Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

101results about How to "Volatile evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electroplating effect imitated plastic paint and preparation method, diluent and process of using same

The invention discloses a plastic paint with simulated electroplating effect. The composition and the weight ratio of the invention are as follows: 30 to 45 of acrylic resin with 50 percent of solid content and 70 to 90 DEG C of Tg, 20 to 30 of cellulose acetate butyrate with 20 percent of solid content, 8 to 12 of triad copolymer vinyl chloride-acetate resin with 30 percent of solid content, 6 to 10 of non-floating aluminum and silver pulp with an average diameter less than or equal to 20 Mum, 0.3 to 0.5 of dispersant, 0.2 to 0.4 of flatting agent, 0.4 to 0.6 anti-settling agent, 6.0 to 10.0 of toluene, 3.5 to 6.0 of ethyl acetate, 3.5 to 6.0 methy isobutyl ketone, 3.0 to 5.0 of isobutanol and 4.0 to 7.0 of glycol butyl ether. The special diluent of the invention, according to the weight ratio, is made from the following components evenly mixed: 20 of white gas, 10 of toluene, 22 of ethyl acetate, 15 of acetone, 25 of isobutanol and 8 of glycol butyl ether. The main paint which comprises the composition and the diluent are evenly mixed according to the ratio of 1: 2-3, then the mixture is used for spray coating; the metallic appearance of the paint film obtained is very close to the effect of the electroplating, and the paint film has good alcohol resistance with high hardness and strong wear resistance, and also has simple process. The aluminum and silver pulp used is a common type, the cost of which is only 5 percent to 10 percent of the simulated electroplating aluminum and silver pulp and about 2 percent of electrosilvering.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

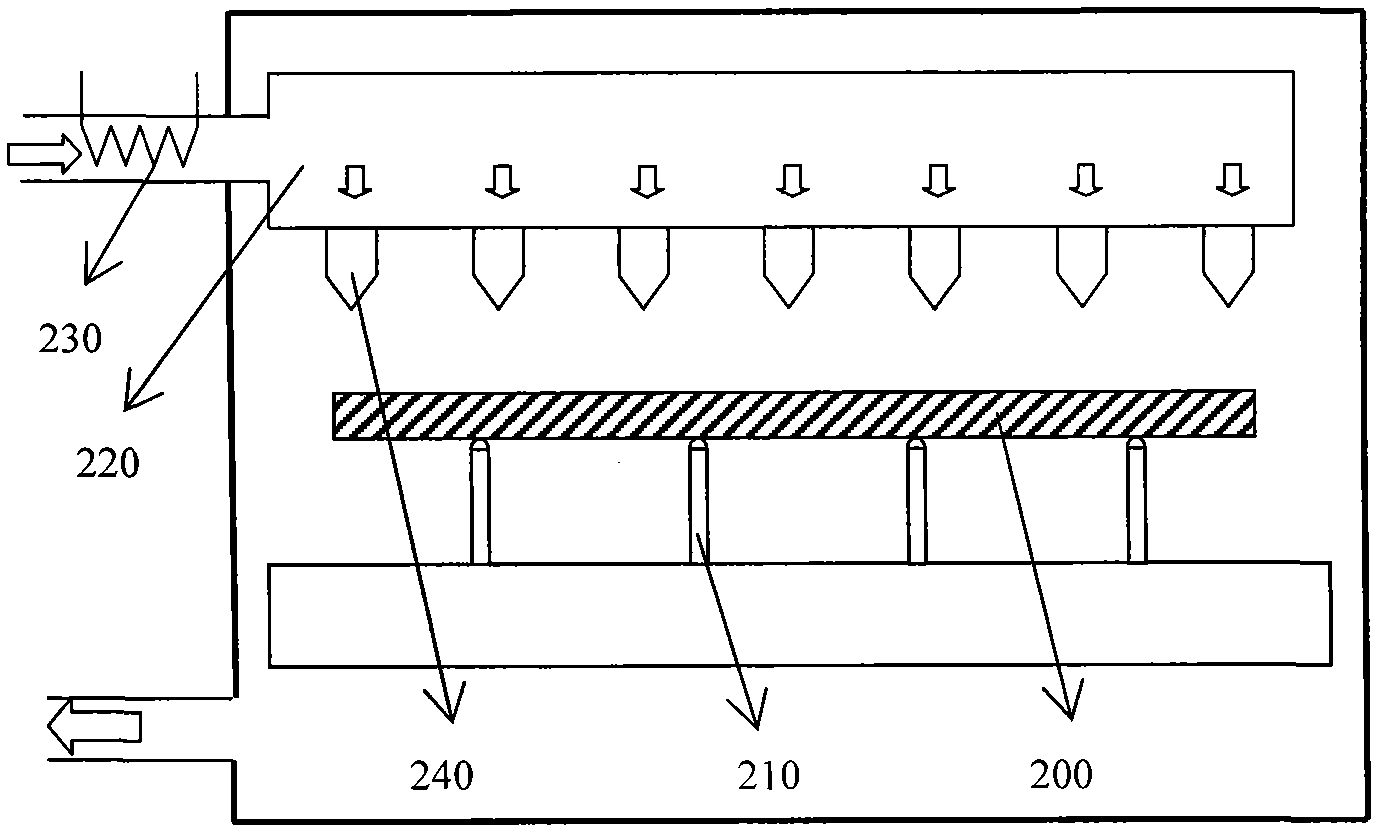

Alignment film drying device and method

InactiveCN102085511AEvenly heatedQuality improvementDrying solid materials with heatPretreated surfacesFilm materialLiquid crystal

The invention provides an alignment film drying device and method which are used for drying an alignment film material which is formed on a first surface of a substrate and diluted by a solvent. The device comprises a heating table, a peripheral support mechanism, multiple support pins and a lifting mechanism, wherein the heating table is used for heating a second surface of the substrate, and multiple air holes are uniformly distributed on the heating table; the peripheral support mechanism is arranged around the heating table and used for supporting the edge of the second surface of the substrate; the multiple support pins are uniformly distributed in the upper surface of the heating table; and the lifting mechanism controls the periphery support mechanism and the support pins to perform lifting. According to the invention, the phenomenon of drying non-uniformity in the drying process of the alignment film can be eliminated, the quality of the alignment film is optimized, the display characteristics of a liquid crystal panel are enhanced, and the quality and acceptability of the liquid crystal panel are improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

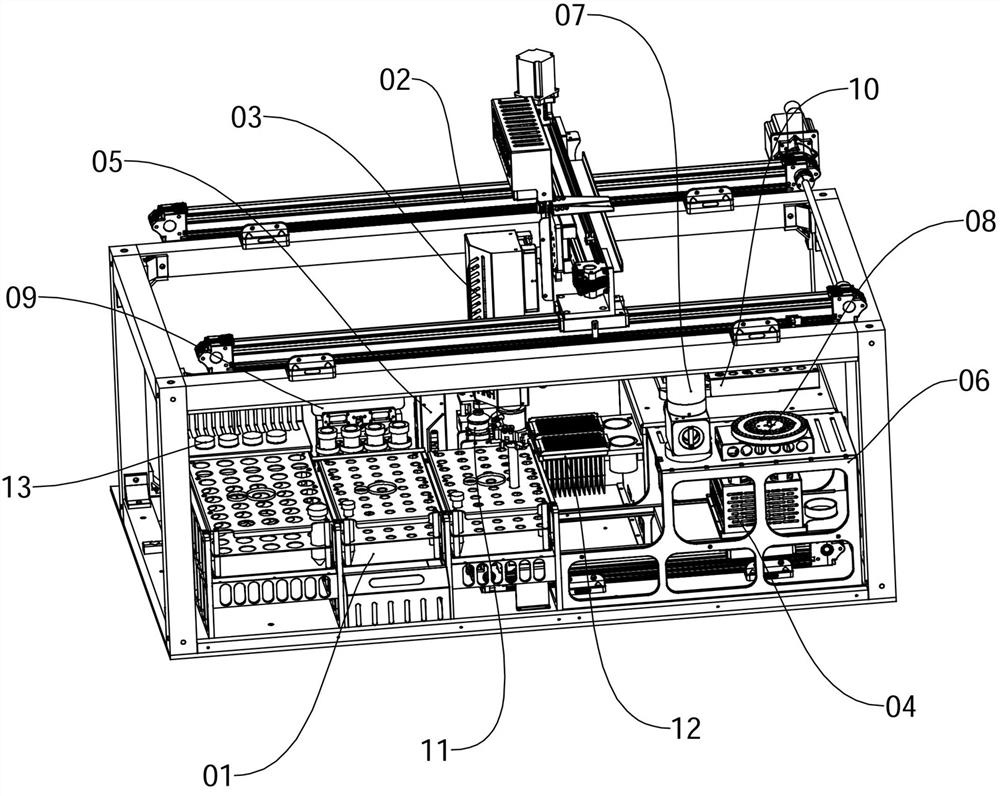

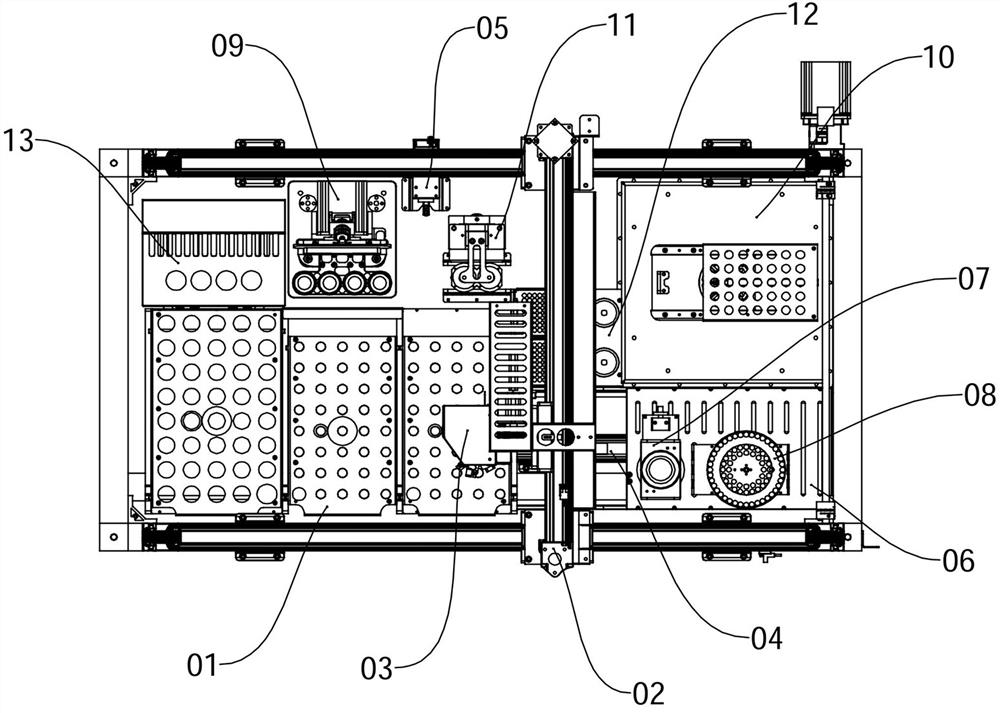

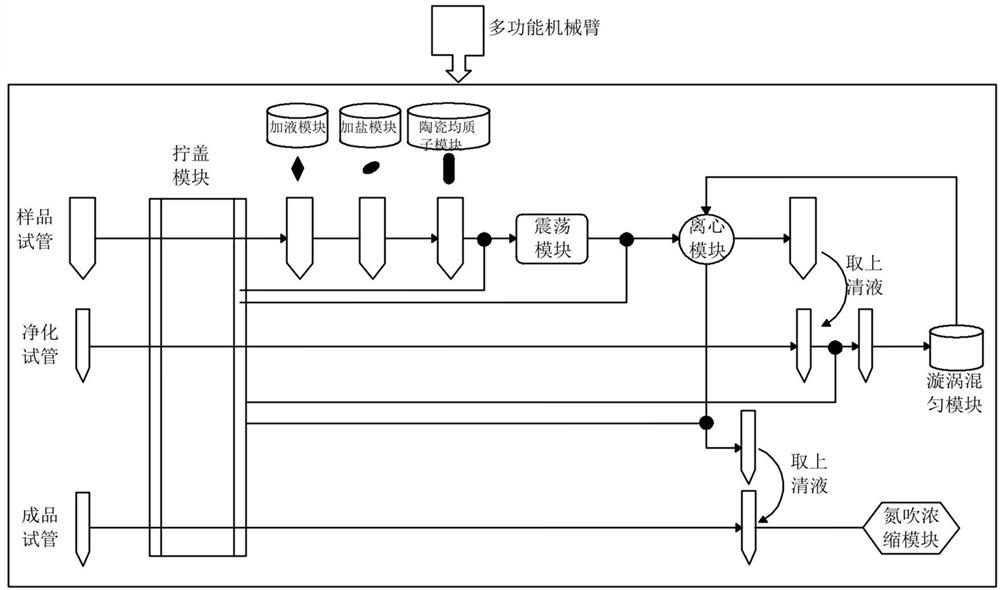

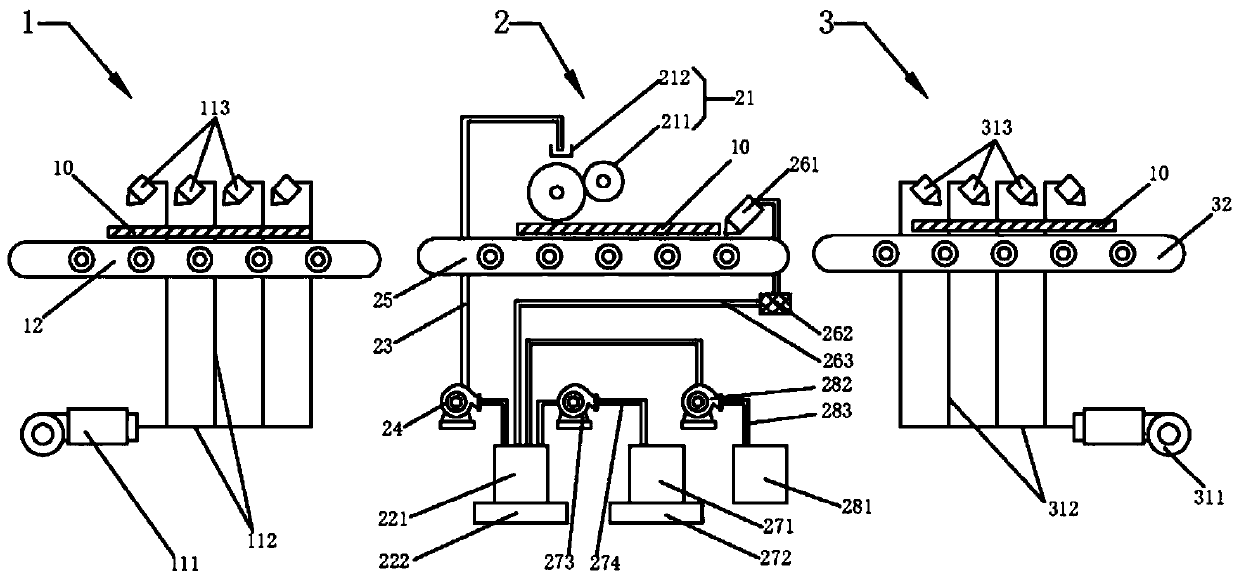

Full-automatic QuECHERS experimental device and experimental method

ActiveCN112198324AHigh degree of experiment automationImprove experimental efficiencyPreparing sample for investigationExperimental methodsSolid phase extraction

The invention discloses a full-automatic QuECHERS experimental device and an experimental method. The full-automatic QuECHERS experimental device comprises a multifunctional mechanical arm, a cap screwing module, a liquid adding module, a centrifugal module, a salt adding module, a ceramic proton homogenization module, a nitrogen blowing concentration module, a vortex uniform mixing module and anoscillation module, and can automatically complete sample transferring, addition of extraction liquid, extraction salt and ceramic homogenization protons, oscillation uniform mixing, centrifugal separation and vortex uniform mixing actions; A method adopting the full-automatic QuECHERS experimental device to carry out experiments mainly integrates the processes of sample liquid adding extraction,centrifugal separation, solid phase extraction and nitrogen blowing concentration, so that the time is saved, the manual operation is reduced, the automation is improved, and the errors are reduced.

