Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

107 results about "Glycerol Trioleate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spontaneous emulsions containing cyclosporine

A pharmaceutical composition contains cyclosporine as the active ingredient. More specifically, the composition is an orally administered pharmaceutical formulation in the form of a spontaneous emulsion comprising cyclosporine, ethanol ethyl oleate and polyoxyethylene glycerol trioleate. A method for preparing an orally administered pharmaceutical composition involves first dissolving cyclosporine in ethanol. Polyoxyethylene glycerol trioleate and an oil component are then added, mixed and diluted in an aqueous media to form a spontaneous emulsion.

Owner:WOCKHARDT EU OPERATIONS SWISS

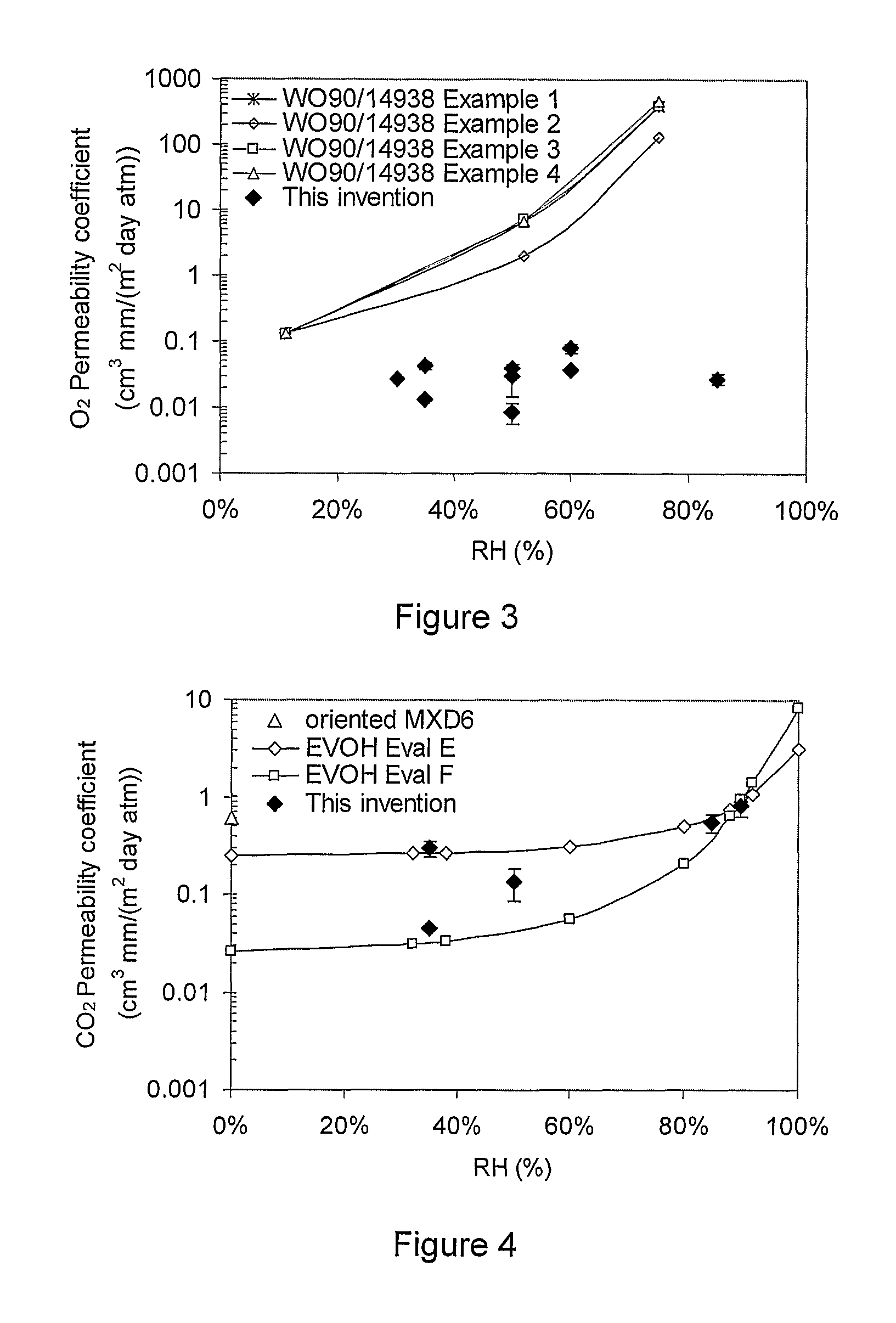

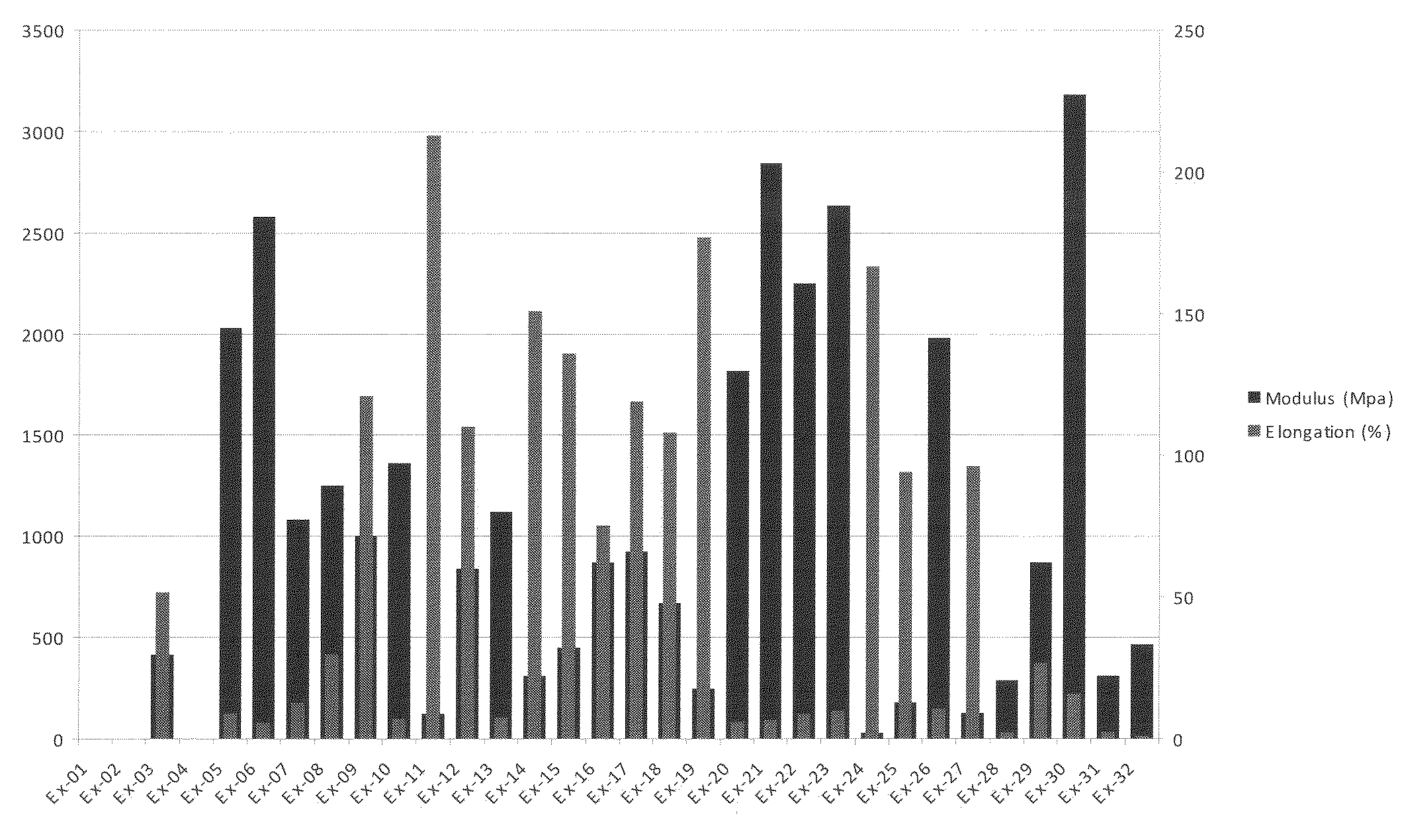

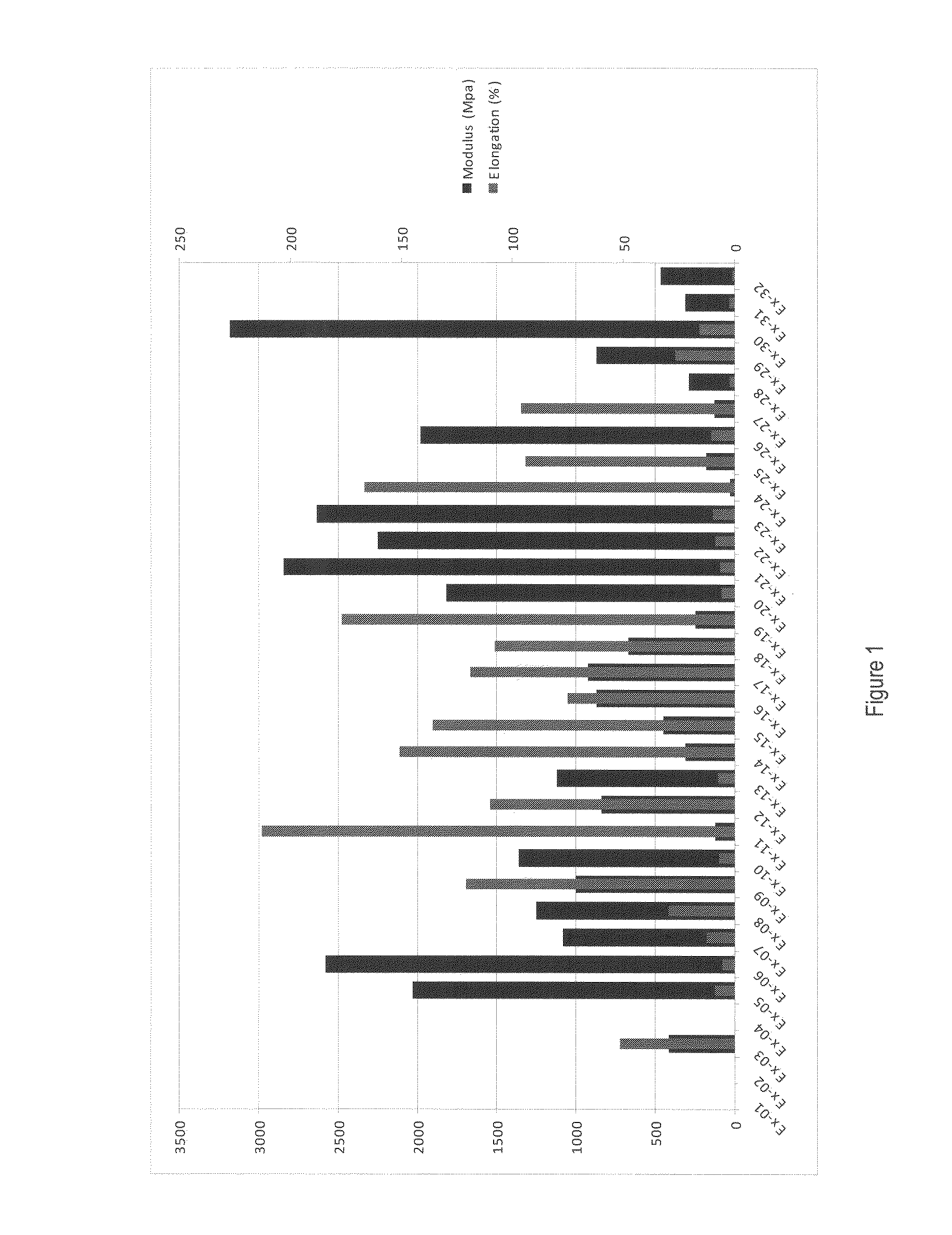

Polymeric films

ActiveUS20090312462A1Excellent oxygen barrier propertiesSuitable for usePaper coatingDomestic articlesMolten statePolymer science

