Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Good abrasion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrophotographic photosensitive member, process cartridge and electrophotographic apparatus

InactiveUS20020119382A1Reduce photosensitivityIncrease in residual potentialElectrographic process apparatusCorona dischargeProtection layerElectric charge

An electrophotographic photosensitive member exhibiting a good durability and stable electrophotographic performances regardless of environmental change is provided by coating the photosensitive layer with a specific protective layer. The protective layer comprises a cured phenolic resin and a charge-transporting compound having at least one group selected from the group consisting of hydroxyalkyl groups, hydroxyalkoxy groups and hydroxyphenyl groups capable of having a substituent.

Owner:CANON KK

Electroplating effect imitated plastic paint and preparation method, diluent and process of using same

The invention discloses a plastic paint with simulated electroplating effect. The composition and the weight ratio of the invention are as follows: 30 to 45 of acrylic resin with 50 percent of solid content and 70 to 90 DEG C of Tg, 20 to 30 of cellulose acetate butyrate with 20 percent of solid content, 8 to 12 of triad copolymer vinyl chloride-acetate resin with 30 percent of solid content, 6 to 10 of non-floating aluminum and silver pulp with an average diameter less than or equal to 20 Mum, 0.3 to 0.5 of dispersant, 0.2 to 0.4 of flatting agent, 0.4 to 0.6 anti-settling agent, 6.0 to 10.0 of toluene, 3.5 to 6.0 of ethyl acetate, 3.5 to 6.0 methy isobutyl ketone, 3.0 to 5.0 of isobutanol and 4.0 to 7.0 of glycol butyl ether. The special diluent of the invention, according to the weight ratio, is made from the following components evenly mixed: 20 of white gas, 10 of toluene, 22 of ethyl acetate, 15 of acetone, 25 of isobutanol and 8 of glycol butyl ether. The main paint which comprises the composition and the diluent are evenly mixed according to the ratio of 1: 2-3, then the mixture is used for spray coating; the metallic appearance of the paint film obtained is very close to the effect of the electroplating, and the paint film has good alcohol resistance with high hardness and strong wear resistance, and also has simple process. The aluminum and silver pulp used is a common type, the cost of which is only 5 percent to 10 percent of the simulated electroplating aluminum and silver pulp and about 2 percent of electrosilvering.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

Zinc-aluminium embedding co-penetrating method for iron and steel products and its penetrant

InactiveCN1428454AImprove corrosion resistanceImprove abrasion resistanceSolid state diffusion coatingMaterials scienceZinc aluminium

The present invention relates to a zinc-aluminium embedding copenetrating method of iron and steel products and its penetrant. Its method includes the following steps: embedding iron or steel product in the penetrant, heat-insulating treatment for 3-10 hr at 400 to 600 deg.C, then a zinc-aluminium copenetrated layer with double-layer structure whose external layer is enriched with aluminium and internal layer is enriched with zinc is formed on the surface of iron or steel product, so that the iron or steel product can have more excellence anticorrosion property and resistance to abrasion.

Owner:中国石油乌鲁木齐石油化工有限公司 +1

Electrophotographic photosensitive member, and process cartridge and electrophotographic apparatus including the photosensitive member

InactiveUS6492081B2Free image and image flowHigh quality imagingElectrographic process apparatusMetal particleEngineering

An electrophotographic photosensitive member exhibiting a good durability and stable electrophotographic performances regardless of environmental change is provided by coating the photosensitive layer with a specific protective layer. The protective layer has a thickness of 1-7 mum and comprises a cured phenolic resin and metal particles or metal oxide particles dispersed therein.