Owner:BEIJING HUIRONGHE TECH

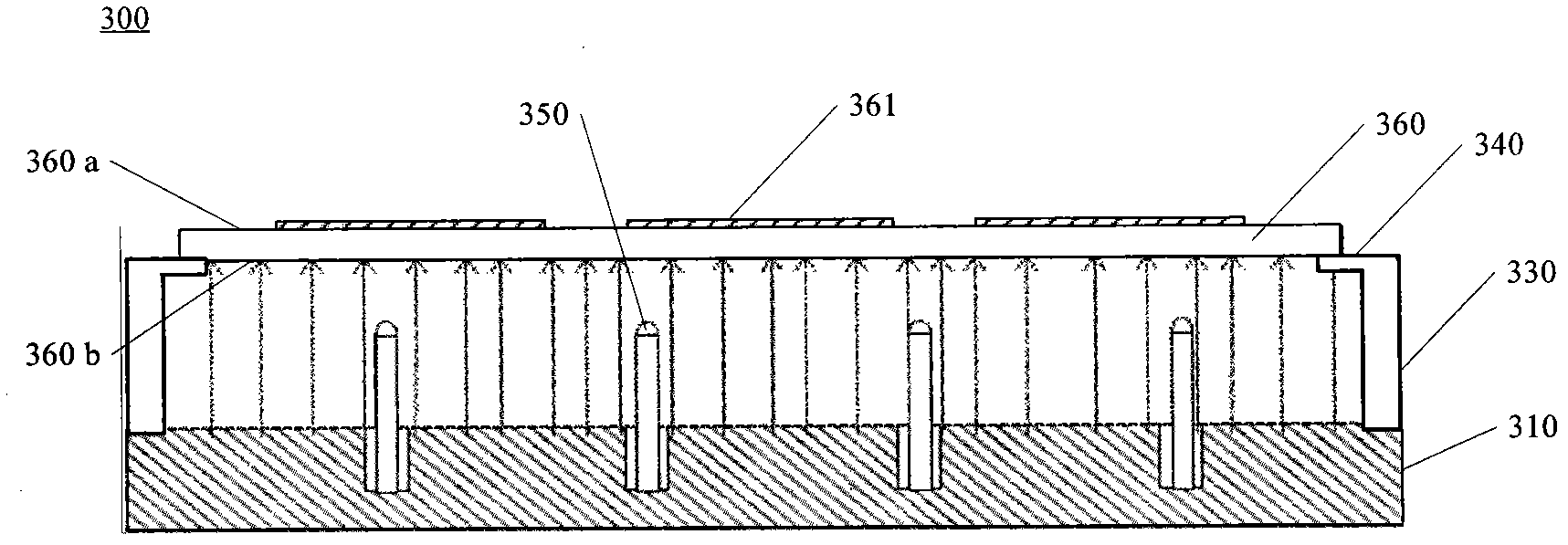

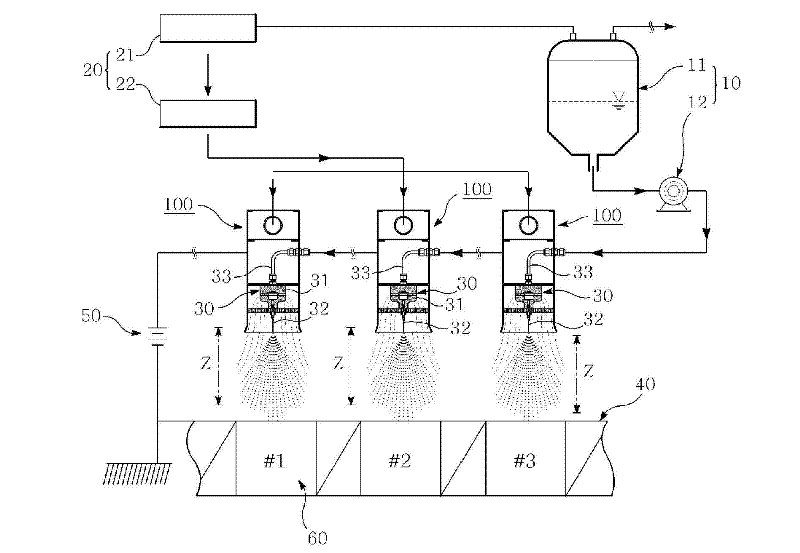

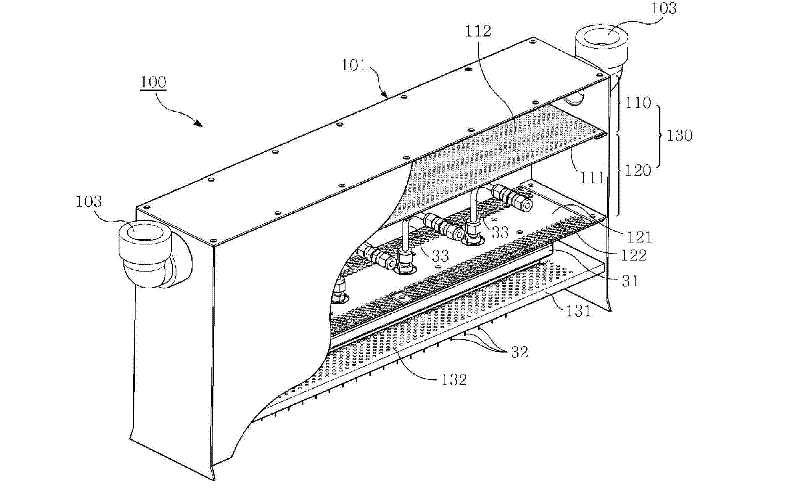

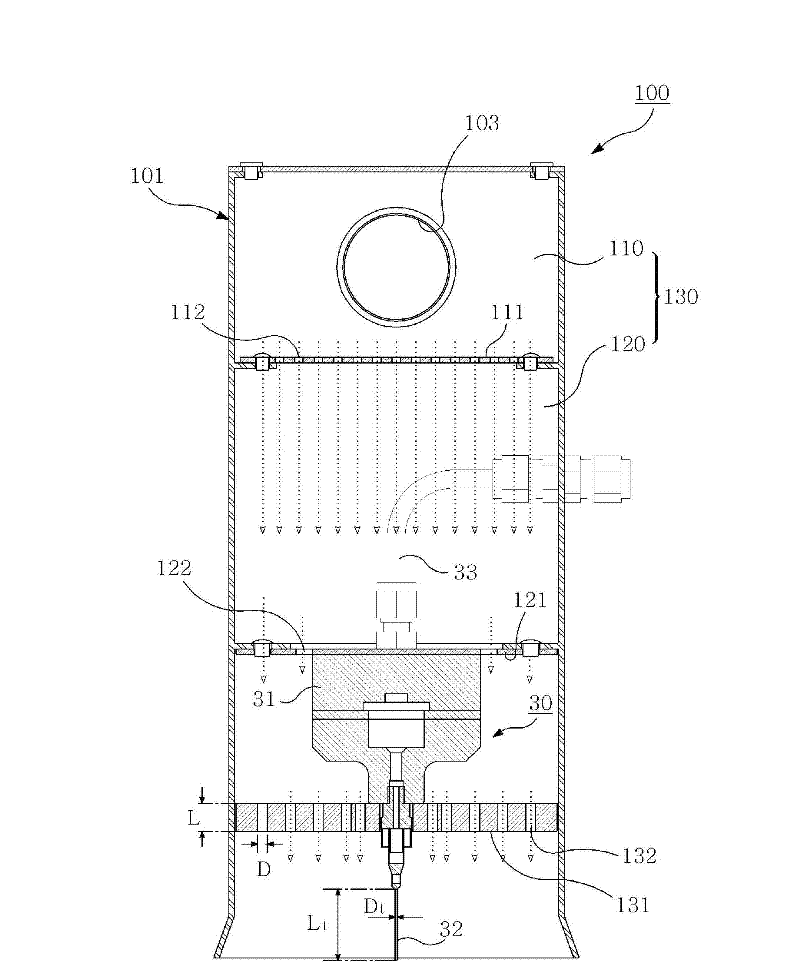

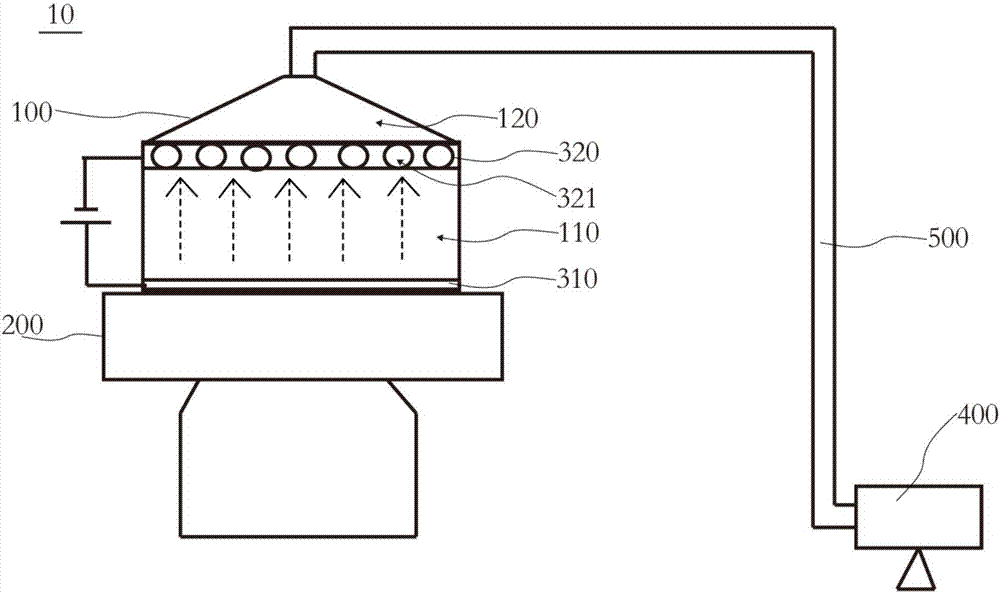

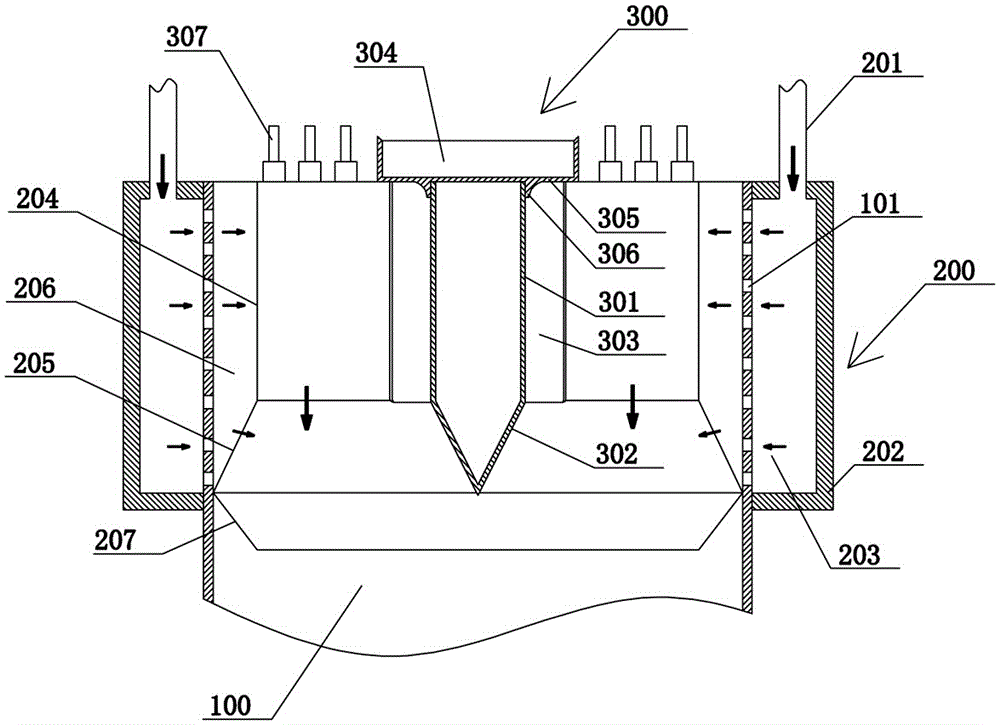

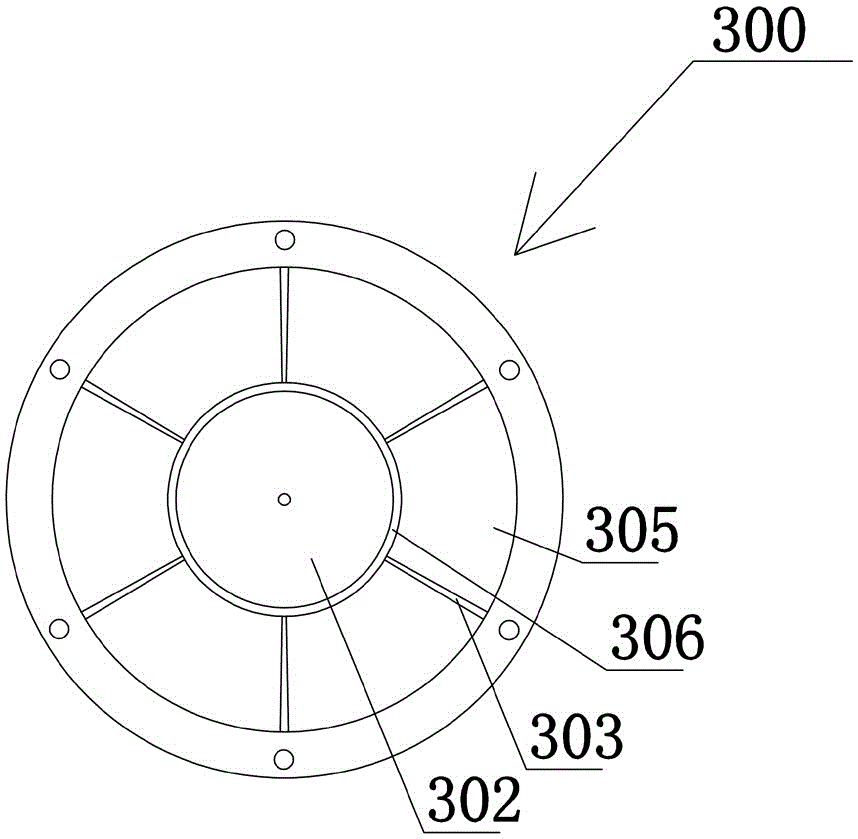

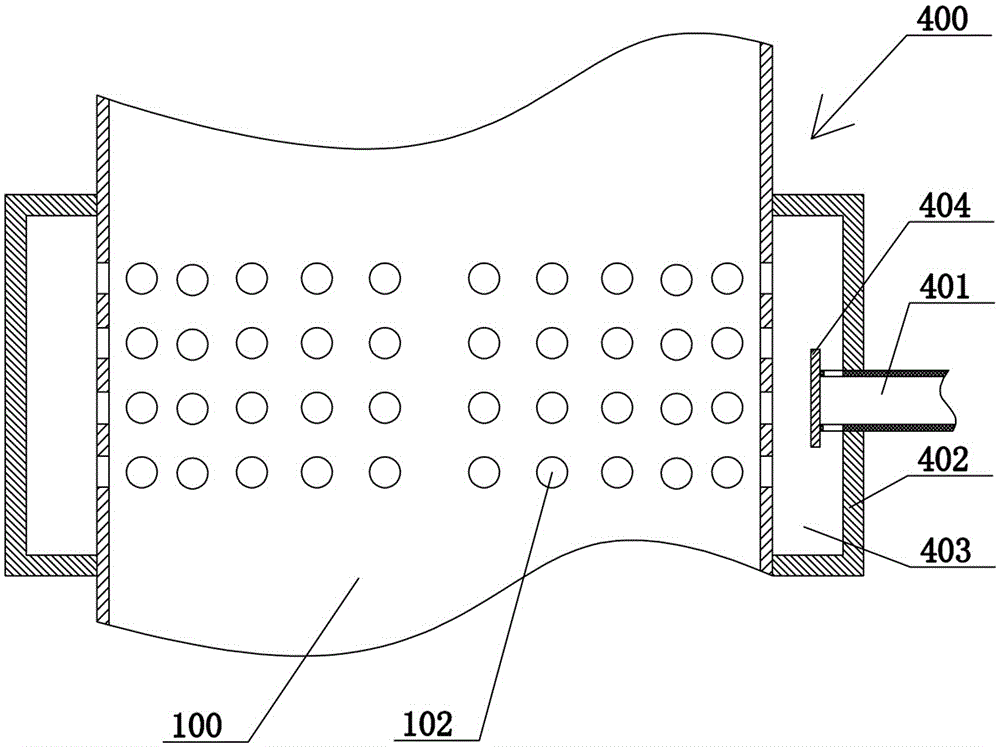

Electrospinning apparatus for producing nanofibres and capable of adjusting the temperature and humidity of a spinning zone