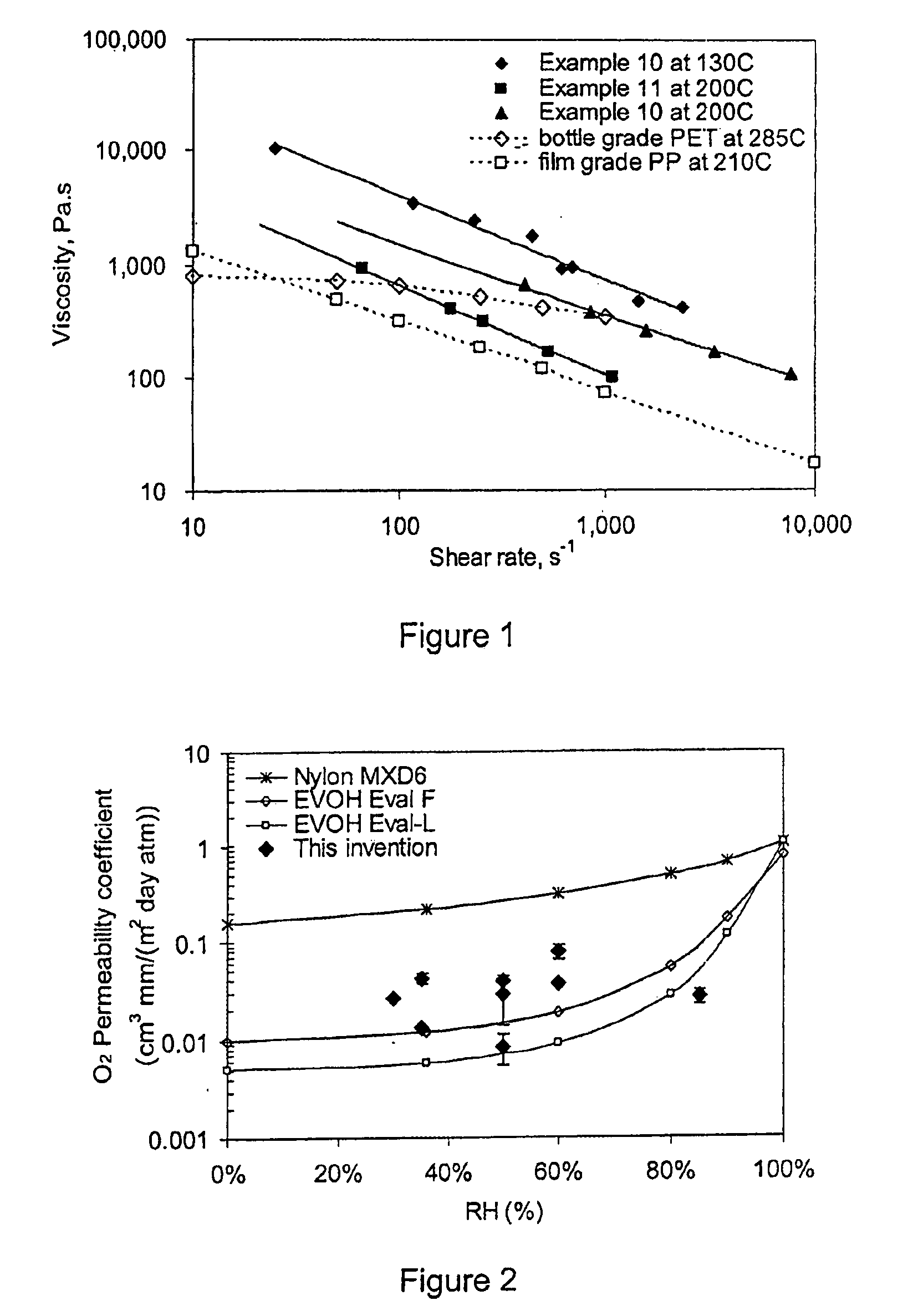

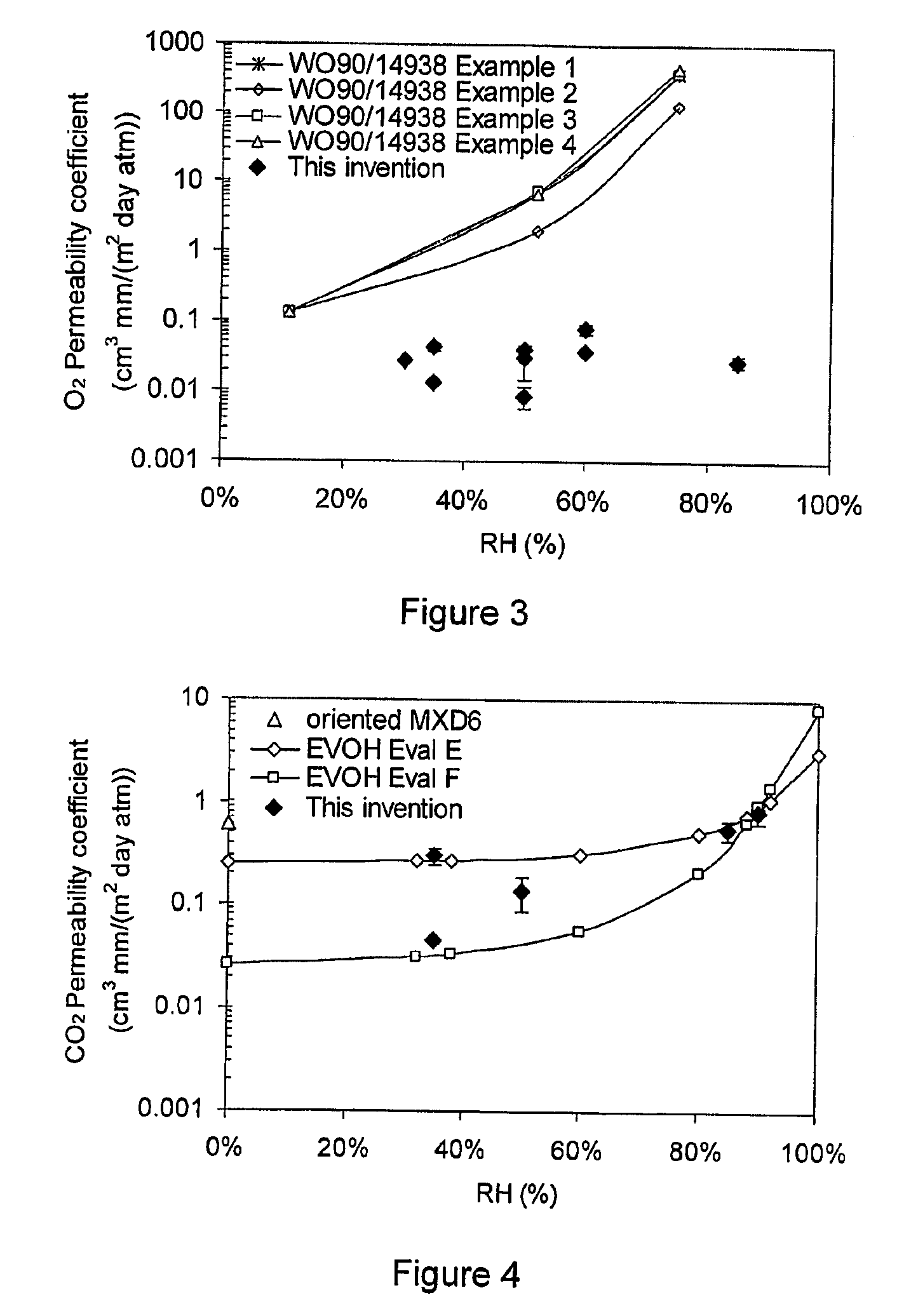

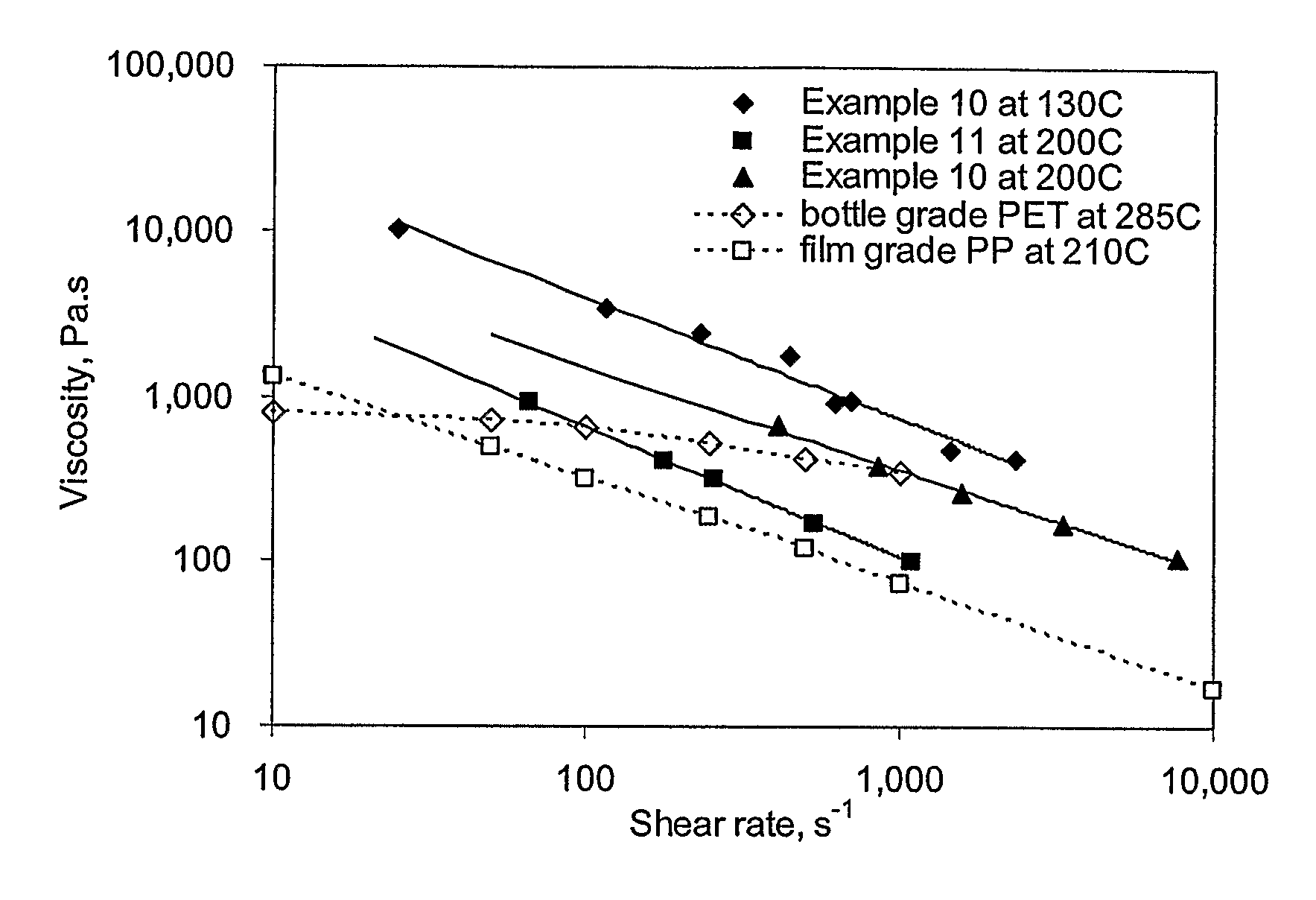

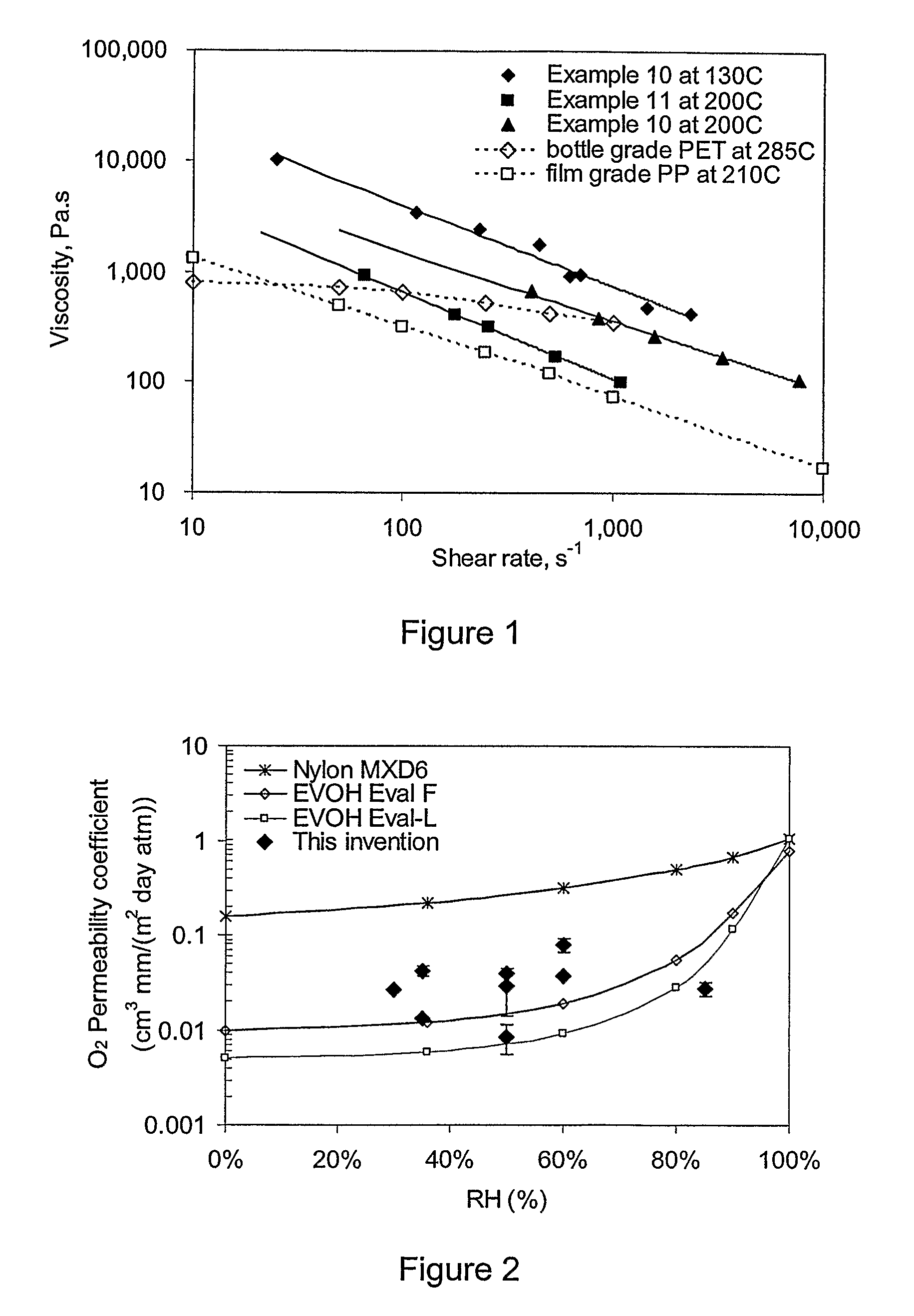

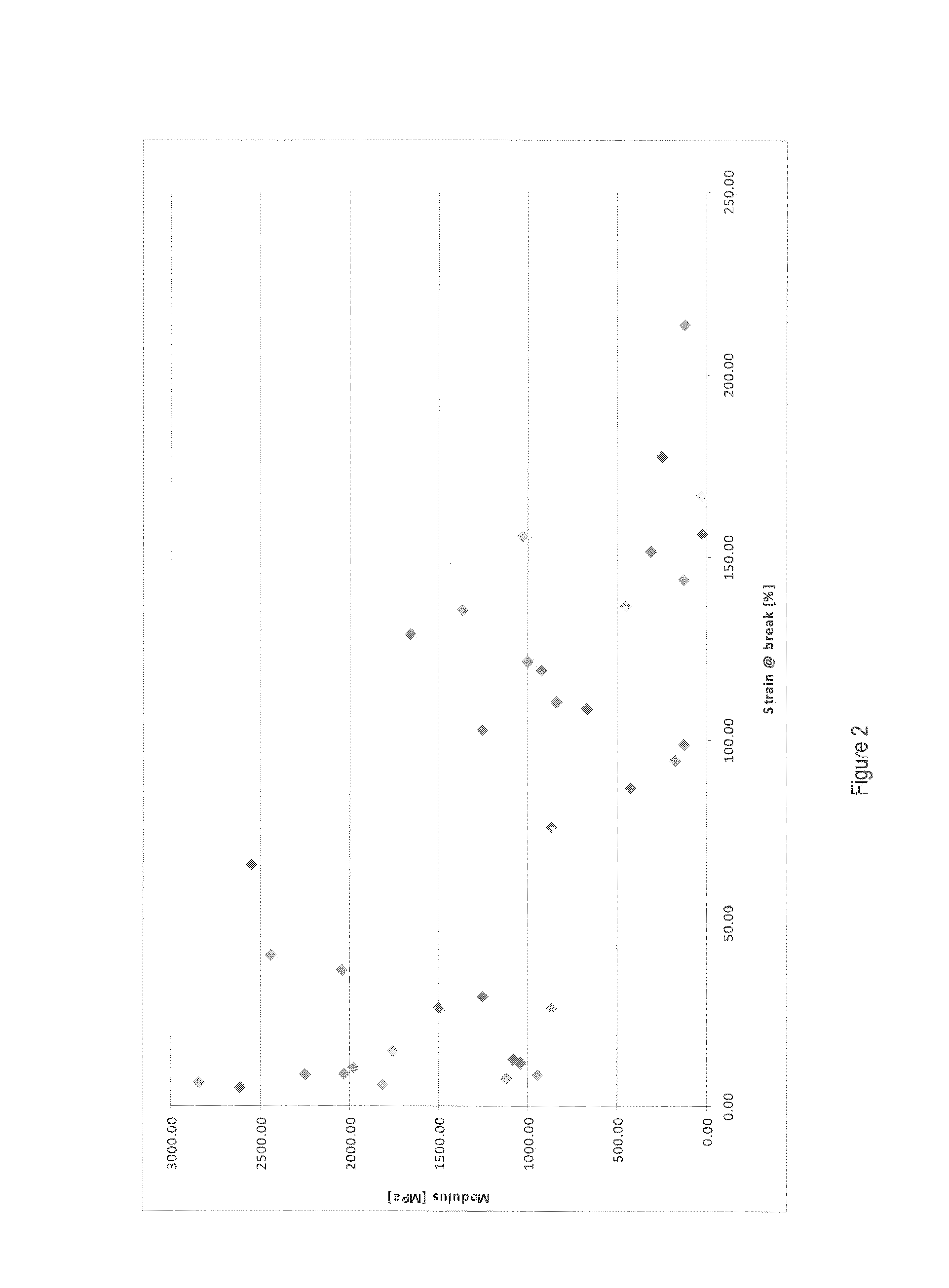

A polymer composition and its use for thin film packaging applications including on a dry basis: a) from 45 to 90% by weight of starch; b) from 0.1 to 15% by weight of a water soluble polymer selected from polyvinyl alcohol, polyvinylacetate, and copolymers of ethylene and vinyl alcohol which have a melting point compatible with the molten state of the starch component; and c) from 5 to 45% by weight of one or more plasticizers having a molecular weight in the range of 50-6000, more preferably 50-2500 and more preferably still 100-400 and desirably selected from the group consisting of sorbitol, glycerol, maltitol, xylitol, mannitol, erythritol, glycerol trioleate, tributyl citrate, acetyl tri-ethyl citrate, glyceryl triacetate, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate, polyethylene oxide, ethylene glycol, diethylene glycol or polyethylene glycol.

Owner:PLANTIC TECH

Barrier film

InactiveUS20090110942A1Stable mechanical propertiesImprove homogeneityFireproof paintsFibre treatmentMolten statePolyethylene oxide

A barrier composition which is injection mouldable and able to be made into a transparent film or incorporated (by co-extrusion and / or lamination) into multi-layer film products, the composition on dry basis: a) from 45 to 90% by weight of a starch and / or a modified starch selected from starches modified by reaction with a hydroxyl alkyl group, an acetate or a dicarboxylic acid anhydride or a grafting polymer; b) from 4 to 12% by weight of a water soluble polymer selected from polyvinyl alcohol, polyvinylacetate, and copolymers of ethylene and vinylalcohol which have a melting point compatible with the molten state of the starch components c) from 5 to 45% by weight of a non-crystallising mixture of sorbitol and at least one other plasticizer selected from glycerol, maltitol, xylitol, mannitol, glycerol trioleate, epoxidised linseed or soybean oil, tributyl citrate, acetyl tri-ethyl citrate, glyceryl triacetate, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate; polyethylene oxide or polyethylene glycol; d) from 0.3 to 2.5 % by weight of a C12-22 fatty acid or salt; e) from 0.25% to 3% of an emulsifier system having a hydrophilic lipophilic balance value between 2 and 10. The barrier film may be co-injection moulded with polyethylene terephthalate (PET) or polylactic acid (PLA) for blow moulding into beverage bottles, with polyethylene (PE) or polypropylene (PP) or biodegradable polymers for high gas-barrier containers or closures, or may be co-extruded with polyethylene, polypropylene or polylactic acid for thin film packaging applications or for blow-moulded containers.

