Super-wear-resisting and scratch-resistant and waterproof plastic floor and manufacturing method thereof

A plastic floor, ultra-wear-resistant technology, applied in chemical instruments and methods, building structures, paper/cardboard layered products, etc., can solve problems such as cracking, poor waterproof and moisture-proof performance of laminate flooring, and swelling of laminate flooring, and achieve super Strong wear-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

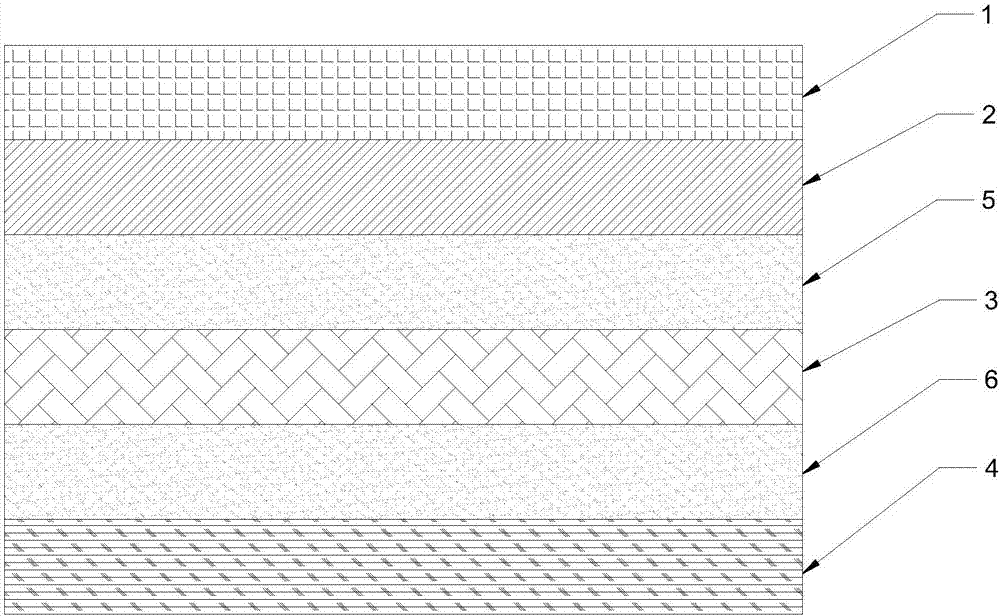

[0053]A super wear-resistant, scratch-resistant and waterproof plastic floor, including a wear-resistant layer 1, a decorative layer 2, a base layer 3 and a balance layer 4 arranged in sequence from top to bottom, and also includes a layer arranged between the decorative layer 2 and the base layer 3 The first connection layer 5 and the second connection layer 6 arranged between the base layer 3 and the balance layer 4, the wear-resistant layer 1 is aluminum oxide wear-resistant paper, the decorative layer 2 is a layer of melamine Resin-impregnated paper, the base layer 3 is a PVC sheet layer or a PVC hard board layer or a multi-layer combination of a PVC sheet layer and a PVC hard board layer or other polymer materials, and the balance layer 4 is a balance paper or adopts The veneer is made by impregnating and curing the veneer with melamine resin; the weight of the aluminum oxide wear-resistant paper is 5-100g / ㎡; the thickness of the base layer 3 is 1mm; the balance paper is s...

Embodiment 2

[0066] The structure of a super wear-resistant, scratch-resistant and waterproof plastic floor is as in Example 1;

[0067] The grammage of the aluminum oxide wear-resistant paper is 5-100g / ㎡; the thickness of the base layer 3 is 10mm; the balance layer 4 is made by impregnating veneer with melamine resin and curing; the first Both the connecting layer 5 and the second connecting layer 6 have a thickness of 1mm and a grammage of 253g / m 2 ;

[0068] Both the first connection layer 5 and the second connection layer 6 include paste resin, plasticizer and stabilizer in a mass ratio of 100:50-100:2-5.