Owner:CANON KK

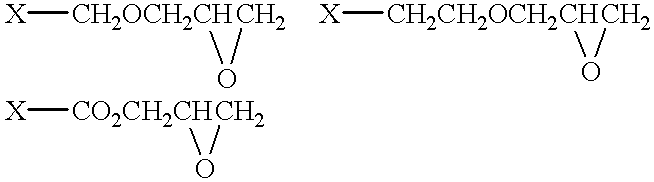

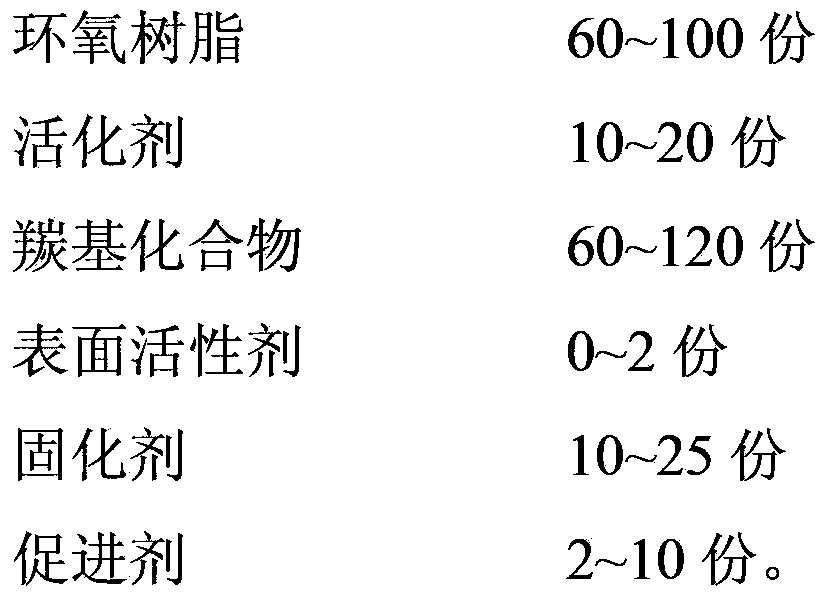

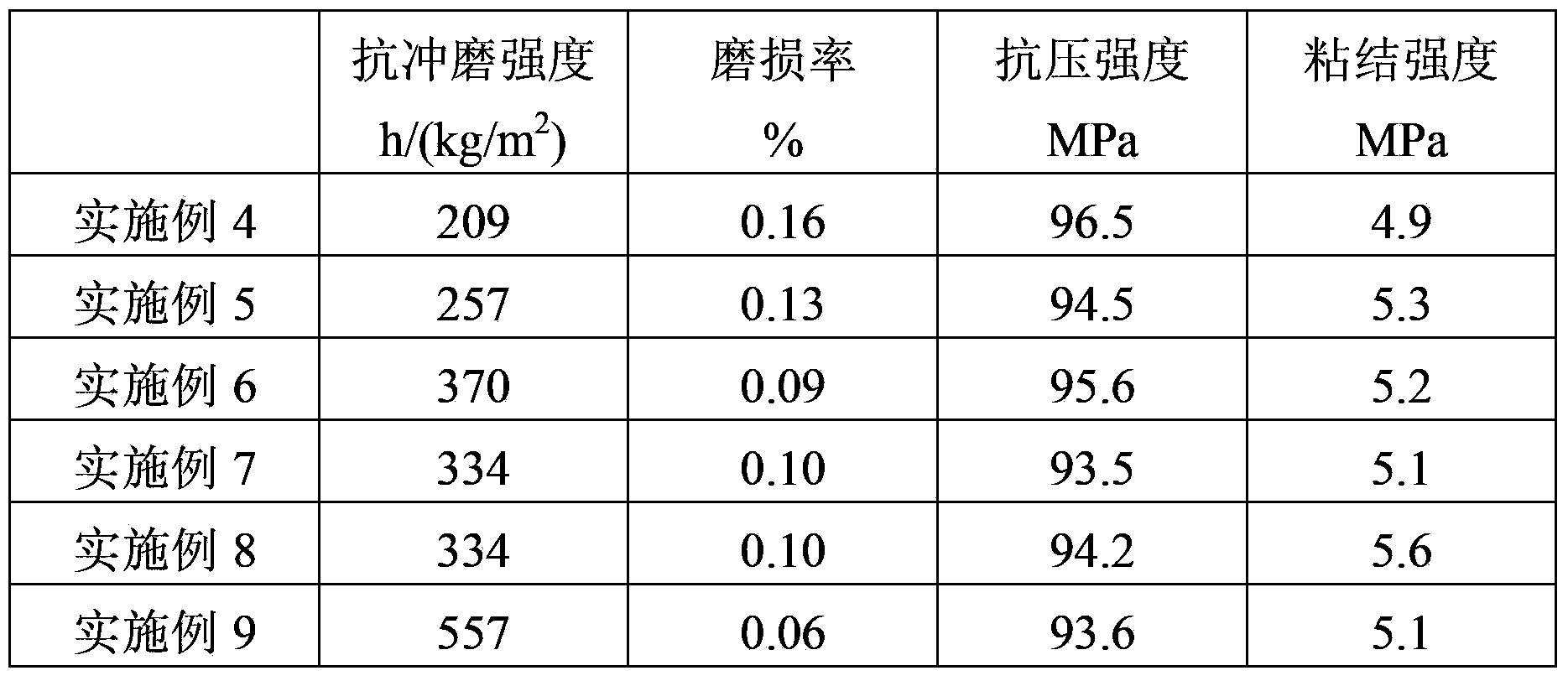

Abrasion-resistant epoxy mortar and preparation method thereof

InactiveCN103359977AImproved impact and abrasion resistance and durabilityGood abrasion resistanceBuilding materialBonding strength

The invention belongs to the technical field of hydraulic structure construction materials and discloses abrasion-resistant epoxy mortar and a preparation method thereof. The abrasion-resistant epoxy mortar consists of the following components in parts by weight: 80-100 parts of sand, 25-40 parts of powder and 18-26 parts of epoxy resin slurry, wherein the epoxy resin slurry consists of the following components in parts by weight: 60-100 parts of epoxy resin, 10-20 parts of activating agent, 60-120 parts of carbonyl compound, 0-2 parts of surfactant, 10-25 parts of curing agent and 2-10 parts of accelerant. The abrasion-resistant epoxy mortar has excellent abrasion resistance (over 200h / (kg / m<2>) and low wear rate (below 0.16 percent), the compressive strength is over 90MPa, the bonding strength is over 4.9MPa, and the abrasion-resistant epoxy mortar can serve as an abrasion-resistant material and is applied to the field of hydraulic structure buildings.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Electrophotographic photosensitive member, process cartridge and electrophotographic apparatus

InactiveUS6555279B2Reduce photosensitivityIncrease in residual potentialElectrographic process apparatusCorona dischargeProtection layerChemistry

An electrophotographic photosensitive member exhibiting a good durability and stable electrophotographic performances regardless of environmental change is provided by coating the photosensitive layer with a specific protective layer. The protective layer comprises a cured phenolic resin and a charge-transporting compound having at least one group selected from the group consisting of hydroxyalkyl groups, hydroxyalkoxy groups and hydroxyphenyl groups capable of having a substituent.

Owner:CANON KK

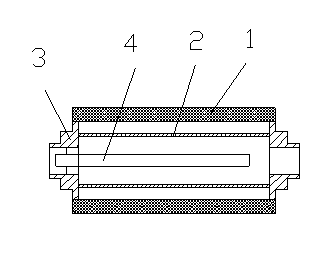

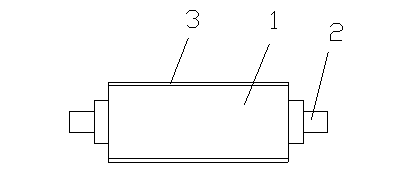

Novel electrical heating corrugated roller

InactiveCN103213323ASimple heating structureGood abrasion resistanceMechanical working/deformationHeat conductingWear resistant

The invention discloses a novel electrical heating corrugated roller, which comprises a corrugated roller outer roller with a plurality of outer teeth processed on the outer surface, a corrugated roller inner roller and two spindle heads, wherein the corrugated roller outer roller is in welded connection with the spindle heads; the corrugated roller inner roller is in welded connection with the spindle heads; a cavity is formed between the corrugated roller outer roller and the corrugated roller inner roller; heat conducting oil is arranged in the cavity; a heating pipe is arranged in the corrugated roller inner roller; a wear-resistant layer is arranged on outer surfaces of the outer teeth on the corrugated roller outer roller. Through the mode, the novel electrical heating corrugated roller is simple in a heating structure, better in wear-resistant performance and durability, and simple and practical.

Owner:虞伯林

Electrophotographic photosensitive member, and process cartridge and electrophotographic apparatus including the photosensitive member

InactiveUS20020034701A1Free image and image flowHigh quality imagingElectrographic process apparatusMetal particleEngineering

An electrophotographic photosensitive member exhibiting a good durability and stable electrophotographic performances regardless of environmental change is provided by coating the photosensitive layer with a specific protective layer. The protective layer has a thickness of 1-7 mum and comprises a cured phenolic resin and metal particles or metal oxide particles dispersed therein.

Owner:CANON KK

Composite powder for abradable seal coating and preparation method of coating

InactiveCN104294202AHigh bonding strengthGood abrasion resistanceMolten spray coatingHexagonal boron nitrideBoron nitride

The invention provides composite powder for an abradable seal coating and a preparation method of the coating. The composite powder consists of the following substances in percentage by weight: 1.5-2.5 percent of graphite, 15.0-20.0 percent of hexagonal boron nitride, 4.0-8.0 percent of silicon dioxide, 10.0-13.0 percent of copper dioxide, 3.0-5.0 percent of cadmium dioxide, 3.0-5.0 percent of aluminum and the balance of nickel. The method for preparing the abradable seal coating by utilizing the composite powder is a plasma spraying method, and the spraying parameters comprise the current of 500-600A, the hydrogen flow of 8-14L / min, the argon flow of 30-40L / min, the spraying distance of 100-150mm and the powder feeding amount of 10-20g / min. By utilizing the composite powder and the coating preparation method disclosed by the invention, the use temperature of the prepared seal coating can reach 600 DEG C.