InactiveCN102597341AUniform diameterVolatile evenlySpinnerette packsMelt spinning methodsFiberNanofiber

The present invention relates to an electrospinning apparatus for producing nanofibers, comprising: a spinning solution supply unit (10); a spinning unit (30) including a plurality of spinning nozzles (32), and a nozzle block (31) in which the spinning nozzles (32) are equidistantly arranged and supported; a nanofiber-collecting unit (40) which collects nanofibers spun from the spinning unit (30); a power supply (50) which forms an electric field in a spinning zone (Z); a process gas supply unit (20) which generates and supplies process gas to control the temperature and humidity of the spinning zone (Z) to a range appropriate for the electrospinning conditions for nanofibers; and a process gas laminar flow distribution device (100) which divides the process gas supplied from the process gas supply unit (20) into laminar flows within the process gas laminar flow distribution device (100), and distributes the process gas from an upper portion of the spinning unit (30) to the spinning zone (Z).

Owner:FIBRANE

Large power thick film circuit resistance paste of stainless steel substrate and preparing method thereof

InactiveCN101038797AImprove bindingVolatile evenlySolid-state devicesSemiconductor/solid-state device manufacturingSolid componentAdhesive

The invention relates to a large-power thick-film circuit resistor sizing agent based on a stainless steel substrate and a manufacturing method thereof. The invention provides a resistor sizing agent with a low resistance, excellent insulative performance, printing characteristic and burning characteristic, and which is matched with an insulated stainless steel substrate. The manufacturing method of the invention comprises: A, manufacturing glass powders; B, preparing an organic adhesive; C, concocting the sizing agent: concocting a solid component of silver powers, palladium powers and crystallite glass powers in proportion, arranging the solid component and the organic adhesive in a milling pot in proportion, and milling the solid component and the organic adhesive in the milling pot. The invention selects crystallite glass as binding phase, an expanding coefficient of a resistor track layer of the invention is matched and combined with a stainless steel well; the resistor track layer of the invention has advantages of low resistance, compatible with medium mateiral used of the thick film circuit of the stainless steel substrate and electrode sizing agent, and good conductive performance, etc.

Owner:吴胜红 +1

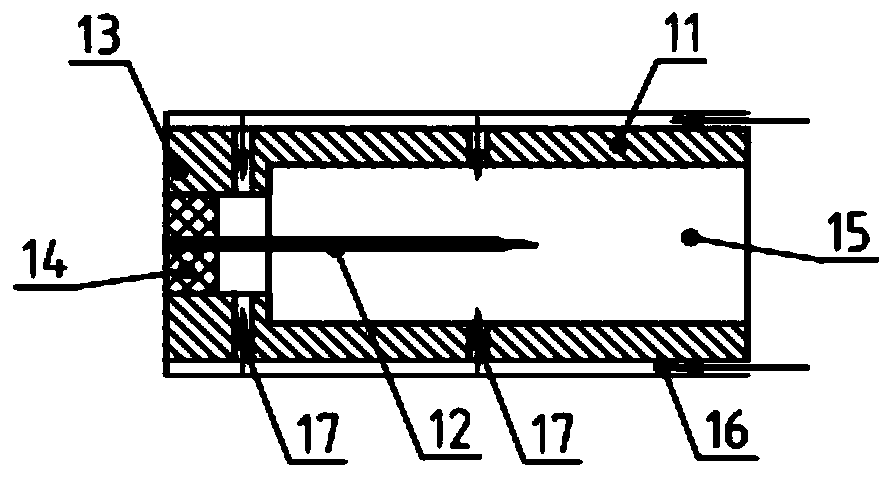

Coaxial heating chamber and electronic cigarette device with coaxial heating chamber

PendingCN110141002AHeating evenlyThere will be no local high temperatureTobacco devicesElectrical conductorElectronic cigarette

The invention discloses a coaxial heating chamber and an electronic cigarette device with the coaxial heating chamber. The electronic cigarette device with the coaxial heating chamber includes a coaxial heating chamber which is formed by the fact that an outer conductor chamber is regarded as a chamber, and an inner conductor column which is regarded as a column and inserts from one end of the outer conductor chamber into the outer conductor chamber; and a microwave source from one end of the inner conductor column inserted into the outer conductor chamber into the coaxial heating chamber to conduct microwave transmission to achieve the heating of microwave to a tobacco. A coaxial transmitter and the coaxial heating chamber are used, microwaves with the frequency of 915MHz and 2.45GHz canbe transmitted in the coaxial transmitter and the coaxial heating chamber, and therefore, a relatively mature solid-state microwave device can be used, especially 915MHz electrical conversion efficiency is higher; the size of the device can be effectively controlled; and due to the fact that the microwave has no temperature, through high frequency alternating electric field, polar molecules in thetobacco is made directly to move and heat, tobacco overall temperature is controlled in 200~300 DEG C, local high temperature does not exist, higher temperature does not exist in the overall coaxialheating chamber and the tobacco, cracking does not occur, and aldehyde or other harmful substances cannot be produced.

Owner:YUNNAN TOBACCO BIOLOGICAL TECH CO LTD +1

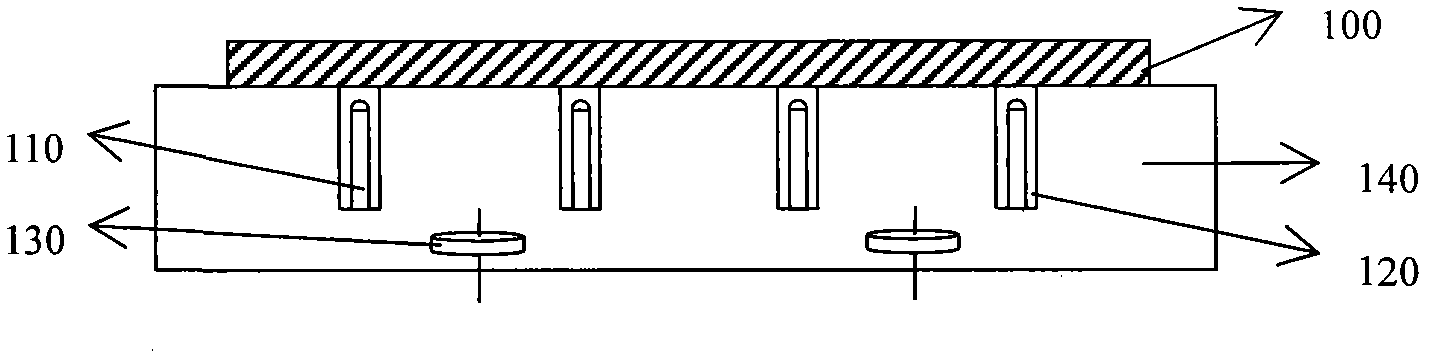

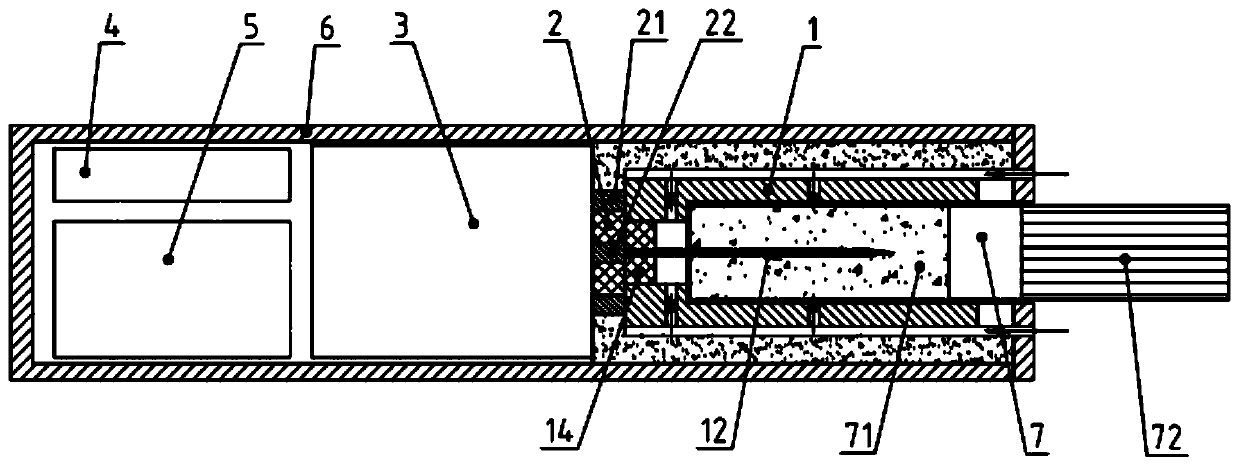

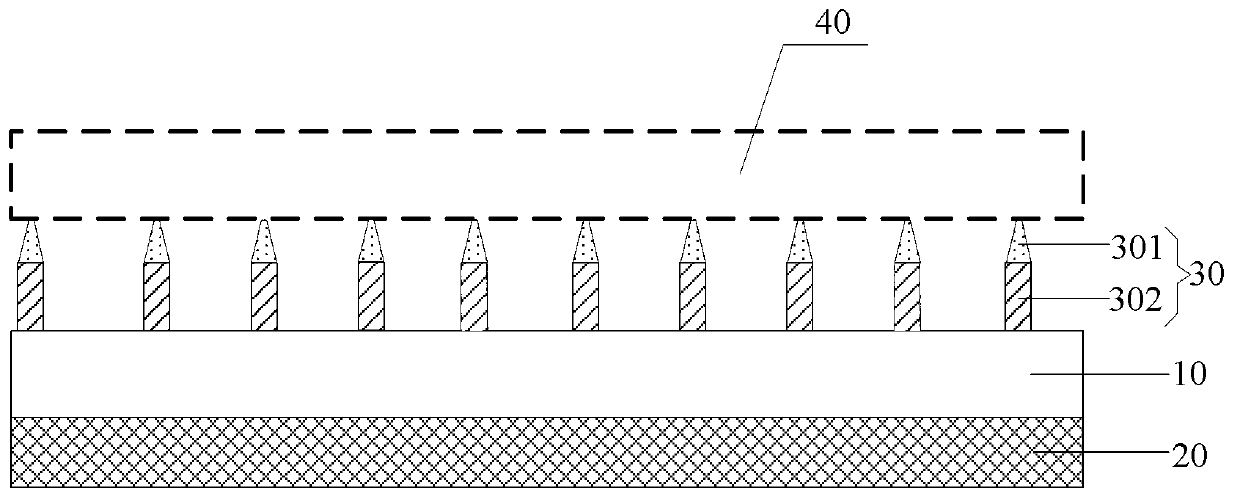

Alignment film pre-solidifying device

InactiveCN103278966AAvoid compromising qualityVolatile evenlyDrying solid materials with heatNon-linear opticsLiquid-crystal displayImaging quality

The invention provides an alignment film pre-solidifying device and relates to the manufacturing field of liquid crystal displays. The alignment film pre-solidifying device does not affect quality of an alignment film and image quality of the display. The alignment film pre-solidifying device comprises a workbench and a heating plate arranged below the workbench and further comprises multiple supporting needles used for supporting a substrate. The supporting needles are arranged between the substrate and the workbench. The diameter of the top end of each of the supporting needles ranges from 0.5mm to 0.8mm. A part which at least comprises the top end of a supporting needle in each supporting needle is made of heat-resistant and thermally insulative materials. The alignment film pre-solidifying device is used for manufacturing liquid crystal displays.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

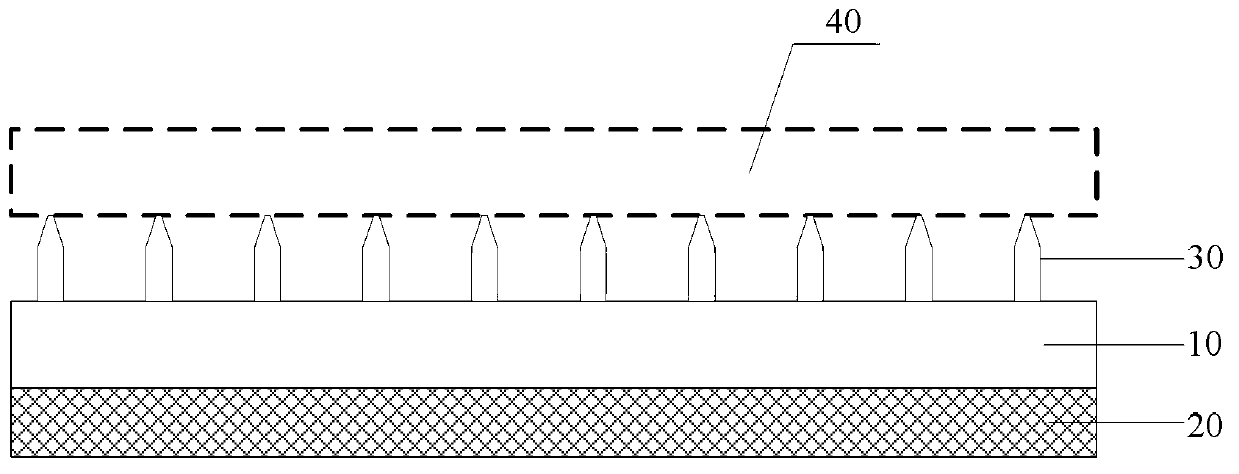

Vacuum drying equipment and preparation method of display panel

InactiveCN107962877AImprove mobilityImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingThermostatEngineering

The invention discloses vacuum drying equipment and a preparation method of a display panel. The vacuum drying equipment comprises a vacuum cavity, a thermostat, an electric field generation device and a vacuum pump. The thermostat is located below the vacuum cavity. The electric field generation device is provided with a first metal plate and a second metal plate which are arranged in the vacuumcavity. The first metal plate is located on the bottom surface of the vacuum cavity. The second metal plate is arranged over the first metal plate in parallel. The second metal plate divides the vacuum cavity into a first sub-cavity located between the first metal plate and the second metal plate and a second sub-cavity located on the other side of the second metal plate. The second metal plate isprovided with a plurality of volatilization through holes communicating with the first sub-cavity and the second sub-cavity. The first metal plate and the second metal plate are used for being connected with a circuit. The vacuum pump communicates with the second sub-cavity. The vacuum drying equipment can achieve effective control over molecular alignment, so that the migration rate of an organic thin film is increased to the maximum extent.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

