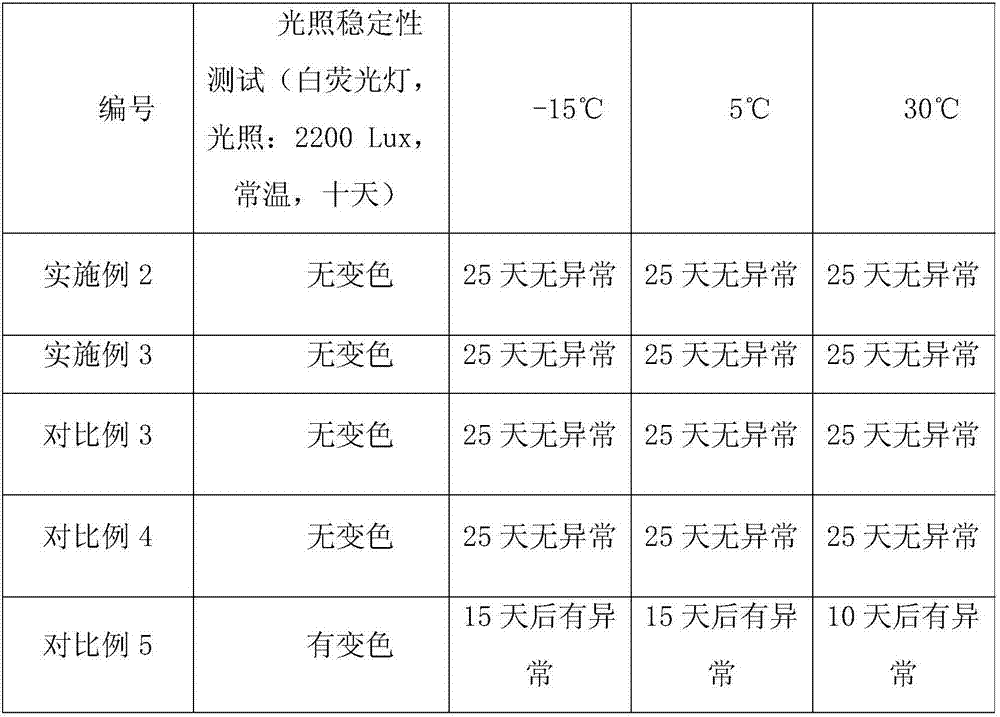

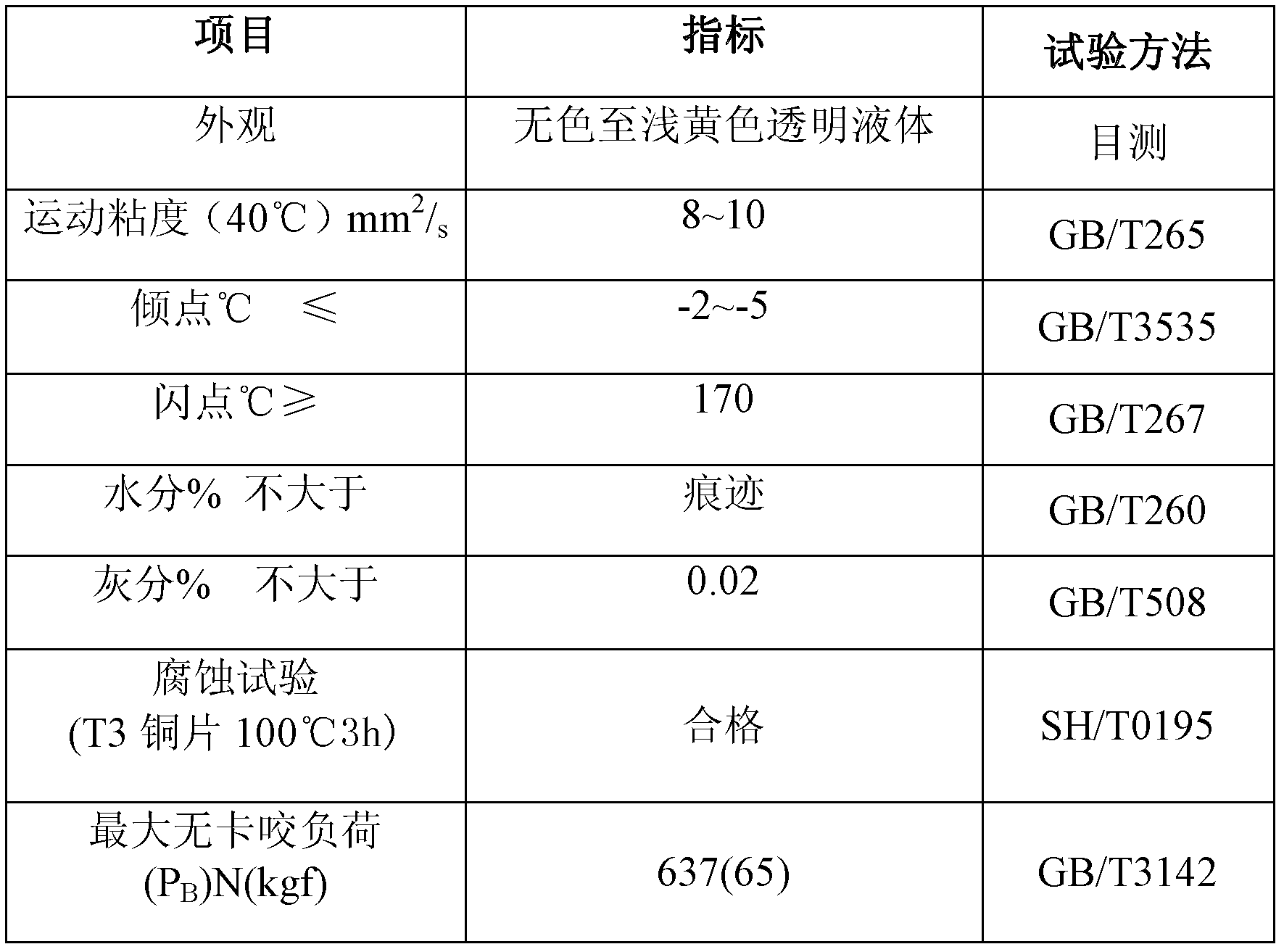

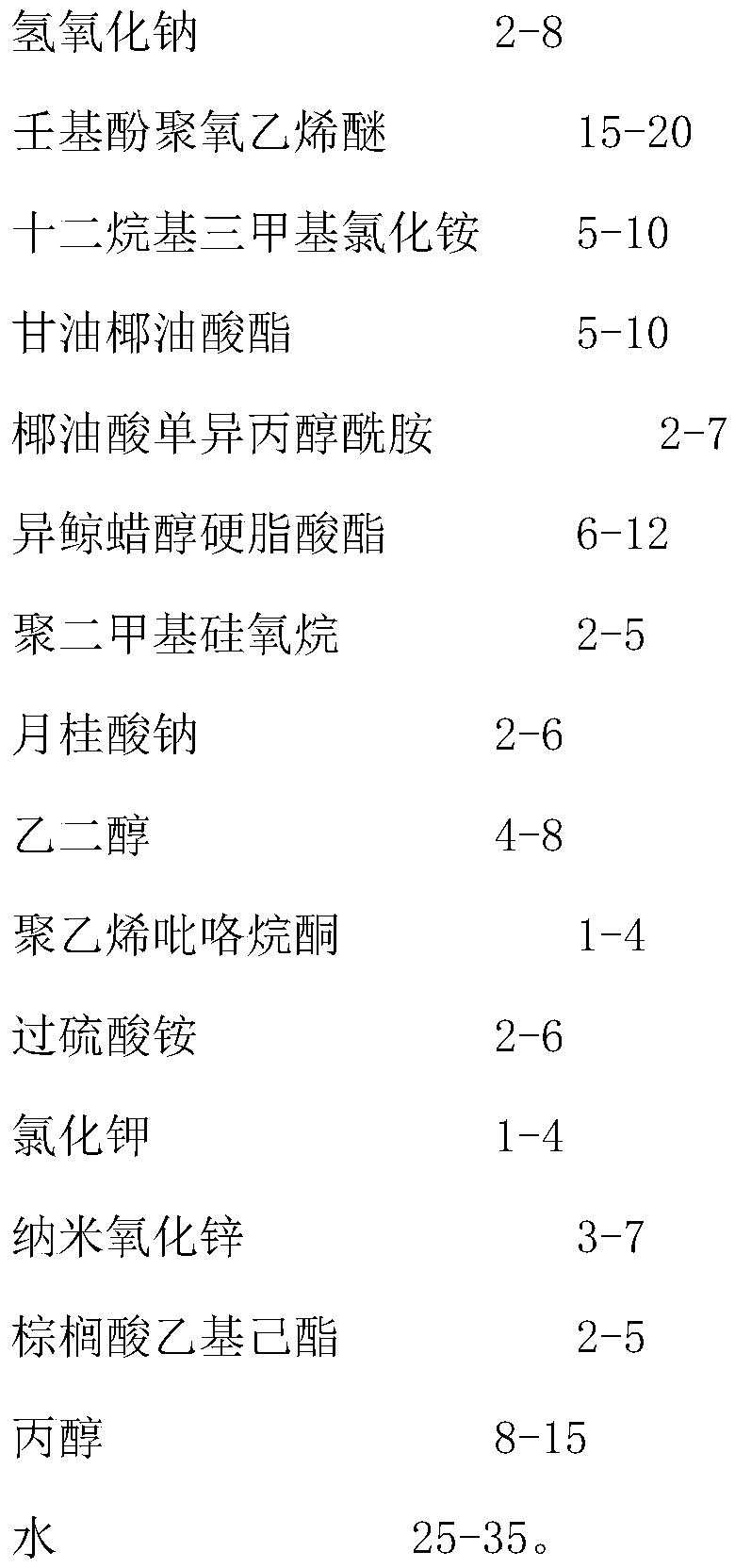

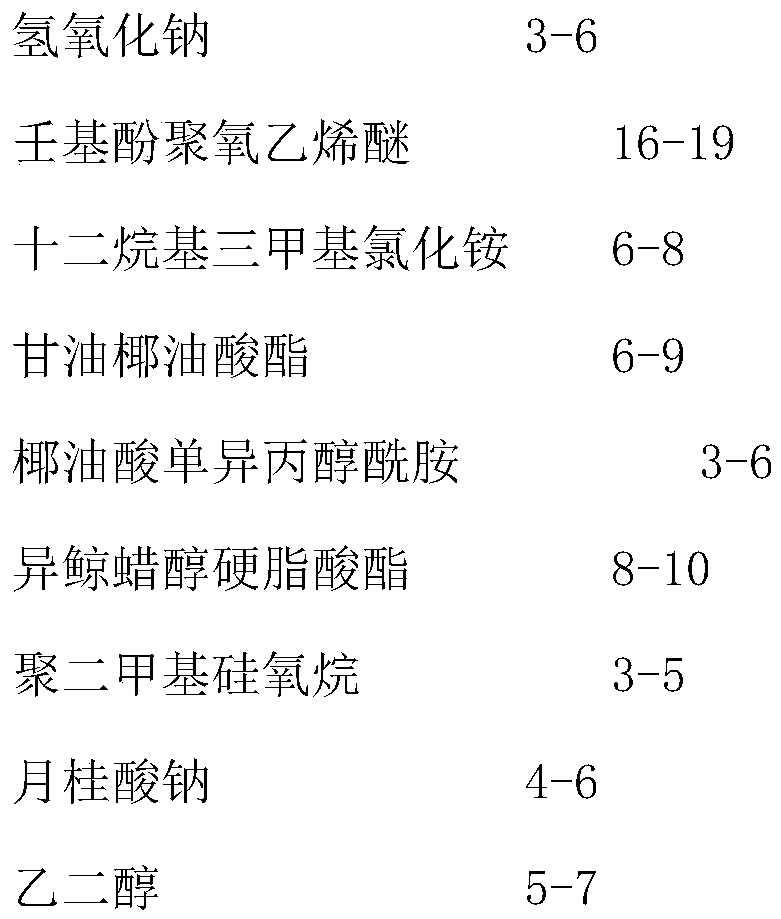

The invention aims at overcoming the defects in the prior art, and provides a desizing agent with the advantages that the desizing effect is good; the damage on fabrics is small; the treated fabrics have a good wool effect, hand feeling and whiteness; in addition, the seepage performance and the dispersion performance are good; the refining effect is achieved. The invention provides the desizing agent, which is prepared from the following ingredients in parts by weight: 2 to 8 parts of sodium hydroxide, 15 to 20 parts of nonylphenol polyoxyethylene ether, 5 to 10 parts of dodecyl trimethyl ammonium chloride, 5 to 10 parts of glyceryl cocoate, 2 to 7 parts of coconut acid monoisopropanolamide, 6 to 12 parts of isocetyl stearate, 1 to 3 parts of polydimethylsiloxane, 2 to 6 parts of sodium laurate, 4 to 8 parts of glycol, 1 to 4 parts of polyvinylpyrrolidone, 2 to 6 parts of ammonium persulfate, 1 to 4 parts of potassium chloride, 1 to 4 parts of nano-zinc oxide, 2 to 5 parts of ethylhexyl palmitate, 8 to 15 parts of propyl alcohol and 25 to 35 parts of water. The desizing rate of the fabrics treated by the desizing agent provided by the invention is 96.1 percent or higher; in addition, the fabrics cannot be damaged.

