Anti-blue light film and manufacturing method thereof

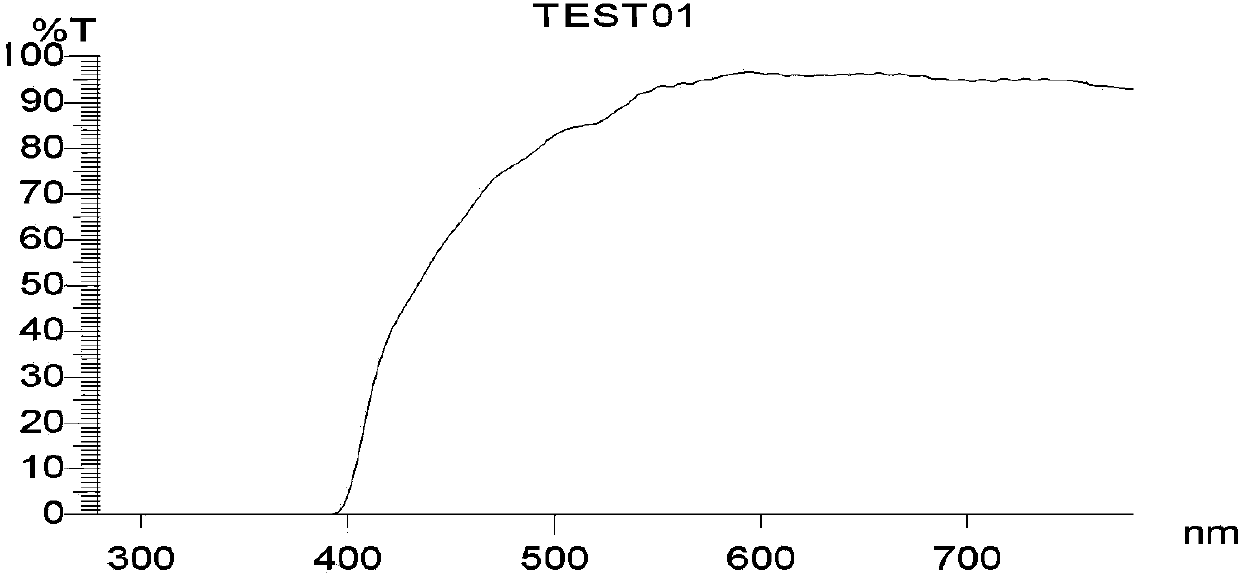

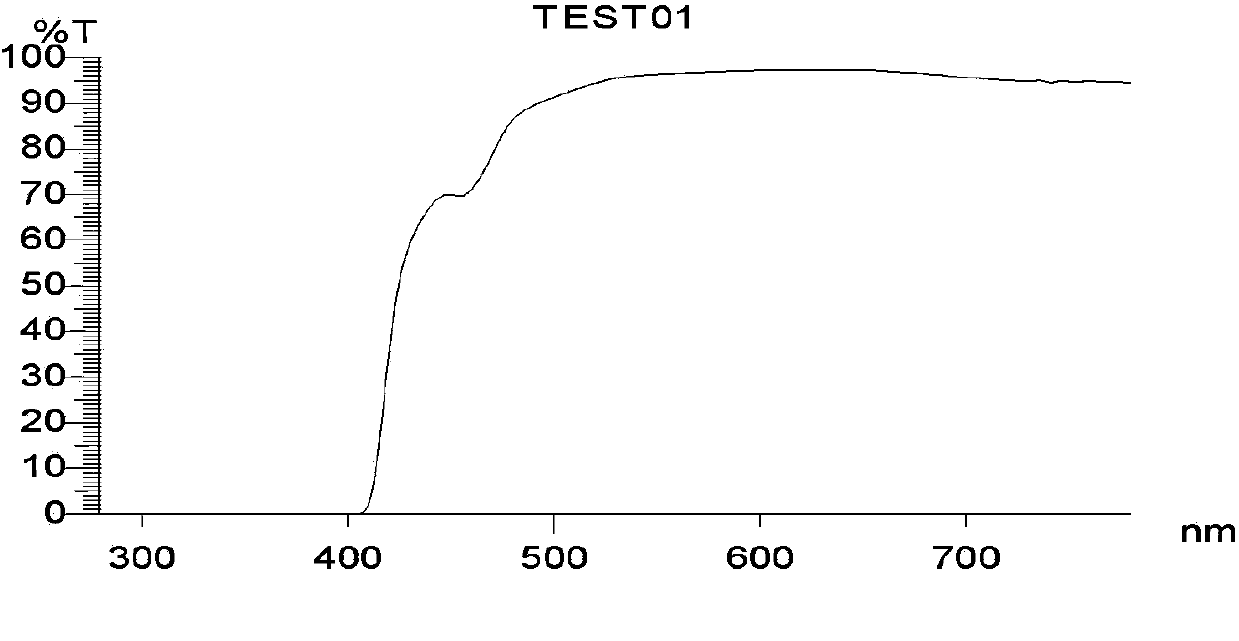

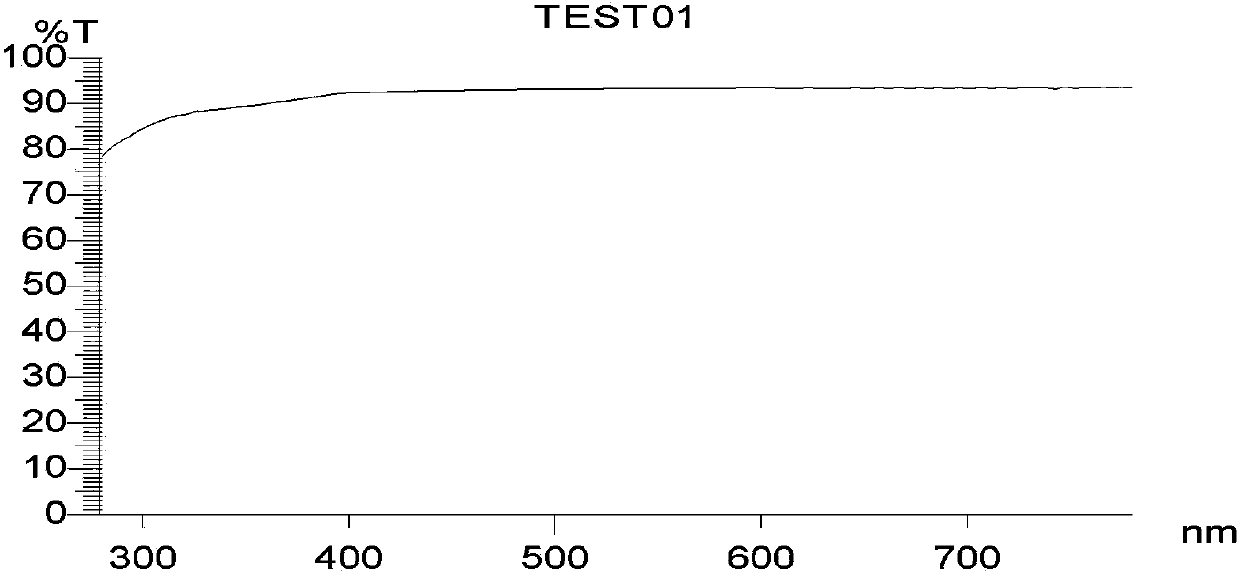

An anti-blue light and film technology, applied in the field of optical materials, can solve the problems of low transmittance, serious color shift, and no targeted protection, and achieve the effect of free matching, slight color shift, and good anti-blue light effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] The manufacturing method of the anti-blue light film includes the following steps:

[0083] (1), the preparation of absorbable anti-blue light strengthening liquid: 40% of the oligomer main resin that provides basic performance: one of acrylic urethane and acrylic polyester;

[0084] Monomeric diluents with 20% performance adjustment: acrylates of one or more of the three types of monofunctional, difunctional and polyfunctional;

[0085] Monofunctional

[0086] THFA Tetrahydrofurfuryl Acrylate

[0087] bifunctional

[0088] HDDA1, 6-Hexanediol Dimethanol Diacrylate 1.6-Hexanediol Dimethanol Diacrylate

[0089] Three types of multifunctional groups

[0090] TMPTA Trimethylol propane triacrylate

[0091] After fully reacting with 8% of the initiator for polymerization and cross-linking reaction, it is then uniformly mixed with 10% of the polymer anti-blue light absorber and 3% of the fluorine surfactant that reduces the surface tension, and finally added 19% solvent...

Embodiment 2

[0109] An anti-blue light lens, characterized in that the anti-blue light film produced by the present invention is used as the main layer and the composite film layer lens ( Figure 10 ).