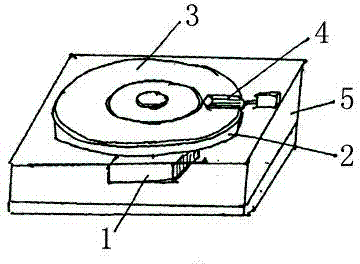

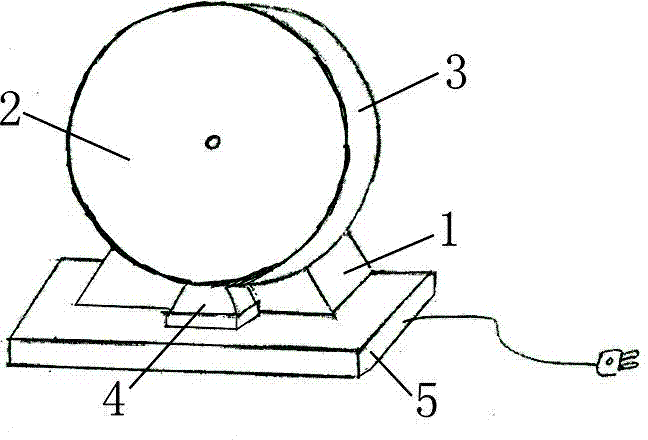

Rotating disc type electric mosquito heater

The invention discloses a rotating disc type electric mosquito heater which comprises a rotating disc which is driven by a rotator and can rotate, wherein a sheet-type substrate which is used for accommodating a mosquito repellent liquid medicine can be arranged on at least one surface covering the rotating disc; a heater which is radially arranged at the surface side of the sheet-type substrate and can be used for heating the surface of an adjacent sheet-type substrate; the rotating disc is arranged in a stand and comprises a motor and a speed-reducing driving mechanism connected to the rotating disc; the heater is an electric heating block or an electric heating rod arranged on a base frame and forms a strip heater; the strip heater is arranged on at least one surface side of the sheet-type substrate; and the rotating disk is flatly or vertically arranged on the base frame. The rotating disc type electric mosquito heater has the characteristics of simple structure, convenience in use, favorable service effect, capability of volatilizing the mosquito repellent liquid medicine for a longer time, and the like.

Owner:李经春

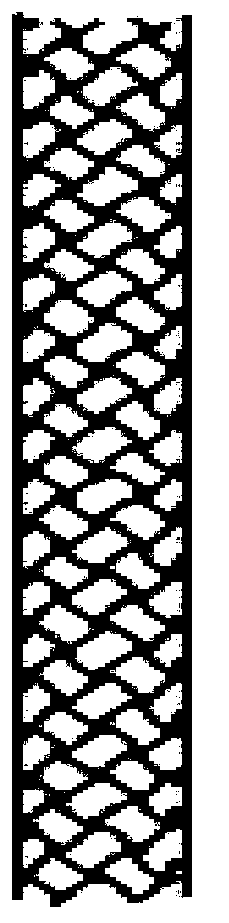

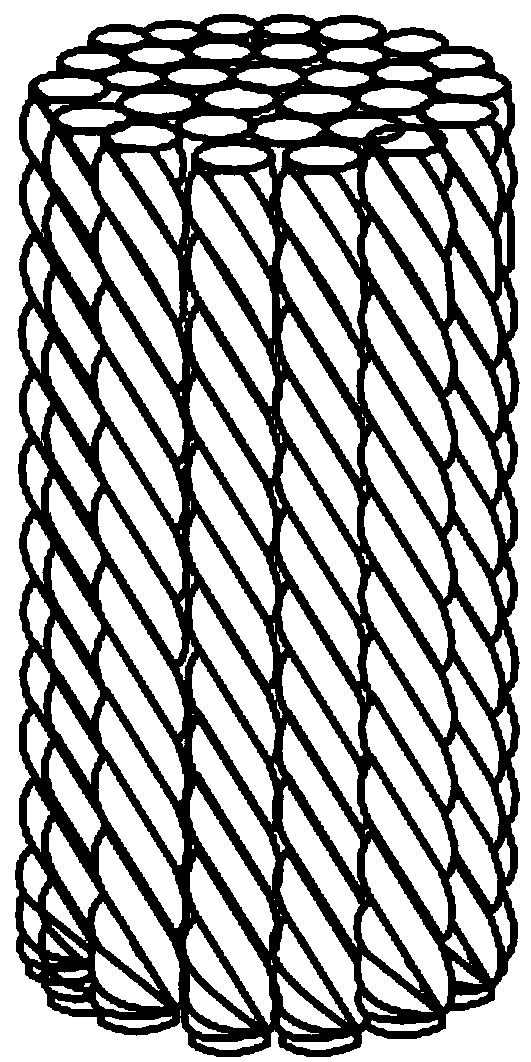

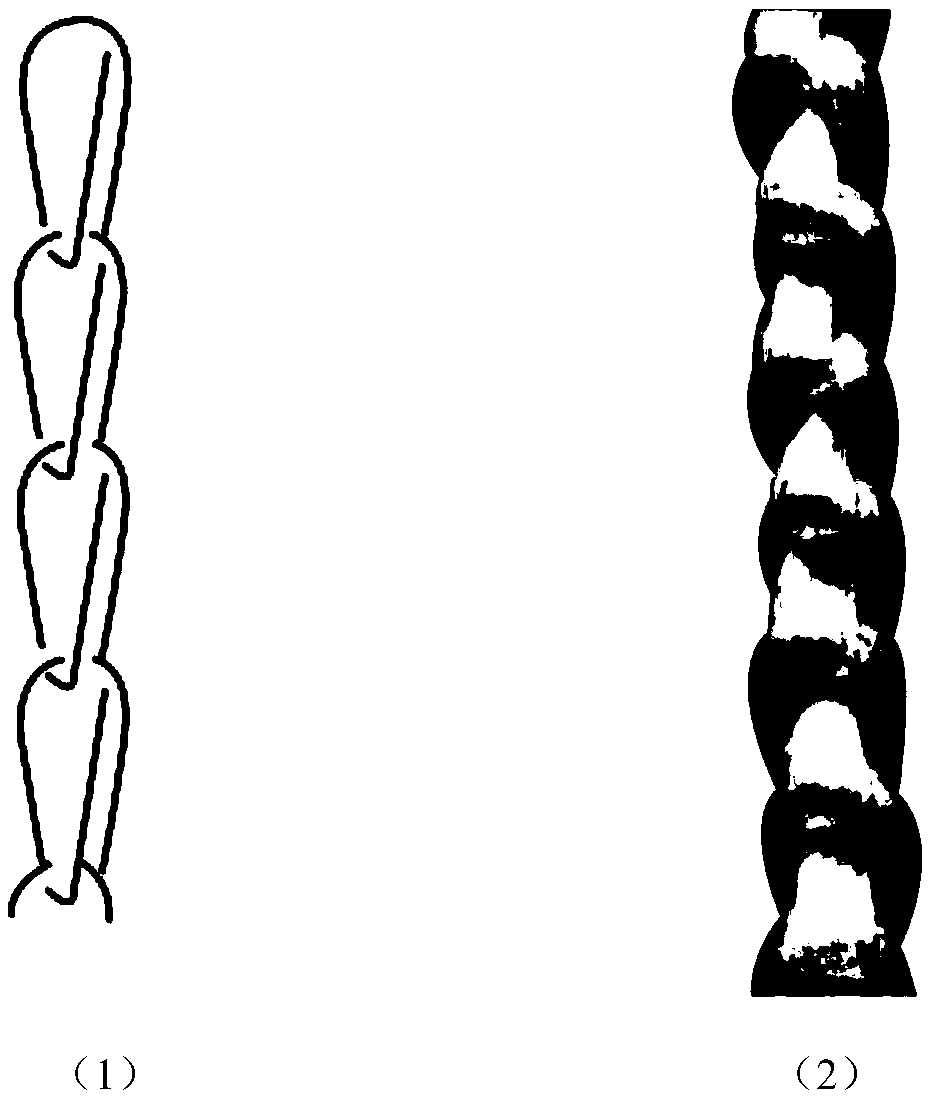

Degradable odor generation element for non-burned cigarette and cigarette product

InactiveCN108685192ASimple processIncrease productivityTobacco devicesEnvironmental chemistryAfter treatment

The invention provides a degradable odor generation element for a non-burned cigarette. The odor generation element is made of biodegradable polylactic acid monofilaments, and is formed by preparing several polylactic acid monofilaments into a rope or knitted fabric structure through one or more processes of weaving, knitting and twisting and then carrying out cutting. The odor generation elementfurther comprises polylactic acid monofilaments without perfume and polylactic acid monofilaments with perfume adhering to the surfaces after treatment, and when a hot airflow passes through a longitudinal extension channel defined by the polylactic acid monofilaments, the original odor of smoke and a generated volatile aroma are kept respectively. The process is simple, and the production efficiency is high; the adopted polylactic acid monofilaments have good biodegradability and environmental friendliness.

Owner:CHANGZHOU LOONG TOP NEW MATERIALS TECH

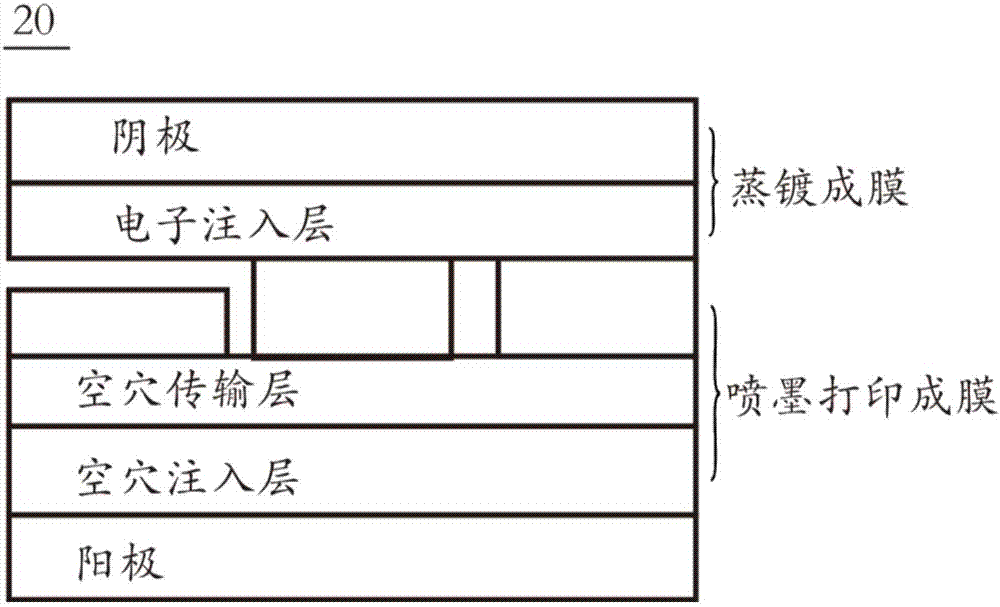

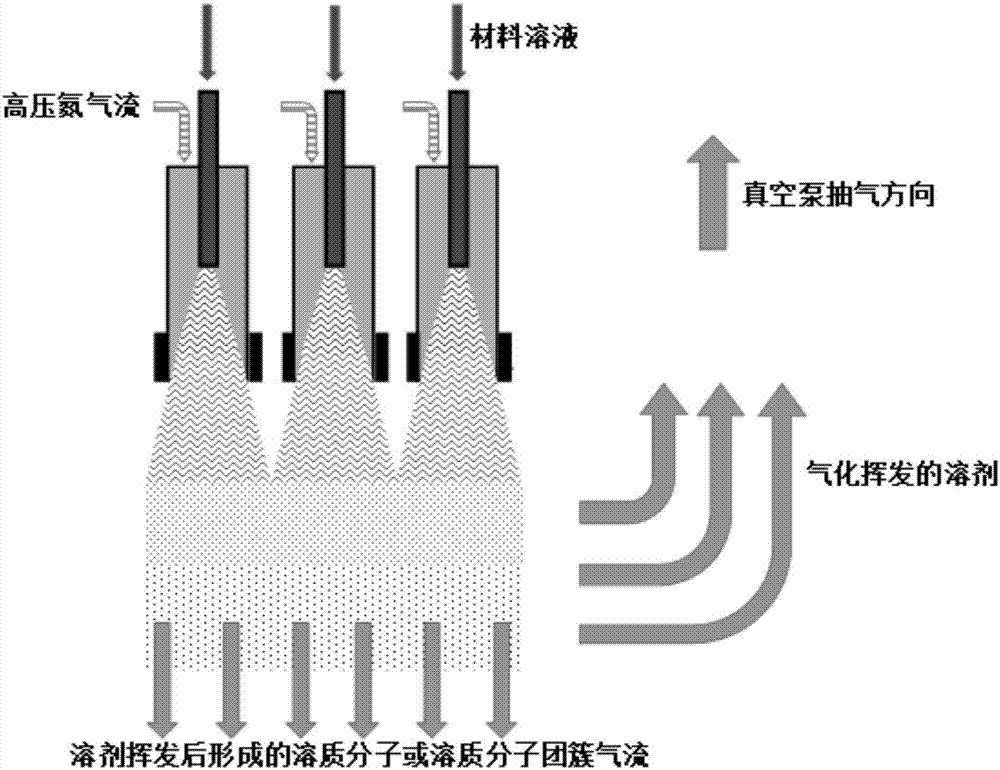

OLED and film deposition method thereof

ActiveCN107359277AUniform thicknessSmall sizeSolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceSolvent

The invention relates to an OLED and a film deposition method thereof. The film deposition method comprises the following steps of: preparing a material solution: dissolving a material to be deposited in a solvent to obtain the material solution; and providing an atomization device comprising an atomization system, a cavity, a vacuum tube and a support plate; and depositing: placing a substrate on the support plate, switching on a vacuum device, vacuuming the cavity through the vacuum tube, and atomizing the material solution through the atomization system to deposit the material solution on the substrate. The film deposition method of the OLED utilizes a combination of vacuum and a spray process to deposit the film of the OLED, does not need to heat and sublimate the material to be deposited at a high temperature, and is suitable for materials hard to sublimate or liable to thermally decompose. Further, droplets formed by spray are small, and the vacuum environment allows the solvent to be uniformly volatilized, thereby forming a uniform film thickness.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