Owner:多恩生物科技有限公司

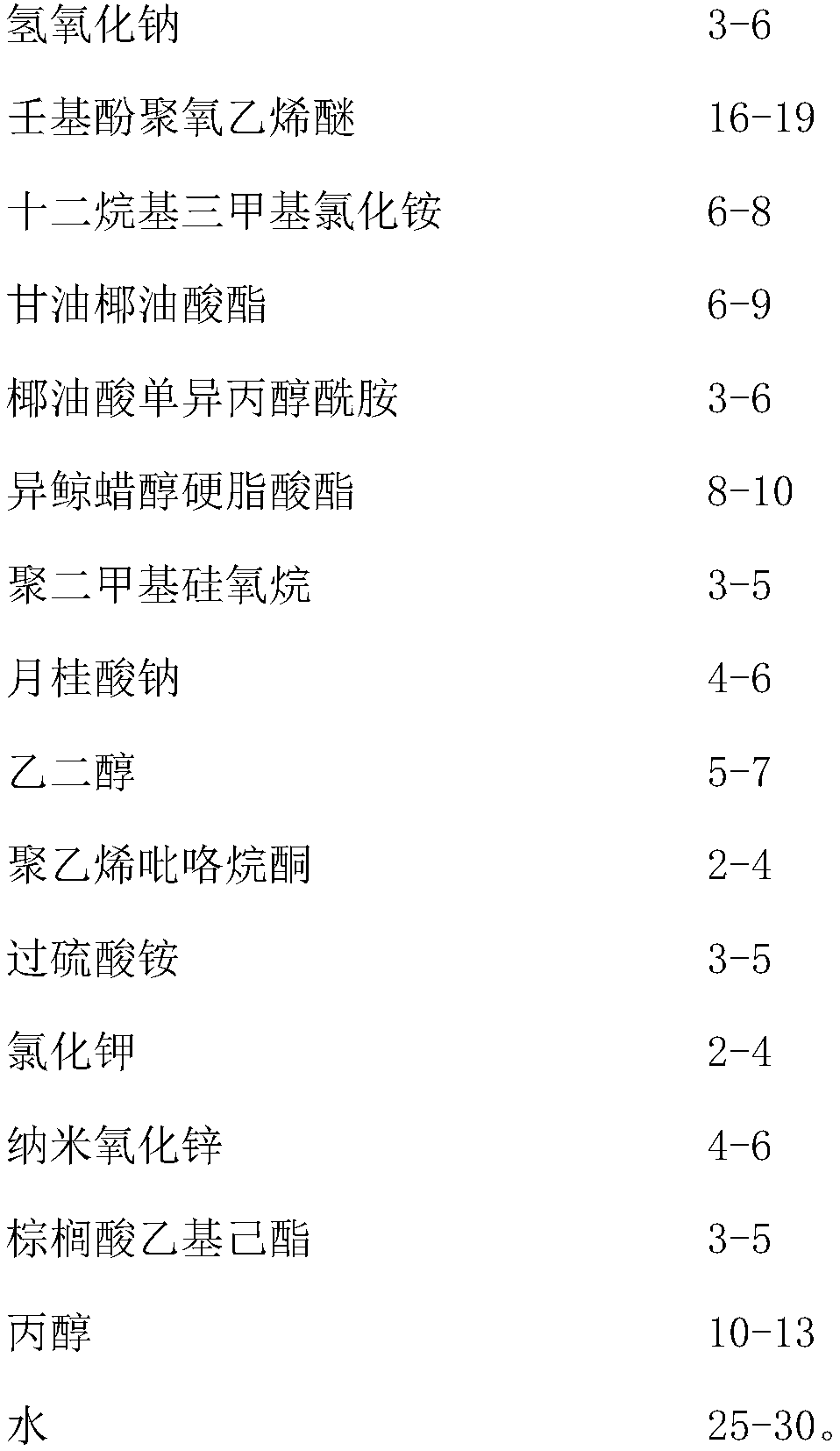

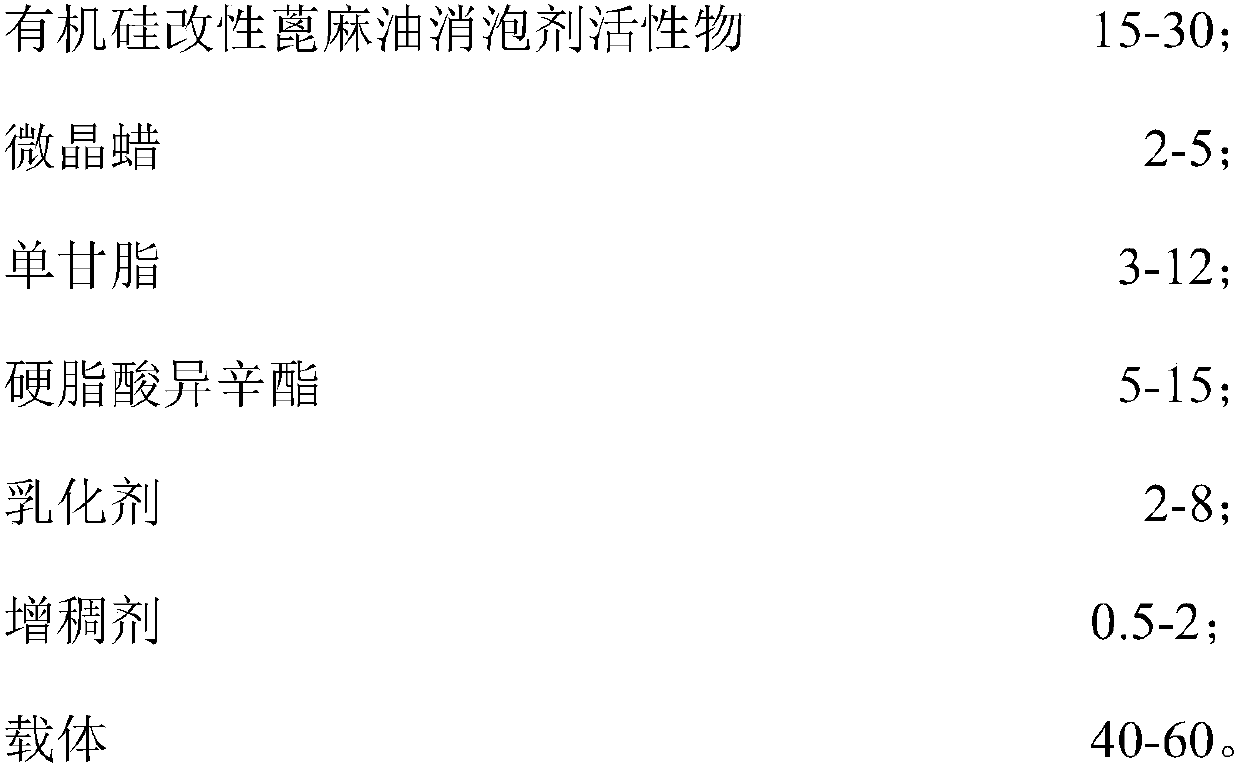

Antifoaming agent containing organosilicone modified castor oil for PVA (Polyvinyl Alcohol) production and preparation method of antifoaming agent

ActiveCN107551609AReduce adhesionReduce negative impactFoam dispersion/preventionMicrocrystalline waxMonoglyceride

The invention discloses an antifoaming agent containing organosilicone modified castor oil for PVA (Polyvinyl Alcohol) production and a preparation method of the antifoaming agent and belongs to the field of organosilicone modified antifoaming agents. The preparation method comprises the following steps: carrying out an addition reaction between hydrogen containing silicone oil and castor oil in an N2 protective catalyst system so as to obtain an organosilicone modified castor oil antifoaming agent active matter; and by utilizing the modified antifoaming agent active matter as well as microcrystalline wax, monoglyceride, isooctyl stearate, an emulsifier, a thickening agent and a carrier, thereby obtaining the antifoaming agent containing organosilicone modified castor oil. The antifoamingagent containing organosilicone modified castor oil produced according to the method disclosed by the invention is applied to eliminating foam produced in PVA production, has tiny negative effects onadhesiveness of slurry and mechanical property of slurry membranes, and has the characteristics of being small in dose, high in antifoaming speed, high in foam inhibition ability, nontoxic, harmless,simple in process and the like.