Owner:PLA NO 5719 FACTORY

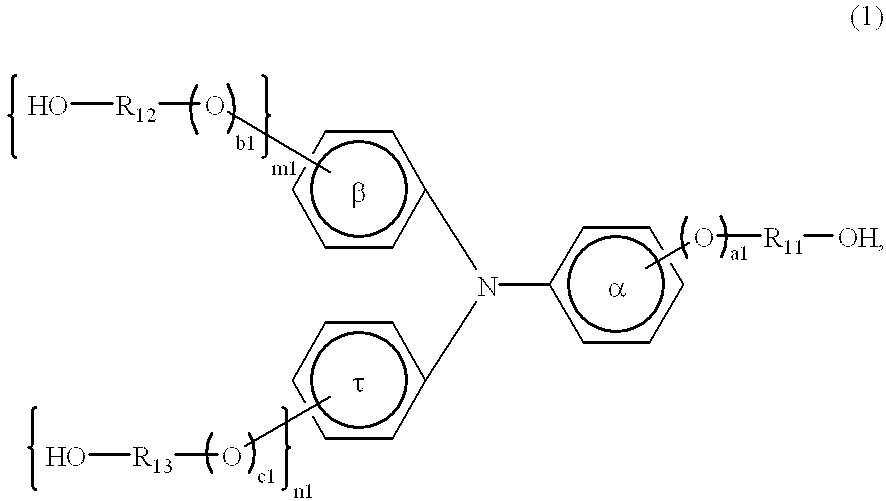

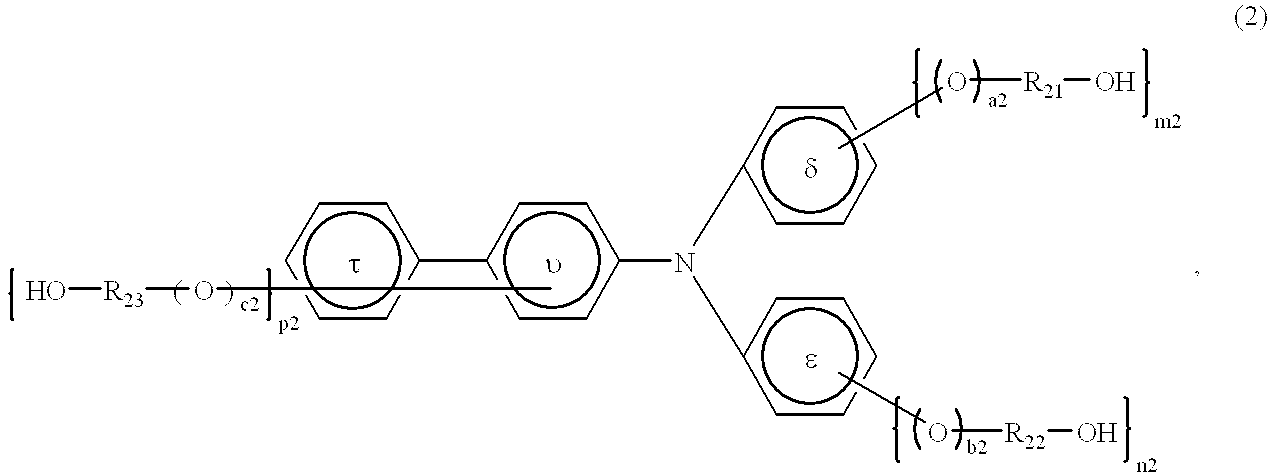

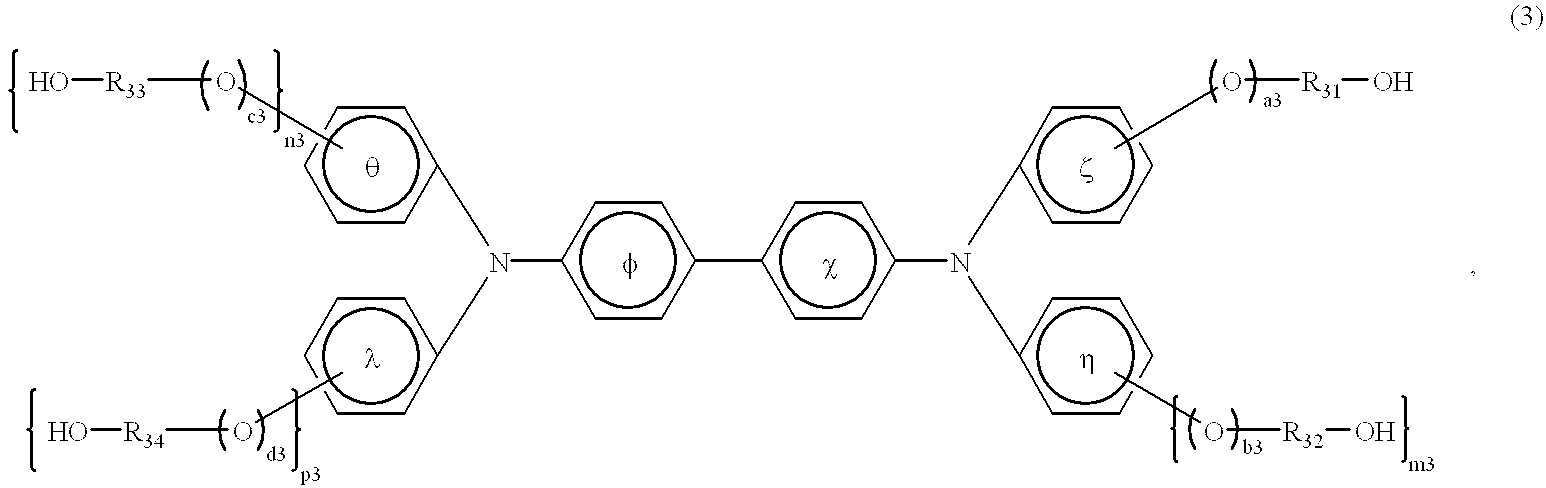

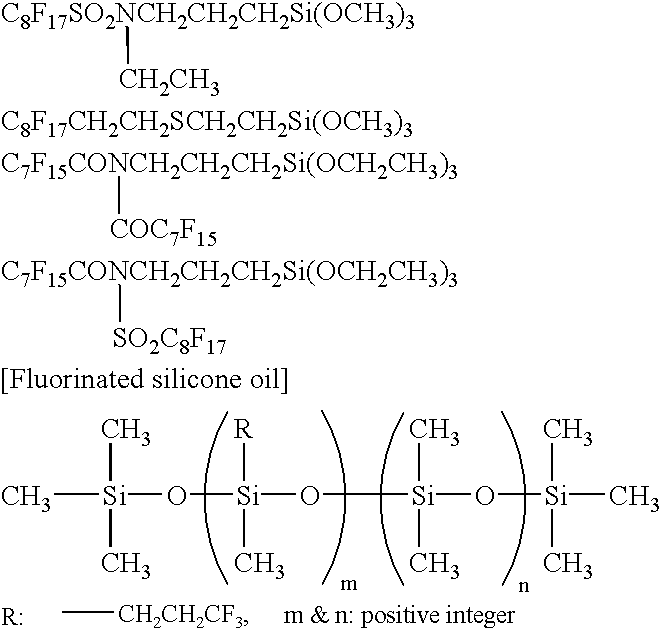

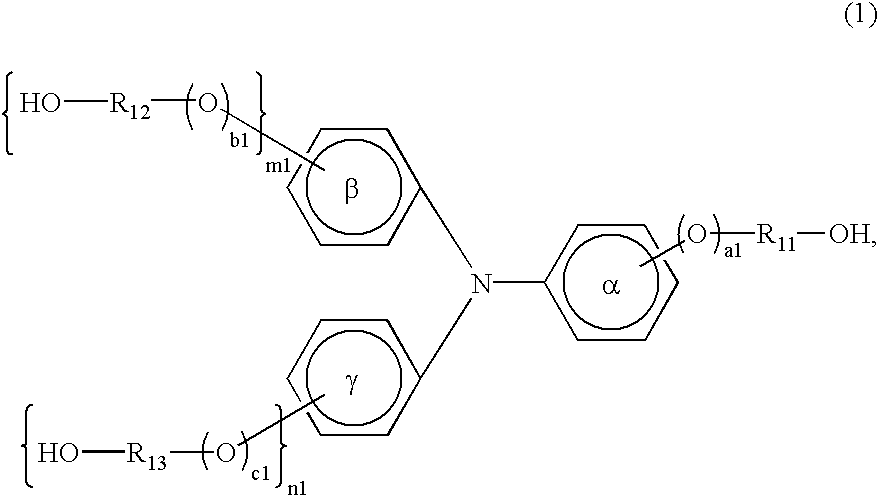

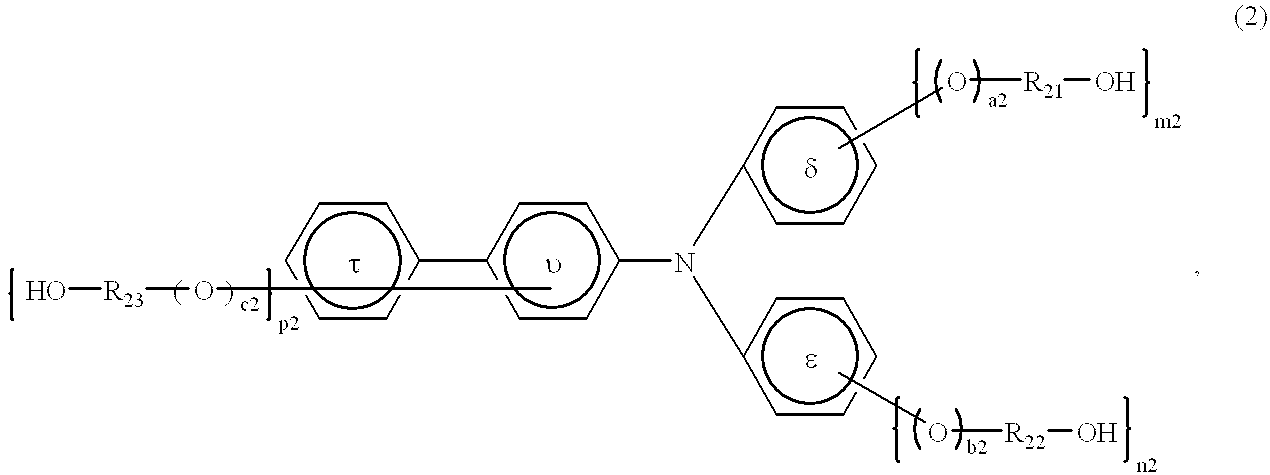

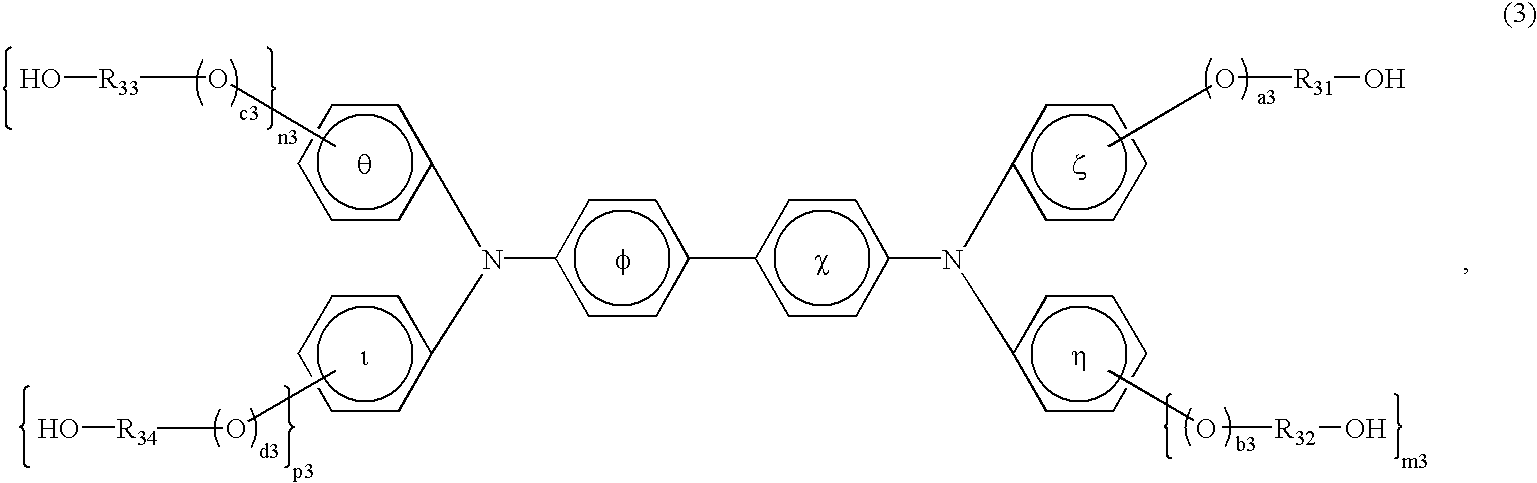

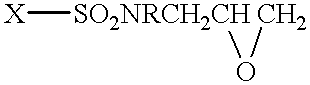

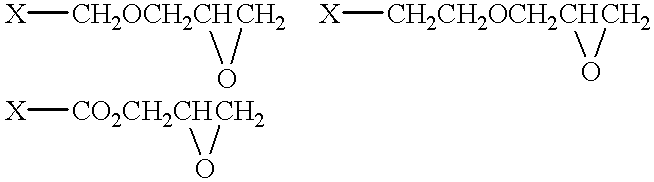

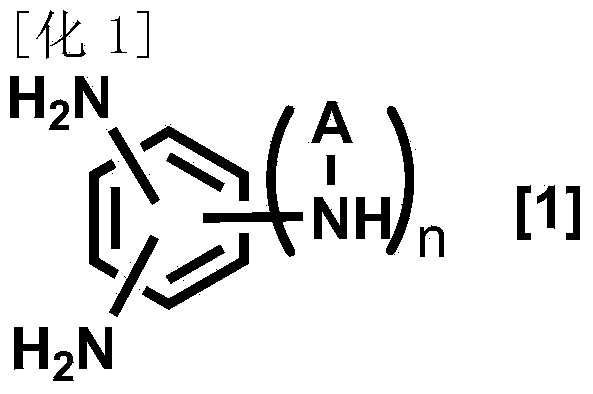

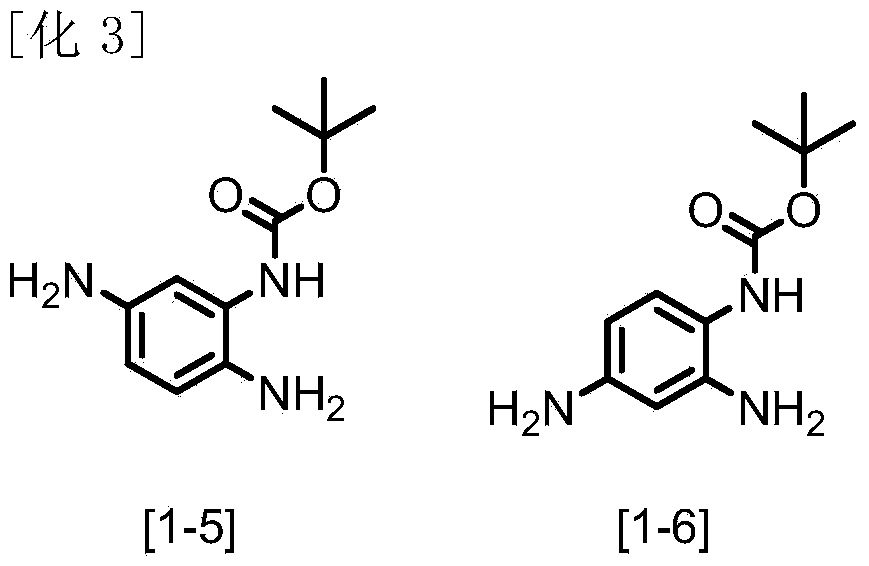

Novel diamine, polymer, liquid crystal alignment agent, and liquid crystal alignment film, and liquid crystal display element using same

ActiveCN104220488AGood solubilityGood abrasion resistanceNon-linear opticsPolyamideLiquid-crystal display

A polymer comprising a polyimide obtained by dewatering cyclization (imidization) of a polyamide, polyamic acid, polyamic acid ester, or the polyamic acid and / or polyamic acid ester obtained using a diamine represented by general formula [1]. (In the formula, A represents a thermally desorbable organic group; n number of NHA groups are provided (n = 1 or 2), and the NHA groups are present at the ortho position with respect to the amino groups (NH2 groups); and the amino groups are present at the meta position or the para position.)