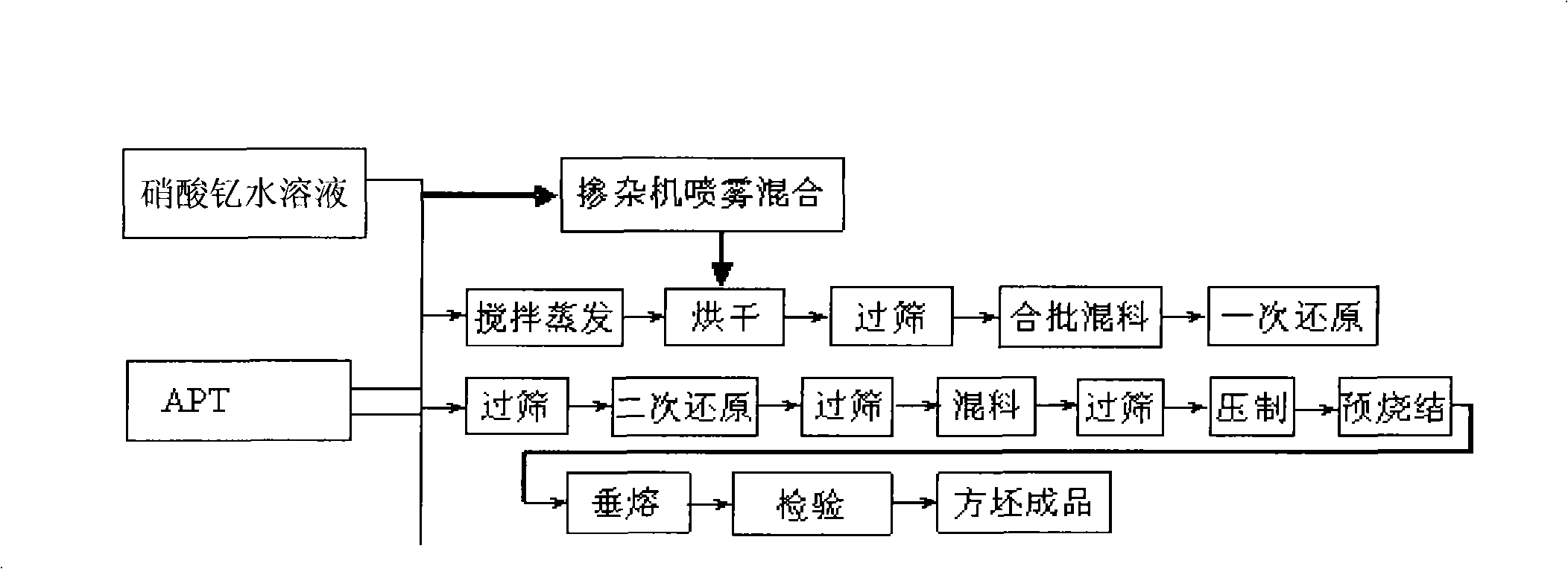

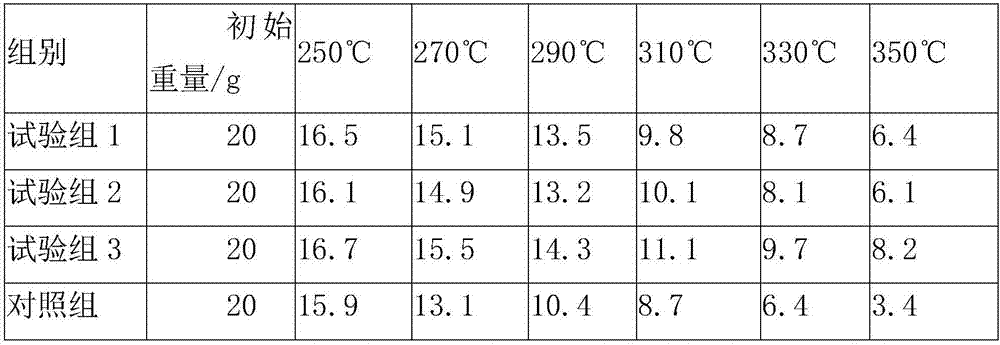

Method for preparing square tungsten-yttrium blank

The invention discloses a method for preparing tungsten-yttrium square billets, which comprises the following steps: a. dispersing yttrium nitrate aqueous solution in a spraying mode evenly and coating the yttrium nitrate aqueous solution on the surface of ammonium paratungstate, and performing mixing agitation, heating, and drying at the same time to obtain tungsten-yttrium coating powder after drying; and b. performing primary and secondary reductions, compaction, presintering and incipient fusion sintering on the tungsten-yttrium coating powder to be prepared into the uniform tungsten-yttrium square billets with metallicity, wherein the incipient fusion sintering process comprises that the temperature is increased for 10 to 30 minutes and the temperature is kept for 20 to 50 minutes, and the electric current in the process of keeping the temperature is between 2,500 and 4,000 amperes. The method has a simple process and prepares the tungsten-yttrium coating powder by adopting the spraying mode, thus the even distribution degree of elements added to square billet raw materials is ensured, and the tungsten-yttrium coating powder with comparatively even dispersion; besides, the process of the subsequent incipient fusion sintering is controlled to raise the temperature for 10 to 30 minutes, keep the temperature for 20 to 50 minutes, and keep the electric current in the process of keeping the temperature between 2,500 and 4,000 amperes, thus each point of the prepared tungsten-yttrium square billets is volatilized evenly; and under the cooperation of the method and the incipient fusion sintering, the prepared tungsten-yttrium square billets have good evenness.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

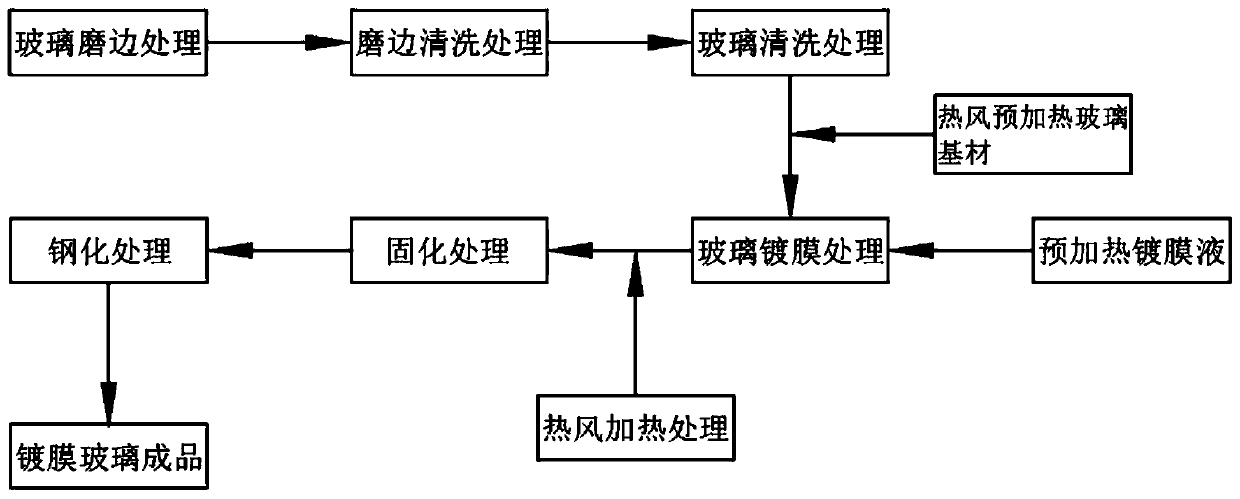

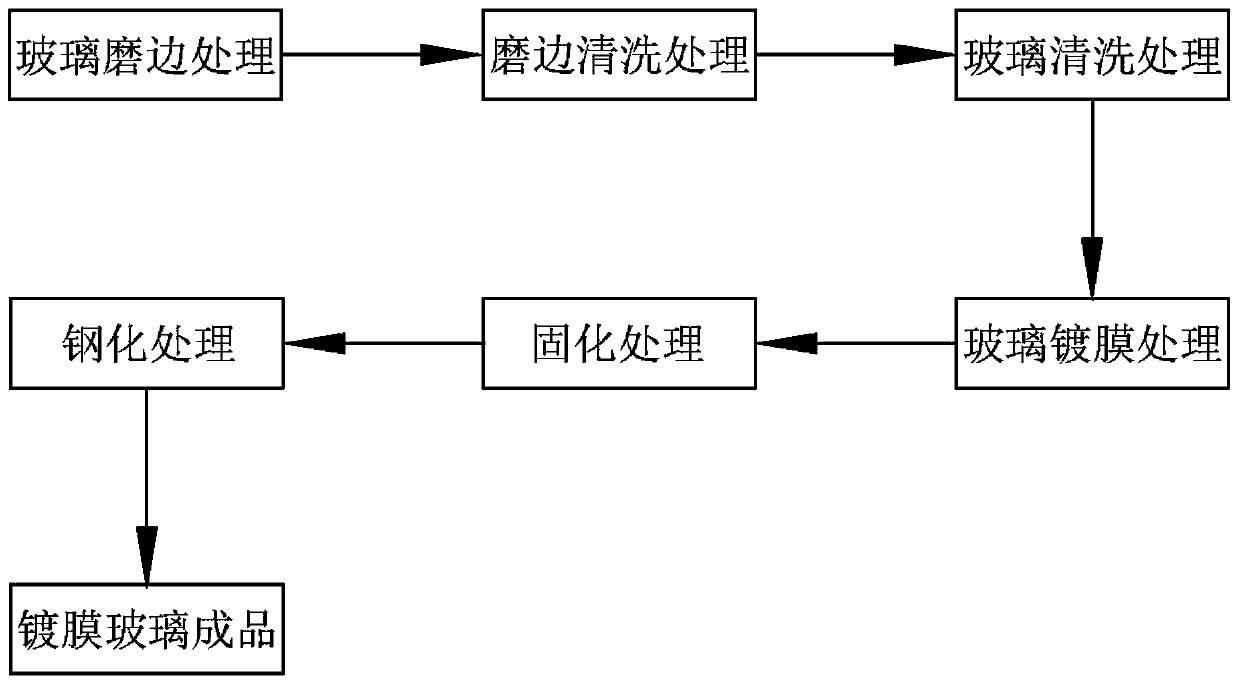

Preheating method and equipment for coated glass production

The invention relates to the technical field of coated glass, in particular to a preheating method and equipment for coated glass production. The preheating method comprises the following steps: S1, preheating a glass substrate: spraying hot air on the surface of the glass substrate until the temperature of the glass substrate is 40-60 DEG C; S2, preheating a coating solution, namely heating the coating solution to 30-40 DEG C, and coating the heated coating solution on the surface of the glass substrate preheated in the step S1; and S3, conducting post-heating treatment, specifically, adopting hot air for blowing and spraying the glass base material coated with the coating liquid in the step S2, so that the temperature of the glass base material reaches 50-70 DEG C, and the preheated coated glass is prepared for standby application and waiting for curing. The preheating method disclosed by the invention is simple to operate, high in production efficiency and low in production cost, the volatilization rate uniformity of the solvent in a wet film state can be accelerated, the adhesive force between the film layer and the glass substrate is improved, and the light transmittance, weather resistance and hardness of the film layer are improved.

Owner:DONGGUAN CSG SOLAR GLASS +1

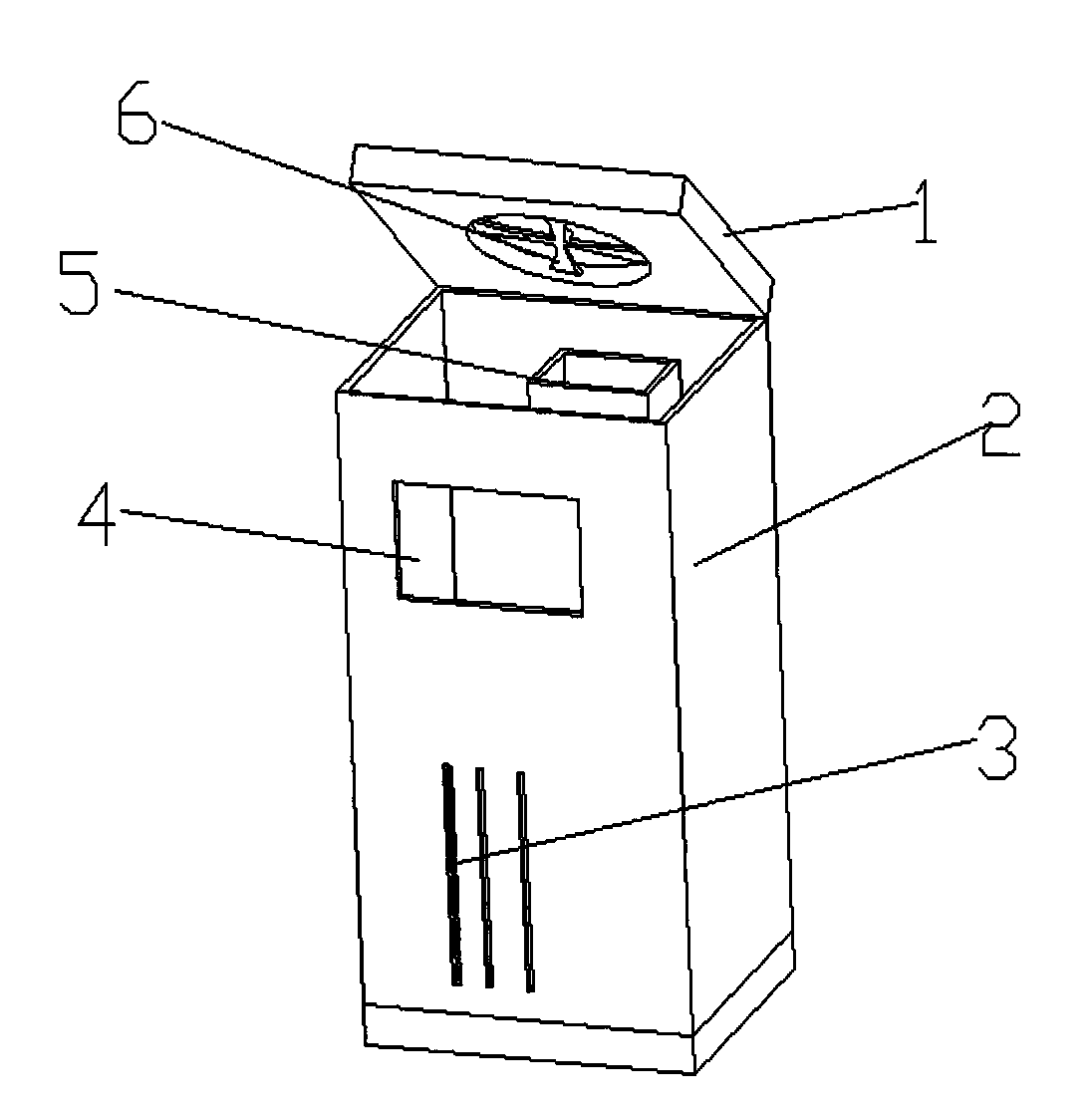

Solar deodorant garbage can

InactiveCN104029969AEfficient use ofAchieve sustainable useWaste collection and transferRefuse receptaclesNatural resourceDeodorant

The invention belongs to the field of public facilities and discloses a solar deodorant garbage can which is composed of a solar cell panel, a garbage can body, ventilation ports, a garbage placement port, an iron box and a fan. The garbage can body is combined with the solar cell panel, solar energy is utilized as an energy source to drive the fan to rotate, the fan is mounted inside an upper can cover of the garbage can body, the solar cell panel serves as the upper can cover of the garbage can, the ventilation ports are formed in the front can face of the garbage can body, deodorant is placed on the iron box in the garbage can, and the iron box is welded in the garbage can body. The solar deodorant garbage can has the advantages that natural resources can be fully utilized as the energy source for deodorization, so that low carbon, environment protection and sustainability are realized.