Owner:PLANTIC TECH

Barrier film

InactiveUS7854994B2Improve the level ofImprove homogeneityFibre treatmentBottlesPolyethylene terephthalate glycolPolyethylene oxide

A barrier composition which is injection mouldable and able to be made into a transparent film or incorporated (by co-extrusion and / or lamination) into multi-layer film products, the composition on dry basis: a) from 45 to 90% by weight of a starch and / or a modified starch selected from starches modified by reaction with a hydroxyl alkyl group, an acetate or a dicarboxylic acid anhydride or a grafting polymer; b) from 4 to 12% by weight of a water soluble polymer selected from polyvinyl alcohol, polyvinylacetate, and copolymers of ethylene and vinylalcohol which have a melting point compatible with the molten state of the starch components c) from 5 to 45% by weight of a non-crystallising mixture of sorbitol and at least one other plasticizer selected from glycerol, maltitol, xylitol, mannitol, glycerol trioleate, epoxidised linseed or soybean oil, tributyl citrate, acetyl tri-ethyl citrate, glyceryl triacetate, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate; polyethylene oxide or polyethylene glycol; d) from 0.3 to 2.5% by weight of a C12-22 fatty acid or salt; e) from 0.25% to 3% of an emulsifier system having a hydrophilic lipophilic balance value between 2 and 10. The barrier film may be co-injection moulded with polyethylene terephthalate (PET) or polylactic acid (PLA) for blow moulding into beverage bottles, with polyethylene (PE) or polypropylene (PP) or biodegradable polymers for high gas-barrier containers or closures, or may be co-extruded with polyethylene, polypropylene or polylactic acid for thin film packaging applications or for blow-moulded containers.

Owner:PLANTIC TECH

Plasticizing system for rubber composition

ActiveUS7834074B2Improved resistance to cutImprove chippingIn situ pavingsSpecial tyresCross-linkElastomer

Owner:MICHELIN RECH & TECH SA

Mouldable Biodegradable Polymer

InactiveUS20100297458A1Synthetic resin layered productsCellulosic plastic layered productsMolten statePolyethylene oxide

A biodegradable injection mouldable polymer composition including on a dry weight basis from 45-85% w / w by weight of a starch and / or a modified high amylose starch, from 2-15% w / w by weight of a water soluble polymer preferably selected from polyvinyl alcohol, polyvinyl acetate and copolymers of ethylene and vinyl alcohol which have a melting point compatible with the molten state of the starch components, and from 5-45% w / w by weight of one or more polyol plasticizers having a molecular weight in the range of 50-6000, more preferably 50-2500, and still more preferably 100-400 and preferably selected from the group consisting of sorbitol, glycerol, maltitol, xylitol, mannitol, erythritol, polyglycerol, glycerol trioleate, tributyl citrate, acetyl tri-ethyl citrate, glyceryl triacetate, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate, polyethylene oxide, ethylene glycol, diethylene glycol or polyethylene glycol; more preferably glycerol, maltitol, sorbitol, erythritol and xylitol. The composition is preferably substantially soluble in water.

Owner:PLANTIC TECH

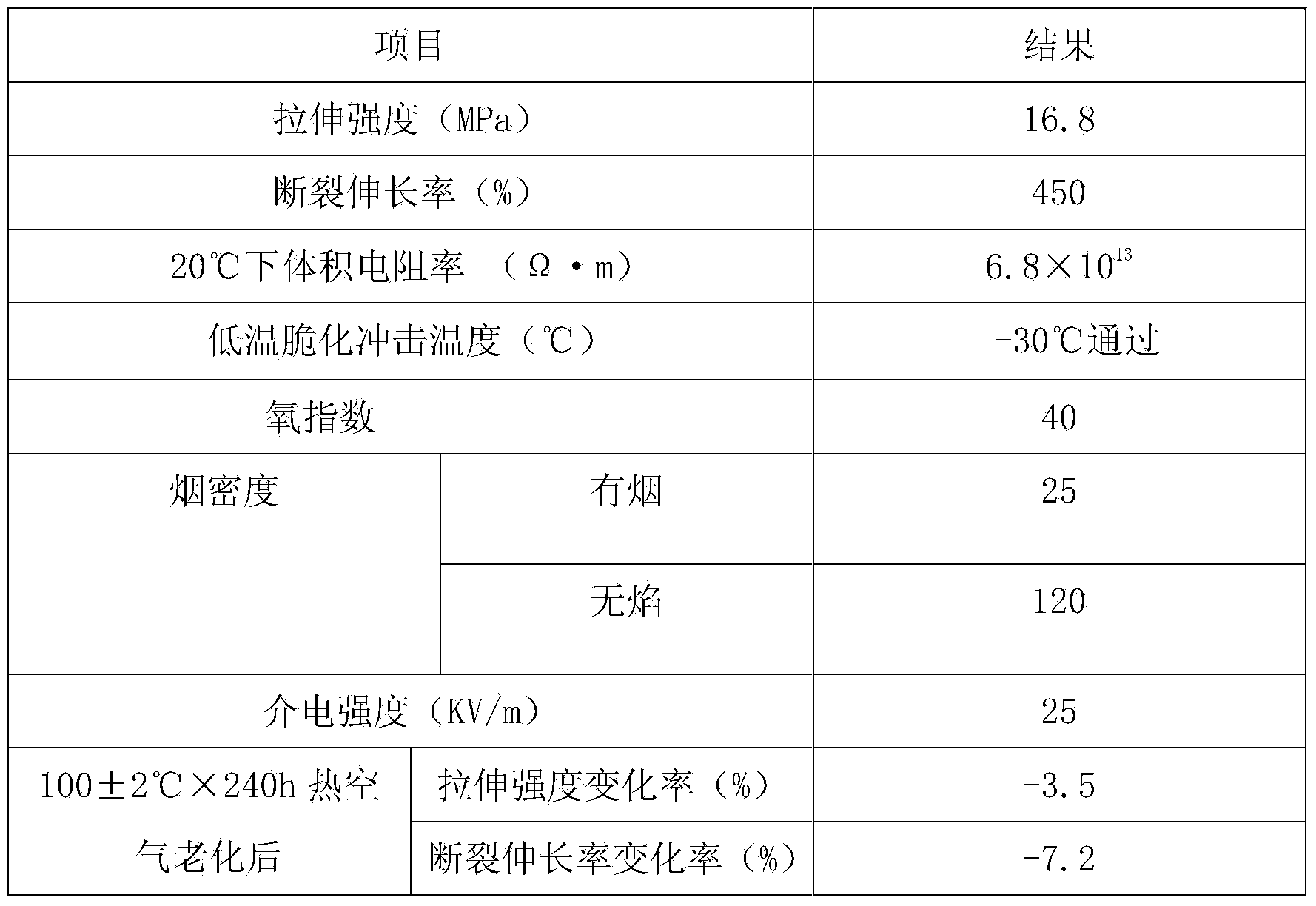

Flame-retardant oil-resistant aging-resistant thermoplastic elastomer cable material

ActiveCN103524913AFlame retardant hasFlame retardant and oil resistantPlastic/resin/waxes insulatorsInsulated cablesCalcium silicatePolyvinyl chloride

The invention provides a flame-retardant oil-resistant aging-resistant thermoplastic elastomer cable material prepared from the following raw materials in parts by weight: 100 parts of polyvinyl chloride SG-3, 10-20 parts of nitrile rubber N26, 10-15 parts of polycarbonate, 10-15 parts of poly(ethylene terephthalateco-1,4-cylclohexylenedimethylene terephthalate), 15-20 parts of a silane coupling agent, 30-40 parts of bisphenol-A bis(diphenyl phosphate), 20-30 parts of calcium carbonate, 1-2 parts of calcium silicate, 30-50 parts of barium stearate, 10-15 parts of cresyl diphenyl phosphate, 3-4 parts of glycerol trioleate, 2-3 parts of a crosslinking agent TAIC, 2-3 parts of stearic acid, 1-2 parts of N,N'-m-phenylenedimaleimide, 5-8 parts of alcohol ester-12, 0.5-1.0 part of PE wax, 1-2 parts of aluminum nitride powder, 1-2 parts of jade powder, and 8-10 parts of a modified filler. The flame-retardant oil-resistant aging-resistant thermoplastic elastomer cable material has the characteristics of flame retardancy, oil resistance, aging resistance, and acid and alkali resistance, and has lower specific density and low manufacture cost.

Owner:滁州君越高分子新材料有限公司

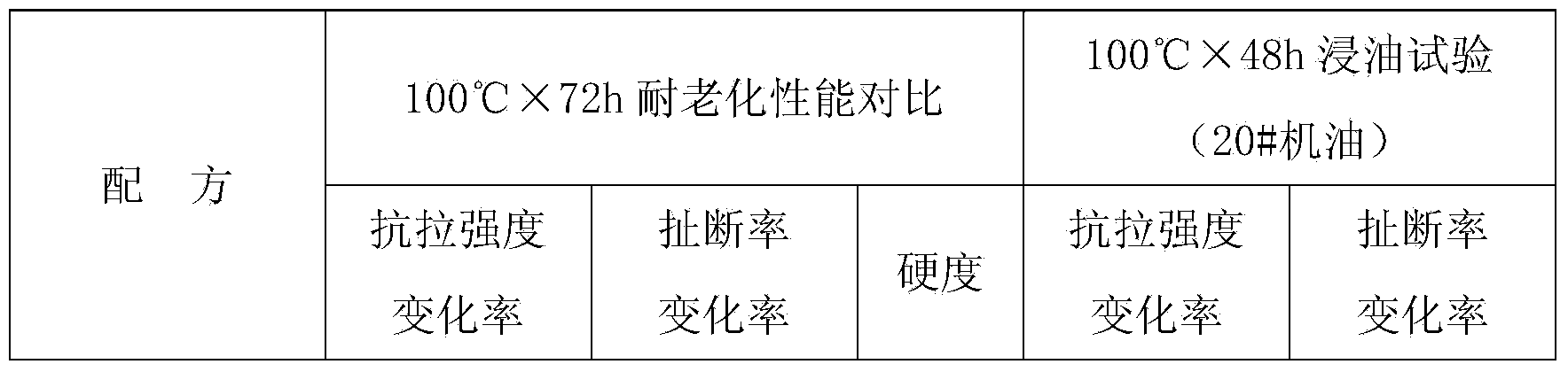

Chlorosulfonated polyethylene (CSM) rubber/butyl rubber gasket and preparation method thereof

ActiveCN103087431AImprove flame retardant performanceAccelerated corrosionPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsTemperature resistanceGlycerol Trioleate

The invention discloses a chlorosulfonated polyethylene (CSM) rubber / butyl rubber gasket. The gasket comprises the following raw materials in parts by weight: 135-145 parts of CSM2305, 10-15 parts of butyl rubber CBK139, 10-15 parts of butyl rubber BBK232, 3-5 parts of glycerol triacetate, 2-5 parts of epoxidized soybean oil, 2-5 parts of glycerol trioleate, 2-5 parts of magnesium oxide, 1-2 parts of imarcaptoacetate dioctyltin, 5-10 parts of zinc oxide and 5-10 parts of attapulgite. The gasket has the advantages of good high temperature resistance, sealing property, flame retardance and corrosion resistance, can work for a long time in such media as acid, alkali and oil, is small in variation of volume and hardness, is not adhered to the metal surfaces, has small friction coefficient, good wear resistance, flexibility of binding with sealing surfaces and good weathering, aging and ozone aging resistance and is durable in use.

Owner:BENGBU TRIUMPH ENG TECH CO LTD

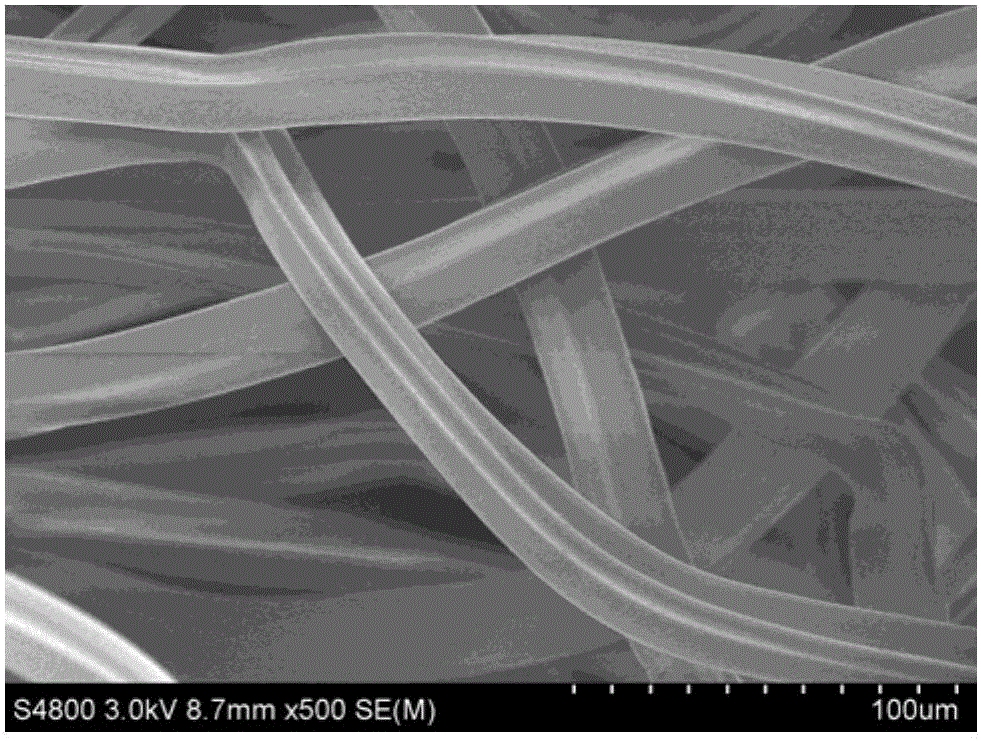

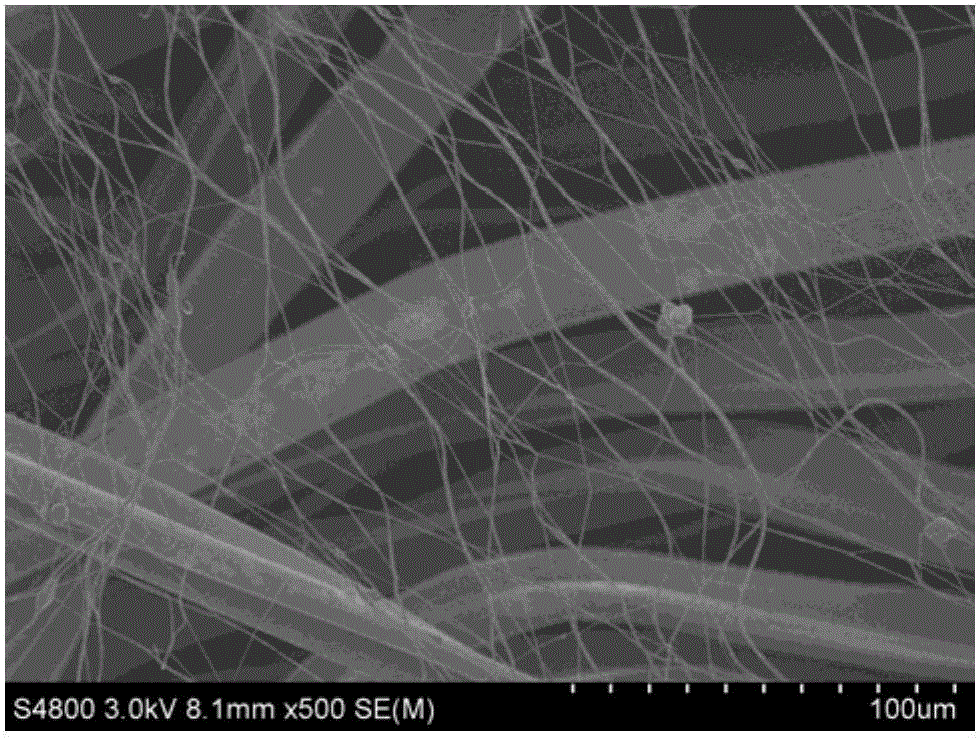

High interface adhesion strength nanofiber composite filament bundle and preparation method and application thereof

ActiveCN105088376AHigh viscosityHigh boiling pointTobacco smoke filtersArtificial filaments from cellulose derivativesCellulose diacetateCellulose acetate

The invention discloses a high interface adhesion strength nanofiber composite filament bundle and a preparation method and application thereof. The preparation method comprises the following steps: 1, preparing a spinning solution with polymer, additives and solvent, wherein the polymer comprises one or more ingredients out of cellulose diacetate, cellulose triacetate, hydroxyethyl cellulose, polyving akohol and polyving akohol, and the additives comprise one or more ingredients out of ethanediol, glycerol, pentaerythritol, diacetin, glycerol triacetate, glycerol trioleate, glycerol palmitate and glyceryl stearate; 2, taking a cigarette-used filament bundle as base materials, conducting electrostatic spinning on the spinning solution which is obtained in step 1, and obtaining the high interface adhesion strength nanofiber composite filament bundle. By means of the high interface adhesion strength nanofiber composite filament bundle, the phenol release amount and NNK release amount in mainstream smoke of a cigarette can be effectively reduced, the phenol release amount is reduced by 16-30%, and the NNK release amount is reduced by 12-36%.

