Waterborne anti-doodling and self-cleaning coating and preparation method thereof

An anti-graffiti and self-cleaning technology, applied in the field of coatings, can solve the problems of complex manufacturing process, poor weather resistance and self-cleaning ability of self-cleaning coatings, and achieve good wiping resistance, improved long-term self-cleaning effect, and wear resistance. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

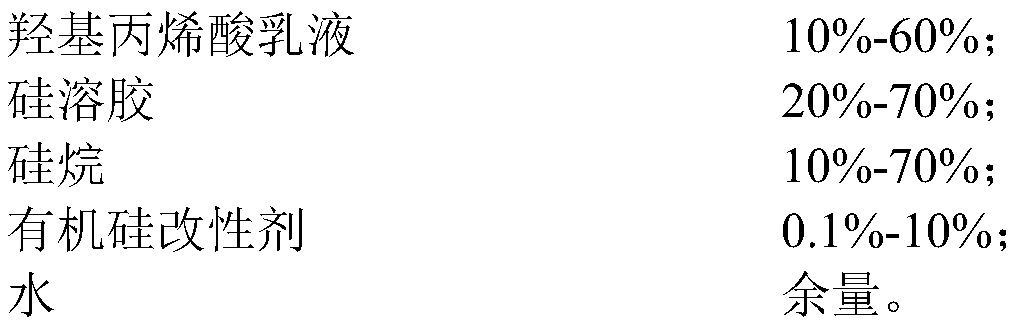

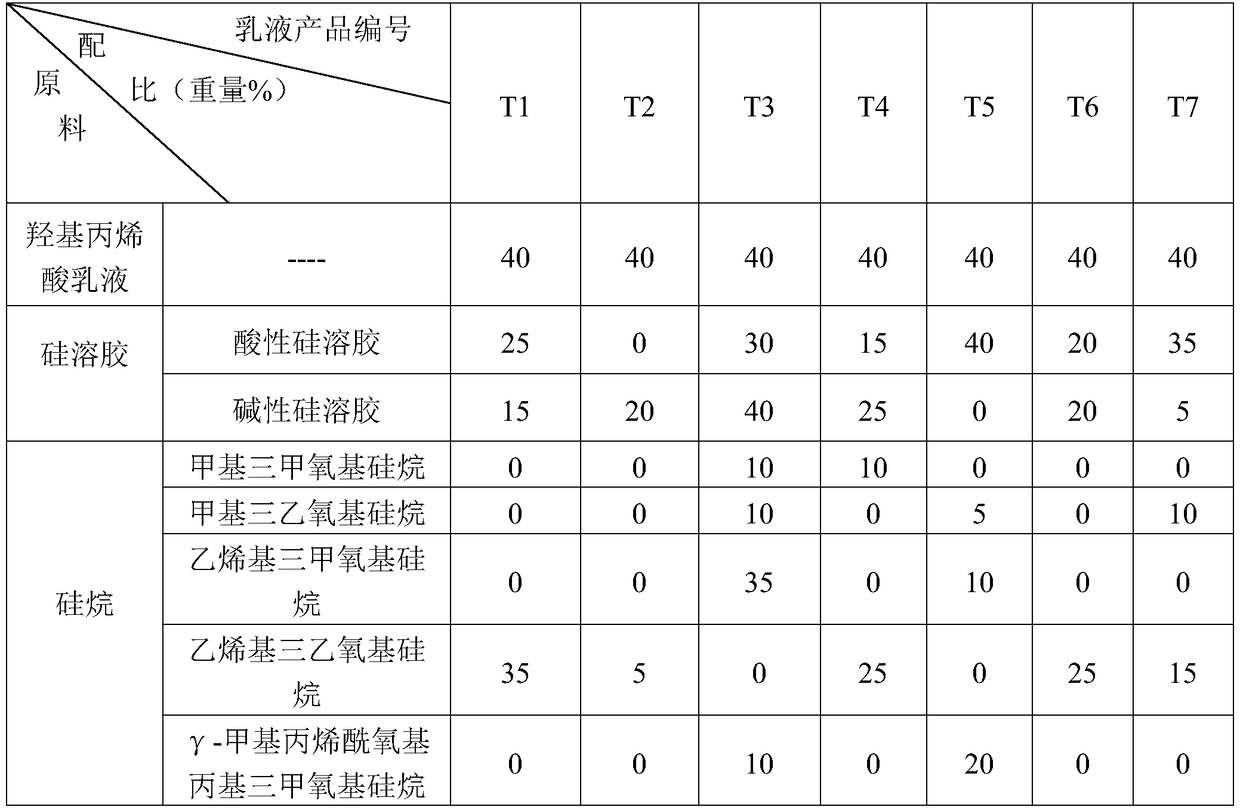

[0052] Using the same preparation method, 7 groups of emulsion products were prepared, respectively marked as T1-T7, and the raw materials and proportions of each group of emulsion products are shown in Table 1 below.

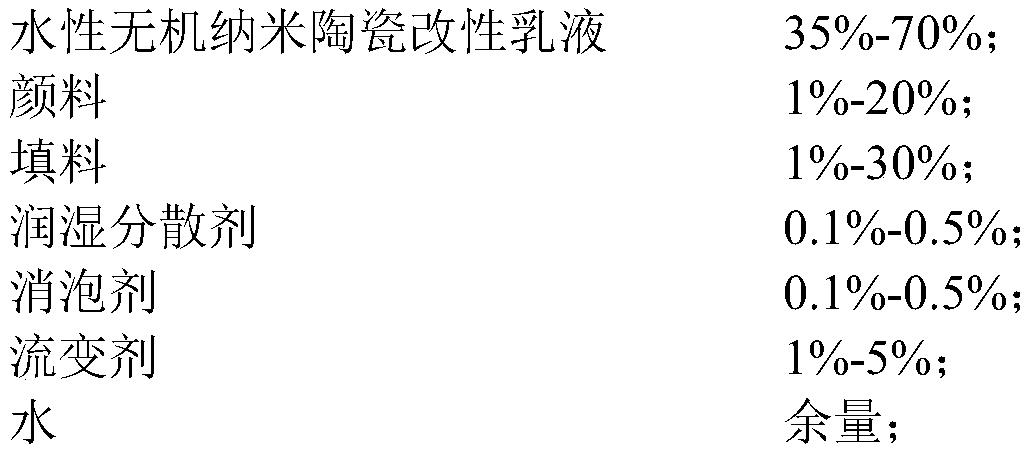

[0053] Second, the preparation of water-based anti-graffiti self-cleaning coating:

[0054] ① Mix the prepared water-based inorganic nano-ceramic modified emulsion, pigments and fillers, and disperse them with a wetting and dispersing agent for 25 minutes to obtain a dispersion;

[0055] ② Use a horizontal sand mill for grinding, and adjust the temperature of the cooling water at the same time to ensure that the temperature of the grinding material is 50 ° C, and the grinding time is 1.5 hours;

[0056] ③ Add defoamer, rheological agent and water, stir evenly, and get water-based anti-graffiti self-cleaning coating.

[0057] Using the same preparation method, a total of 9 groups of water-based anti-graffiti self-cleaning coatings were prepared, which are respe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com