Owner:XIAN SUNY FINE CHEM

Adhesive for textiles and preparation method thereof

InactiveCN106221590AApplicable processingImprove adhesionMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesCarvacryl acetateTributyl citrate

The invention discloses adhesive for textiles and a preparation method thereof. The adhesive comprises the following components in parts by weight: 120-300 parts of vinyl acetate, 60-150 parts of vinyl versatate, 30-120 parts of butyl acrylate, 5-20 parts of acrylic acid, 400-500 parts of deionized water, 50-150 parts of a non-ortho-benzene plasticizer, and 1-5 parts of an antiseptic. The non-ortho-benzene plasticizer is one of tributyl citrate and diisooctyl sebacate. The adhesive for textiles has bonding strength which is better than the bonding strength of other adhesives, and has the advantages of usage convenience and wide applicability. The adhesive for textiles has the advantages of easily available raw materials, low cost, and simple preparation technology. The adhesive for textiles does not have toxicity, bad smell, pollution corrosion, inflammability, and the like, and gluing of the adhesive does not have wire drawing.

Owner:FOSHAN CITY YONGHENGDA NEW MATERIAL TECH CO LTD

Anti-corrosion rolling oil composition and application thereof

ActiveCN106281600AImprove corrosion resistanceReduced risk of corrosionLubricant compositionPhosphatePhosphoric acid

The invention relates to an anti-corrosion rolling oil composition and application thereof. The composition is prepared from, by weight, 70-90 parts of a component a, 5-15 parts of a component b, 1-10 parts of a component c, 0.1-5 parts of a component d, 0.01-5 parts of a component e and 0.01-1 part of a component f, wherein the component a is deep refined mineral oil, the component b is selected from at least one of pentaerythritol oleate, trimethylolpropane trioleate, isooctyl palmitate, diisooctyl sebacate, dibutyl phthalate and branched-chain polyhydroxy alcohol fatty acid ester, the component c is selected from at least one of inactive sulfurized olefin, inactive sulfide aliphatic acid ester, tributyl phosphate, tricresyl phosphate, dibutyl phosphate, tricresyl phosphate, dibutyl phosphate, lauryl alcohol phosphate acid ester and amine-neutralized phosphate, the component d is selected from at least one of 2,6-butylated hydroxytoluene, N-phenylnaphthylamine, benzotriazole octadecylamine salt and alkyl diphenylamine, the component e is selected from at least one of alkenyl succinic acid, allyl succinate, sorbitan fatty acid ester, succinic acid alkyl half-ester and imidazoline, and the component f is selected from at least one of polyether, methyl silicone oil and polydimethylsiloxane.

Owner:CHINA PETROLEUM & CHEM CORP

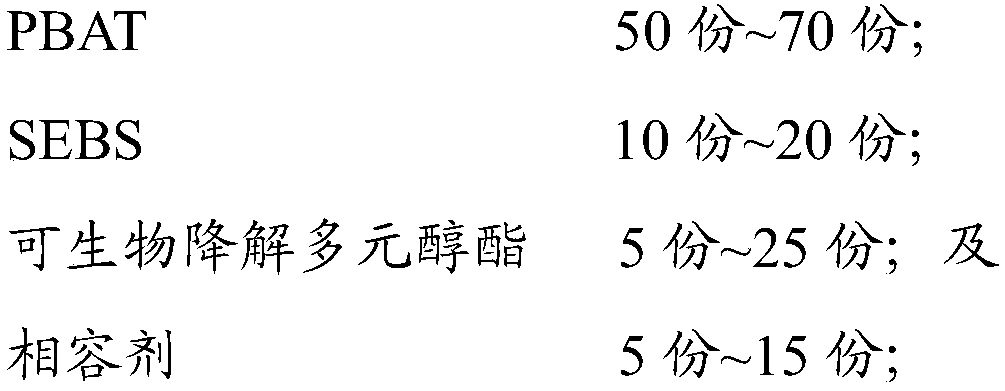

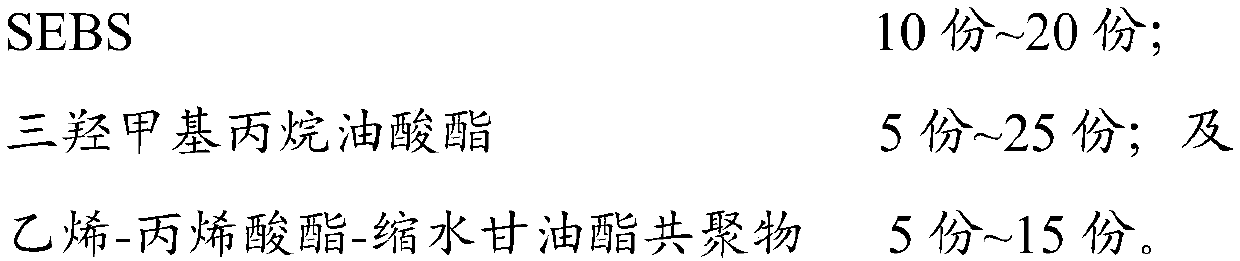

Biodegradable thermoplastic elastomer material and preparation method thereof

The invention relates to a biodegradable thermoplastic elastomer material and a preparation method thereof. The biodegradable thermoplastic elastomer material comprises, in parts by mass, 50-70 partsof PBAT, 10-20 parts of SEBS, 5-25 parts of a biodegradable polyol ester, and 5-15 parts of a compatibilizer, wherein the biodegradable polyol ester is at least one selected from trimethylolpropane oleate, trimethylolpropane caprylate / caprate, pentaerythritol oleate, and isooctyl stearate, and the compatibilizer is at least one selected from maleic anhydride grafted SEBS, maleic anhydride graftedpolypropylene, maleic anhydride grafted POE, a styrene-maleic anhydride copolymer, an ethylene-acrylate-maleic anhydride copolymer, and an ethylene-acrylate-glycidyl ester copolymer. The biodegradablethermoplastic elastomer material has relatively good elasticity and relatively good degradation performance.