Owner:NISSAN CHEM IND LTD

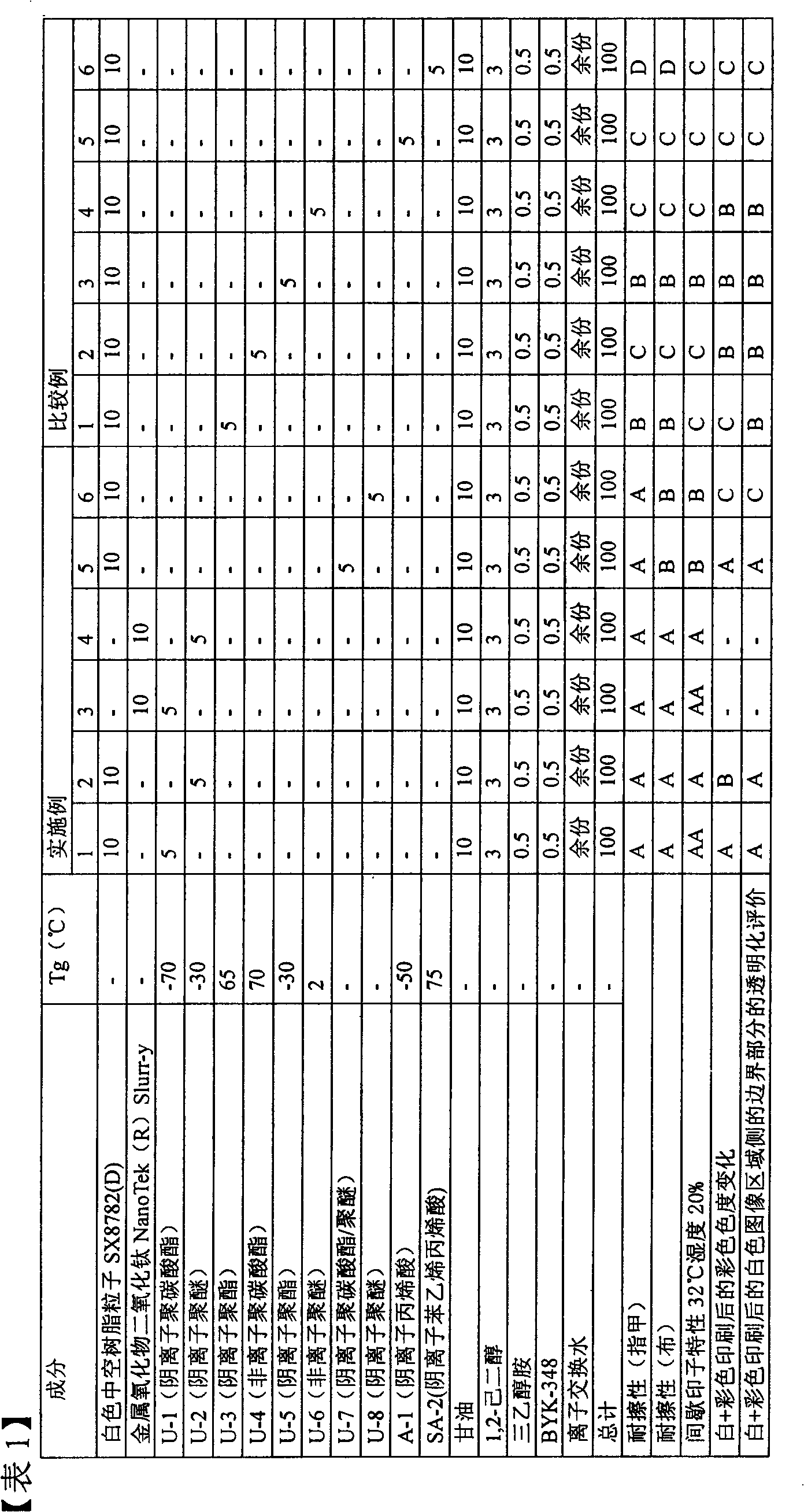

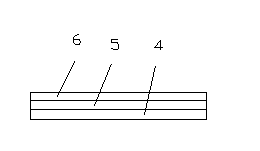

Wear-resistant antifouling high-physical-property polyurethane synthetic leather for consumer electronics and preparation method of wear-resistant antifouling high-physical-property polyurethane synthetic leather

The invention discloses wear-resistant antifouling high-physical-property polyurethane synthetic leather for consumer electronics and a preparation method of the wear-resistant antifouling high-physical-property polyurethane synthetic leather. The wear-resistant antifouling high-physical-property polyurethane synthetic leather for consumer electronics sequentially comprises an antifouling layer, asurface layer, a middle layer, a bonding layer and a base cloth layer from outside to inside, wherein the antifouling layer is made of water-based polyacrylic acid slurry, the surface layer is made of polycarbon type polyurethane slurry, the middle layer is made of polyether type polyurethane slurry, the bonding layer is made of double-component polyether type polyurethane slurry, and the base cloth is polyester knitted fabric. According to the wear-resistant antifouling high-physical-property polyurethane synthetic leather for consumer electronics, high-wear-resistant and high-hydrolysis-resistance polyurethane resin is adopted to be attached to the cloth base, then treatment is carried out through a water-based polycarbon type polyurethane antifouling treatment agent, the prepared high-physical-property synthetic leather for consumer electronics is full in hand feeling, fine and smooth in touch feeling and high in durability, and a new choice is provided for materials for consumer electronics.

Owner:ANHUI ANLI MATERIAL TECH

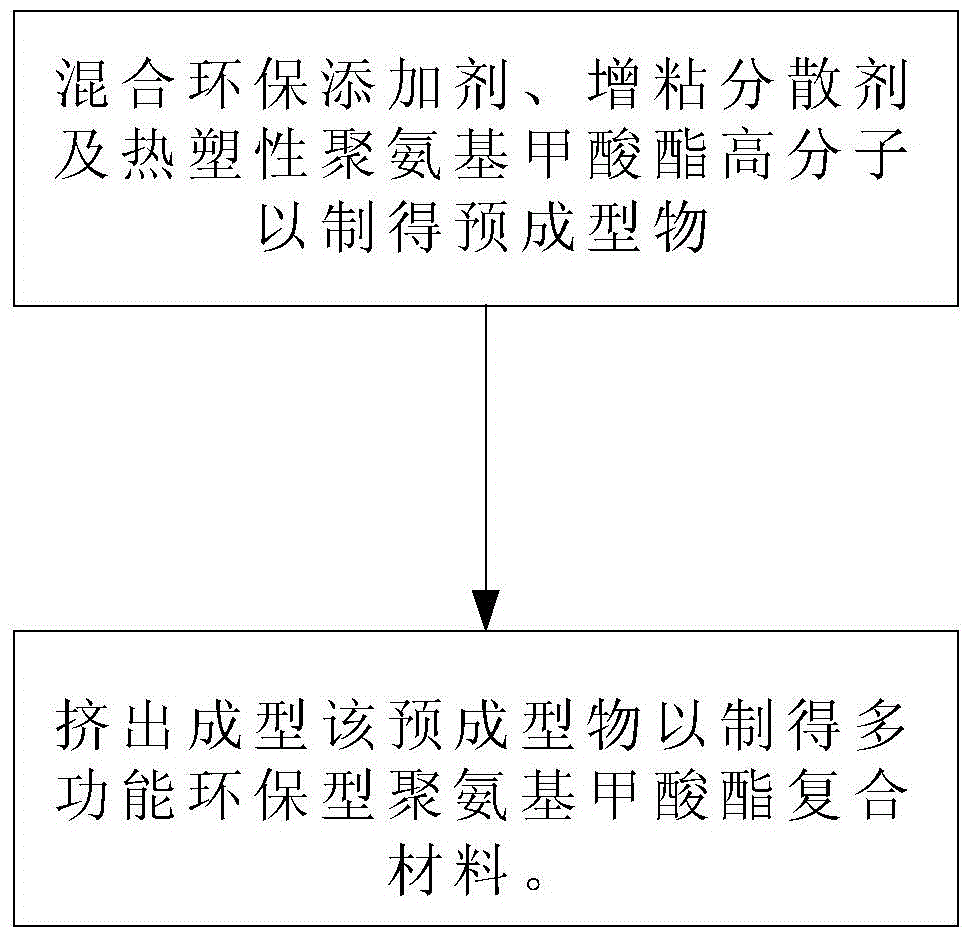

Multifunctional environment-friendly polyurethane composite material and preparation method thereof

