Self-adhesive enameled wire

A technology of self-adhesive paint and covered wire, applied in the direction of coatings, conductors, electrical components, etc., to achieve the effect of good slipperiness and strong scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

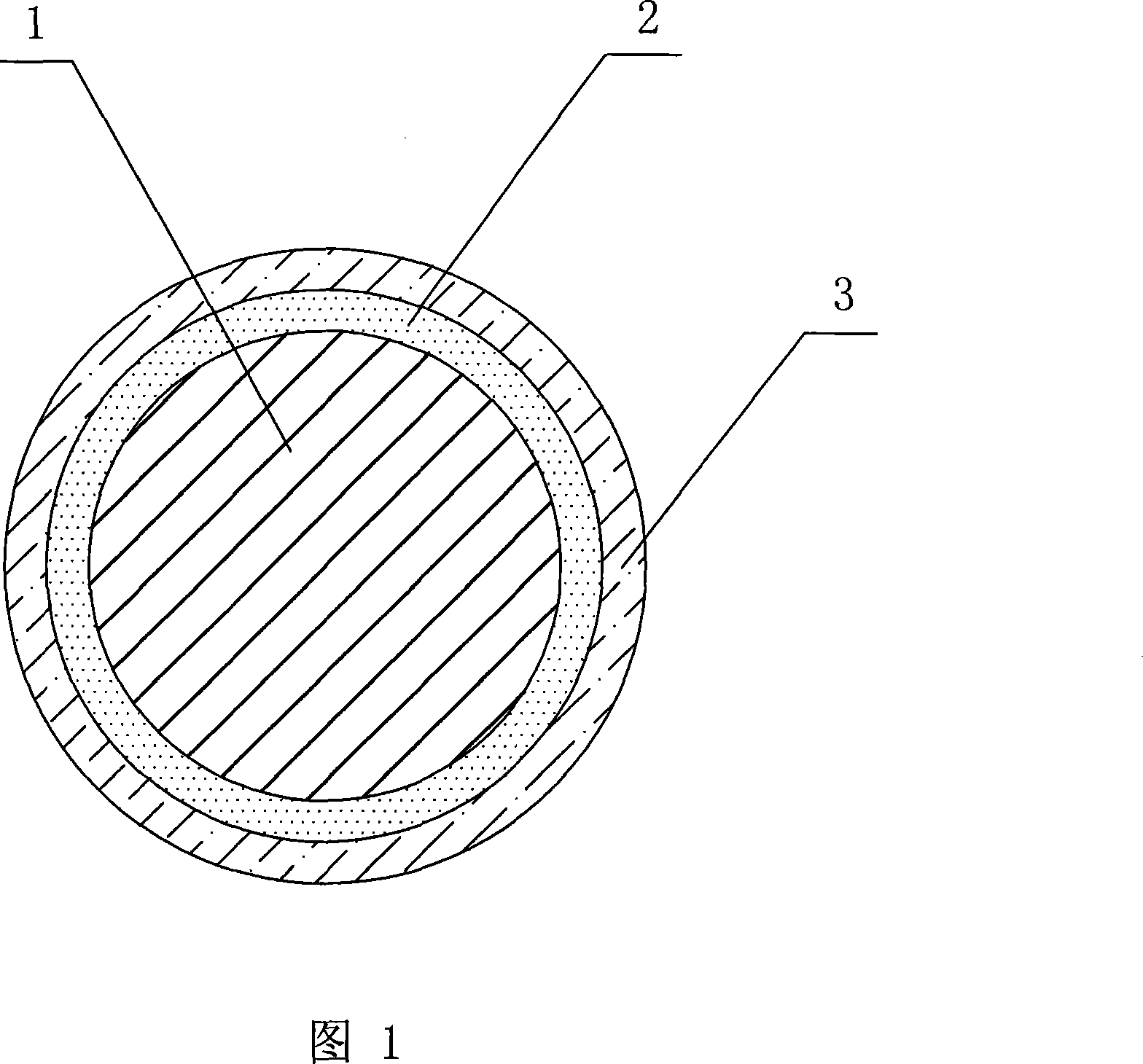

[0010] A self-adhesive enameled wire as shown in FIG. 1 includes a copper wire 1 and a polyurethane varnish insulating layer 2 coated thereon, and a self-lubricating self-adhesive varnish layer 3 is also covered on the surface of the polyurethane varnish insulating layer 2 .

[0011] The chemical composition of the self-lubricating self-adhesive paint in the self-lubricating self-adhesive paint layer 3 and the concentration percentage content of each composition are: polyamide resin 10%~13%, cresols 33%~36%, phenols 33% ~36% and xylene 15%~18%.

[0012] Compared with the existing ordinary self-adhesive enameled wire, the surface of the self-adhesive enameled wire of the present invention has stronger scratch resistance and better slipperiness, so it is closer to the mechanical properties of the enameled wire proposed by the modern motor industry. higher requirements.

[0013] The self-adhesive enameled wire of the present invention is suitable for winding voice coils of vario...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com