Owner:王进

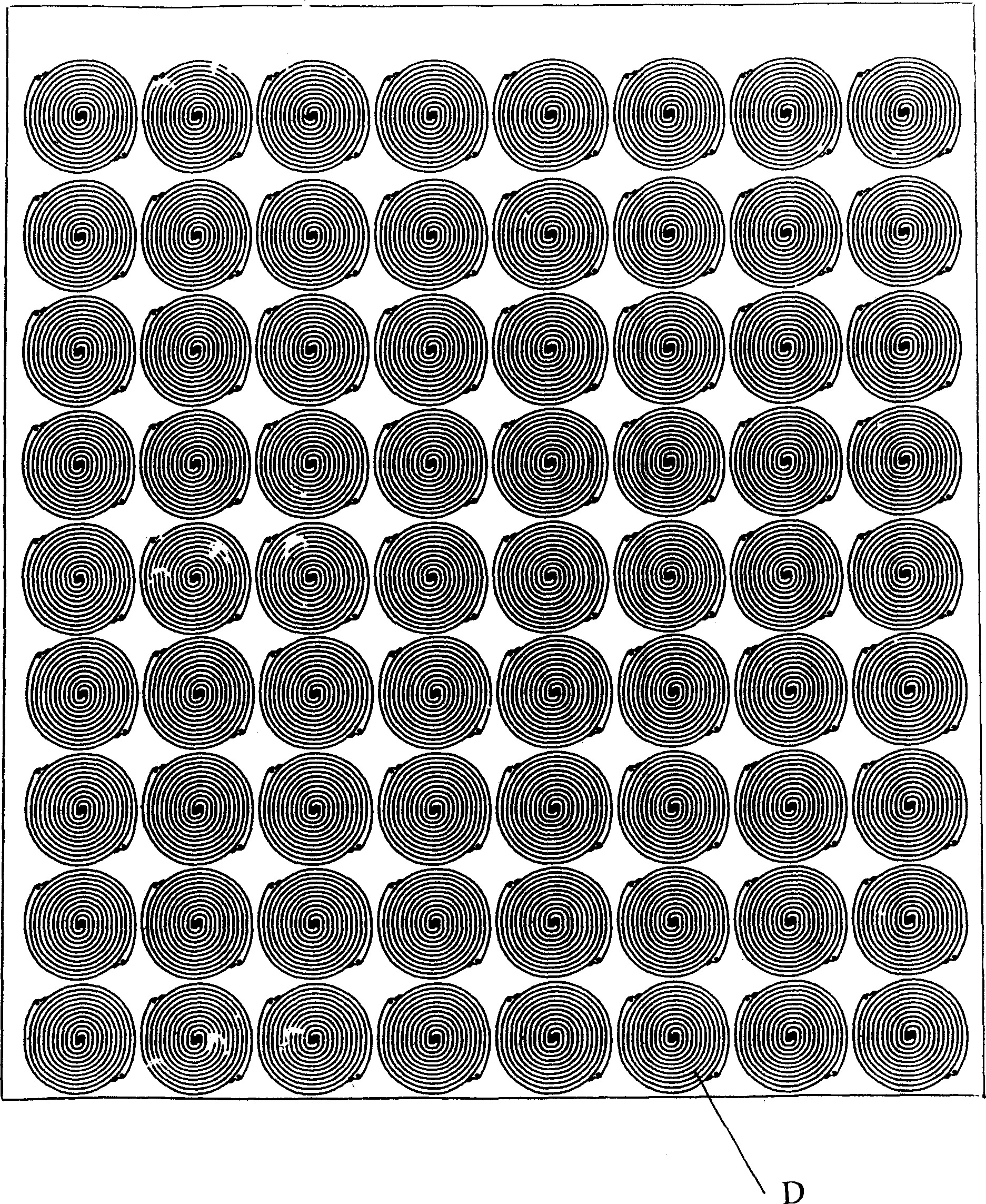

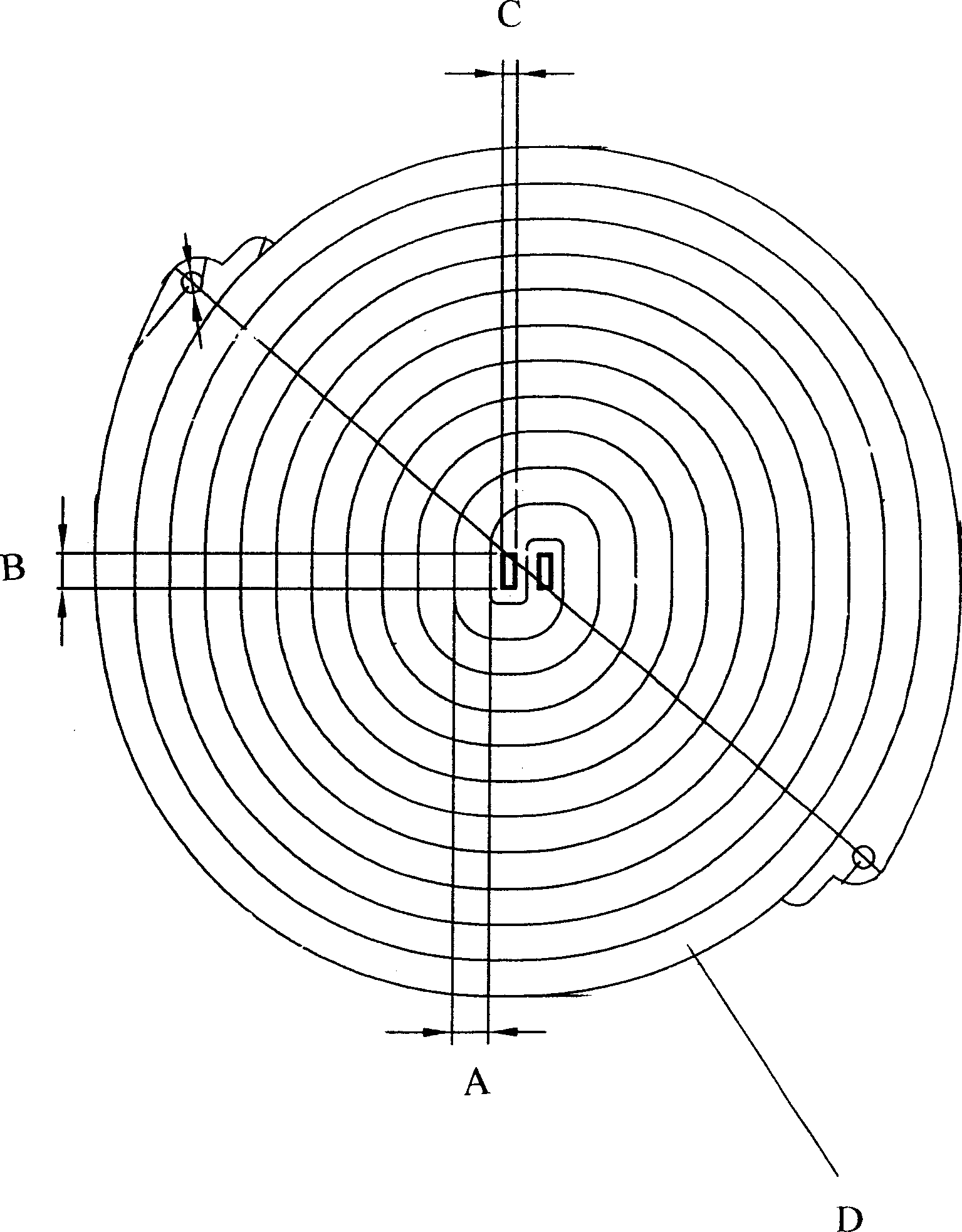

Disk-shaped mosquito-repellent incense of paper, and preparation technique

A coiled mosquito-repellent paper incense is composed of two coiled flat and lender incense strips, and is made up of the basic material prepared from plant fibers, the powder of wooden (or bamboo) charcoal, and light calcium carbonate and / or kaolinite, and the mosquito-repellent liquid prepared from pyrethrins, octachorodipropyl ether and essence through spray said liquid onto the basic material.

Owner:邵锦春

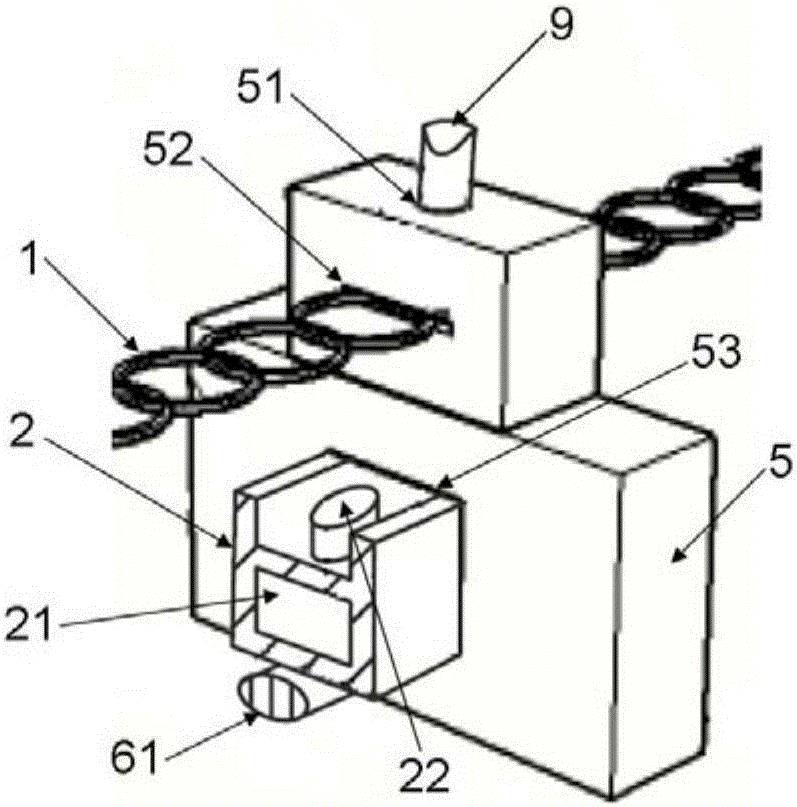

Electrostatic spinning device for preparing nano-fibers on large scale

The invention discloses an electrostatic spinning device for preparing nano-fibers on a large scale. According to the electrostatic spinning device, a straightened metal chain serves as a fiber emitting electrode, the metal chain is connected with a positive electrode of a high-voltage direct current power source, a collector is arranged over the metal chain, the collector is connected with a negative electrode of the high-voltage direct current power source or grounded, a power supply system for jetting airflow upwards is arranged under the metal chain, and a liquid supply system for applying a spinning precursor solution to the metal chain is arranged on the metal chain. The device is simple in operation, the electrospinning fiber efficiency can be remarkably improved, electrospinning fibers with the uniform diameter are obtained, and large-scale production of the micro-nano fibers is achieved.

Owner:聚纳达(青岛)科技有限公司

Repair method for car paint

The invention provides a repair method for car paint, and relates to the technical field of cars. The repair method for the car paint comprises the following steps of (1) pretreatment of damaged partsof the car paint, (2) spraying of a painting make-up agent, (3) spraying of colored paint, (4) spraying of varnish and (5) grinding and polishing. The repair method for the car paint repairs the damaged parts of the car paint, the whole repair process is simple and easy to realize, the effect is obvious, time for painting make-up is short, the working efficiency is improved, and the time-saving and labor-saving effect is achieved.

Owner:广西速道汽车维修服务有限公司

Ceramic product and method for preparing same by aid of gel casting technologies on basis of hydantoin epoxy resin

The invention provides a ceramic product and a method for preparing the same by the aid of gel casting technologies on the basis of hydantoin epoxy resin. Gel systems used in the gel casting technologies comprise the hydantoin epoxy resin and 3, 3'-diamino dipropyl amine which is a curing agent. The ceramic product and the method have the advantages that the method is simple and is low in toxicity and short in period, and the large and thin ceramic product which is high in density, excellent in comprehensive performance such as mechanical properties, low in cost and easy to transport and store can be prepared by the aid of the method.

Owner:NANHUA UNIV

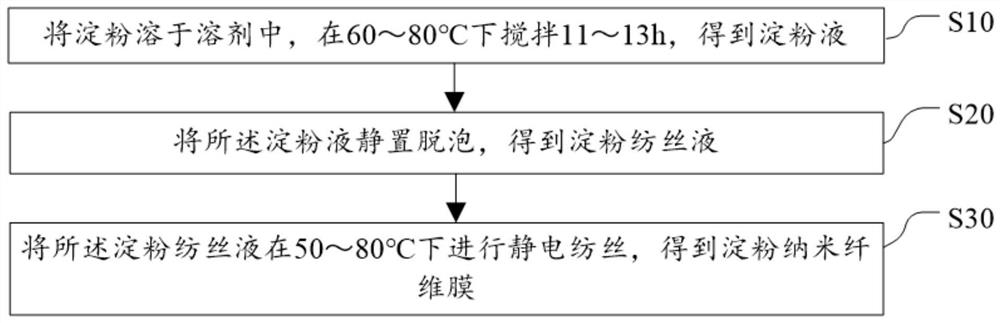

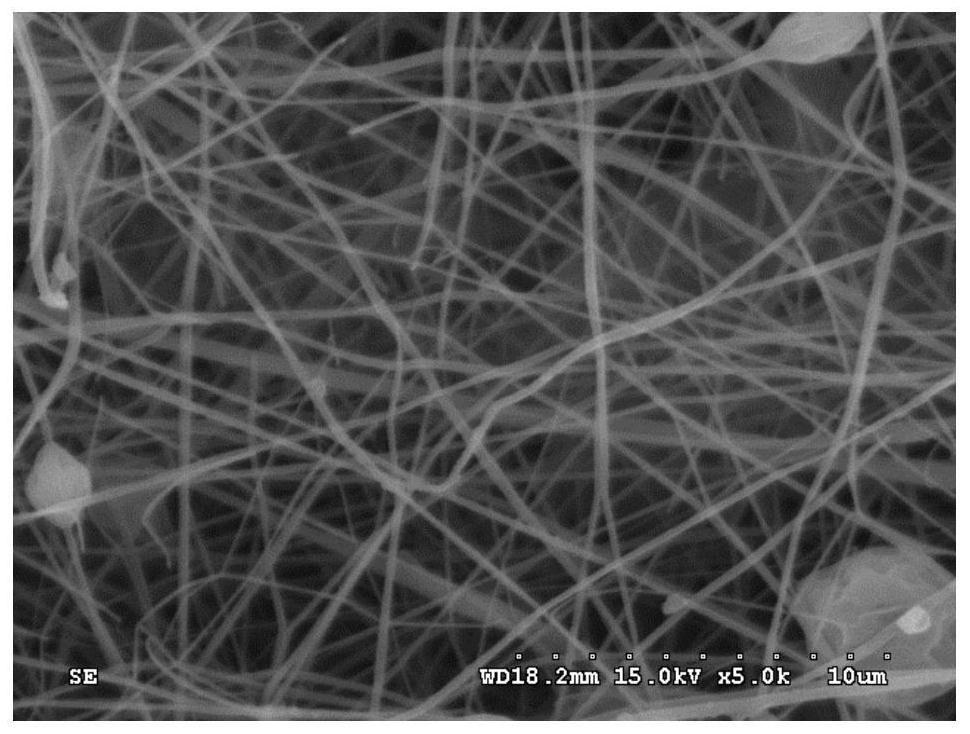

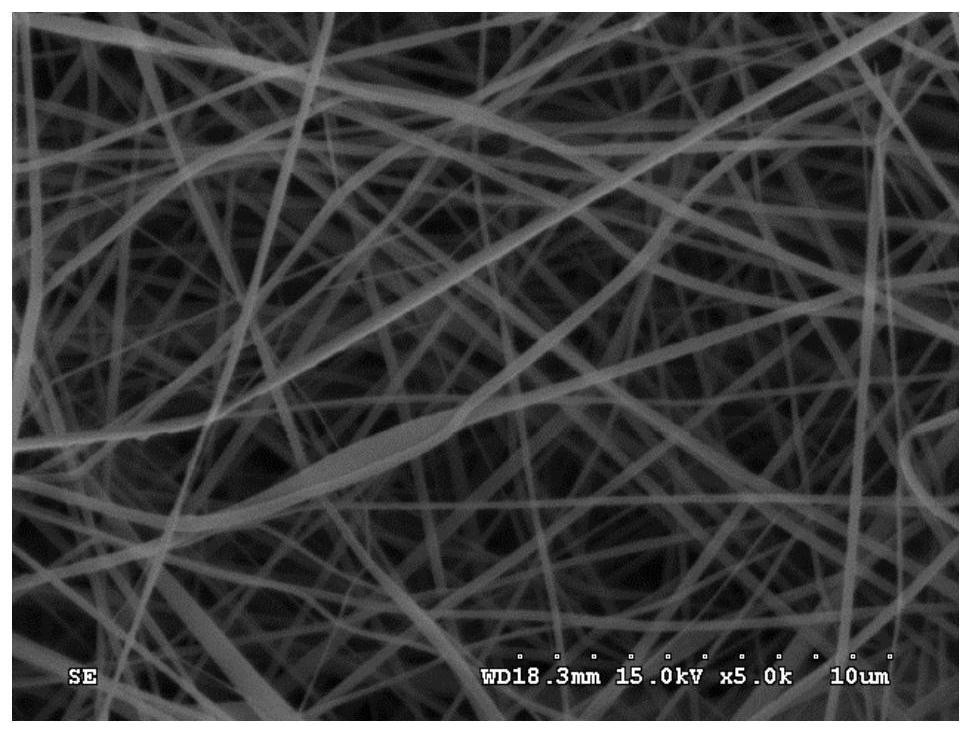

Preparation method of starch nanofiber membrane and starch nanofiber membrane

InactiveCN113026210AFlat surfaceVolatile evenlyElectro-spinningNon-woven fabricsPolymer scienceSpinning

The invention discloses a preparation method of a starch nanofiber membrane and the starch nanofiber membrane, and relates to the technical field of nanofibers. The preparation method of the starch nanofiber membrane comprises the following steps of S10, dissolving starch in a solvent, and stirring at 60-80 DEG C for 11-13 hours to obtain starch solution; S20, standing and defoaming the starch solution to obtain a starch spinning solution; and S30, carrying out electrostatic spinning on the starch spinning solution at 50-80 DEG C to obtain the starch nanofiber membrane. According to the preparation method of the starch nanofiber membrane, the electrostatic spinning technology is assisted at the temperature of 50-80 DEG C, so that in the electrostatic spinning process, a solvent is volatilized uniformly, nanoscale starch fibers with uniform thickness and smooth surfaces are formed favorably, the preparation process is simple, the direct membrane forming property is good, no processing inhibitor is added, and the starch nanofiber membrane with uniform thickness and smooth surface can be prepared.