Owner:CHINA TOBACCO ZHEJIANG IND

High-temperature leveling agent

The present invention discloses a high-temperature leveling agent, which is characterized by comprising, by weight, 5 parts of glyceryl trioleate, 10 parts of tartaric acid, 15 parts of fatty amine polyoxyethylene ether, 5 parts of sodium lauryl diphenyl ether disulfonate, 3.5 parts of di-tert-butyl o-benzoate, 8 parts of carboxymethyl cellulose, 9.5 parts of ethylene glycol fatty acid ester, 7 parts of glycerin ether oleate, and 4.5 parts of polyvinylpyrrolidone. The high-temperature leveling agent of the present invention has characteristics of excellent dye migration, slow dyeing and dispersion property.

Owner:CHANGSHU MIAOQUAN SHENGDA AUX FACTORY

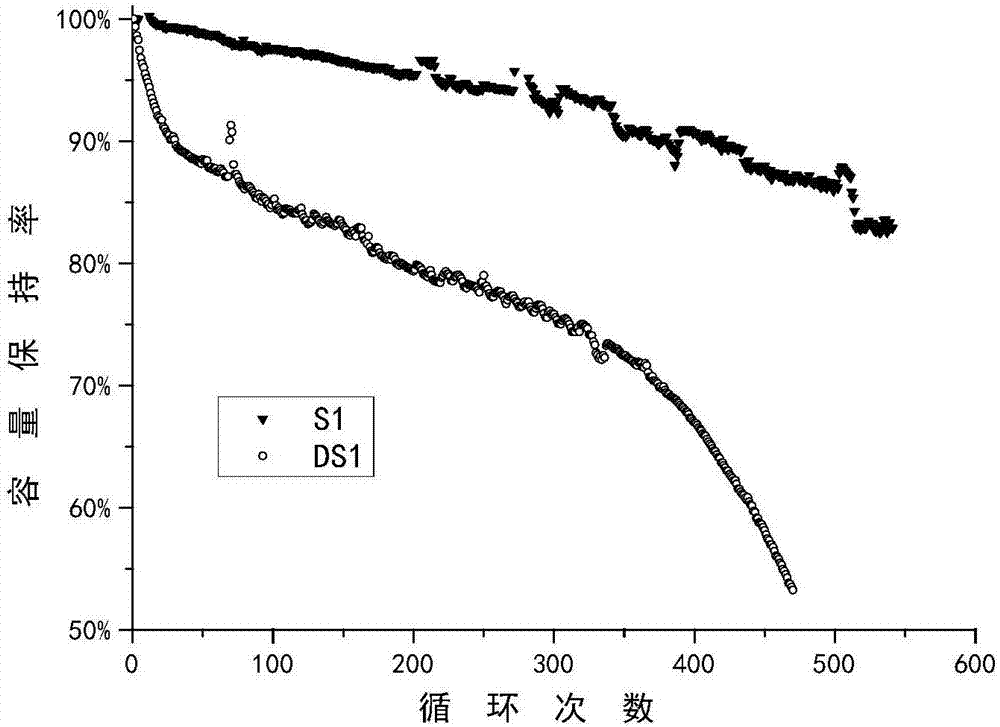

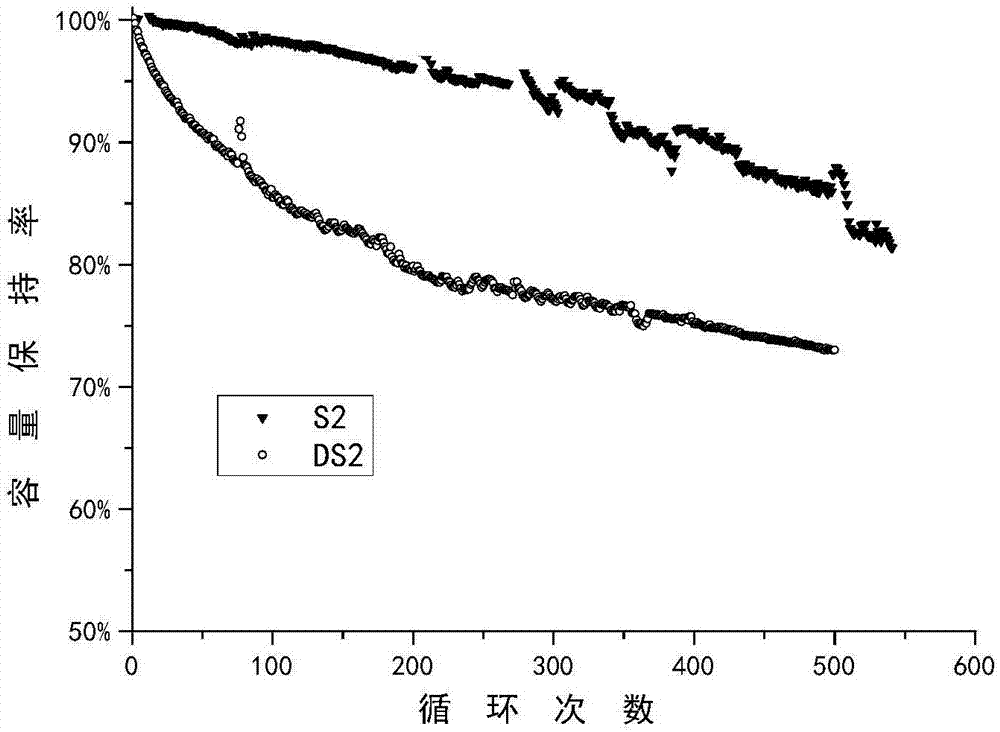

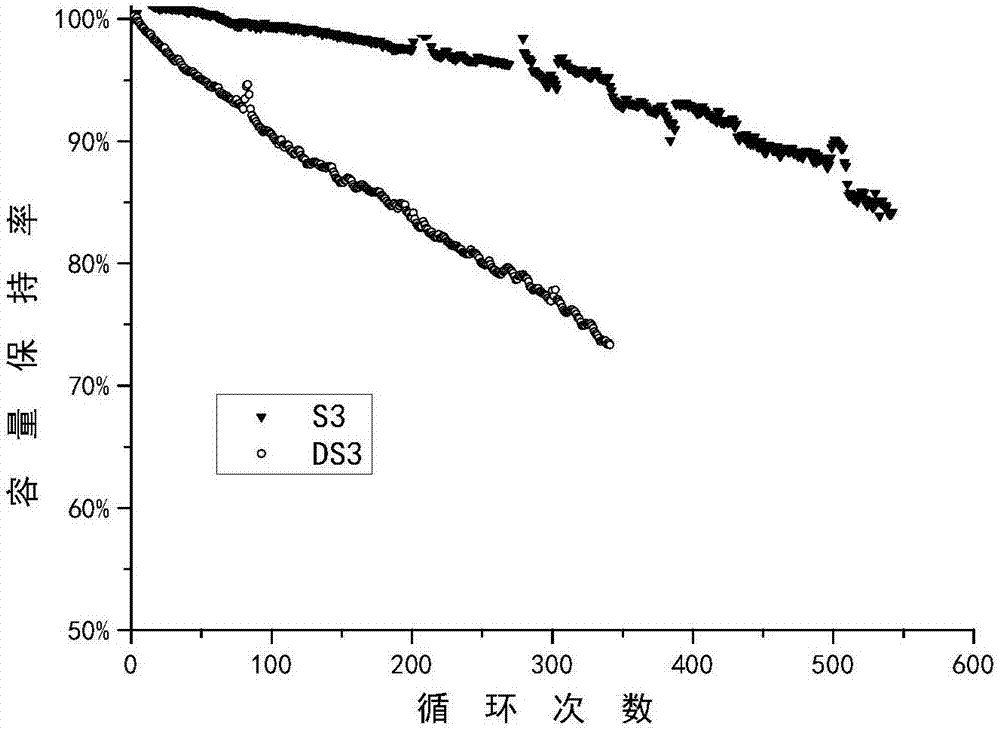

Electrolyte used for 5V high-voltage lithium secondary battery and lithium secondary battery containing same

ActiveCN107887647AUndamagedImprove performanceSecondary cells servicing/maintenanceHigh temperature storageOrganic solvent

The invention discloses electrolyte used for a 5V high-voltage lithium secondary battery. The electrolyte contains a cathode film-forming additive, an electrolyte stabilizer, electrolyte lithium saltand a non-water organic solvent. The electrolyte is characterized by also containing an anode film-forming additive and an immersion agent, wherein the anode film-forming additive is prepared from phenyl acid anhydride substances, and the immersion agent is prepared from one or two of glyceryl tristearate and glyceryl trioleate. The invention aims at providing the electrolyte used for the 5V high-voltage lithium secondary battery, and the electrolyte has the advantage that high temperature storage performance and cycle performance of the 5V high-voltage lithium secondary battery can be effectively improved. Meanwhile, the invention also discloses a 5V high-voltage lithium secondary battery adopting the electrolyte.

Owner:GUANGZHOU TINCI MATERIALS TECH

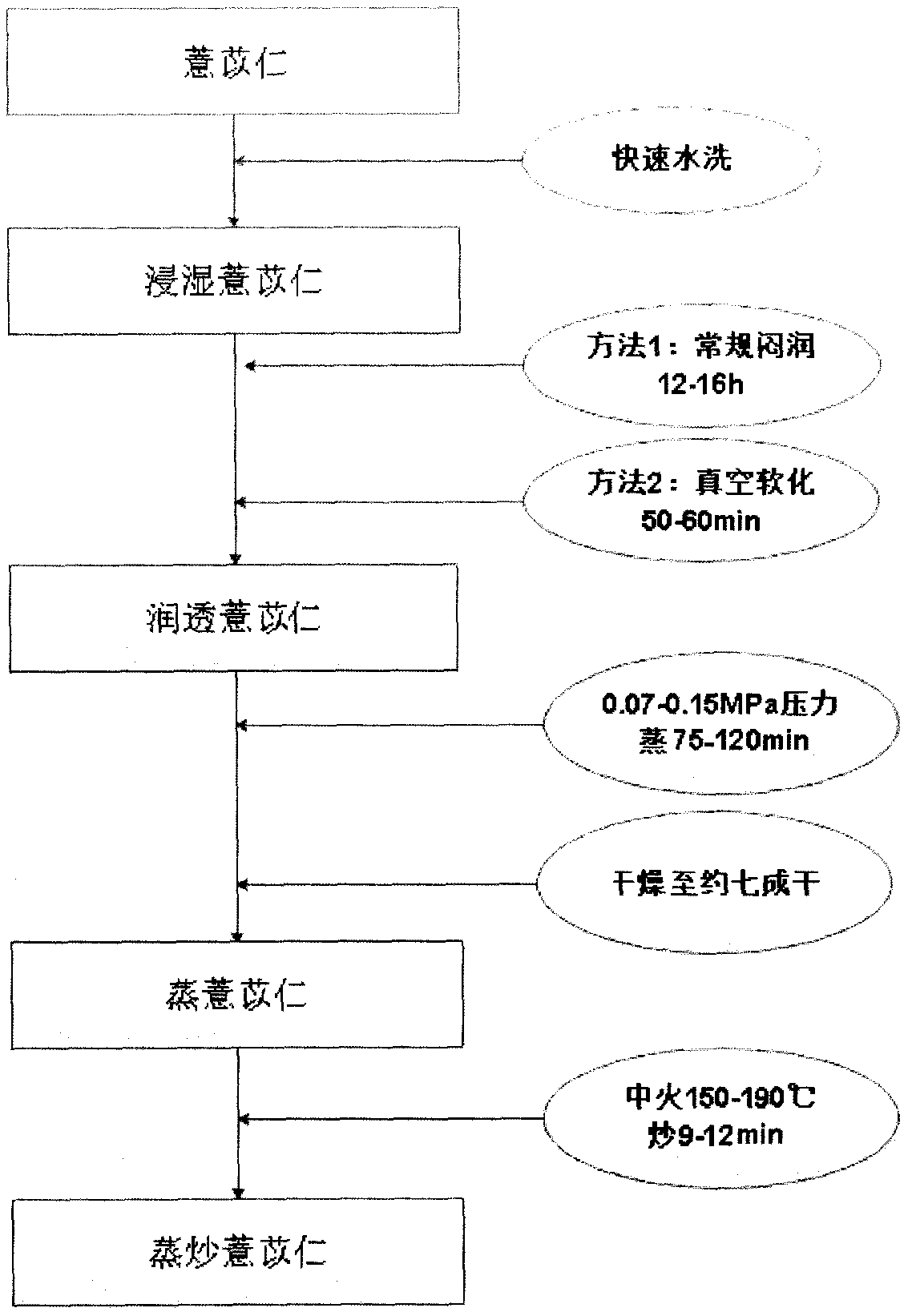

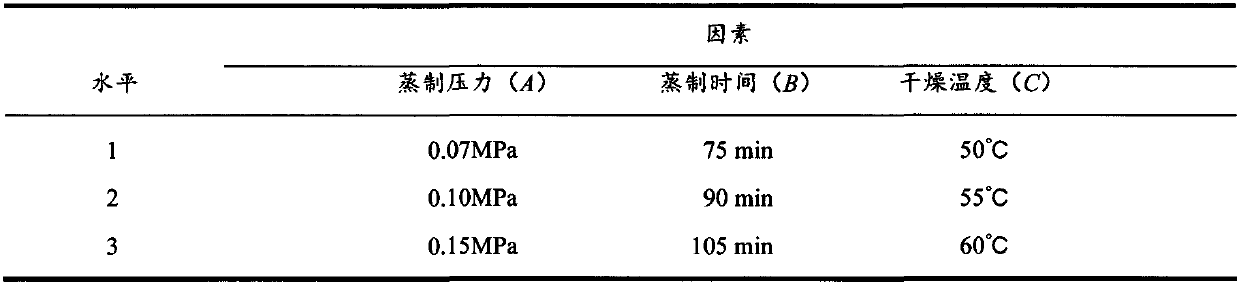

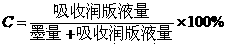

Steamed and fried coix seeds processing method

The invention provides a method for processing coix seeds, which comprises the steps of: washing the coix seeds, and moistening for 12-16 hours; performing high pressure steaming at 0.07 to 0.15 MPa for 75 to 120 minutes, and drying the material; performing stir frying on the coix seeds, then removing the coix seeds, and the cooling the material to obtain the processed coix seeds. The processing method of the present invention is compared with a traditional processing technology and other processes for frying the coix seeds by bran, the processed glycerin trioleate and an extract of the coix seeds have higher content and higher quality. The processing method shortens the processing time, saves time and labor, and precisely controls the heating degree.

Owner:GUANGDONG HOSPITAL OF TRADITIONAL CHINESE MEDICINE

Non-phosphorus fountain solution and preparation method thereof

The invention discloses a non-phosphorus fountain solution which is characterized by comprising, by weight, 2-6 parts of 2-hydroxyethyl-beta-cyclodextrin, 1-4 parts of cetearyl glucoside, 1-4 parts of glycerol trioleate, 1-2 parts of terpineol, 1-3 parts of menthone, 0.5-1 part of tartaric acid, 1-3 parts of imidazolidinyl urea, 1-3 parts of sodium lauroamphoacetate, 1-2 parts of sodium xylene sulfonate, 0.5-1 part of benzalkonium chloride, 0.2-1 part of span 60, 5-10 parts of addition agents and 30-50 parts of water. The fountain solution contains no phosphorus, can effectively avoid the adverse effect of phosphorus containing materials on a device, is favorable for device maintenance and reduces cost; deterioration of water quality caused by phosphorus containing emissions is avoided, and the environmental protection requirements are met.