Owner:SUNGALLON PLASTICS SHENZHEN CO LTD

Nylon full drawn yarn (FDY) oiling agent and application

The invention relates to the technical field of auxiliary agent preparation in a fiber processing technology, in particular to nylon full drawn yarn (FDY) oiling agent and application. The nylon FDY oil comprises the following components: 55-60 percent of stearic acid isooctyl ester, 5-7 percent of scouring agent, 5-7 percent of oleic acid, 8-10 percent of coconut oil diethanol amine, 5-7 percentof hydrogenated castor oil polyoxyethylene ether, 5-7 percent of fatty alcohol polyoxyethylene ether, 1-2 percent of oleic acid creatine, 0.5-1 percent of hypophosphorous acid, 1-1.5 percent of potassium hydroxide and 5-7 percent of wetting agent. The nylon FDY oil is added into deionized water and stirred into 8-15 percent of emulsion, the emulsion is added into a cured sliver, and the oiling rate is 0.8-1.5 percent. The invention provides the nylon FDY oiling agent, which has the advantages of high heat stability, less volatilization, no coking, low kinetic friction coefficient in a drawingphase and favorable cohesive force, and application.

Owner:JIAXING NEW & HIGH TECH FIBER

Energy-saving and environment-friendly PU synthetic leather and production method thereof

InactiveCN104594061AImprove comfortImprove the simulation effectSynthetic resin layered productsTextiles and paperOleumChloride

The invention discloses an energy-saving and environment-friendly PU synthetic leather which is prepared from the following raw materials in parts by weight: 80-100 parts of polyurethane resin, 80-100 parts of dimethylformamide, 4-8 parts of camellia seed meal, 1-2 parts of peanut shell, 1-2 parts of wheat straw, 1-2 parts of maize straw, 0.2-0.4 part of a silane coupling agent KH-550, 0.5-1 part of isocetyl stearate, 1-2 parts of oleum menthae, 3-6 parts of sodium carboxymethylcellulose, 0.5-1 part of aluminum chloride, 1-2 parts of white carbon black, 4-8 parts of mill base and 2-4 parts of a performance additive. The synthetic leather disclosed by the invention has good water-absorbing and ventilating properties, light weight, wear resistance, good simulation, energy saving and environment friendliness, and accords with the requirement of sustainable development.

Owner:ANHUI YUTANG RAIN GEAR

Drilling fluid lubricating agent

ActiveCN101486896BMeet the requirements of lubricating performanceImprove the lubrication effectDrilling compositionOrganic acidPentaerythritol

The invention relates to a lubricant for drilling fluid, which essentially solves the problems of the prior art that the lubricant for drilling fluid has poor lubricating property in the high-density drilling fluid. The lubricant for drilling fluid comprises the following components calculating by weight percentage: a) 1 to 35 percent of long-chain organic acid oiliness agent; b) 1 to 35 percent of synthetic ester oiliness agent; c) 0.1 to 8 percent of emulsifier; and d) 25 to 90 percent of base oil; in which the synthetic ester oiliness agent is selected from at least one of isooctyl stearate, butyl isostearate, trimethylolpropane trioleate, trimethylolpropane palm kernel ester, trimethylolpropane ethylhexoate, neopentyl glycol oleate, methyl laurate or pentaerythritol caproate, therefore, the technical proposal solves the problem preferably, and can be used in the industrial production of lubricant for drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP

High-water-resistance high-lubricating rolling oil composition and application thereof

ActiveCN106318570AGood water separation effectReduce generationLubricant compositionEthylhexyl palmitateButylated hydroxytoluene

The invention relates to a high-water-resistance high-lubricating rolling oil composition and application thereof. The composition is prepared from, by weight, 70-92 parts of component a which is highly refined mineral oil, 5-20 parts of component b selected from at least one of pentaerythritol oleate, trimethylolpropane trioleate, ethylhexyl palmitate, isooctyl stearate, dibutyl phthalate and branched chain type polyhydroxy alcohol fatty acid ester, 1-5 parts of component c selected from at least one of inactive sulfurized olefin, inactive sulfide aliphatic acid ester, sulfurized animal oil and alkyl sulfide, 1-10 parts of component d selected from at least one of tributyl phosphate, tricresyl phosphate and dibutyl phosphate, 0.1-5 parts of component e selected from at least one of 2,6-butylated hydroxytoluene, N-phenyl naphthylamine, 1H-benzotriazole and alkyl diphenylamine, and 0.01-1 part of component f selected from at least one of polyether, methyl silicone oil and polydimethylsiloxane.

Owner:CHINA PETROLEUM & CHEM CORP

Rolling oil composition soluble in degreasing agent and application of composition

The invention relates to a rolling oil composition soluble in a degreasing agent and application of the composition mainly in order to solve the problems that existing rolling oil and the degreasing agent are poor in separation performance and the service life of the degreasing agent is affected. The composition is prepared from, by weight, 75-95 parts of component a which is highly refined mineral oil, 2-15 parts of component b selected from at least one of pentaerythritol oleate, isooctyl palmitate, isooctyl stearate, dibutyl phthalate or methyl palmitate, 1-8 parts of component c selected from at least one of inactive sulfurized olefin, tributyl phosphate, tricresyl phosphate, dibutyl phosphate and amine neutralized phosphate ester, 0.01-3 parts of component d selected from at least one of alkenyl succinic acid, butanedioic acid and alkyl succinic acid half-ester, 0.01-1.0 part of component e selected from at least one of propylene epoxide diamine polycondensate, ethylene oxide / propylene epoxide block polyether and polyether silicone oil comb-type copolymer and 0.1-5 parts of component f selected from at least one of N-phenylnaphthylamine, 1H-benzotriazole and alkyl diphenylamine.

Owner:CHINA PETROLEUM & CHEM CORP

Environment-friendly cutting oil and preparation method thereof

The invention provides environment-friendly cutting oil. The environment-friendly cutting oil comprises components in percentage by mass as follows: 25%-35% of isooctyl stearate, 30%-40% of Guerbet alcohol, 20%-40% of diisooctyl sebacate and 2%-5% of pentaerythritol oleate. The environment-friendly cutting oil is good in lubricating effect and environmentally friendly.