InactiveCN104788936ARestrain the increase in garbage volumeReduce wasteThermoplastic polyurethaneVegetable fibers

The invention relates to a multifunctional environment-friendly polyurethane composite material and a preparation method thereof. The multifunctional environment-friendly polyurethane composite material comprises a thermoplastic polyurethane macromolecule, an environment-friendly additive which includes at least one substance selected from the group consisting of a recovered high polymer material, vegetable fiber, mineral and metal powder, and a tackifying dispersant which includes substances selected from the group consisting of natural rubber and synthetic rubber. In virtue of the tackifying dispersant, the environment-friendly additive can uniformly bond with the thermoplastic polyurethane macromolecule, so the composite material is formed. The environment-friendly additive enables environmental protection effect to be obtained; besides, cooperation between the environment-friendly additive and the tackifying dispersant enables the composite material to have the advantages of light weight, good slip limiting performance, excellent wear resistance, good formability and low cost.

Owner:SUNKO INK

Environment-friendly efficient ice-melting coating material and preparation method and application thereof

The invention discloses an environment-friendly efficient ice-melting coating material and a preparation method and an application thereof and aims to solve the technical problem that the deicing costis high, and a deicer pollutes the environment, harms roads and the environment and cannot play roles effectively durably. The coating is prepared from the following raw materials: a deicer, a bonding material, a hydrophobic coating material, a hydrophilic coating material, a hydrophobic plasticizer, a hydrophilic plasticizer, glycerinum, an antisticking agent, talc powder, filler, a semi-fortifier, a flatting agent, a coupling reagent, a defoamer, a pore-foaming agent and hydrophobic fumed silica. The invention further provides a preparation method of the coating material. The coating material is applied to deicing traffic roads. The environment-friendly efficient ice-melting coating material is free of harmful ions, does not lead to corrosion and damage the environment during deicing durably, and has relatively good curing action to the pavement. The raw materials are wide in source, low in cost, simple in production process and easy to operate, and can be popularized and applied ona large scale. A lot of manpower and material resources are reduced, and the environment-friendly efficient ice-melting coating material has important economical value.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