Owner:ANHUI SOYA DECORATIVE MATERIALS

Preparation method of vulcanized glyceryl trioleate and stainless steel tube drawing oil containing vulcanized glyceryl trioleate

InactiveCN107827795AAvoid pulling hairAvoid breakingOrganic compound preparationCarboxylic acid esters preparationPolymer scienceTriglyceride

The invention belongs to the field of metal processing production of lubricating oil, and particularly relates to a preparation method of vulcanized glyceryl trioleate and stainless steel tube drawingoil containing the vulcanized glyceryl trioleate. The vulcanized glyceryl trioleate prepared by the invention has excellent abrasion resistance and excellent extreme pressure property, and the requirements on abrasion resistance and extreme pressure property of the drawing oil can be met at the same time; the anti-abrasion stainless steel tube drawing oil is prepared by mixing diakyl pentasulfide, vulcanized triglyceride, calcium alkylbenzene sulfonate with high base number, dialkyl ammonium dithiophosphate, a phenolic antioxidant and an amine antioxidant, has excellent properties and characteristics of abrasion resistance, extreme pressure resistance, good lubricity, die protection and the like, and has a very good promotion and application value.

Owner:SHANDONG YUANGEN PETROLEUM CHEM

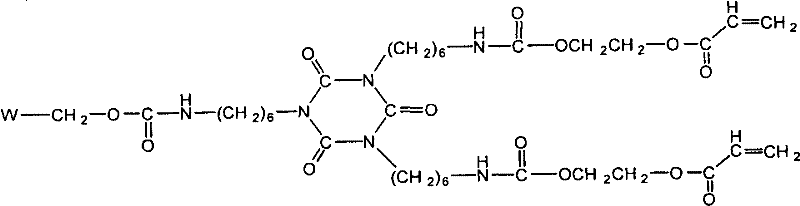

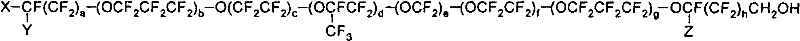

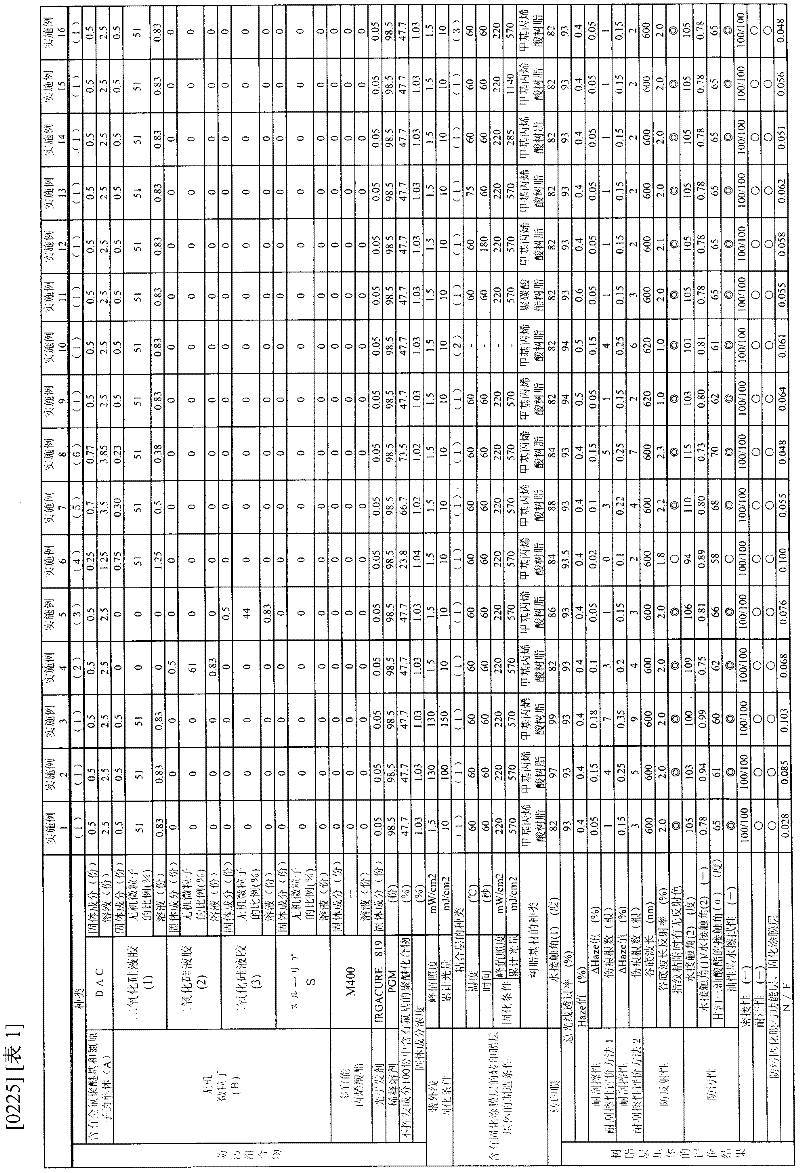

Transfer film, resin laminate, method for producing the transfer film, and method for producing the resin laminate

ActiveCN102648091AImprove hydrophobicityGood oleophobic effectSynthetic resin layered productsThin material handlingPerspirationHigh surface

Disclosed is a transfer film which uses a film having high surface tension and is provided with an antifouling layer by a wet process, and on which a functional layer such as an antireflection layer can be laminated. The transfer film is capable of providing a laminate that has excellent water repellency, oil repellency, transparency, abrasion resistance and perspiration resistance. Also disclosed is a method for producing the transfer film. Specifically disclosed is a transfer film which is obtained by laminating an antifouling cured film on the surface of a transparent base film. The transfer film is characterized in that the water contact angle (1) of a surface of the antifouling cured film, said surface being not in contact with the transparent base film, is 100 DEG or less, the water contact angle (2) of a surface of the antifouling cured film, said surface being in contact with the transparent base film, is 90 DEG or more, and the contact angle (a) thereof with triolein is 55 DEG or more.