Owner:WUHAN POLYTECHNIC UNIVERSITY

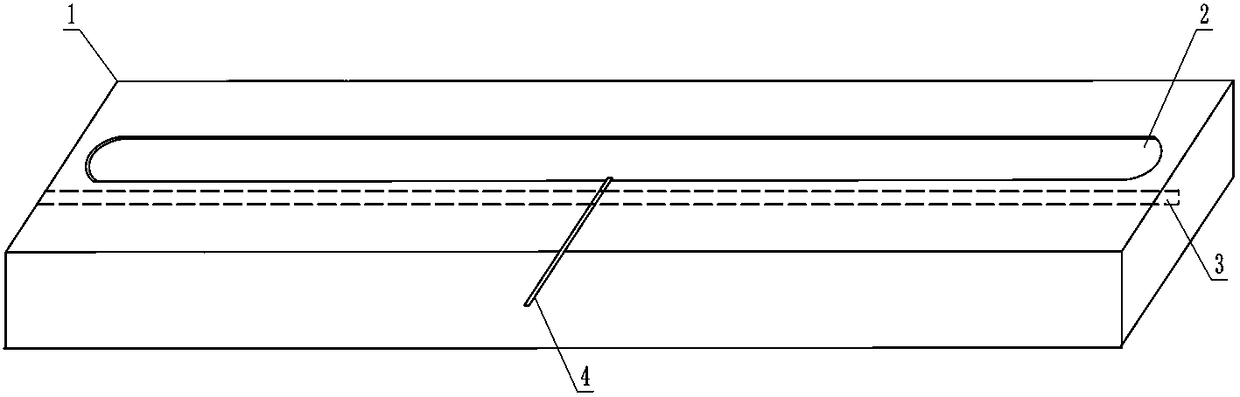

Oil shielding volatilization device

PendingCN108842134AVolatile evenlyOil evenlyVacuum evaporation coatingSputtering coatingEvaporationOil pressure

The invention provides an oil shielding volatilization device. The oil shielding volatilization device comprises a boat type heating plate, an electric heating pipe, an oil supply pipe and a micro flow control pump. The upper surface of the boat type heating plate is provided with an evaporation shallow groove. The bottom surface of the evaporation shallow groove is of a horizontal flat structure.The electric heating pipe is embedded in the boat type heating plate and arranged under the evaporation shallow groove. The oil inlet end of the oil supply pipe is connected with an oil outlet of themicro flow control pump. The oil outlet end of the oil supply pipe communicates with the evaporation shallow groove. The oil shielding volatilization device has the advantages of scientific design, stable oil quantity, uniform oil pressure and good product quality.

Owner:郑州华晶新能源科技有限公司

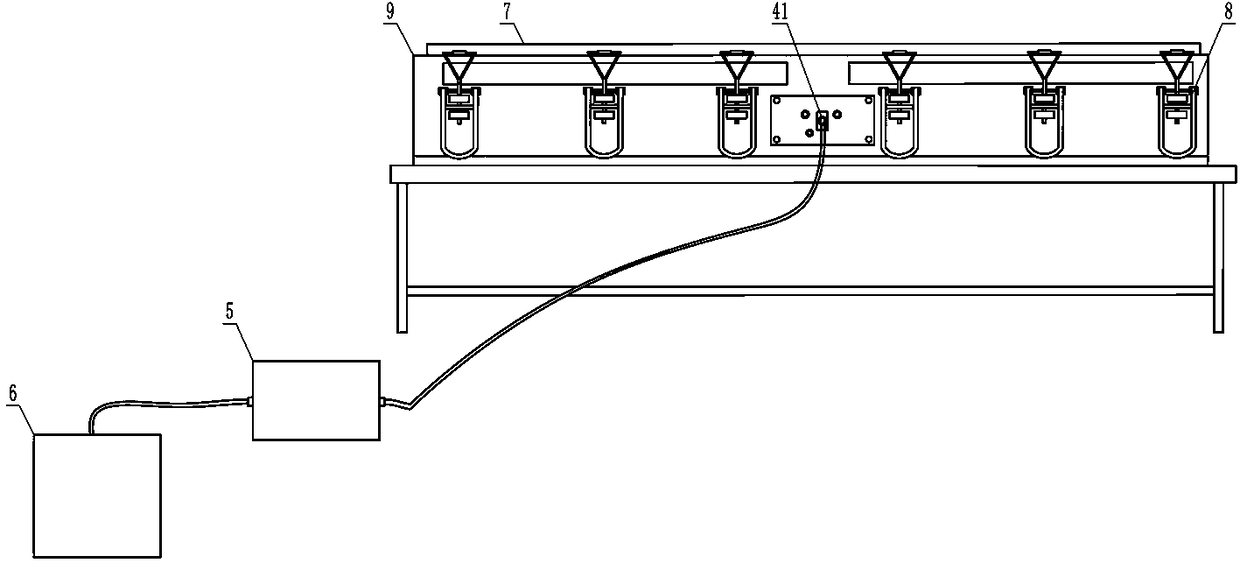

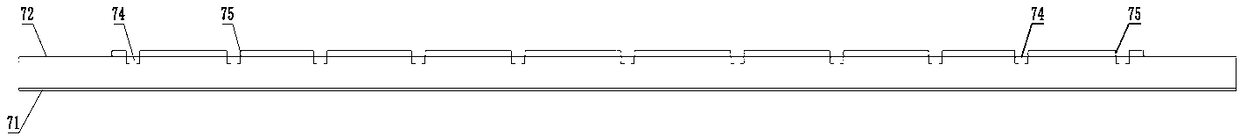

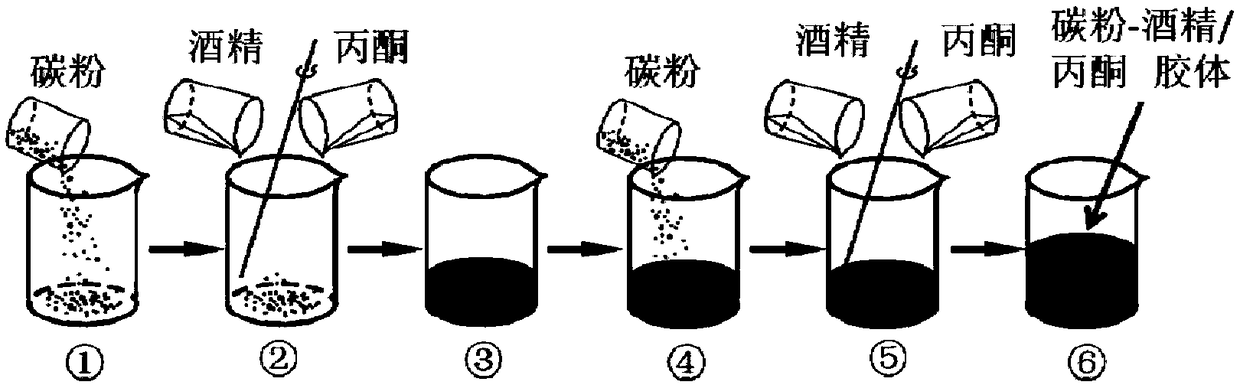

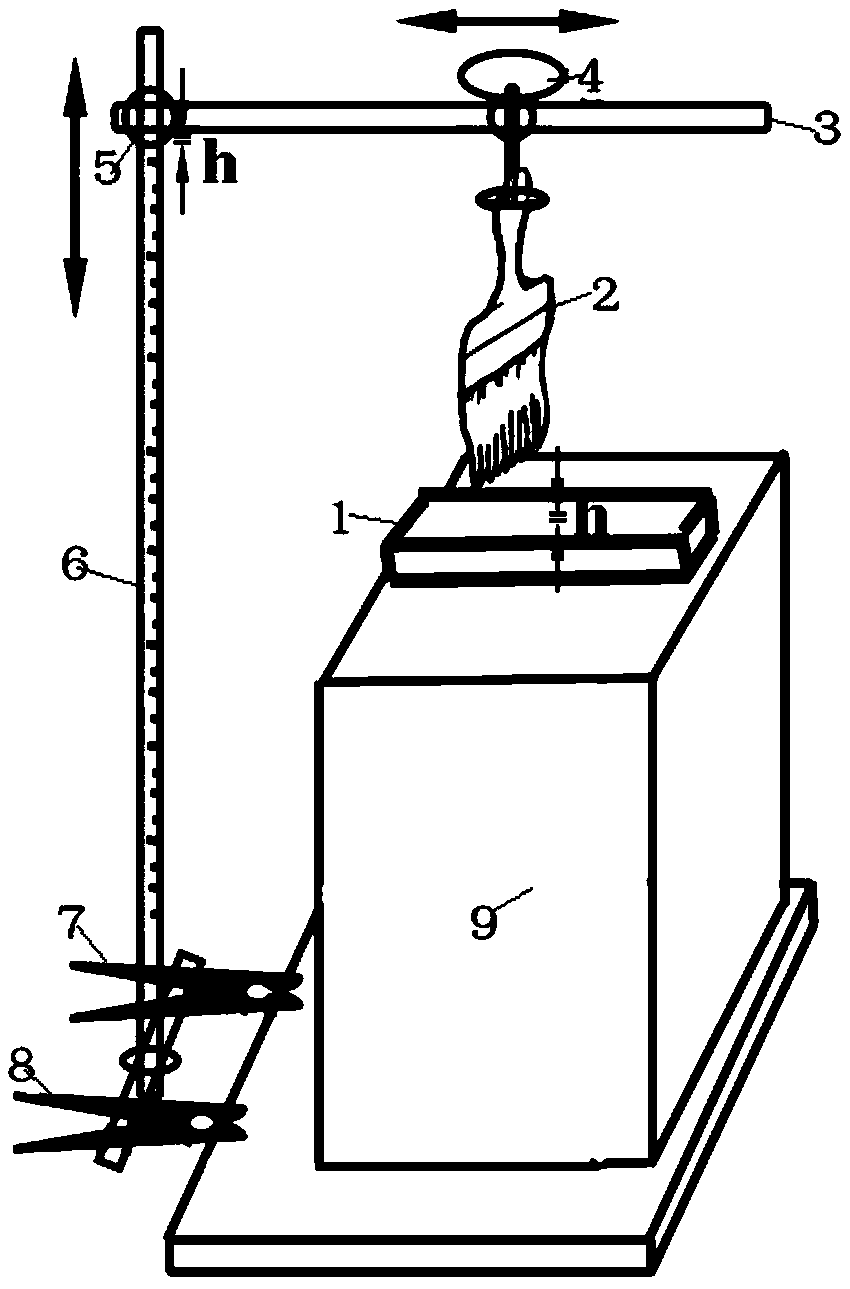

Laser-surface carburization process for metal materials and carbon coating device thereof

InactiveCN108914051AImprove surface activityEvenly dispersedSolid state diffusion coatingAlcoholColloid

The invention relates to a laser-surface carburization process for metal materials and a carbon coating device thereof. The carburization process comprises the steps of: using a carbon coating deviceto uniformly and quantitatively coat nano carbon powder-alcohol-acetone colloid; drying the metal material coated with the nano carbon powder-alcohol-acetone colloid; using laser beams to melt the dried metal material under the atmosphere protection. The laser-surface carburization process has the beneficial effects that a special powder-laying mode is adopted to prefabricate process carbon, the nanosize carbon powder is selected as an added material, is prepared into nano carbon powder colloid by a specific preparation mode, then the prepared nano carbon powder colloid is coated on the metalsurface by a special carbon-coating device, and the process is optimized from multiple aspects of shape and size of carbon powder, laying mode and content control and the like, so that the powder laying defect is reduced; the whole carburization process is simple and efficient.

Owner:北京煜鼎增材制造研究院股份有限公司

Spinning channel system

InactiveCN105040131AGuaranteed stabilitySmooth full contactArtificial thread manufacturing machinesDry spinning methodsCylindrical channelFiber

The invention belongs to the technical field of spinning devices, and relates to a spinning channel system. The spinning channel system comprises a cylindrical channel body, an upper air feed mechanism, a flow correcting mechanism, a main air return mechanism, an auxiliary air return mechanism and a bottom air return mechanism. The upper air feed mechanism and the flow correcting mechanism are arranged at the top of the cylindrical channel body, and the upper air feed mechanism is arranged on the periphery of the flow correcting mechanism; the main air return mechanism is fixedly arranged in the middle of the cylindrical channel body and located between the upper air feed mechanism and the auxiliary air return mechanism; the auxiliary air return mechanism is arranged on the lower portion of the cylindrical channel body and located above the bottom air return mechanism; the bottom air return mechanism is arranged at the bottom of the cylindrical channel body. While increasing the air volume of the channel, the spinning channel system ensures stability of airflow, so that the character of final spandex fiber finished products tends to be stable, and product differentiation is reduced.

