Gear oil composition for automobile

A composition and gear oil technology, applied in the directions of lubricating compositions, petroleum industry, additives, etc., can solve the problems of unsatisfactory improvement of anti-wear ability, extreme pressure thermal oxidation stability, etc. Seizure load, good maintenance, improved antioxidant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

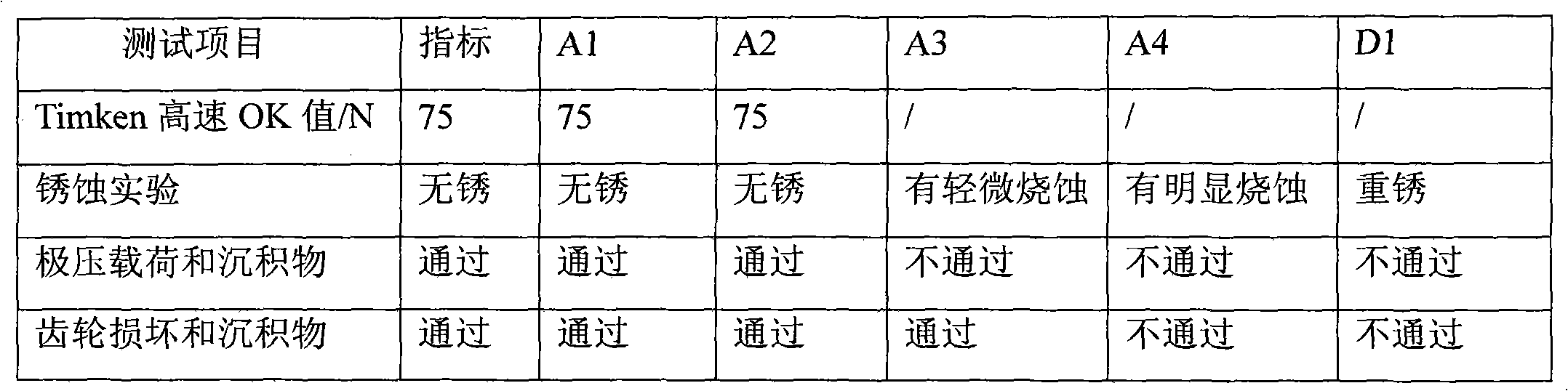

Examples

Embodiment 1

[0020] This example is used to illustrate the gear oil disclosed in the present invention.

[0021] First prepare 946.2 parts by weight of SAE 80W / 90 viscosity-adjusted base oil, heat at 70-80°C and stir for 60-90 minutes, then add 20 parts by weight of octyl stearate (Shanghai Huayi Chemical Auxiliary Co., Ltd. Produced by the company), 8.5 parts by weight of sulfurized isobutylene (T321 produced by Nanjing Runyou Chemical Additive Co., Ltd.), 8 parts by weight of sulfurized olefin cottonseed oil (T405 produced by Jinzhou Kangtai Lubricating Oil Additive Co., Ltd.), 6 parts by weight of trimethyl phosphate Phenyl ester (T306 produced by Jinzhou Kangtai Lubricating Oil Additive Co., Ltd.), 5 parts by weight of zinc dialkyldithiophosphate (T202 produced by Jinzhou Kangtai Lubricating Oil Additive Co., Ltd.), 5 parts by weight of dinonyl naphthalene sulfonic acid Barium (T705 produced by Jinzhou Kangtai Lubricating Oil Additive Co., Ltd.), 10 parts by weight of ultra-basic calci...

Embodiment 2

[0023] This example is used to illustrate the gear oil disclosed in the present invention.

[0024] First prepare 928.3 parts by weight of SAE 75W viscosity-adjusting base oil, heat at 70-80°C and stir for 60-90 minutes, then add 23 parts by weight of octyl stearate, 9.2 parts by weight of isobutylene vulcanization, 8.4 parts by weight of Parts of sulfurized olefin cottonseed oil, 6.8 parts by weight of tricresyl phosphate, 6.8 parts by weight of zinc dialkyldithiophosphate, 5 parts by weight of barium dinonyl naphthalene sulfonate, 12 parts by weight of superbasic value sulfonic acid Calcium, 0.5 parts by weight of benzotriazole, and continue to heat and stir at 70-80°C for 90 minutes to prepare the high-load gear oil A2 provided by the invention that can meet the requirements of automatic transmissions. Wherein the mass ratio of sulfur to phosphorus in A2 is 18.

Embodiment 3

[0026] The preparation process is the same as in Example 1, except that 20 parts by weight of octyl stearate is replaced by 20 parts by weight of isooctyl palmitate (produced by Guangzhou Jiayi Chemical Co., Ltd.), to obtain gear oil composition A3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com