Owner:MITSUBISHI CHEM CORP

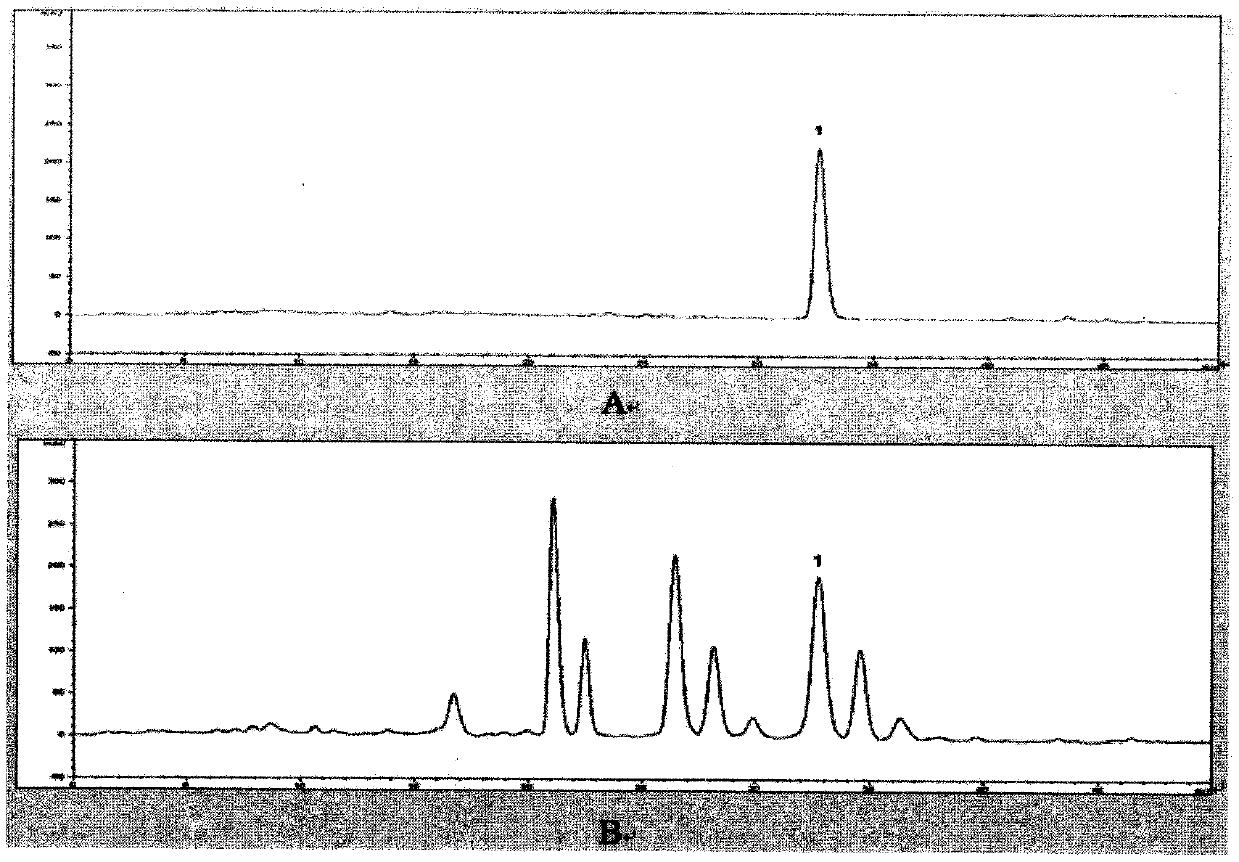

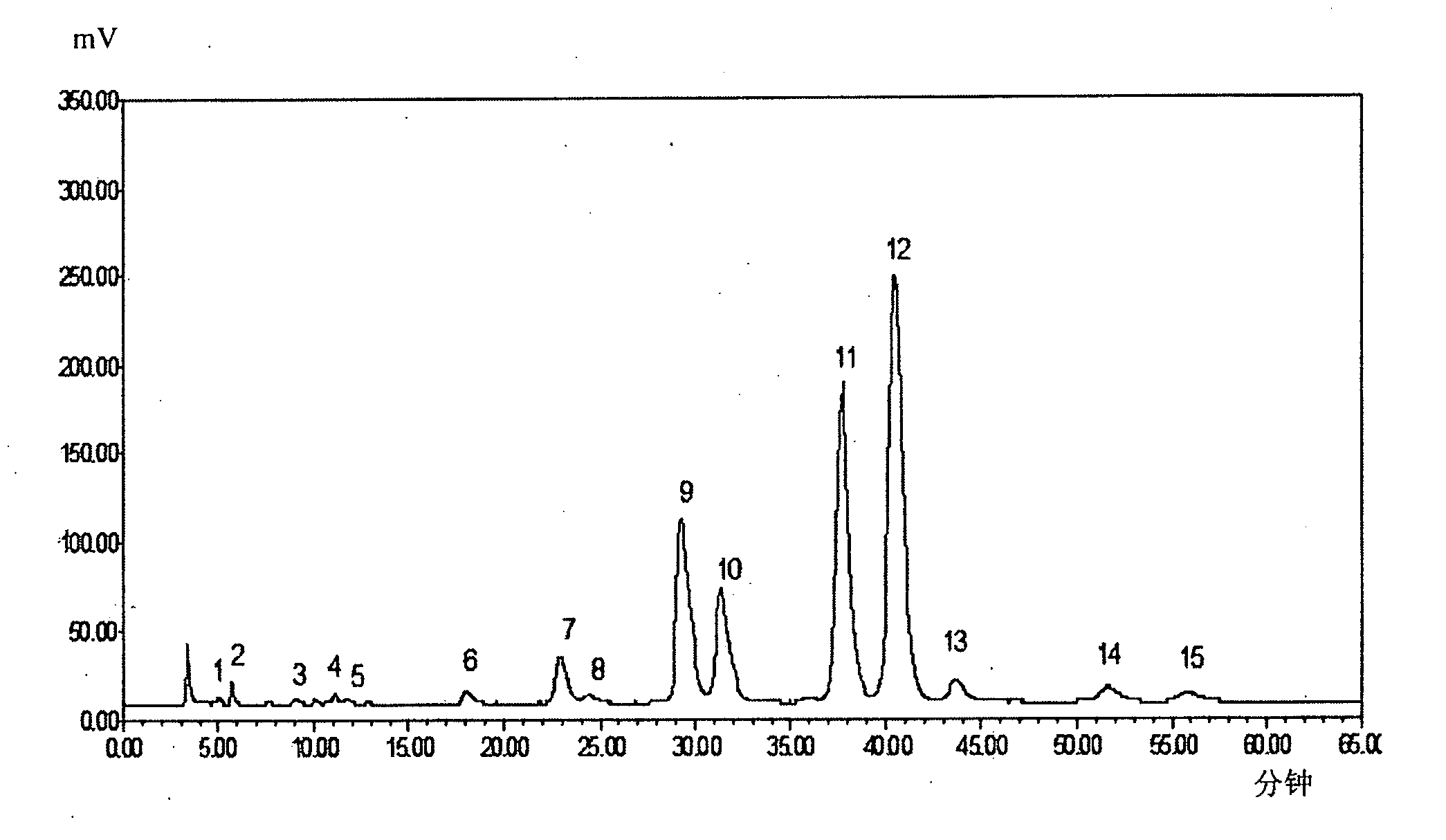

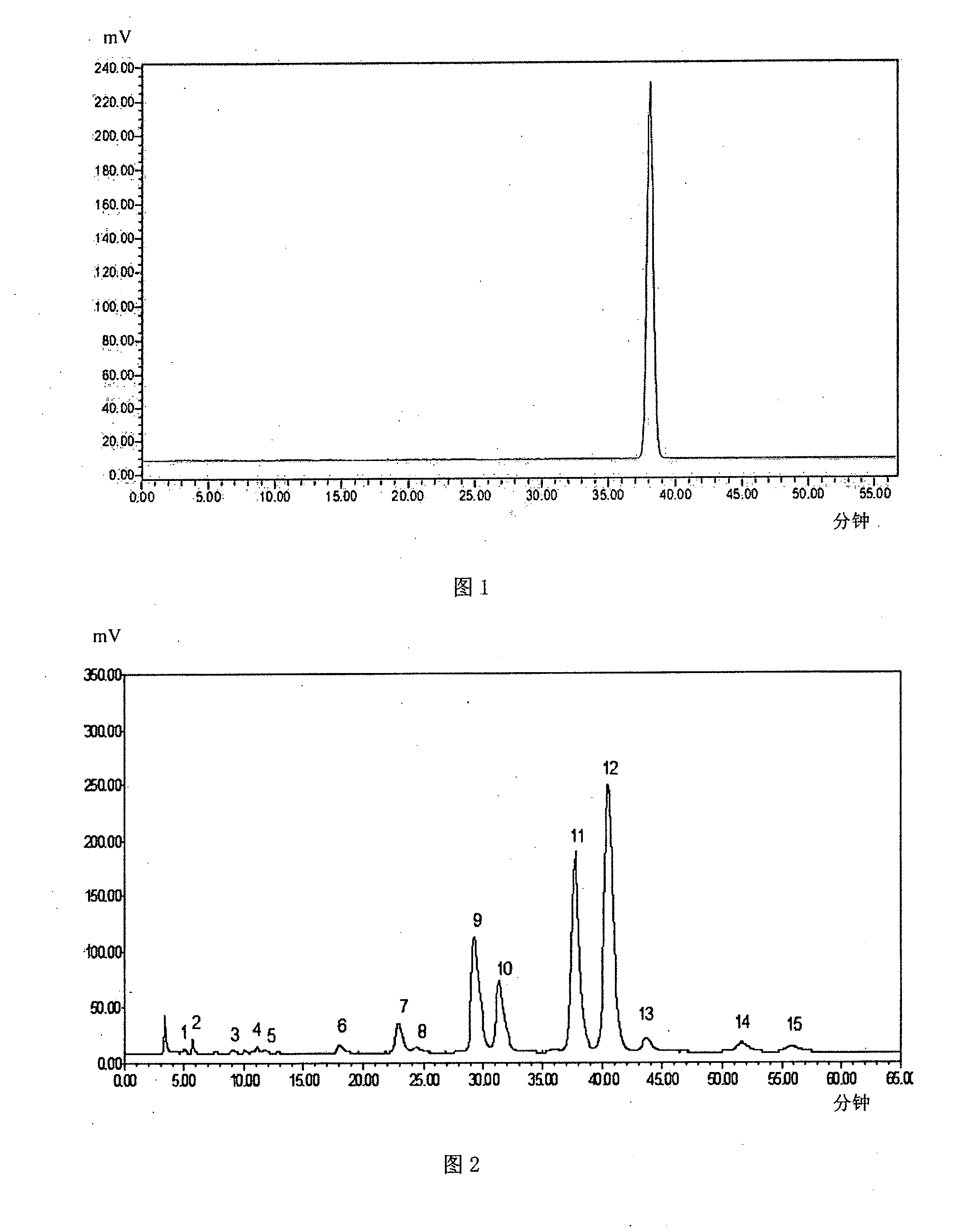

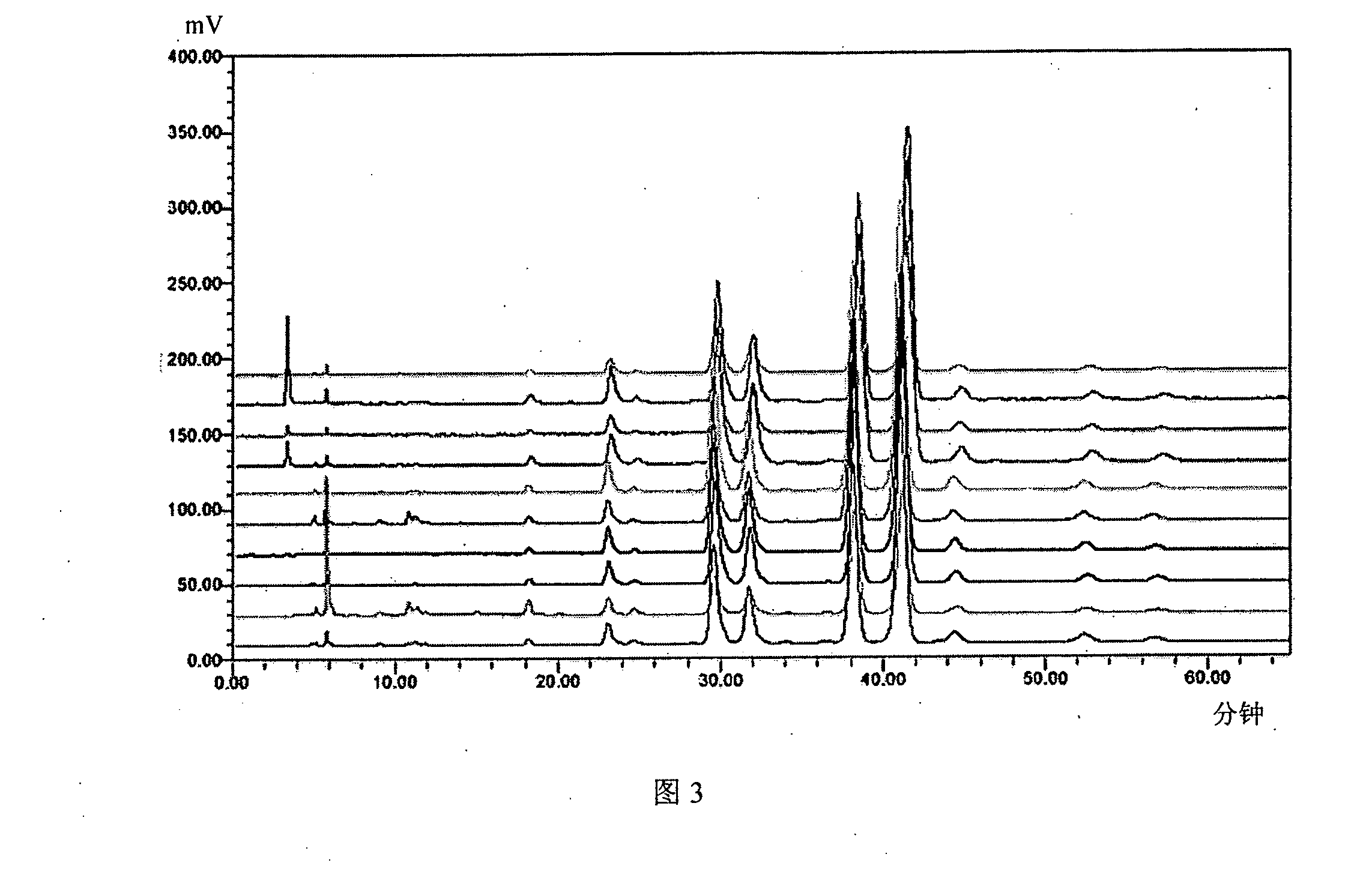

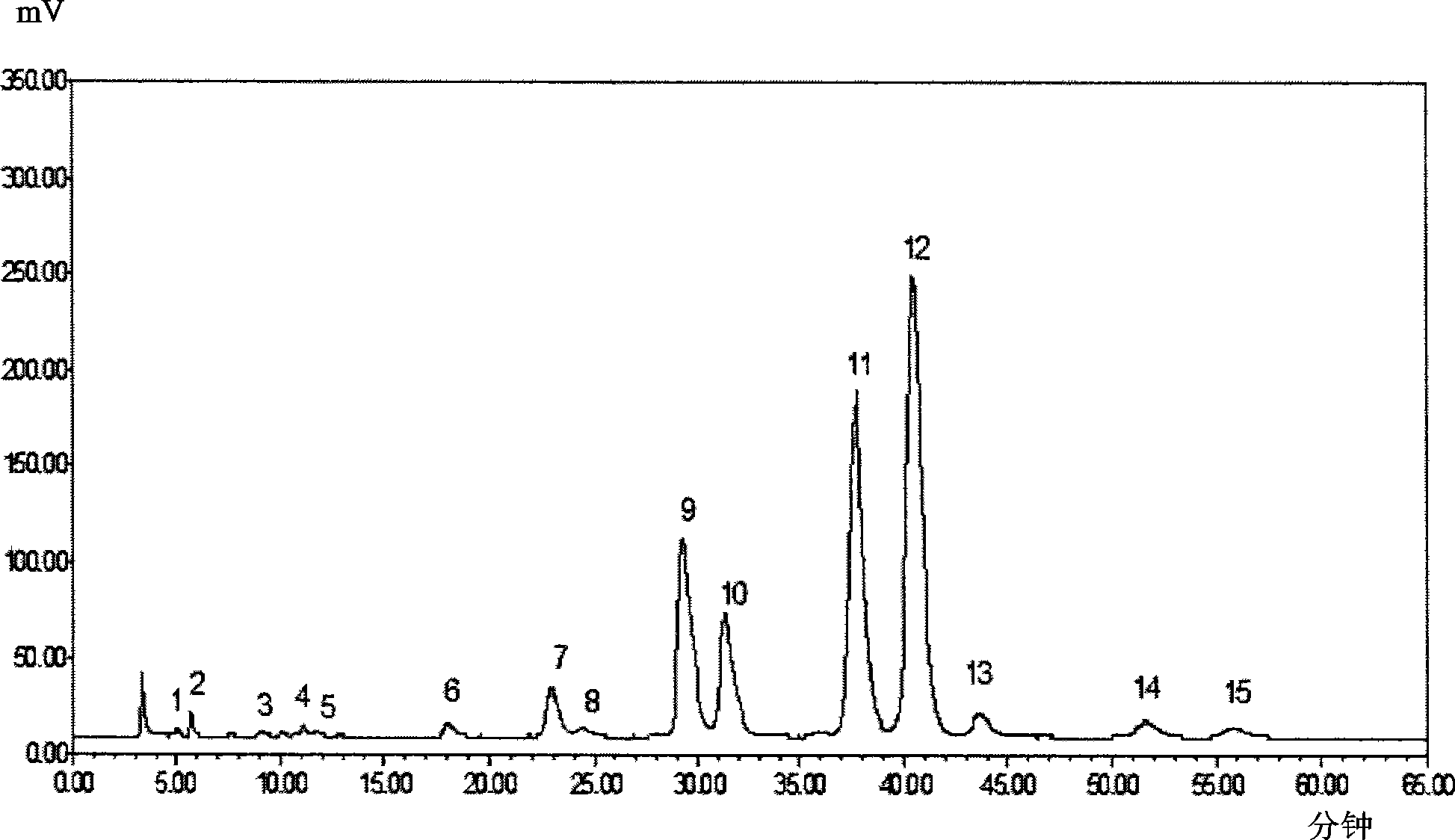

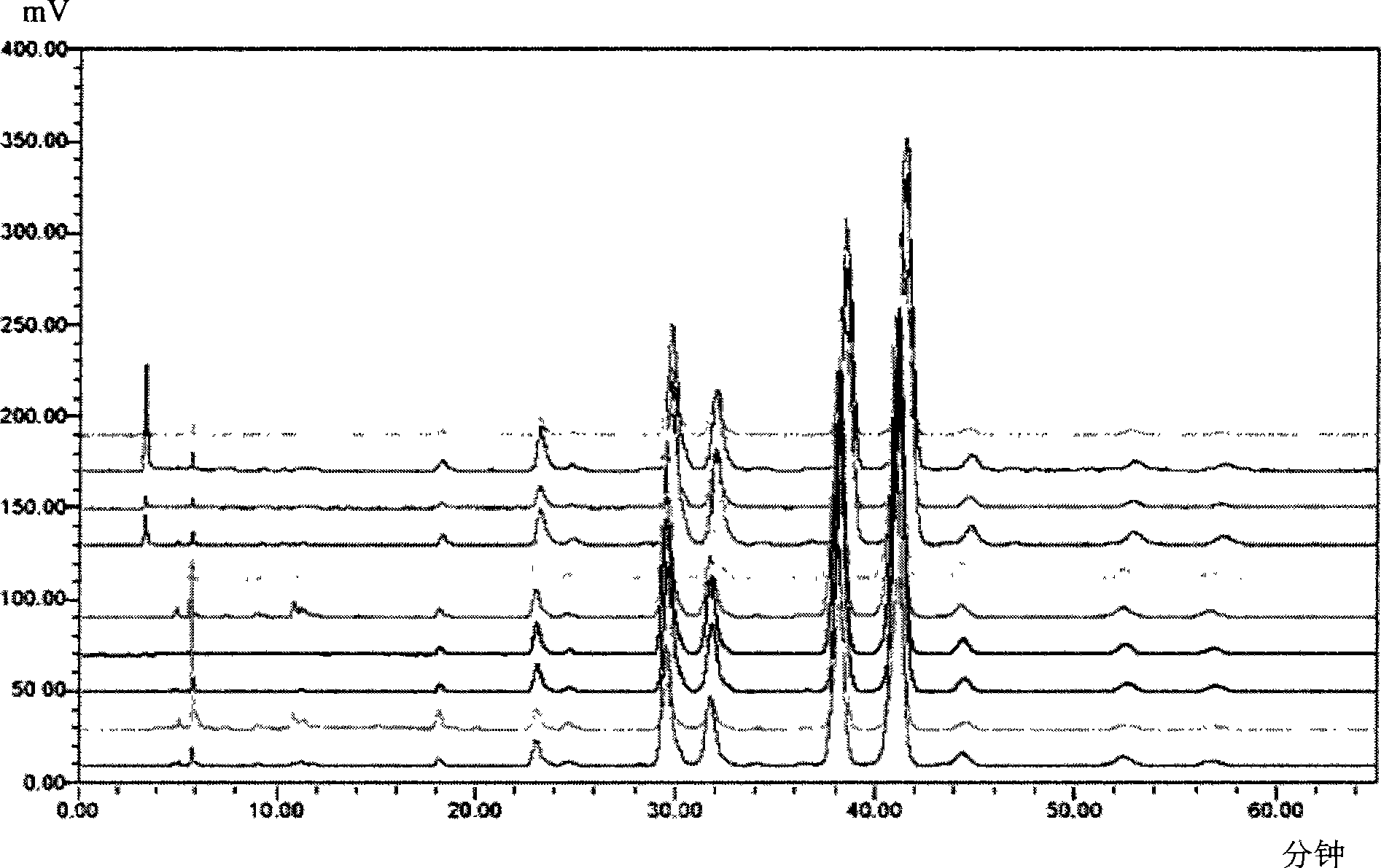

The quality control method and application of a kind of ganoderma lucidum spore oil fat emulsion

This invention discloses a kind of quality control method and application of Ganoderma lucidium spore oil fat emulsion. Which includes Ganoderma lucidium spore oil 2˜25%, emulsifier 0.5˜10%, isosmotic agent 0.2˜5%, the remaining content is water and the final pH of Fat emulsion is adjusted to 6˜9. The quality control method of this invention can accurately determine the content of 1,2-oleic-3-palmitic triglyceride and glycerol trioleate in the preparation, and accurately determine the ergosterol content, which serves as the method and basis for quality control of this product. Fingerprints are utilized to grasp the product quality from the overall characteristics of Chromatogram. This invention has clearly defined active ingredients, with excellent bioactivity, and is capable of tumor treatment, while improving the organism's immunity, as well as the life quality of tumor patients undergoing radiotherapy and chemotherapy, and relieving the drug toxicity after treatment. This invention is particularly suitable for both intra-arterial injection and intravenous injection, enabling the Ganoderma lucidium spore oil to directly gain access to the human blood circulation, with short time to onset and complete absorption as well as high security, reliable quality, and low drug toxicity.

Owner:GUANGZHOU HANFANG NATURAL MEDICINE RES & DEV

Method for controlling quality of ganoderma lucidum spore and ganoderma lucidium spore oil and their preparation

ActiveCN1850125ASimple methodEasy to operateComponent separationTesting medicinal preparationsSporeGanoderma pseudoferreum

The present invention relates to a method for controlling ganoderma spore, ganoderma spore oil and its preparation quality. It is characterized by that it utilizes high performance liquid chromatography to determine 1.2-oleinic acid-3-triglyceride palmitate and / or glycerin trioleate content. Every 1g of ganoderma spore, ganoderma spore oil or its preparation respectively contain 12.0 mg-60.0 mg and 100.0 mg-250.0 mg of 1.2-oleinic acid-3-triglyceride palmitate and / or 8.0 mg-45.0 mg and 80.0 mg-200.0 mg of glycerin trioleate.

Owner:GUANGZHOU HANFANG PHARMA

Leather brightening and stain removing agent

InactiveCN104356955ADelay aging oxidationIncrease brightnessSurface-active detergent compositionsDetergent compounding agentsPolymer scienceAcrylic resin

The invention discloses a leather brightening and stain removing agent, which is prepared from the following raw materials in parts by weight: 13 to 19 parts of glycerol trioleate, 6 to 10 parts of N-alkyl stearamide, 3 to 7 parts of a mildew preventive, 6 to 11 parts of nonylphenol polyoxyethylene ether, 3 to 8 parts of acetone, 7 to 13 parts of montan wax emulsion, 3 to 6 parts of propylparaben, 2 to 5 parts of ethanol, 1 to 5 parts of methyl hydrogen silicone oil, 2 to 8 parts of oleic acid, 1 to 3 parts of lavender essential oil, 4 to 10 parts of amino silicone oil and 2 to 10 parts of waterborne acrylic resin emulsion. The leather brightening and stain removing agent has the benefits of stains on the surface of leather can be well removed; meanwhile, a layer of protective film is formed on the surface of the leather, so that the aging and oxidation of the leather are retarded, and the brightness of the leather is improved.

Owner:QINGDAO KELIKE INFORMATION TECH

Ganoderma spore oil fat emulsion and quality control method and application thereof

InactiveCN101518551AActive ingredient clearImprove biological activityComponent separationPharmaceutical non-active ingredientsBiotechnologyImmunocompetence

The invention discloses ganoderma spore oil fat emulsion and quality control method and application thereof, comprising 2 percent to 25 percent of ganoderma spore oil, 0.5 percent to 10 percent of emulsifier, 0.2 percent to 5 percent of isotonic agent, and the rest of water; the final pH of the fat emulsion is adjusted to be six to nine. By accurately measuring the contents of 1, 2-oleic acid-3-palm acid triglyceride and glycerin trioleate as well as ergosterol in the preparation, the quality control method is used as the method and basis for controlling the product quality. By using a fingerprint, the product quality is controlled from the overall chromatographic feature appearance. The invention has clear product active ingredient and good biological activity, can be used for treating the tumor and enhancing the immune capacity of an organism, improves the survival quality of the radiotherapy and chemotherapy tumor patients and alleviates the drug toxicity after the treatment. The product is especially suitable for artery and intravenous injection; the ganoderma spore oil directly enters the human blood; and the product has the advantages of fast effect, complete absorption, high security, reliable quality and low toxicity.

