Low-friction and biaxially oriented polypropylene heat-sealing membrane and manufacturing method thereof

A technology of biaxial stretching and polypropylene, applied in the field of polymers, can solve problems such as difficulty in meeting ultra-high-speed production, and achieve good physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

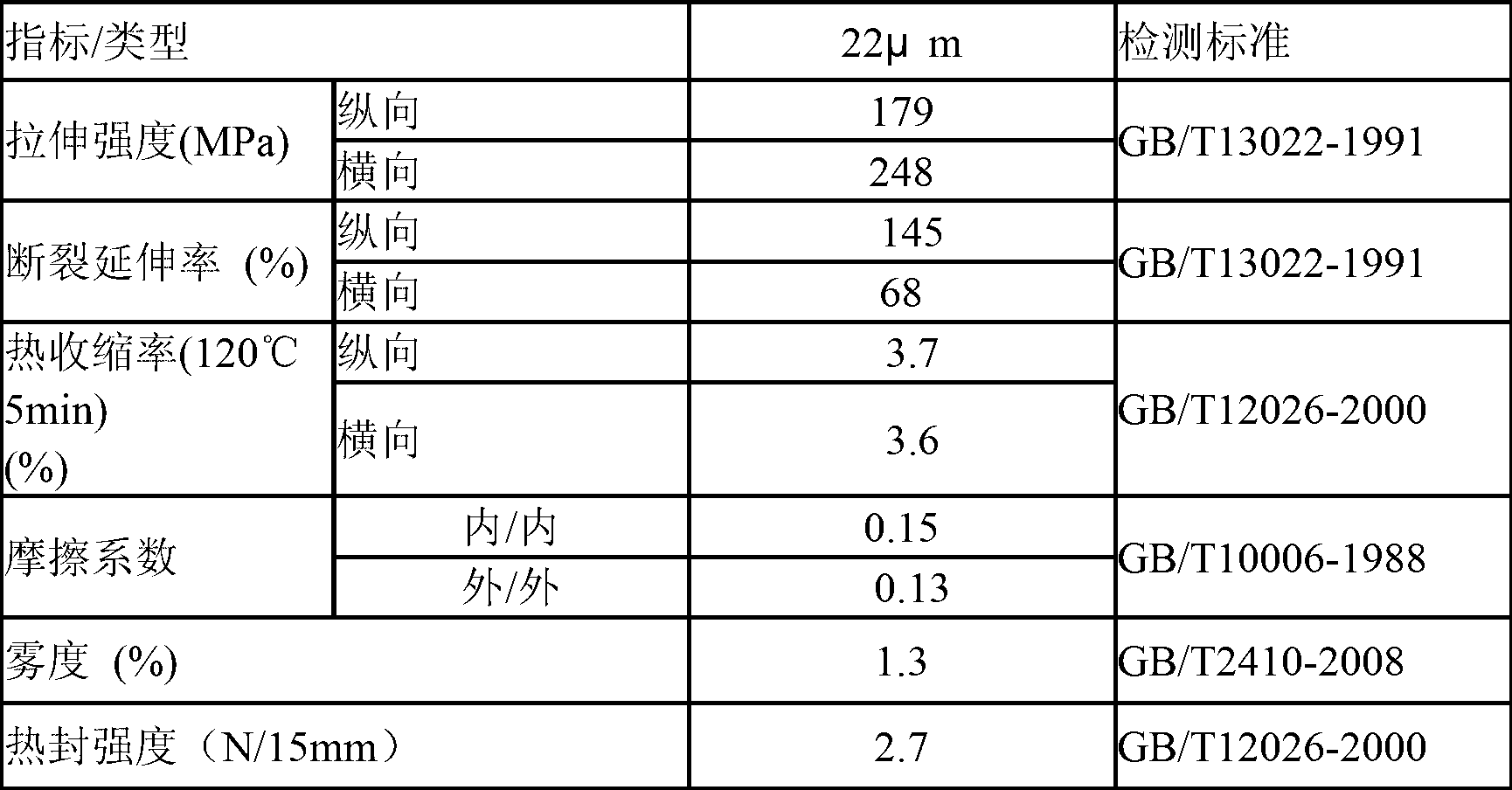

Embodiment 1

[0024] Films with a thickness of 22 microns were produced. Ingredients: The thickness of the upper layer is 1.0 microns, of which the content of copolymerized polypropylene is 97%, the particle size of 2 μm polybutylene terephthalate is 1%, the polymer silicone is 2%; the thickness of the middle layer is 20 microns, of which homopolypropylene 98%, blended antistatic agent 2% with 20% erucamide, 40% ethoxylated amine and 40% glyceryl monostearate. The thickness of the lower layer is 1.0 microns, and the content of copolymerized polypropylene is 99%, and the content of synthetic silica is 1%.

[0025] Film production: The low-friction coefficient biaxially oriented polypropylene heat-sealing film of the present invention is produced by using a biaxially oriented co-extrusion process, wherein the temperature of the extruder: 225°C; the temperature of the casting machine: 20°C; the longitudinal stretch ratio: 500 %, longitudinal stretching preheating temperature: 112°C, longitudi...

Embodiment 2

[0029] Films with a thickness of 18 microns are produced. Ingredients: the thickness of the upper layer is 0.9 microns, of which the content of copolymerized polypropylene is 97%, polybutylene terephthalate with a particle size of 2 μm is 1.5%, and high molecular silicone is 1.5%; the thickness of the middle layer is 16 microns, of which all polypropylene 99%, blended antistatic agent 1% containing 20% erucamide, 40% ethoxylated amine and 40% glyceryl monostearate. The thickness of the lower layer is 1.1 microns, and the content of copolymerized polypropylene is 99%, and the content of synthetic silica is 1%.

[0030] Film production: The low-friction coefficient biaxially oriented polypropylene heat-sealing film of the present invention is produced by using a biaxially oriented co-extrusion process, wherein the temperature of the extruder: 245°C; the temperature of the casting machine: 25°C; the longitudinal stretch ratio: 530 %, longitudinal stretching preheating temperat...

Embodiment 3

[0032] Films with a thickness of 25 microns are produced. Ingredients: the thickness of the upper layer is 1.0 microns, of which the content of copolymerized polypropylene is 96%, polybutylene terephthalate with a particle size of 2 μm is 2%, high molecular silicone 2%; the thickness of the middle layer is 23 microns, of which homopolypropylene 98%, blended antistatic agent 2% containing 30% erucamide, 30% ethoxylated amine and 40% glyceryl monostearate. The thickness of the lower layer is 1.0 microns, the content of copolymerized polypropylene is 99.5%, and the content of synthetic silica is 0.5%.

[0033] Film production: The low-friction coefficient biaxially oriented polypropylene heat-sealing film of the present invention is produced by using a biaxially oriented co-extrusion process, wherein the temperature of the extruder: 235°C; the temperature of the casting machine: 20°C; the longitudinal stretch ratio: 490 %, longitudinal stretching preheating temperature: 110°C, l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Longitudinal stretching preheating temperature | aaaaa | aaaaa |

| Longitudinal stretch temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com