[0110] The structure of the anti-blue lens is characterized in that: the first film layer is the main layer of the anti-blue light film (TAC is the base material), the second film layer and the third film layer are anti-UV ultraviolet light film layers, and the fourth film layer is the anti-scratch film. The protective layer.

[0111] The first film layer is the main layer of the anti-blue light film (TAC is the base material). Has the following beneficial effects:

[0112] (1), strong scratch resistance. With 0000# steel wool with a total load of 500g applied to the test sample, its pressure direction is consistent with the normal direction of the test surface of the sample, and the reciprocating friction is rubbed 25 times at a frequency of 100 times / min, and the scratch resistance re...

Embodiment 3

[0124] A kind of anti-blue light sticking film, it is characterized in that the composite film layer ( Figure 12 ).

[0125] The structure of the anti-blue light film is characterized in that: the first film layer is an anti-blue light film layer (PET base material) as the main film layer, one side of which is coated with silica gel, and the other side is coated with absorbable anti-blue light strengthening liquid; A. The film layer B is a protective film that protects the two sides of the anti-blue light PET film layer of the main body.

[0126] The above-mentioned film layer one is the main body layer of the anti-blue light film (PET base material), which has the following beneficial effects:

[0127] (1), strong scratch resistance. With 0000# steel wool with a total load of 500g applied to the test sample, its pressure direction is consistent with the normal direction of the test surface of the sample, and the reciprocating friction is rubbed 25 times at a frequency of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com