Polyvinyl chloride (PVC) trade mark producing process

A trademark and process technology, applied to other household appliances, etc., can solve problems such as material leakage, high cost expenditure, and flow marks in the injection process, and achieve the goals of reducing energy consumption, improving secondary processability, and improving fluidity and slipperiness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

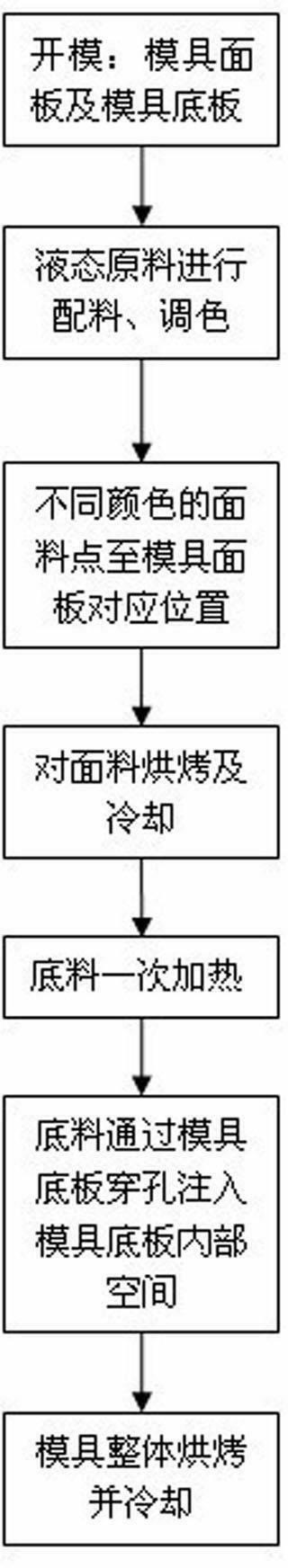

[0019] The PVC trademark production process of the present invention mainly includes the following steps:

[0020] a. Open the mold according to the shape and size of the trademark. The mold for making the trademark includes a mold panel and a mold bottom plate that can be folded together;

[0021] b. Mix various liquid raw materials in a certain composition ratio and stir evenly to make ingredients;

[0022] c. Divide the finished ingredients into the surface layer liquid material that constitutes the surface text and pattern and the bottom layer liquid material that constitutes the bottom surface of the trademark, and add various colorants to color the various surface layer liquid materials and the bottom layer liquid materials. Pigments of various colors required to become a trademark;

[0023] d. Use dispensing equipment to point the surface layer liquid materials of various corresponding colors to the corresponding position of the mold panel that forms the characters or patterns ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com