Owner:DG ARMORINE ENERGY EFFICIENT & ECO FRIENDLY TECH

Aerosol deodorant antiperspirant compositions

InactiveUS20160296428A1Fast dryingLong-lasting effectCosmetic preparationsToilet preparationsDodecaneCeanothic acid

The present invention relates to a deodorant antiperspirant composition including: an anti-perspirant; a deodorant; an oil absorbent selected from the group consisting of aluminum starch octenylsuccinate, tapioca starch, and polymethylsilsesquioxane; a carrier comprising dodecane, an ester selected from the group consisting of isopropyl myristate, ethylhexyl stearate, isocetyl stearate, isopropyl isostearate, and myristyl myristate, and helianthus annuus seed oil; a suspending agent; and at least one propellant, wherein the composition is substantially free of silicone.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

Terylene spinning oil

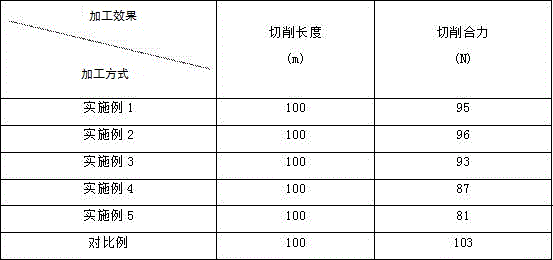

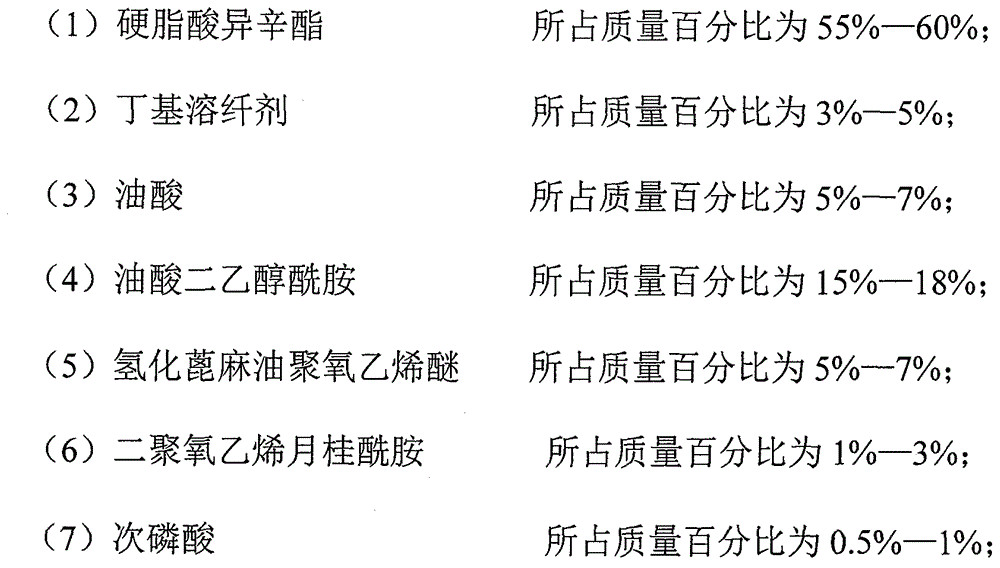

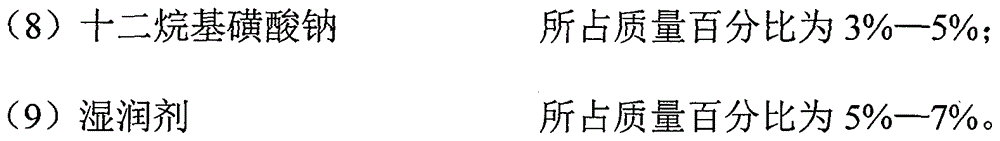

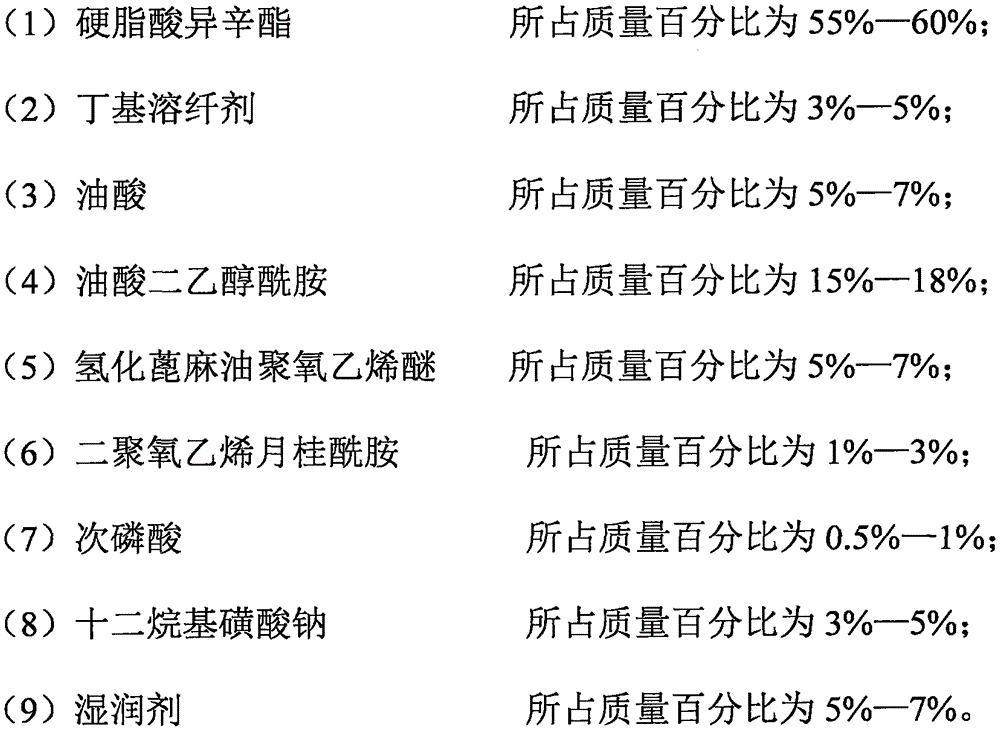

The invention relates to the technical field of fabrication of auxiliary agents used in fiber processing technology, specifically to a terylene spinning oil and a preparation method thereof. The terylene spinning oil comprises the following components by mass: (1) 55 to 60% of isooctyl stearate; (2) 3 to 5% of butyl cellosolve; (3) 5 to 7% of oleic acid; (4) 15 to 18% of diglycolamide oleate; (5) 5 to 7% of hydrogenated castor oil polyoxyethylene ether; (6) 1 to 3% of bis(polyoxyethylene) lauramide; (7) 0.5 to 1% of hypophosphorous acid; (8) 3 to 55 of sodium dodecanesulphonate; and (9) 5 to 7% of a wetting agent.

Owner:宋新祥

Hyaluronic-acid-containing bath foam

InactiveCN105434197AReduce tensionRelieve stressCosmetic preparationsNervous disorderSide effectThermal insulation

The invention relates to a daily supply, particularly a hyaluronic-acid-containing bath foam. The hyaluronic-acid-containing bath foam is composed of the following components in percentage by weight: 5.0-10.0% of stearic acid, 0.05-0.15% of hyaluronic acid, 4.0-8.0% of glycerol, 1-2% of essential oil, 4-8% of squalane, 6.0-12.0% of lauric acid, 6-10% of isooctyl stearate, 0.05-0.15% of skin whitening agent, 7.5-10.0% of myristic acid, 0.02-0.08% of salicylate and the balance of pure water. The hyaluronic-acid-containing bath foam can relieve nervousness, pressure, hemicrania, indigestion and insomnia, has favorable thermal insulation effect, is extracted from pure natural substances, and thus, has no toxic or side effect.

