Bio-based biodegradable multi-block copolymer as well as preparation method and application thereof

A multi-block copolymer and biodegradable technology, which is applied in the field of bio-based biodegradable multi-block copolymers, can solve the problems of destroying the earth's ecological environment, inability to use flexible packaging materials, and inability to degrade, etc., to achieve excellent comprehensive mechanical properties, Guaranteed biodegradability, good effect of biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

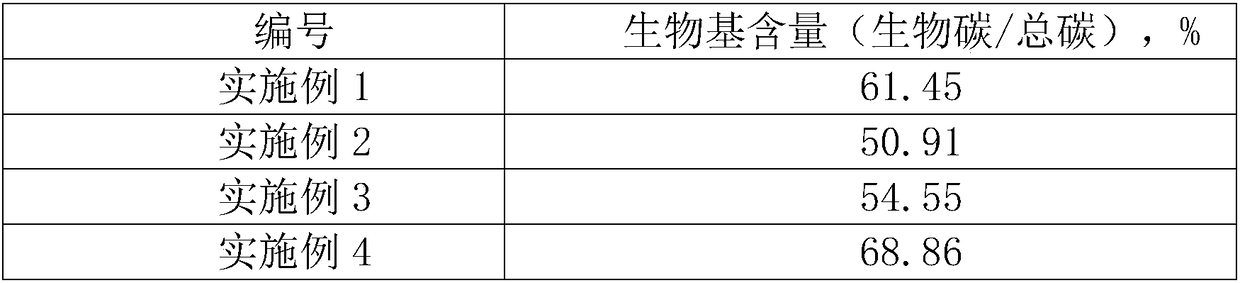

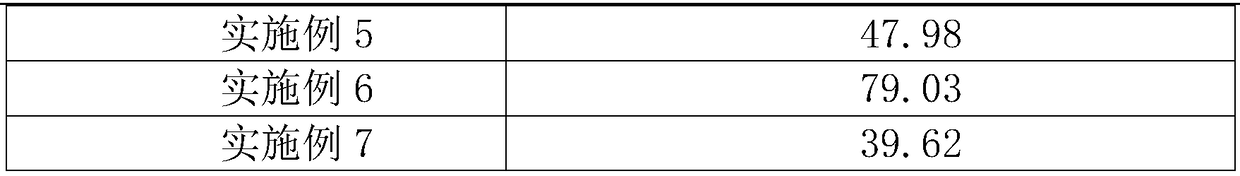

Examples

Embodiment 1

[0041] step one:

[0042] Weigh 5.15 kg of bio-based succinic acid, 5.57 kg of 2,5-furandicarboxylic acid, 18 kg of petroleum-based 1,4-butanediol, 30 grams of bio-based glycerin, 32 grams of tetrabutyl titanate, add to 50 liters In the esterification reaction kettle, the temperature was raised to 200-250° C. by means of a temperature program, and the reaction was stirred for 2-5 hours until the esterification rate reached more than 97%, and the esterified product A was obtained.

[0043] Transfer the esterified product A to a 50-liter polycondensation kettle with a decompression device, vacuumize it to an absolute pressure of 3-5Kpa while stirring, and raise the temperature to 200-250°C at the same time, stir and react for 1-2 hours, and further reduce the pressure to an absolute pressure 100-200Pa, continue to react for 1-3 hours. The end point of the reaction is judged according to the change of the stirring current, and the segment A aliphatic-aromatic copolyester prepoly...

Embodiment 2

[0050] step one:

[0051] Weigh 5.56 kg of bio-based succinic acid, 5.2 kg of petroleum-based terephthalic acid, 17.0 kg of petroleum-based 1,4-butanediol, 1500 grams of lactic acid, and 10 grams of ethylene glycol antimony, and add them to a 50-liter esterification reaction kettle In the process, the temperature was raised to 210-230° C. by means of temperature programming, and the reaction was stirred for 3-5 hours until the esterification rate reached more than 97%, and the esterified product A was obtained.

[0052] Transfer the esterified product A to a 50-liter polycondensation kettle with a decompression device, vacuumize it to an absolute pressure of 3-5Kpa while stirring, and raise the temperature to 230°C at the same time, stir and react for 2-3 hours, and further reduce the pressure to an absolute pressure of 100-5Kpa 200Pa, continue to react for 2 to 5 hours. The end point of the reaction is judged according to the change of the stirring current, and the segment A...

Embodiment 3

[0059] step one:

[0060] Weigh 4.80 kg of bio-based adipic acid, 1.85 kg of dimer acid, 4.85 kg of terephthalic acid, 14.5 kg of petroleum-based 1,4-butanediol, 300 grams of glycerin, and 30 grams of tetrabutyl titanate, add to 50 In the esterification reaction kettle, the temperature was raised to 230° C. by means of a temperature program, and the reaction was stirred for 2 to 5 hours until the esterification rate reached more than 97%, and the esterified product A was obtained.

[0061] Transfer the esterified product A to a 50-liter polycondensation kettle with a decompression device, vacuumize it to an absolute pressure of 3-5Kpa while stirring, and raise the temperature to 230°C at the same time, stir and react for 1-2 hours, and further reduce the pressure to an absolute pressure of 100-5Kpa 200Pa, continue to react for 2 to 5 hours. The end point of the reaction is judged according to the change of the stirring current, and the segment A aliphatic-aromatic copolyester...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com