Aqueous woodenware matte clean finishing coat and its preparation method

A clear topcoat, water-based technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of easy whitening of the paint film, reduction of the transparency of the paint film, and the difficulty in reducing the gloss of the water-based wood paint film. Strong scratch resistance and super adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

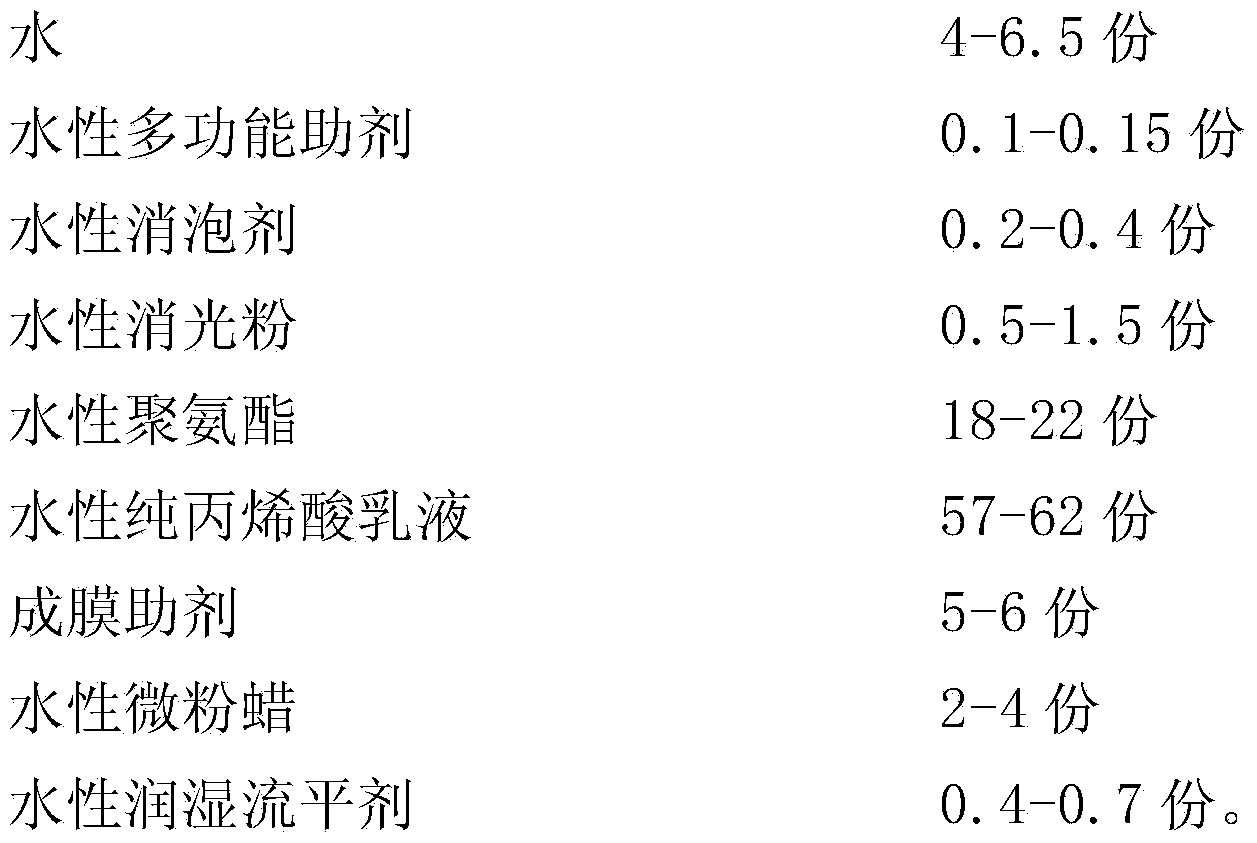

[0044] A kind of water-based matte varnish for woodware is formulated by the following raw materials according to the following weight ratio:

[0045]

[0046]

[0047] The preparation method of this water-based woodware matte varnish comprises the following steps carried out in sequence:

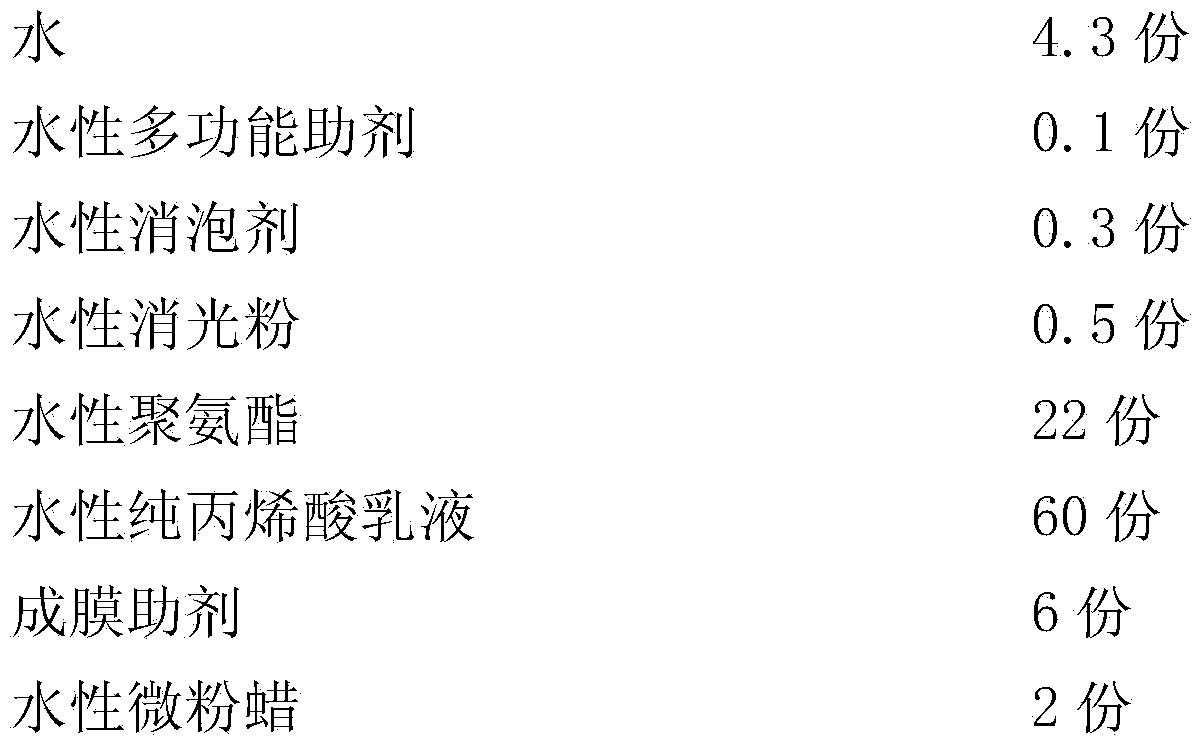

[0048] (1) Start the disperser and adjust the speed to 400 rpm. At this speed, first add 4.3 parts of water, 0.1 part of water-based multifunctional additive, 0.3 part of water-based defoamer and 0.5 part of water-based matting powder, and then adjust the disperser Speed to 1800 rpm, disperse for 10 minutes;

[0049] (2) Adjust the speed of the disperser to 800 rpm, and check whether the fineness of the paint liquid is ≤30 μm, and if the fineness is ≤30 μm, proceed to step (3);

[0050] Through the above steps, the fineness will usually be ≤30μm. If it is not achieved, it can be dispersed for a period of time before testing. If the long-term dispersion test fails to meet the requir...

Embodiment 1-2

[0053] A kind of water-based matte varnish for woodware is formulated by the following raw materials according to the following weight ratio:

[0054]

[0055] The preparation method of this water-based woodware matte varnish comprises the following steps carried out in sequence:

[0056] (1) Start the disperser and adjust the speed to 400 rpm. At this speed, first add 4 parts of water, 0.1 part of water-based multifunctional additive, 0.3 part of water-based defoamer and 1.5 parts of water-based matting powder, and then adjust the disperser Speed to 1800 rpm, disperse for 10 minutes;

[0057] (2) Adjust the speed of the disperser to 800 rpm, and check whether the fineness of the paint liquid is ≤30 μm, and if the fineness is ≤30 μm, proceed to step (3);

[0058] Through the above steps, usually the fineness will be ≤30μm. If it is not reached, it can be dispersed for a period of time before testing. If the long-term dispersion test fails to meet the requirements, it means...

Embodiment 1-3

[0061] A kind of water-based matte varnish for woodware is formulated by the following raw materials according to the following weight ratio:

[0062]

[0063] The preparation method of this water-based woodware matte varnish comprises the following steps carried out in sequence:

[0064] (1) Start the disperser and adjust the speed to 450 rpm. At this speed, first add 6.5 parts of water, 0.1 part of water-based multifunctional additive, 0.3 part of water-based defoamer and 1.0 part of water-based matting powder, and then adjust the disperser Speed to 1900 rpm, disperse for 13 minutes;

[0065] (2) Adjust the speed of the disperser to 900 rpm, and check whether the fineness of the paint liquid is ≤30 μm, and if the fineness is ≤30 μm, proceed to step (3);

[0066] Through the above steps, usually the fineness will be ≤30μm. If it is not reached, it can be dispersed for a period of time before testing. If the long-term dispersion test fails to meet the requirements, it me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com