Owner:QINGDAO HAITE XINLAN BIOTECH CO LTD

Lavender makeup-removing emulsion

The invention discloses a lavender makeup-removing emulsion which is prepared from the following raw materials in parts by weight: 10-15 parts of lavender extract liquid, 4-7 parts of dimethicone, 20-40 parts of de-ionized water, 11-16 parts of white oil, 3-5 parts of Vaseline, 3-5 parts of isocetyl stearate, 2-6 parts of paraffin, 4-7 parts of wool fat, 4-6 parts of tween-80, 7-14 parts of sorbitol, 3-7 parts of bee wax, 4-8 parts of propanediol, 3-6 parts of olive oil, 4-8 parts of alkyl glycoside and 2-6 parts of isothiazolinone. The lavender makeup-removing emulsion provided by the invention is high in oil stain removal speed, convenient to use, low in irritation, aromatic, pleasant and free from side effects.

Owner:QINGDAO CHENXUTONG COMMERCE & TRADE

Cosmetic composition with three changed textures

InactiveCN105496823ARealization of physical layered homogeneityGood moisturizing effectCosmetic preparationsToilet preparationsPolymer scienceActive agent

The invention discloses a cosmetic composition with three changed textures. The cosmetic composition is characterized in that the cosmetic composition with three changed textures consists of a component A, a component B and a component C. The cosmetic composition is different from an ordinary cosmetic in single skin-touch texture, and is prepared from water, humectants including glycine soja oil, glycerinum, and sunflower seed oil, skin conditioning agents including polydimethylsiloxane, isocetyl stearate, and isononyl isononanoate, and surfactants including polyglycerol-2 stearate, PEG-8 stearate and disodium stearoyl glutamate. Nano-scale condensed dew is formed through a special high-pressure microjet nano homogenizer, so that physical layering homogeneous phase of the cosmetics is realized, and thus good moisturizing effect and skin affinity are obtained.

Owner:苏州工业园区安诺科斯化妆品研发有限公司

Rolling oil composition

The invention discloses a rolling oil composition, which is prepared from the following raw materials in parts by weight: 25-50 parts of white oil, 4-12 parts of neopentyl glycol ester, 2-6 parts of pentaerythritol fatty acid ester, 2-4 parts of diisooctyl sebacate, 4-12 parts of an antirust agent T711, 3-6 parts of an antiwear agent T306, 3-9 parts of diethylene glycol, 2-8 parts of triethanolamine, 1-5 parts of octadecanamide, 5-10 parts of neopentyl glycol, 3-6 parts of dimeric pentaerythritol, 4-6 parts of dist coconut fatty acid, 5-8 parts of a benzotriazole derivative, 2-8 parts of polyacrylamide and 3-9 parts of polybutylene. The rolling oil composition disclosed by the invention is good in processing property, good in filterability, safe and environmentally friendly; the service life of rolling oil is prolonged; the production cost is reduced; and energy consumption is reduced.

Owner:QINGDAO KERUN PLASTIC MACHINERY

Moisturizing whitening cream

ActiveCN107049861APromote hydrationClosed system is goodCosmetic preparationsToilet preparationsNano structuringStearate

Moisturizing whitening cream and a preparation method thereof are provided. The moisturizing whitening cream comprises a composite whitener nano-structure lipid carrier, sea buckthorn oil, corn germ oil, sesame seed oil, evening primrose oil, sweet almond oil, squalane, hyaluronic acid, isooctyl stearate, sorbitol, ethylparaben, zinc acetate, sodium diisooctyl sulfosuccinate, methyl 4-hydroxybenzoate, pearl powder, and deionized water. In preparation, the components except for the composite whitener nano-structure lipid carrier are heated and stirred well before emulsifying and homogenizing, after defoaming and cooling, the composite whitener nano-structure lipid carrier is added, and good stirring is performed to obtain the moisturizing whitening cream.

Owner:东莞黄家圣幸生物科技有限公司

Metal rolling oil and preparation method thereof

InactiveCN106675729AImprove the lubrication effectHigh glossLubricant compositionPhosphateAntioxidant

The invention discloses a metal rolling oil and a preparation method thereof. The metal rolling oil is composed of the following formula components in parts by mass: 40-70 parts of base oil, 20-40 parts of pentaerythritol ester, 10-20 parts of phenolic ether phosphate, 15-25 parts of sodium peroxydiphosphate, 15-30 parts of emulsifier, 5-15 parts of rust inhibitor, 2-7 parts of defoaming agent, 10-15 parts of isooctyl stearate, 5-10 parts of triethanolamine, 15-30 parts of laurinol, 4-8 parts of antioxidant, 7-10 parts of butyl laurate, 5-15 parts of ether-ester type surfactant, 5-7 parts of extreme pressure antiwear additive, 5-10 parts of mixed type high temperature antioxidant, 10-15 parts of polyacrylamide, 5-10 parts of nano titanium dioxide, 4-12 parts of sodium benzoate and 10-25 parts of ninol. The metal rolling oil has high lubricating property; and a product machined by using the metal rolling oil is favorable in glossiness and has no rolling scar.

Owner:钦州市科学技术开发中心

Anti-corrosion rolling oil composition and use thereof

ActiveCN106281600BImprove corrosion resistanceReduced risk of corrosionLubricant compositionPhosphatePhosphoric acid

The invention relates to an anti-corrosion rolling oil composition and application thereof. The composition is prepared from, by weight, 70-90 parts of a component a, 5-15 parts of a component b, 1-10 parts of a component c, 0.1-5 parts of a component d, 0.01-5 parts of a component e and 0.01-1 part of a component f, wherein the component a is deep refined mineral oil, the component b is selected from at least one of pentaerythritol oleate, trimethylolpropane trioleate, isooctyl palmitate, diisooctyl sebacate, dibutyl phthalate and branched-chain polyhydroxy alcohol fatty acid ester, the component c is selected from at least one of inactive sulfurized olefin, inactive sulfide aliphatic acid ester, tributyl phosphate, tricresyl phosphate, dibutyl phosphate, tricresyl phosphate, dibutyl phosphate, lauryl alcohol phosphate acid ester and amine-neutralized phosphate, the component d is selected from at least one of 2,6-butylated hydroxytoluene, N-phenylnaphthylamine, benzotriazole octadecylamine salt and alkyl diphenylamine, the component e is selected from at least one of alkenyl succinic acid, allyl succinate, sorbitan fatty acid ester, succinic acid alkyl half-ester and imidazoline, and the component f is selected from at least one of polyether, methyl silicone oil and polydimethylsiloxane.