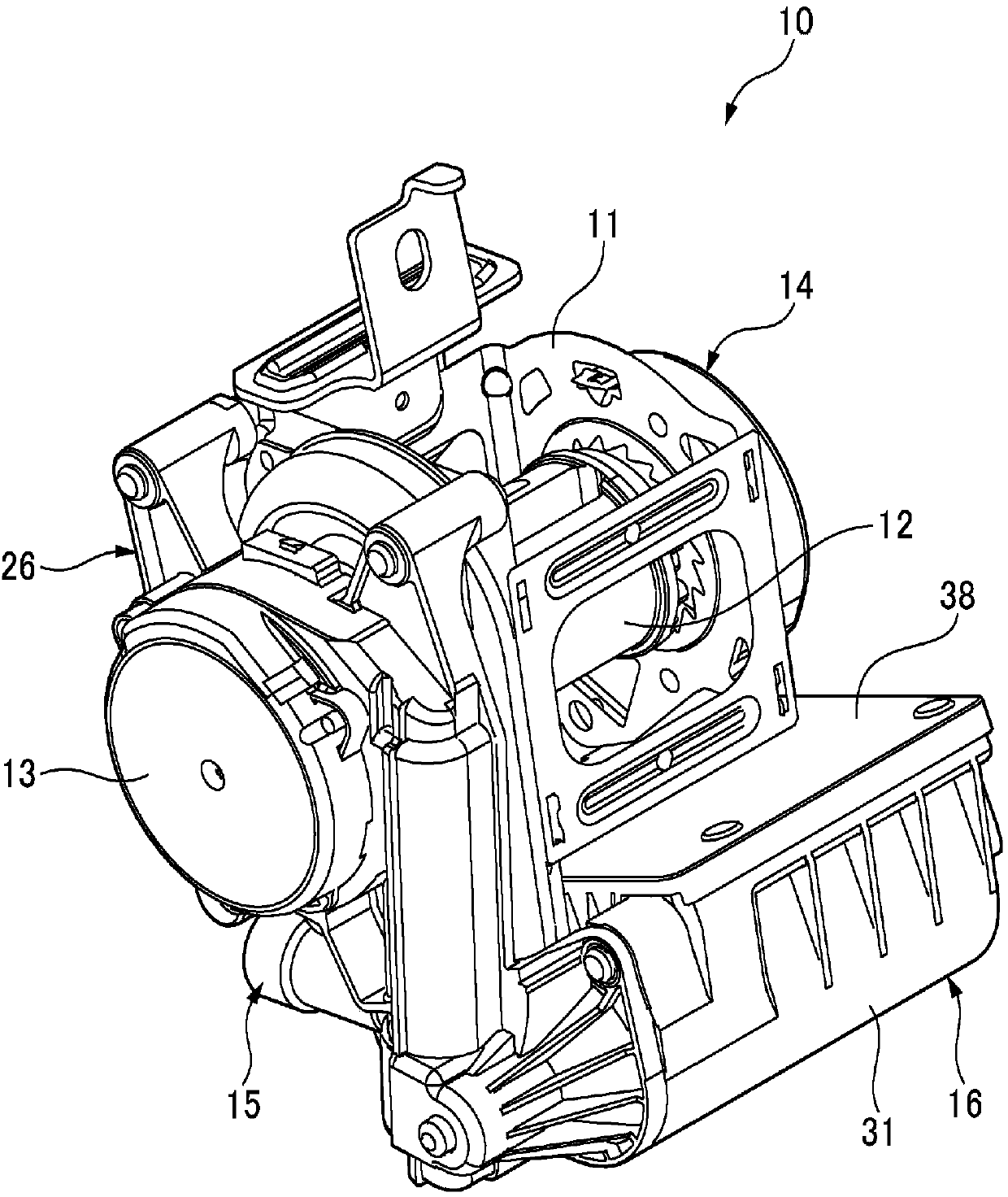

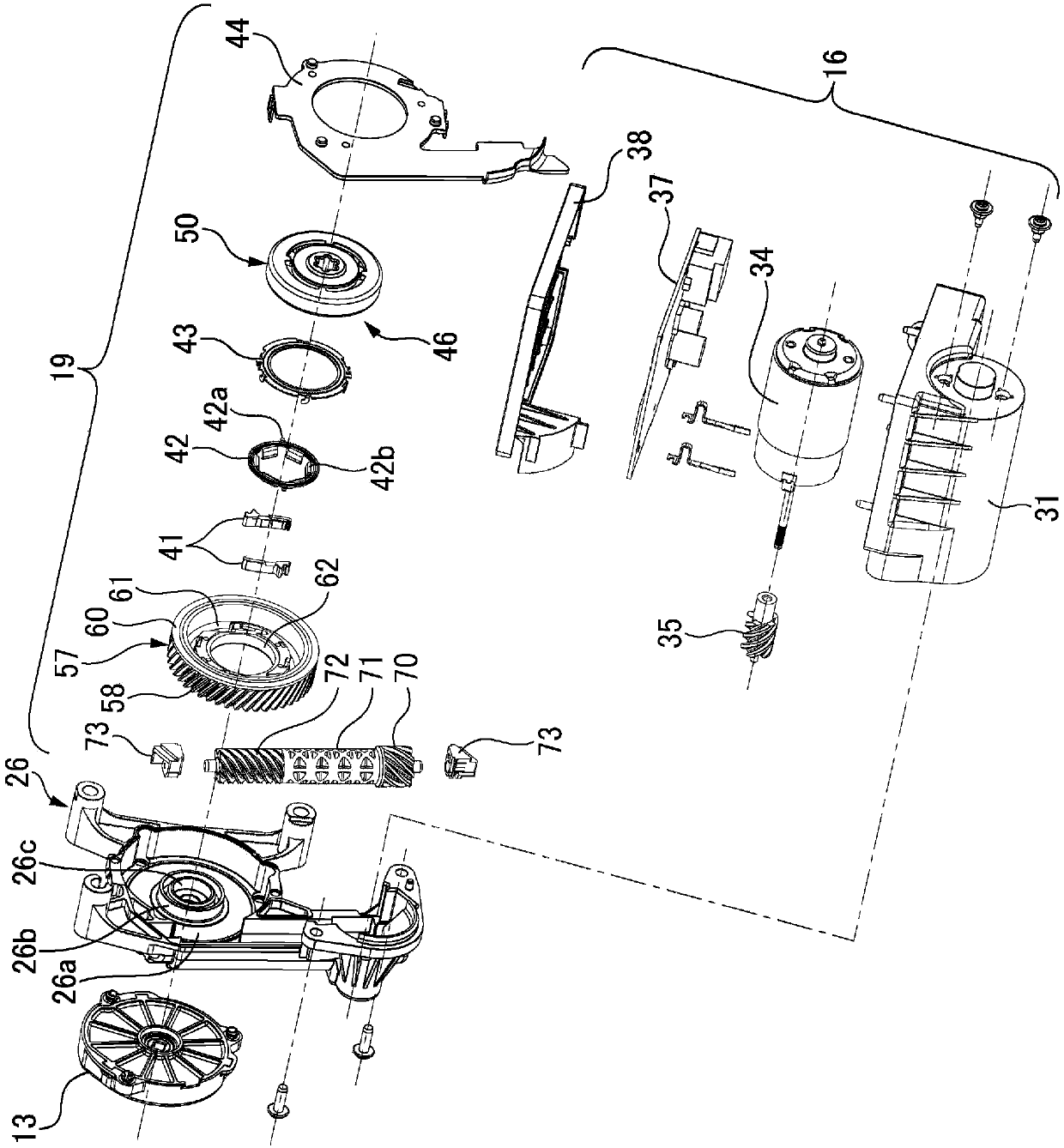

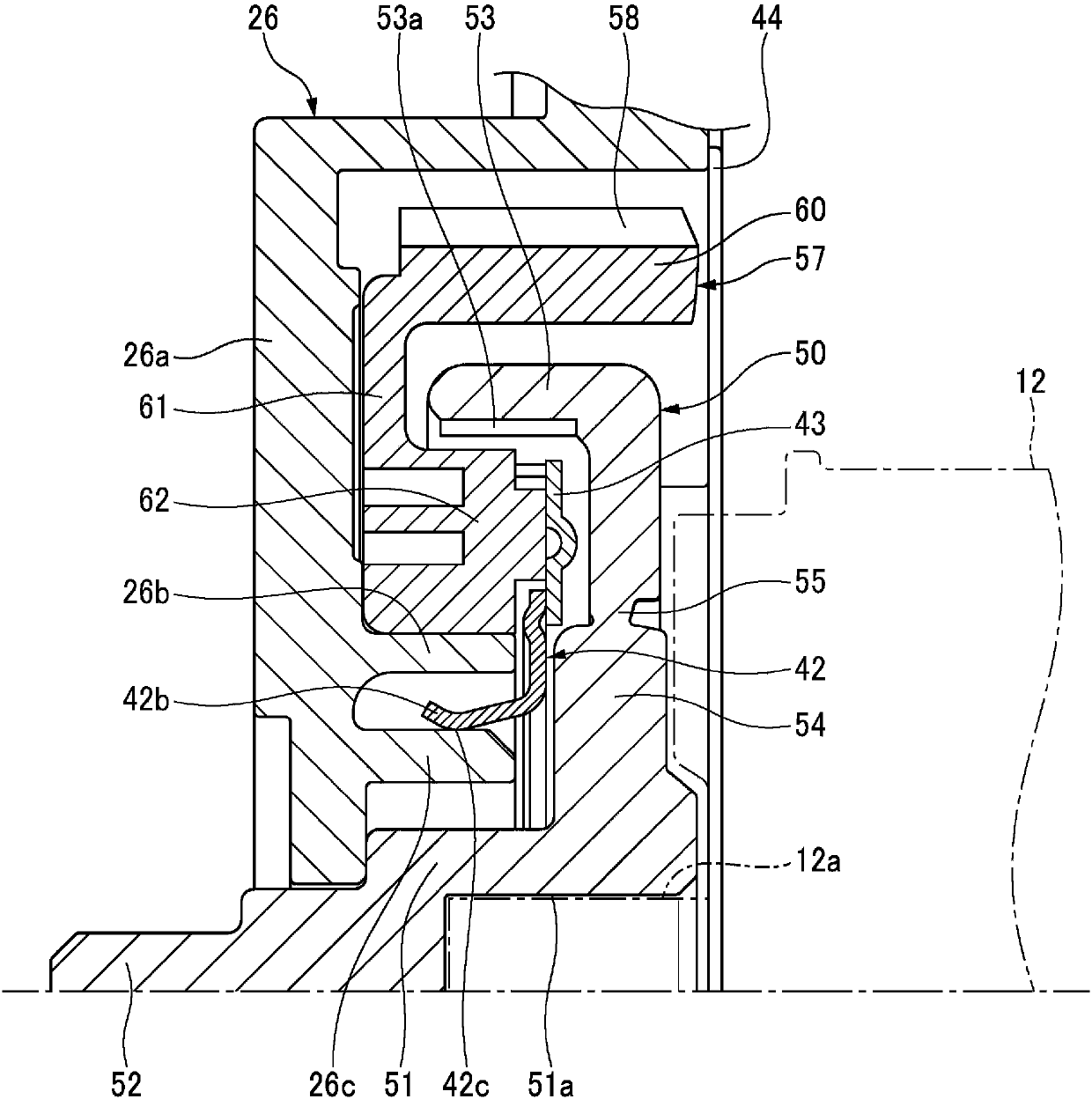

Seatbelt retractor

ActiveCN107635834AEasy to assembleGood abrasion resistanceBelt retractorsGear wheelTransmitted power

This power transmission mechanism (19) for transmitting power from a motor (34) to a spindle (12) is provided with: a clutch housing (50); a pawl (41) that is able to engage with the clutch housing (50); a gear wheel (57) that holds the pawl (41) and rotates according to the rotation of the motor (34); an outer gear cover (26); and a friction ring (42) engaging with the pawl (41) and held on the outer gear cover (26) due to frictional force. The friction ring (42) is provided with: a protrusion part (42a) that engages with an engagement groove (41b) of the pawl (41); and a plurality of contactpieces (42b) that come into contact with the outer peripheral surface of a small diameter ring part (26c) of the outer gear cover (26) and press against the small diameter ring part (26c) toward theinside in the radial direction. Consequently, assembly of the friction ring onto the outer gear cover can be facilitated.