Owner:GUANGZHOU HANFANG PHARMA

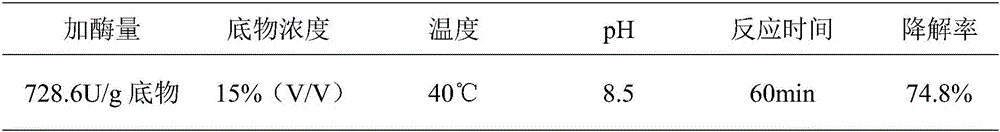

Method for treating papermaking white water by utilizing cutinase

The invention discloses a method for treating papermaking white water by utilizing cutinase and belongs to the technical field of enzyme engineering. The method disclosed by the invention adopts efficient and stable cutinase for carrying out enzyme catalytic decomposition on lipids such as glycerol trioleate and polyvinyl acetate, high temperature heating or vigorous stirring does not need to be carried out, reaction conditions are mild, and degradation rate can reach 83.5%, thereby being environment-friendly. Production of cutinase required by reaction is simple, and production efficiency is improved. Meanwhile, compared with other physical treatment, enzymatic method treatment is simple in steps, and in the actual white water treatment process, when the dose of cutinase is 0.5-1U per g substrate, better treatment effect also can be obtained, and turbidity difference reaches more than 95%. The white water treated by cutinase can be directly reused and partially or completely replaces cleaning water, so that closed circulation of papermaking system water is realized, and zero discharge in real sense is achieved. The advantages become especially important in the modern society with environmental protection taken seriously increasingly.

Owner:JIANGNAN UNIV

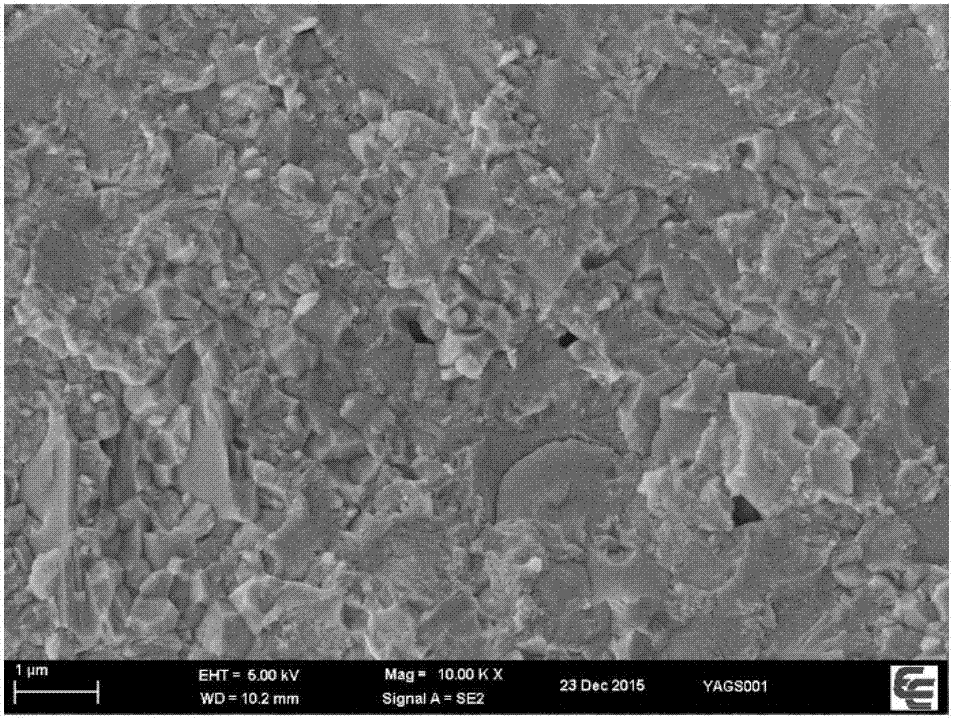

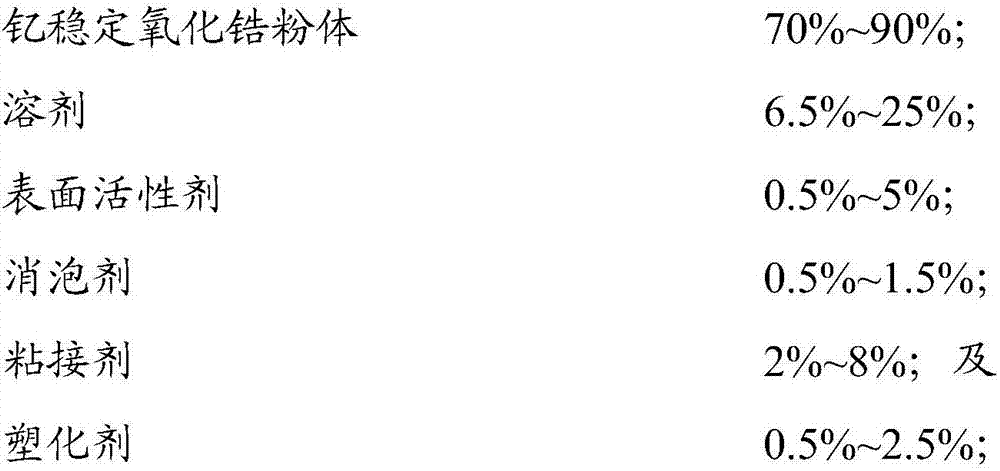

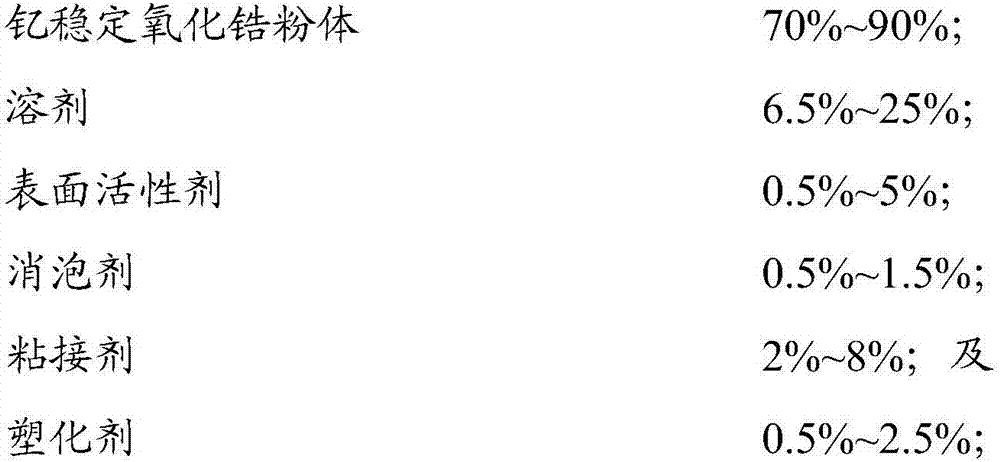

Yttrium-stabilized zirconia slurry, preparation method thereof and preparation method of yttrium-stabilized zirconia green body

The invention relates to yttrium-stabilized zirconia slurry, a preparation method thereof and a preparation method of a yttrium-stabilized zirconia green body. The yttrium-stabilized zirconia slurry comprises the following components in percentage by weight: 70-90% of yttrium-stabilized zirconia powder, 6.5-25% of a solvent, 0.5-5% of a surfactant, 0.5-1.5% of a defoaming agent, 2-8% of adhesive and 0.5-2.5% of a plasticizer, wherein the solvent comprises water and an inorganic solvent, the organic solvent is at least one of tertiary butyl carbitol acetate, n-propyl acetate, olive oil, glycerol, ethanol, hexanediol, isobutanol and terpilenol, percentage content of water in the solvent is 70-95%; and the surfactant is at least one of oleic acid, castor oil, methylacrylate, triethanolamine, glycerol trioleate, menhaden fish oil and acrylate copolymer ammonium salt. The yttrium-stabilized zirconia slurry is more environmentally friendly, and a moulding technology is relatively simple.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Anticorrosive filter paper and preparation method thereof

InactiveCN103334347ANot easy to corrodeImprove corrosion resistanceCorrosion-inhibiting/anti-oxidant agent additionFiltration separationPolyesterFiber

The invention relates to anticorrosive filter paper and a preparation method thereof. The anticorrosive filter paper disclosed by the invention is composed of the following raw materials by weight: 60-70 parts of reed pulp, 35-40 parts of waste paper pulp, 10-15 parts of glass fibers, 10-14 parts of polyester fibers, 2-4 parts of polyacrylamide, 2-3 parts of glycerol, 2-4 parts of nano diatomite, 2-3 parts of sepiolite powder, 1-2 parts of alum powder, 1-2 parts of glycerol trioleate, 1-2 parts of borax, 1-2 parts of sodium silicate, 0.7-1 part of 3-glycidoxypropyl trimethoxysilane, 0.2-0.5 part of urotropine, 4-5 parts of rosin, 10-12 parts of absolute ethyl alcohol, 1-2 parts of ethylene bis(stearamide), 5-7 parts of nano zinc oxide, 0.1-0.2 part of phenethyl phenol polyoxyethylene ether, 0.2-0.3 part of ammonium persulfate and a proper amount of water. The urotropine added in the formula has relatively good anticorrosive performance, so that the filter paper provided by the invention can be used under the environments of acid, alkali and salt, cannot be corroded easily and enlarges the application scope of the filter paper.

Owner:BENGBU PIONEER FILTER

Winebottle cap ABS plastic

The invention discloses a winebottle cap ABS plastic, which comprises the following materials by weight: 10-25 parts of high density polyethylene (HDPE), 5-8 parts of a toughening agent EOC, 10-25 parts of glycerol trioleate, 25-30 parts of polyvinyl ester, 1-9 parts of dimethyltin bis(isooctylmercaptoacetate), 55-85 parts of ABS, 5-9 parts of a plastic filling masterbatch, 5-7 parts of a toughening agent, 10-25 parts of polypropylene, 10-25 parts of linear low density polyethylene, 1-9 parts of white oil, 1-8 parts of a nucleating agent, 10-25 parts of a lubricant dispersant TAF, 1-5 parts of an effect pigment, 4-8 parts of tetrapentaerythritol ester, and 1-8 parts of phosphite triester. The winebottle cap ABS plastic provided in the invention has smaller ABS proportion, each bottle cap uses less ABD, the toughness and low temperature resistance are improved, so that the embrittlement problem of products caused by low temperature in winter can be solved, and cost is low.