Owner:CHINA PETROLEUM & CHEM CORP

Rolling oil for stainless steel

ActiveCN102504919BLow viscosityExtended service lifeLubricant compositionWater sourceChlorinated paraffins

The invention relates to a rolling oil for a stainless steel, which is prepared by the following raw materials by weight: 64.5-79.9% of white oil, 5-15% of neopentyl polyol ester, 5-10% of pentaerythritol aliphatic ester, 2-5% of isooctyl stearate or butyl stearate, 0.5-1.2% of mixed-type high temperature antioxygen, 0.05-0.2% of phenol-type antioxygen, 0.05-0.1% of ethylenediaminetetraacetic acid (EDTA) dipotassium salt, 0.4-0.8% of antirust additive, 0.1-0.5% of metal passivator and 2-3% of antiwear agent. The invention uses synthetic ester to replace chlorinated paraffin, which prevents environmental pollution of chlorinated paraffin, meanwhile avoids using large quantity of water for cooling, saves massive water source and also converts the processing oil into recyclable oil, thereby prolonging the service life of the processing oil greatly. The invention has the features of excellent lubrication performance, cooling performance, rust resistance, cleanness, energy conservation andenvironmental friendliness. The waste liquid is less in volume and can be recycled. Therefore the rolling oil provided by the invention is the preferred processing oil for finishing rolling of stainless steel to obtain high-gloss surface.

Owner:彭美东

A kind of desizing agent and preparation method thereof

ActiveCN108505318BWith desizing effectImprove desizing effectDry-cleaning apparatus for textilesGrip property fibresEthylhexyl palmitatePyrrolidinones

The invention aims at overcoming the defects in the prior art, and provides a desizing agent with the advantages that the desizing effect is good; the damage on fabrics is small; the treated fabrics have a good wool effect, hand feeling and whiteness; in addition, the seepage performance and the dispersion performance are good; the refining effect is achieved. The invention provides the desizing agent, which is prepared from the following ingredients in parts by weight: 2 to 8 parts of sodium hydroxide, 15 to 20 parts of nonylphenol polyoxyethylene ether, 5 to 10 parts of dodecyl trimethyl ammonium chloride, 5 to 10 parts of glyceryl cocoate, 2 to 7 parts of coconut acid monoisopropanolamide, 6 to 12 parts of isocetyl stearate, 1 to 3 parts of polydimethylsiloxane, 2 to 6 parts of sodium laurate, 4 to 8 parts of glycol, 1 to 4 parts of polyvinylpyrrolidone, 2 to 6 parts of ammonium persulfate, 1 to 4 parts of potassium chloride, 1 to 4 parts of nano-zinc oxide, 2 to 5 parts of ethylhexyl palmitate, 8 to 15 parts of propyl alcohol and 25 to 35 parts of water. The desizing rate of the fabrics treated by the desizing agent provided by the invention is 96.1 percent or higher; in addition, the fabrics cannot be damaged.

Owner:多恩生物科技有限公司

Finish for nylon FDY and preparation method

The invention relates to the technical field of auxiliary manufacturing in the fiber processing technology, in particular to finish for nylon FDY and a preparation method. The finish for nylon FDY comprises the following components: 55-60% of isooctyl stearate, 5-7% of scouring agents, 5-7% of oleic acid, 8-10% of coconut oil diethanolamine, 5-7% of hydrogenated castor oil polyoxyethylene ether, 5-7% of fatty alcohol polyoxyethylene ether 4, 1-2% of oleic acid sarcosine, 0.5-1% of hypophosphorous acid, 1-1.5% of potassium hydroxide and 5-7% of wetting agent. The preparation method comprises the process steps of mixing, stirring and testing. The finish for nylon FDY has good thermal stability, is less in volatilization and free of coking and has low coefficient of dynamic friction in the drawing stage and good cohesion.

Owner:JIAXING NEW & HIGH TECH FIBER

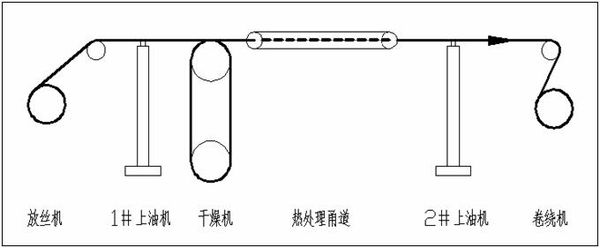

Secondary oiling agent treatment method of heterocyclic aramid

ActiveCN114075784AImprove mechanical propertiesReduce wearFibre typesHeating/cooling textile fabricsPolymer scienceSpinning

The invention discloses a secondary oiling agent treatment method for heterocyclic aramid fibers, and belongs to the technical field of chemical fibers. In a spinning process, first-stage oiling agent treatment is carried out on a heterocyclic aramid precursor, drying and heat treatment are carried out, then second-stage oiling agent treatment is carried out, and then the heterocyclic aramid fiber is wound and formed. The first-stage oiling agent is prepared from isooctyl stearate, fatty alcohol potassium phosphate, polyethylene glycol monooleate and polyoxyethylene sorbitan monooleate; and the second-stage oil agent is prepared from lauryl amine polyoxyethylene ether, dioctyl sodium sulfosuccinate and polyoxyethylene ether sorbitan monooleate. The heterocyclic aramid fiber finished silk fiber treated by two-stage different oil agents is small in mechanical property loss in the forming processing process and good in weaving performance and can be used for preparing high-quality woven cloth, meanwhile, the warp-wise tensile strength and the weft-wise tensile strength of the woven cloth reach 20.3 KN / 5cm and 21.5 KN / 5cm respectively, and the heterocyclic aramid fiber finished silk fiber is suitable for manufacturing high-tech products such as bulletproof chips, aircraft skins and linear motors.

Owner:中蓝晨光化工有限公司 +1

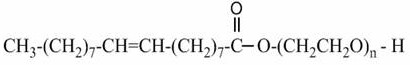

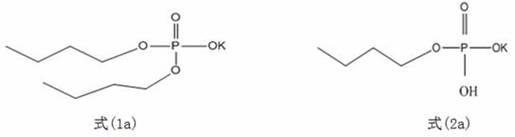

Forming processing oiling agent suitable for treating heterocyclic aramid precursor

ActiveCN114075783ASolve Lubricity ProblemsReduce frictionFibre typesTextile/flexible product manufacturePolymer sciencePolyethylene glycol

The invention discloses a forming processing oiling agent suitable for treating heterocyclic aramid precursor, and belongs to the technical field of chemical fibers. The forming processing oil agent is prepared from the following components in percentage by mass: (a) 20 to 50 percent of isooctyl stearate; (b) 15%-40% of fatty alcohol potassium phosphate; (c) 10%-30% of polyethylene glycol monooleate; and (d) 5%-15% of polyoxyethylene sorbitan monooleate. The oiling agent has the characteristics of lubricity, dispersity and volatility at the same time, is used for treating heterocyclic aramid, not only reduces the friction coefficient between fibers and a yarn guide part, but also enables monofilaments of the fibers to be uniformly dispersed and avoids monofilament adhesion, and meanwhile, solves the problem that volatile matters in the fibers are difficult to remove due to the fact that the oiling agent is attached to the surfaces of the fibers to form mucosa. The oiling agent is used for treating heterocyclic aramid fibers, so that fibers with more excellent performance can be obtained.

Owner:中蓝晨光化工有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com