[0069] The specific steps of the manufacturing method of the super wear-resistant, scratch-resistant and waterproof plastic floor are as follows:

[0070] 1) Production of base layer:

[0071] A, take material according to following parts by weight: 60 parts of PVC powders, 42 parts of plasticizers, 3 parts of stabilizers, 330 parts of fillers, above-mentioned materials make PVC ...

Embodiment 3

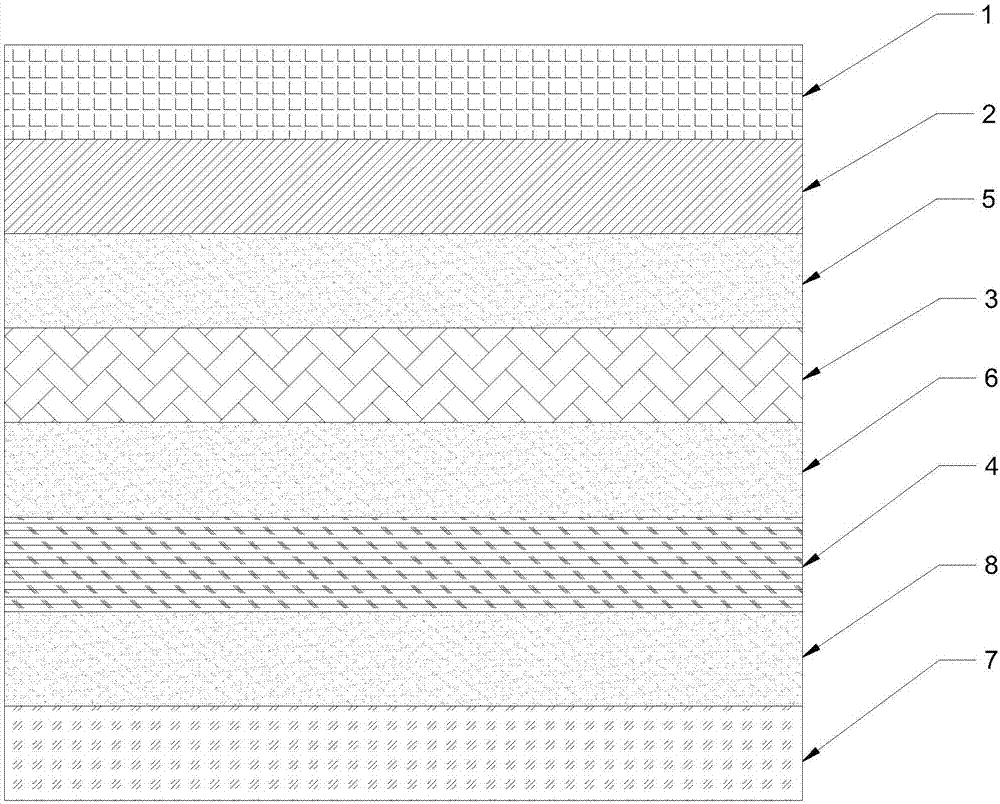

[0081] The structure of a super wear-resistant, scratch-resistant and waterproof plastic floor is as in Example 1;

[0082] The grammage of the aluminum oxide wear-resistant paper is 5-100g / ㎡; the thickness of the base layer 3 is 20mm; the balance paper is kraft paper made from unbleached sulfite wood pulp; the first connection The thickness of layer 5 and the second connection layer 6 are both 2mm, and the weight is 500g / m 2 ;

[0083] The first connection layer 5 and the second connection layer 6 both include paste resin, plasticizer, stabilizer with a mass ratio of 100:50-100:2-5, and a glass fiber grid with a thickness of 0.01-2mm Cloth or non-woven fabric, etc.

[0084] The specific steps of the manufacturing method of the super wear-resistant, scratch-resistant and waterproof plastic floor are as follows:

[0085] 1) Production of base layer:

[0086] A, take material according to following parts by weight: 100 parts of PVC powders, 65 parts of plasticizers, 5 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com