Environment-friendly water-based nano varnish and preparation method

A nanometer, water-based technology, applied in the field of coatings, can solve the problems of slow drying time, high production formula cost, poor weather resistance, etc., and achieve the effect of enhancing affinity and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

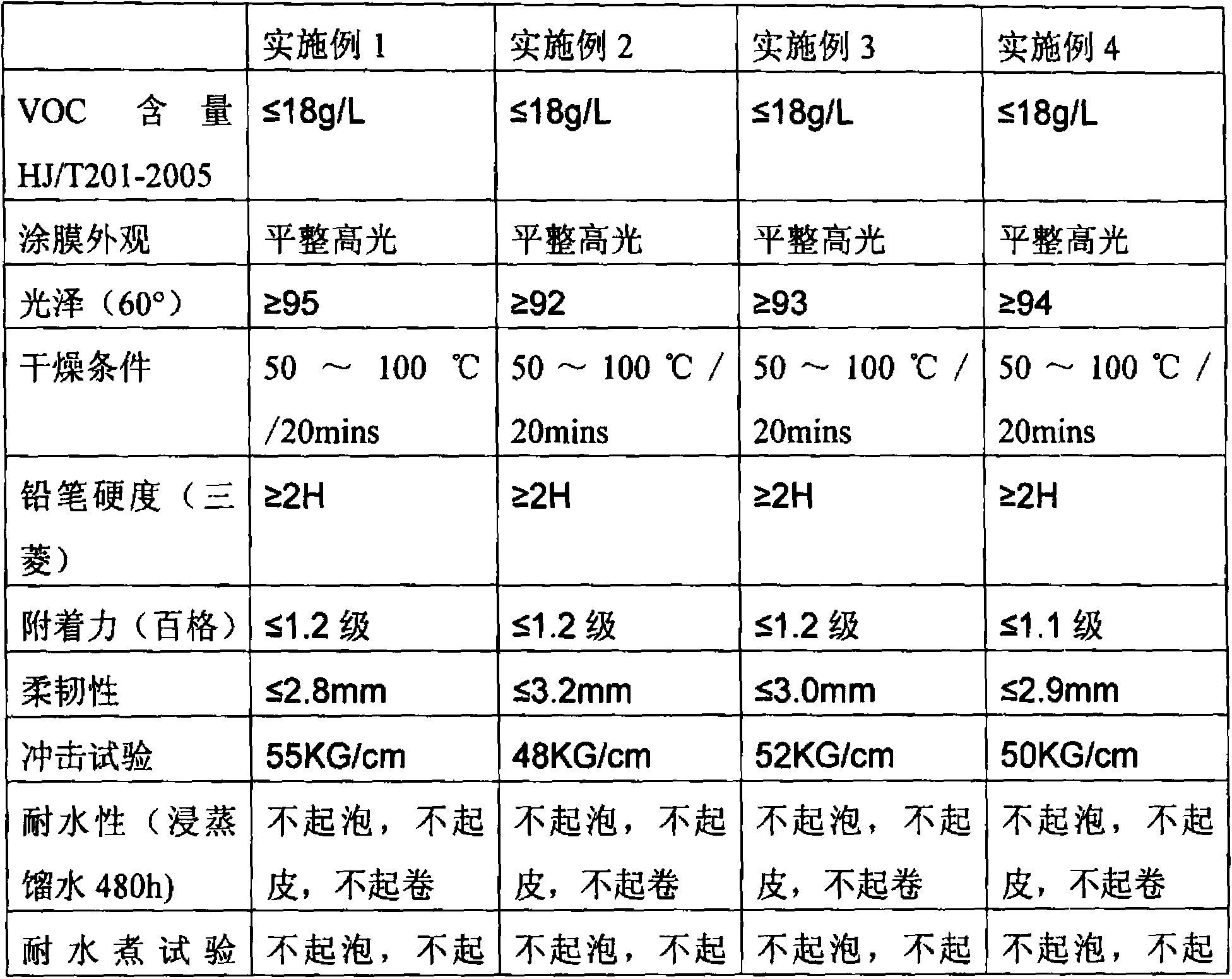

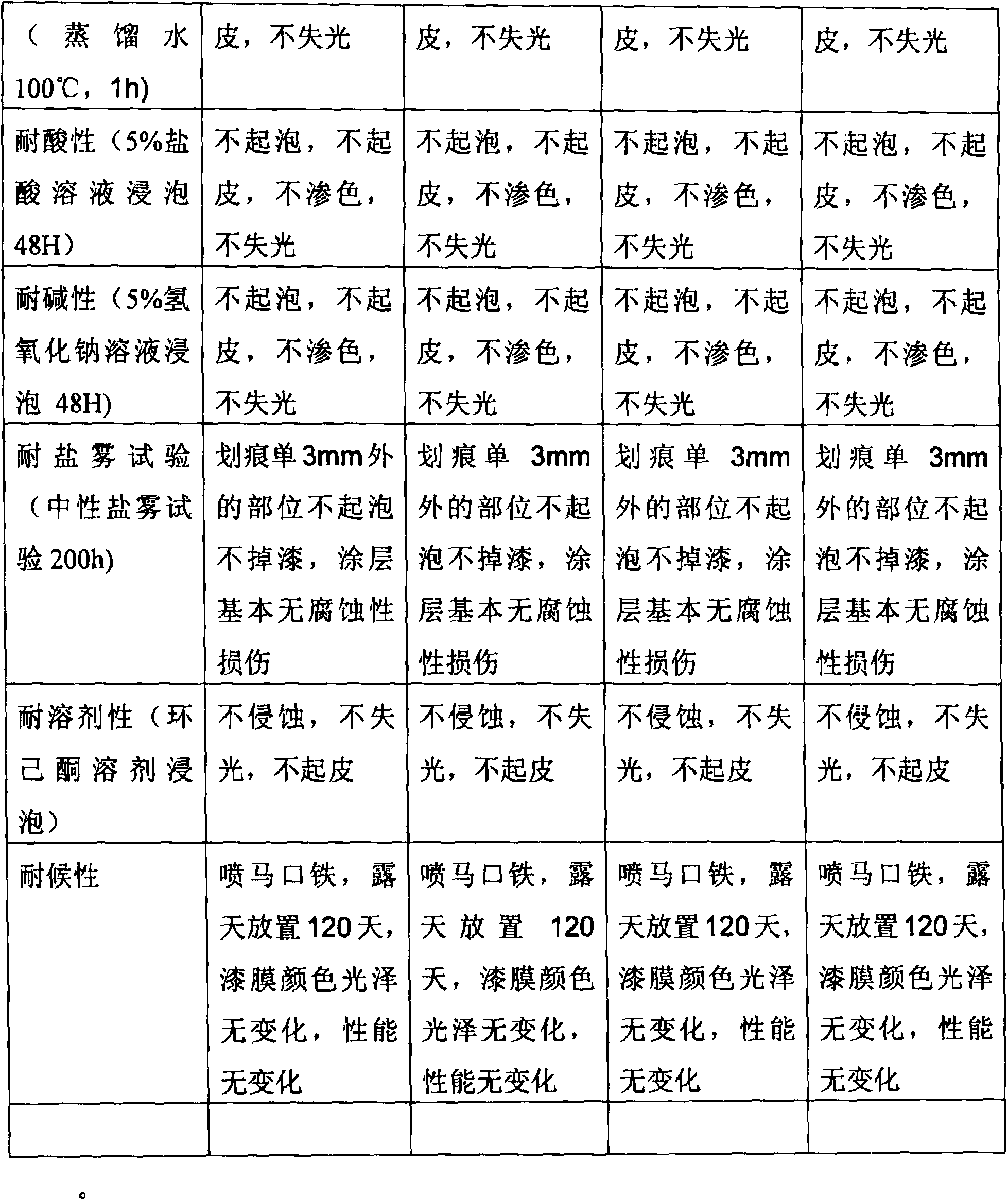

Examples

Embodiment 1

[0030] A kind of preparation method of environment-friendly water-based nano varnish, the method comprises the following steps:

[0031] (1) Nanomaterial agglomerate depolymerization treatment: put transparent nanomaterials (nano silica with strong ultraviolet absorption and infrared reflection characteristics, and can improve the anti-aging performance of coatings) in a dispersion kettle, add deionized water and surfactant, disperse at high speed for 60 minutes; based on the total weight of nanomaterials, deionized water and surfactants as 100%, nanomaterials account for 50%, deionized water account for 45%, and surfactants account for 5%;

[0032] (2) high-energy activation treatment of chemical bonds of nanomaterials: the material treated in step (1) is placed in an ultrasonic reactor, ultrasonically treated for 60 minutes, and the ultrasonic energy range is 3000w, and the obtained product is the water-based nano-activation base material;

[0033] (3) placing 20 parts by we...

Embodiment 2

[0036] A kind of preparation method of environment-friendly water-based nano varnish, the method comprises the following steps:

[0037] (1) Nanomaterial agglomerate depolymerization treatment: put transparent nanomaterials (nano silica with strong ultraviolet absorption and infrared reflection characteristics, and can improve the anti-aging performance of coatings) in a dispersion kettle, add deionized water and surfactant, disperse at high speed for 30 minutes; based on the total weight of nanomaterials, deionized water and surfactants as 100%, nanomaterials account for 70%, deionized water account for 25%, and surfactants account for 5%;

[0038] (2) high-energy activation treatment of chemical bonds of nanomaterials: the material treated in step (1) is placed in an ultrasonic reactor, ultrasonically treated for 30 minutes, and the ultrasonic energy range is 3000w, and the obtained product is the water-based nano-activation base material;

[0039] (3) placing 10 parts by we...

Embodiment 3

[0042] A kind of preparation method of environment-friendly water-based nano varnish, the method comprises the following steps:

[0043] (1) Nanomaterial agglomerate depolymerization treatment: place transparent nano-zinc phosphate in a dispersion kettle, add deionized water and surfactant, and disperse at high speed for 60 minutes; take the total weight of nanomaterials, deionized water and surfactant For 100%, nanomaterials account for 30%, deionized water account for 65%, and surfactants account for 1%;

[0044] (2) high-energy activation treatment of chemical bonds of nanomaterials: the material treated in step (1) is placed in an ultrasonic reactor, ultrasonically treated for 60 minutes, and the ultrasonic energy range is 800w, and the obtained product is the water-based nano-activation base material;

[0045] (3) 30 parts by weight of the water-based nano-activation base material obtained in step (2) was placed in the reactor, and 1 part by weight of aluminate coupling a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com