Owner:ZHEJIANG BAOLIAN FIBER SCI & TECH CO LTD

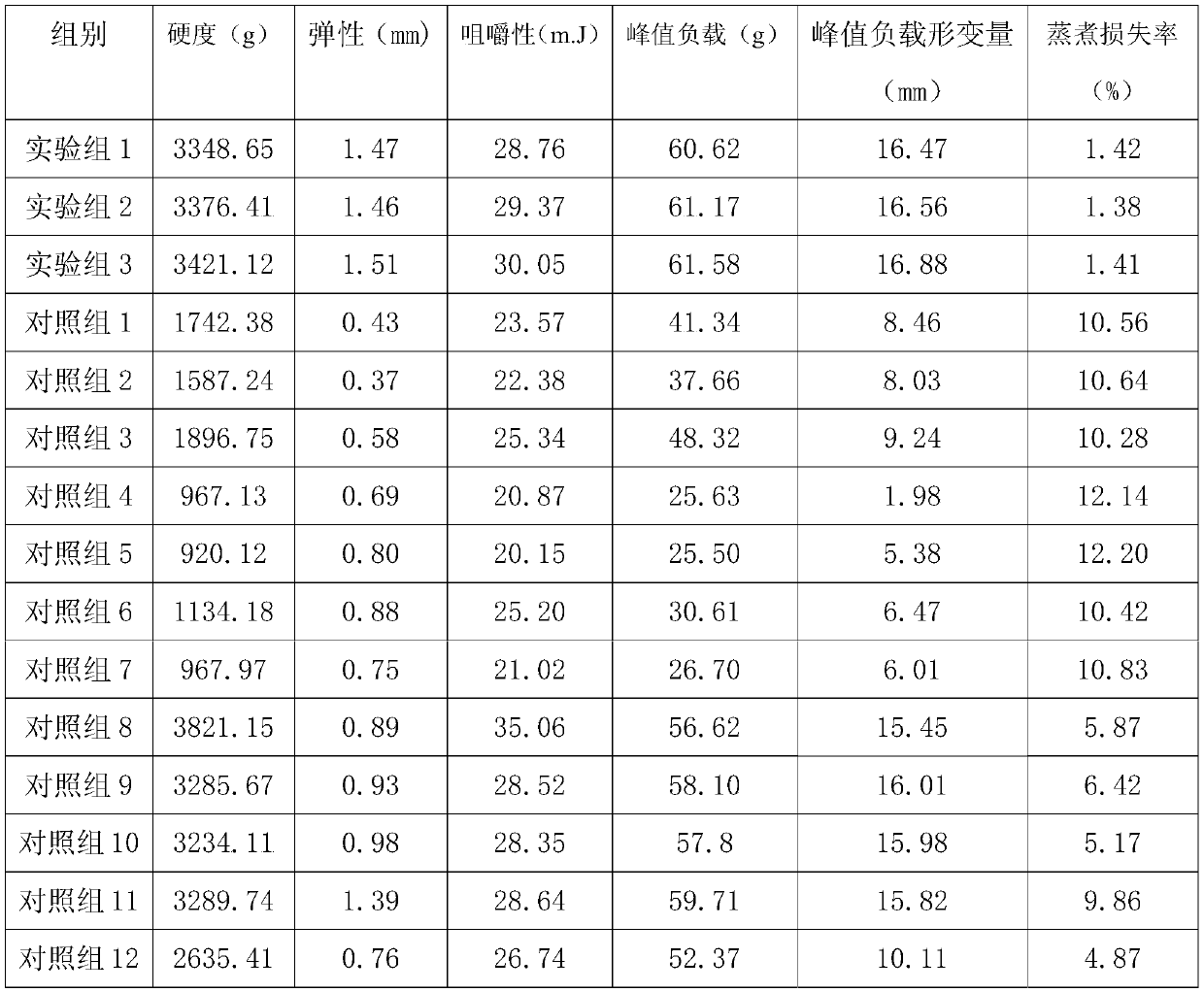

Potato dried rice noodles and preparation method thereof

The invention belongs to the technical field of food processing, and particularly discloses potato dried rice noodles and a preparation method thereof. The preparation method of the potato dried ricenoodles comprises the following steps of (1) preparing rice pulp: soaking rice, and performing grinding to obtain the rice pulp; (2) performing pulp material mixing: mixing the rice pulp with potato whole powder; (3) performing standing with a compounding modifier: mixing the mixed rice pulp with the compounding modifier, and performing standing, wherein the compounding modifier consists of guar gum, xanthogen, low-acyl gellan gum, disodium hydrogen phosphate, distilled glyceryl monostearate, vital wheat gluten and edible corn starch; (4) performing extrusion shaping; (5) performing ageing intwo stages; (6) flushing rice powder and performing compaction; and (7) performing low-temperature middle-humidity 6-stage baking. The invention further provides the potato dried rice noodles. The preparation method of the potato dried rice noodles is simple to operate, industrial production is easy, and the prepared potato dried rice noodles are smooth, complete, low in noodle breaking rate and bending rate, short in rehydration time and high in quality.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

Process for preparing cement clinker additive from stainless steel pickling sludge

InactiveCN111847955ASolve the problem of in-situ safe disposalRealize comprehensive utilizationClinker (waste)Kaolin clay

The invention discloses a process for preparing a cement clinker additive from stainless steel pickling sludge, wherein the process comprises the following steps: S1, adding ferrous sulfate and liquidenvironment-friendly alkali into stainless steel pickling wastewater to obtain stainless steel pickling sludge; S2, adding fly ash into the stainless steel pickling sludge, uniformly mixing, and carrying out high-temperature dehydration treatment; S3, crushing and grinding the dewatered sludge into fine powder, adding 4%-6% of kaolin, uniformly mixing, and granulating; and S4, carrying out high-temperature calcination on the granulated material, and then crushing to obtain the clinker additive. According to the method, heavy metal ions in the pickling sludge generated in the stainless steel production process can be converted into harmless substances meeting the national environmental protection requirements; the content of metal Cr in the cement clinker obtained through the method is lower than 0.47%, the content of Ni in the cement clinker is lower than 0.06%, the quality of the cement clinker meets the index requirements of corresponding national product standards, reliability is high, and operation cost is low.

Owner:清远市博发环保科技有限公司

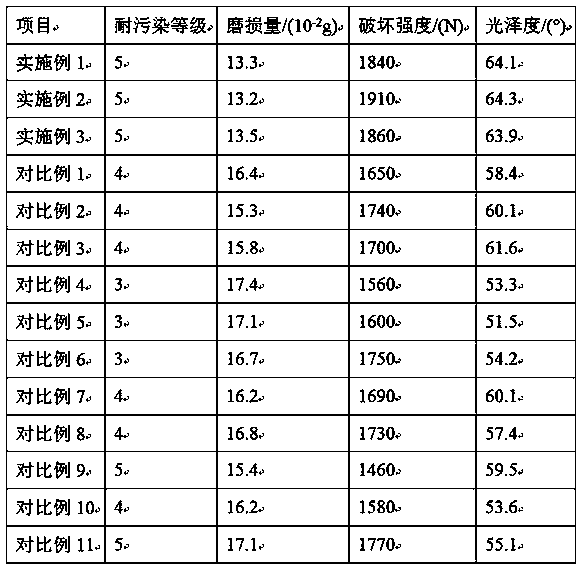

Self-cleaning ceramic tile

InactiveCN109704726AHigh strengthImprove wear resistanceCeramic materials productionClaywaresSodium BentoniteMixed materials

The invention mainly relates to the technical field of ceramic tile processing, and discloses a self-cleaning ceramic tile. The self-cleaning ceramic tile is prepared from the following raw materials:52-54 parts of lithium-based montmorillonite, 33-35 parts of modified bentonite, 24-26 parts of talc powder, 15-17 parts of waste ceramics, 10-12 parts of lightweight calcium carbonate powder, 1.7-1.9 parts of nano titanium dioxide, 1.2-1.4 parts of nano anion powder, and 1.1-1.3 parts of a surface treating agent. The self-cleaning ceramic tile provided by the invention has high strength, strongwear resistance, glossiness of 64.3 degrees, good anti-fouling self-cleaning effects, increases types of ceramic tiles on the market, and meets the needs of consumers; the lithium-based montmorillonite, the modified bentonite and the talc powder are mixed, the mixed material is crushed, so that the pulverization degree of the raw materials is improved, and the strength and wear resistance of the ceramic tile are increased; and the lithium-based montmorillonite has better fluidity and adhesion, so that the flatness and glossiness of the ceramic tile can be improved, the strength and glossinessof the ceramic tile can be increased, and the ceramic tile grade can be improved.

Owner:赵春升

UV conductive silver paste formula and preparation method thereof

InactiveCN107403657AStrong adhesionImprove conductivityNon-conductive material with dispersed conductive materialCable/conductor manufactureTablet computerSilver paste

The invention provides a UV conductive silver paste formula and a preparation method thereof, which relate to the technical field of electronic chemical coatings. The UV conductive silver paste of the invention is prepared with organic carrier solvent, modified silver powder and modified glass powder as main materials and other additives as auxiliary materials. The UV conductive silver paste has the characteristics of strong adhesion of carrier, superior conductivity, good flexibility, good environmental protection property and excellent rheological property, and can be widely applied to chips, touch screens, tablet computers, digital cameras and other printed circuits.

Owner:长沙小新新能源科技有限公司

Environment-friendly thinner for automotive refinishing paint and preparation method of environment-friendly thinner

The invention relates to an environment-friendly thinner for an automotive refinishing paint and a preparation method of the environment-friendly thinner. The environment-friendly thinner comprises the following components in parts by weight: 5-70 parts of methanol, 10-40 parts of methyl acetate, 5-40 parts of ethyl acetate, 10-50 parts of sec-butyl acetate, 5-30 parts of butyl acetate, 5-55 parts of xylene, 3-35 parts of No.100 aromatic solvent oil. The environment-friendly thinner disclosed by the invention is free of benzene and toluene solvents, the production cost is low, and the production process is simple, no waste water and waste slag are discharged in the production process, a small amount of volatile gases are in line with the national emission standards. Meanwhile, the thinner has the advantages of strong dissolving capacity and uniform volatilization speed and the paint film has good leveling effect.

Owner:WEIFANG YIXING CHEM TECH

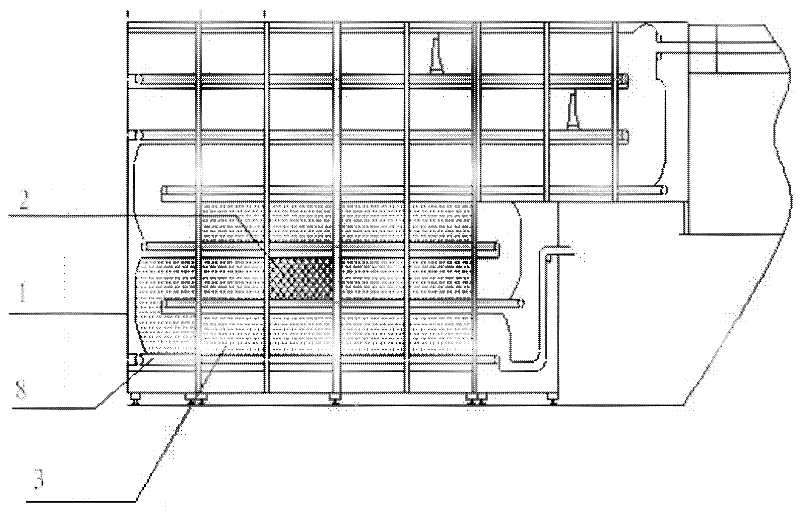

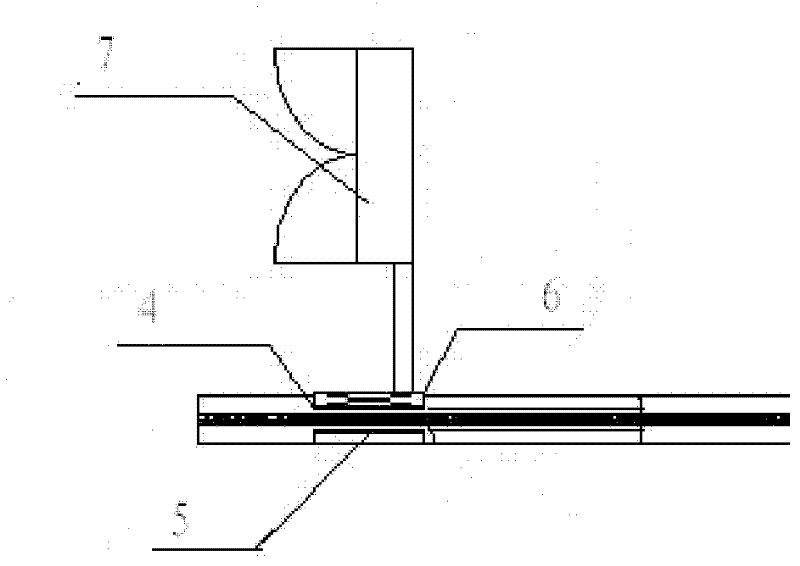

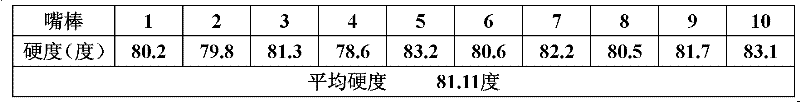

Cigarette filter tip firming method

InactiveCN102499474AEnsure safe productionVolatile evenlyTobacco smoke filtersHardnessElectromagnetic radiation

The invention relates to a cigarette filter tip firming method, which includes: firstly, forming a cigarette filter tip in a former, and spraying glyceryl triacetate into the former; secondly, feeding the cigarette filter tip sprayed with glyceryl triacetate into a storage cabinet, and using an electromagnetic radiation heating device to quickly volatilize the glyceryl triacetate in the storage cabinet; and thirdly, feeding the cigarette filter tip with the glyceryl triacetate volatilized into a sender, and performing subsequent procedures. By means of high-frequency medium heating, the problem that the hardness of the cigarette filter tip is insufficient due to short volatilizing time of the glyceryl triacetate is solved, the glyceryl triacetate can be evenly volatilized within a reasonable time, and the cigarette filter tip is firmed to be reasonably hard.

Owner:YIYANG KEJIA LIGHT IND MACHINERY MFG

Solar cell conductive paste and preparation method thereof

ActiveCN110600162ALower sintering temperatureEvenly dispersedFinal product manufactureNon-conductive material with dispersed conductive materialSolventBoiling point

The invention provides solar cell conductive paste. The nanoscale glass powder and the conductive powder are adopted, the sintering temperature can be effectively reduced, the method can be conveniently applied to occasions with low sintering temperature, such as back passivation solar cells (PERC), moreover, the sphericity degree of the glass powder and the conductive powder is smaller than 0.5 to form the pinning effect and the bridging effect, so not only the glass powder and the conductive powder are dispersed more uniformly in a resin matrix, the adhesion capability is enhanced, but alsoconductivity is improved, and conversion efficiency of a solar cell is enhanced, furthermore, the resin matrix adopts three kinds of solvents with different boiling points, so uniform volatilization of an organic phase is facilitated, and the film forming quality is improved.

Owner:HENAN AGRICULTURAL UNIVERSITY

Resistance paste for YH21CT stainless steel thick film circuit and preparation method thereof

InactiveCN109448885AHeating evenlyEfficient heat storageNon-conductive material with dispersed conductive materialCable/conductor manufactureCelluloseTributyl citrate

The invention discloses a resistance paste for an YH21CT stainless steel thick film circuit and a preparation method thereof. The resistance paste comprises 86%-90% of solid phase component and 10%-14% of organic binder by weight percentage; the solid phase component includes 70%-90% of tungsten-palladium composite powder and 10%-30% of SiO<2>-BaO-Al<2>O<3>-CaO-ZrO<2>-H<3>BO<3> series microcrystalline glass powder by weight percentage; the tungsten-palladium composite powder includes 8%-25% of tungsten powder and 75%-92% of palladium powder by weight percentage; particle sizes of the tungstenpowder and the palladium powder are smaller than 1.5 mum; the raw materials of the SiO<2>-BaO-Al<2>O<3>-CaO-ZrO<2>-H<3>BO<3> series microcrystalline glass powder include 30%-80% of SiO<2>, 2%-20% of BaO, 6%-40% of Al<2>O<3>, 20%-60% of CaO, 2%-20% of H<3>BO<3> and 2%-15% of ZrO<2> by weight percentage; the raw materials of the organic binder include 60%-82% of tributyl citrate, 0.2%-10% of hydrogenated castor oil, 1%-15% of cellulose nitrate, 3%-30% of terpilenol, 1%-18% of span-85 and 0.2%-10% of 4. gamma-butyrolactone by weight percentage; and the preparation steps include steps of preparingthe microcrystalline glass powder, the tungsten-palladium composite powder, the organic binder and the resistance paste.

Owner:浙江亮能机电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com