Owner:青岛永卓真塑料制品有限公司

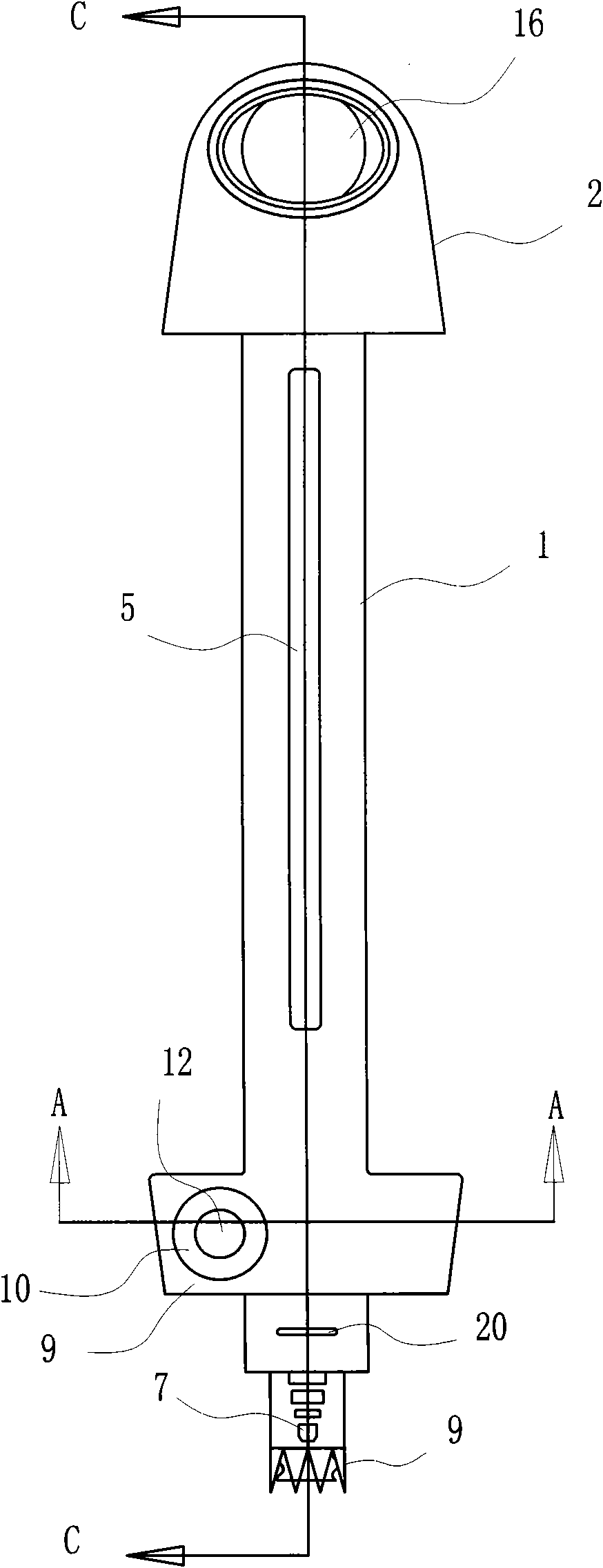

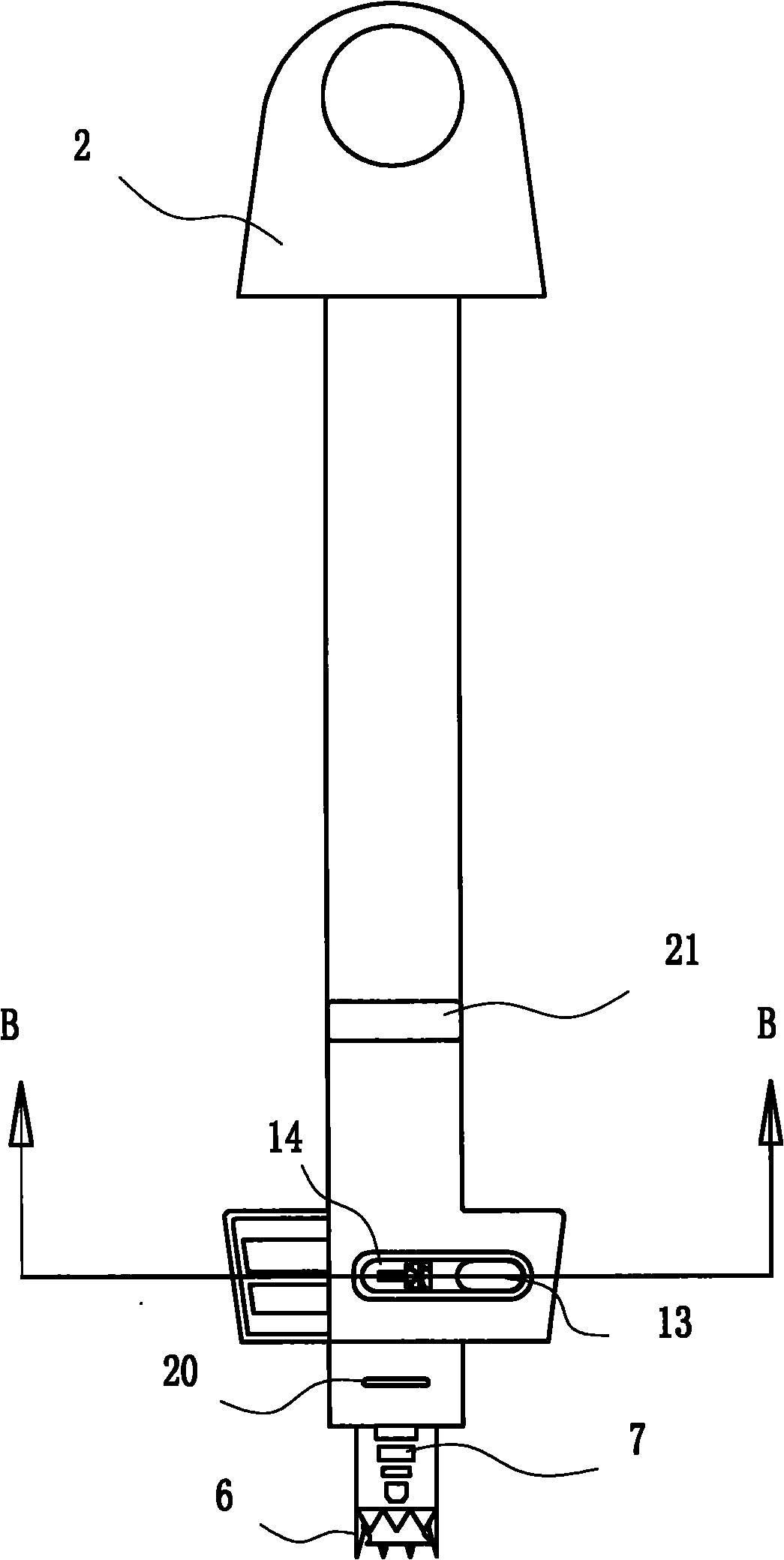

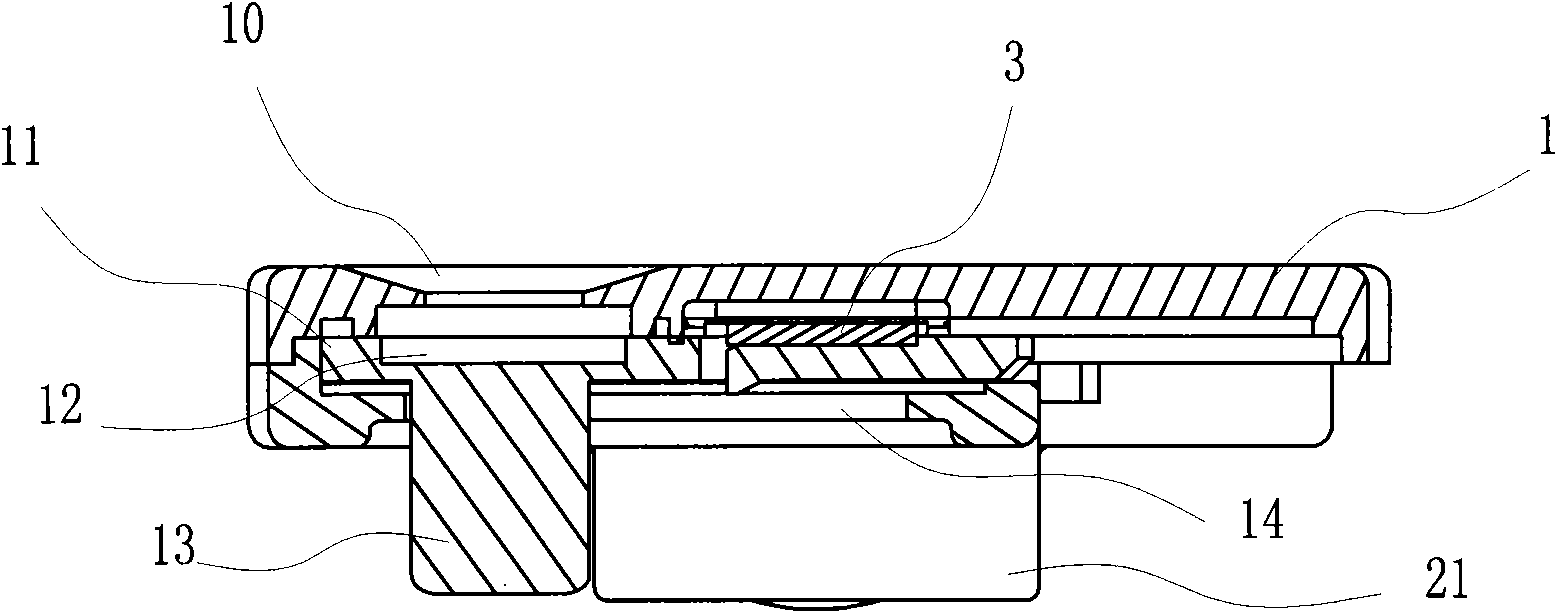

Chromatography type triglyceride self-measuring system

ActiveCN101819154AReal-time measurementSimple structureMaterial analysis by observing effect on chemical indicatorMagnesium saltTriglyceride

The invention discloses a chromatography type triglyceride self-measuring system which comprises a shell, a set of solution-guiding test paper, reaction test paper and color-developing test paper arranged in a cavity of the shell, a solution system and a solution feeding mechanism enabling the solution system to be in contact with the solution-guiding test paper. The main component of a solution in the solution system is a peroxidase solution, and the solution system can be arranged inside or outside the cavity of the shell; the shell is provided with a blood-taking hole, a receiving pad is arranged in the shell, and the receiving pad is provided with two working positions, namely a blood-taking position and a chromatography position; lipoproteinesterase and a substrate are arranged in the receiving pad, and the substrate is selected from glycerol, glycerol trioleate, serum containing triglyceride or plasma containing triglyceride; and the reaction test paper is fixedly provided with lipoprotein lipase, phosphoglycerol oxidase, glycerokinase, adenosine triphosphate and water-soluble magnesium salt. The chromatography type triglyceride self-measuring system can realize instant measurement of triglyceride in blood.

Owner:SUZHOU WELLBRIDGE BIOLOGICAL TECH CO LTD

Anti-abrasive material for automobiles

InactiveCN104479224AImprove rigidityImprove flame retardant performanceElastomerLinear low-density polyethylene

The invention discloses an anti-abrasive material for automobiles. The anti-abrasive material is prepared from raw materials in parts by weight as follows: isotactic polypropylene, rutile type titanium dioxide, linear low-density polyethylene, nanometer calcium sulfate, a POE elastomer, an antioxidant 1010, zinc stearate, zinc oxide, coumarone, an accelerator DM, ABS high-rubber powder, triallylisocyanurate, glycerol trioleate and an additive, wherein the additive is prepared from raw materials in parts by weight as follows: clay, an antibacterial agent, a flame retardant, a coupling agent, a heat stabilizer and a stiffening agent. The rigidity of the anti-abrasive material for the automobiles is improved, and the flame retardance and the water resistance of the anti-abrasive material are improved; meanwhile, the material has the high thermal deformation temperature, the low friction coefficient and the anti-abrasive capacity, is firm and durable, can satisfy specific use environment conditions and has a broad market application prospect.

Owner:CHANGSHU XINJILI METAL PROD

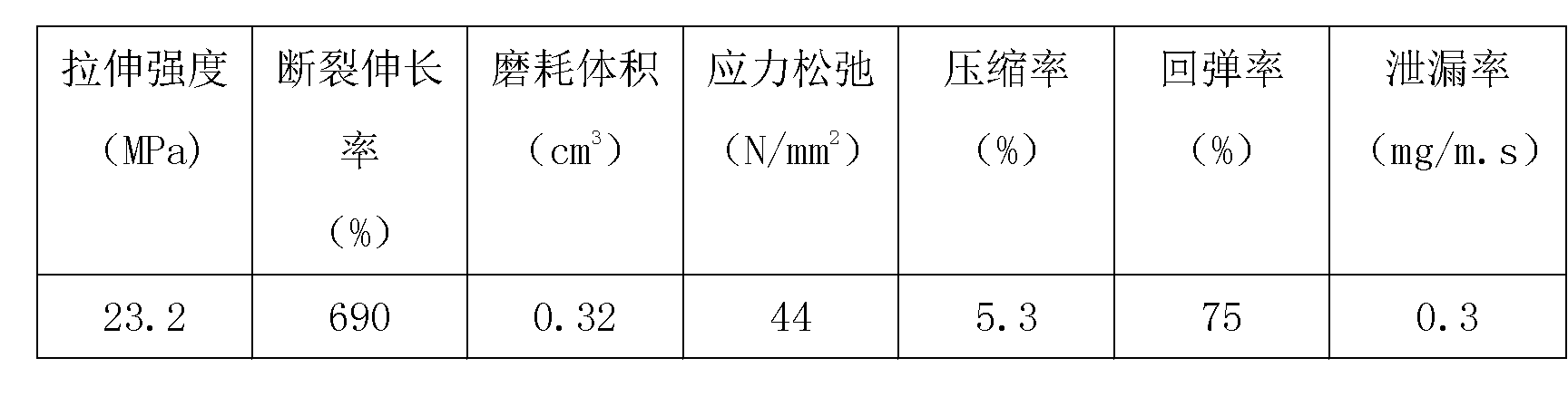

Rubber gasket material used for valves, and preparation method thereof

The invention discloses a rubber gasket material used for valves, and a preparation method thereof. The rubber gasket material comprises following raw materials, by weight, 80 to 90 parts of butadiene-acrylonitrile rubber, 12 to 15 parts of ethylene propylene diene monomer, 3 to 7 parts of zinc oxide, 5 to 8 parts of stearic acid, 2 to 5 parts of sulfur, 4 to 6 parts of DPSDSH, 0.5 to 1 part of promoter M, 1 to 2 parts of promoter TMTD, 10 to 12 parts of aluminium hydroxide, 1 to 2 parts of zinc stearate, 6 to 8 parts of glycerol trioleate, 2 to 4 parts of magnesium oxide, 1.2 to 1.4 parts of anti-scorching agent CTP, 15 to 18 parts of N220 carbon black, 30 to 35 parts of N351 carbon black, and 10 to 12 parts of modified attapulgite. According to the rubber gasket material, modified attapulgite is added, so that processing properties of the rubber gasket material are improved; and environmental friendly accessory ingredients are used, so that toxic and side effects are reduced, and pollution on the environment is reduced. Sealing performance of the rubber gasket material is excellent, formula is reasonable, technology is simple, cost is low, and the rubber gasket material possesses excellent aging resistance and corrosion resistance.

Owner:蚌埠赛英电子科技发展有限公司

Low-temperature-resistant high impact PVC (polyvinyl chloride) tubular product and preparation method thereof

The invention discloses a low-temperature-resistant high impact PVC (polyvinyl chloride) tubular product and a preparation method thereof. The low-temperature-resistant high impact PVC tubular product is prepared from the following raw materials in parts by weight: 38-54 parts of SG-7 type PVC resin, 22-36 parts of ACS resin, 10-15 parts of polyurethane thermoplastic elastomer, 11-17 parts of graphite, 6-9 parts of polytetrafluoroethylene micro powder, 12-16 parts of carbon nanofibers, 10-15 parts of tetraethylene glycol diheptylate, 8-12 parts of glycerol trioleate, 4-6 parts of oxidized polyethlene wax, 5-10 parts of dioctyl azelate, 10-15 parts of triethylene glycol di-2-ethylhexoate, 3-5 parts of ethylene bis stearamide, 14-18 parts of aluminum powder, 15-20 parts of fumed silica, 5-10 parts of sludge dry powder, 10-15 parts of pelelith powder, 2-3 parts of lead cyanurate, 1-2 parts of a calcium-zinc composite stabilizer, 10-15 parts of composite nano powder, 1.5-2.5 parts of tri(sulfydryl ethyl ester stearate) antimony, 1-2 parts of an antioxidant 1035, and 1-2 parts of an antioxidant 168. The PVC tubular product has the characteristics of low temperature resistance, high impact strength and high toughness; on the premise of the high impact strength, the low-temperature resistance and the toughness of the PVC tubular product are greatly improved, so that the tubular product can be normally used for a long time at (-)50 DEG C, and thus, the service life of the PVC tubular product is prolonged.

Owner:RUIZHAN TONGLING TECH

Polypropylene fiber finisher

The present invention discloses a polypropylene fiber finisher, which comprises dioctyl sebacate, mineral oil, glycerol trioleate and polyethylene glycol (400) dilaurate. The polypropylene fiber finisher of the present invention has characteristics of reasonable formula, good use effect and low production cost.

Owner:朱品桥

Polymeric films

ActiveUS8410200B2Suitable for useFibre treatmentSynthetic resin layered productsMolten statePolymer science

Owner:PLANTIC TECH

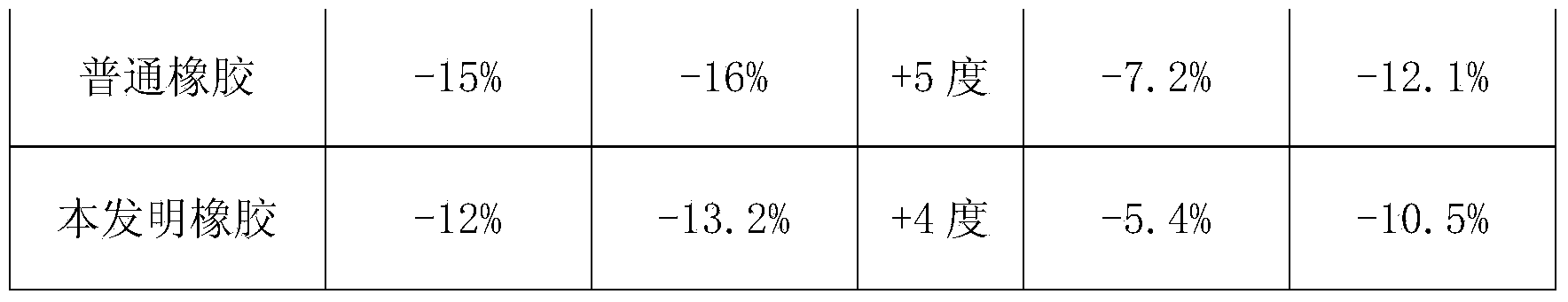

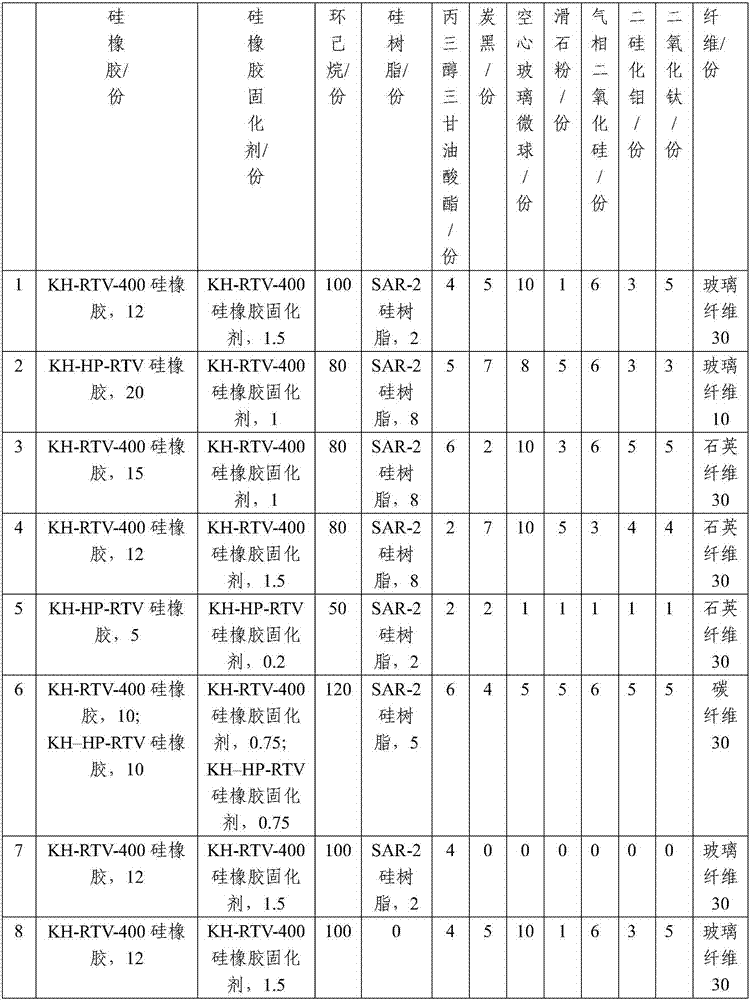

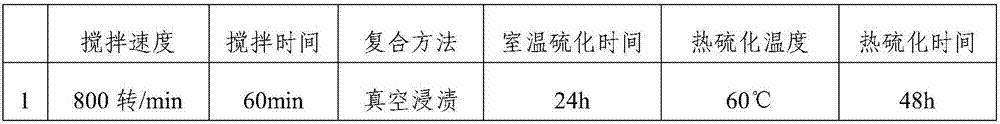

Sealing material with high temperature resistance and high rebound resilience and preparation method of sealing material

ActiveCN107177205AImprove high temperature resistanceImprove temperature resistanceFiberThermal insulation

The invention relates to a sealing material with high temperature resistance and high rebound resilience and a preparation method of the sealing material. The sealing material is prepared from following components in parts by weight: a component A, a component B and 10-30 parts of fibers, wherein the component A contains 5-20 parts of silicone rubber, 2-8 parts of silicon resin, 0.2-1.5 parts of a silicone rubber curing agent, 2-6 parts of glycerol trioleate and 50-120 parts of cyclohexane, and the component B contains 2-7 parts of carbon black, 1-5 parts of talcum powder, 1-6 parts of fumed silica, 1-10 parts of hollow glass microspheres, 1-5 parts of molybdenum disilicide and 1-5 parts of titanium dioxide. The rubber sealing material is resistant to the temperature of 450 DEG C or higher, and temperature resistance level of the sealing material is better than that of an existing thermal sealing material; furthermore, the sealing material can meet the high-rebound deformation thermal sealing demands in multiple coupling work states such as temperature, pressure, vibration, displacement and the like, and strain rebound response time is short; besides, the sealing material has good thermal insulation performance.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com