Owner:AUTOLIV DEV AB

Ink composition, recorded material, recording method, and recording apparatus

Owner:SEIKO EPSON CORP

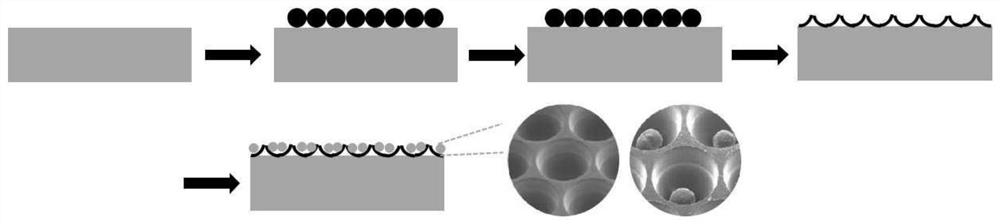

Wear-resistant self-cleaning super-amphiphobic coating and preparation method thereof

ActiveCN112375244AHigh transparencyGood abrasion resistanceAnodisationVacuum evaporation coatingSurface energyCorrosion resistant

The invention provides a wear-resistant self-cleaning super-amphiphobic coating and a preparation method. A groove type microstructure is constructed on a transparent base material, then a nano structure grows on the groove type microstructure, then low surface energy modification is carried out, and finally the wear-resistant self-cleaning super-amphiphobic coating is constructed on the transparent base material. The water-oil contact angle of the coating is larger than 150 degrees, the rolling angle of the coating is smaller than 10 degrees, and the coating is high in transparency, excellentin abrasion resistance, corrosion resistance, salt spray resistance and aging resistance and good in durability, and effectively solves the common problems of insufficient light transmittance and mechanical strength in a super-amphiphobic coating.

Owner:武汉中科先进材料科技有限公司

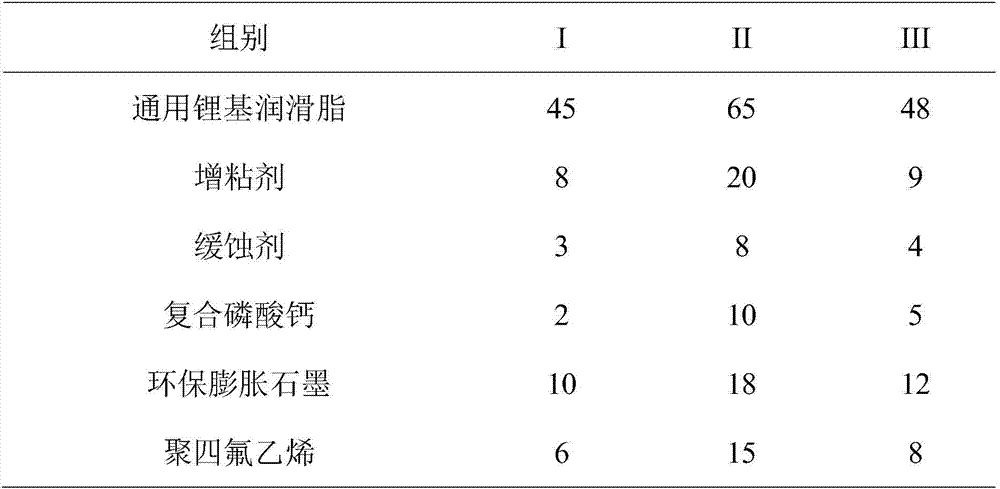

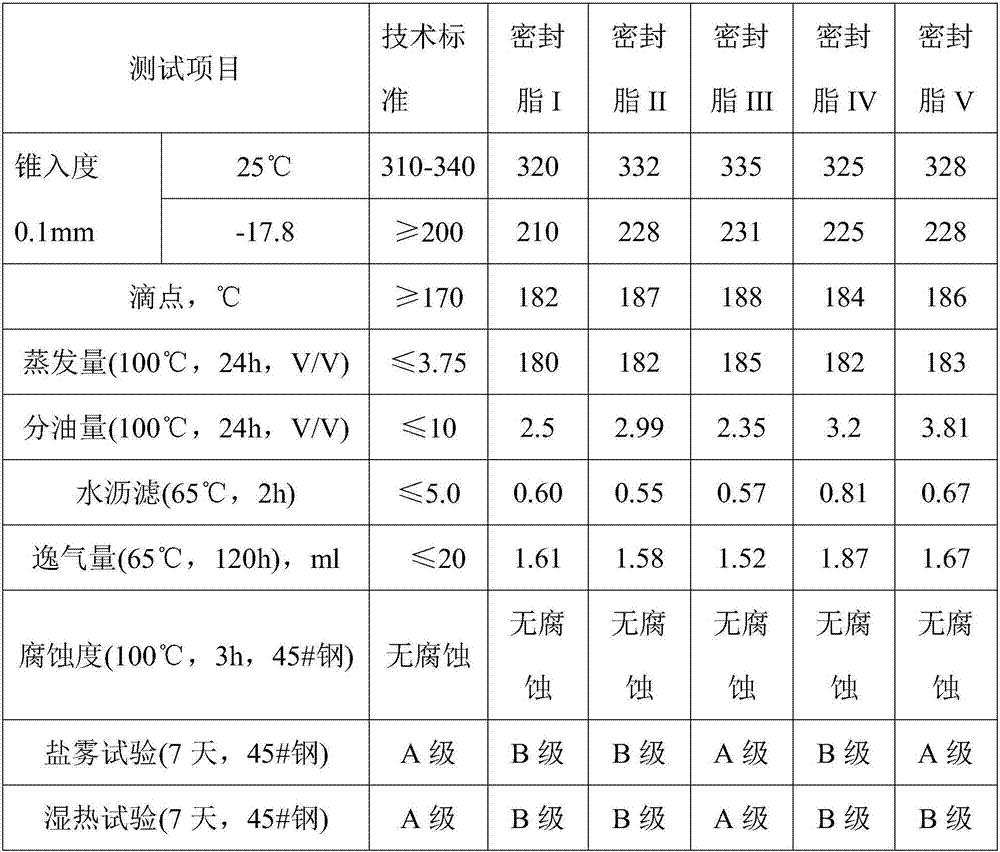

Antirust, wear-resistant, and environment-friendly sealing grease and preparation method thereof

InactiveCN107129857AImprove wear resistanceGood abrasion resistanceOther chemical processesLubricant compositionWear resistantTackifier

The invention discloses an antirust, wear-resistant, and environment-friendly sealing grease, which is composed of lithium-based lubricating grease, a tackifier, a corrosion inhibitor, composite calcium phosphate, environment-friendly expanded graphite, and polytetrafluoroethylene. Compared with the prior art, the provided sealing grease contains a corrosion inhibitor and composite calcium phosphate and thus has multiple antirust functions; composite calcium phosphate is slightly dissolved in water under an corrosive environment, has a strong chelating performance on metals, can form a passive coating on the iron surface, has an excellent antirust effect, and is green and environment-friendly; the expanded graphite does not contain sulfur or is low in sulfur, and has a high expanding rate and excellent anticorrosion performance and anti-wear property; different from conventional sealing grease, provided sealing grease has a better anti-rubbing performance and anticorrosion performance; moreover, zinc powder is not needed, the performance of thread grease is not influenced at the same time, the heavy metal pollution to the environment is reduced, the damage to the users is reduced, and the provided sealing grease is environment-friendly.

Owner:江苏海川卓越密封材料有限公司

Lubricant oil and preparation method of same

InactiveCN107603705AImprove performanceGood abrasion resistanceLubricant compositionChemistryTriethanolamine

The invention discloses lubricant oil which is composed of, by weight, 100-150 parts of basic oil, 10-20 parts of an anti-wear agent, 5-10 parts of an anti-wear enhancer, and 3-10 parts of an anti-rust agent. Compared with the prior art, the lubricant oil has the following advantages: 1) a mixture composed of ferrocene, 3-(2-thiophene)propionic acid and ethyl 2-chloro-6-fluorophenylacetate, in special ratio, is employed as the anti-wear enhancer, so that the performance of anti-wear agents in the prior art is greatly improved, and the lubricant oil is excellent in anti-abrasion performance; 2)by means of the basic oil in specific weight ratio, namely, a mixture comprising mineral oil of which the ISO-VG viscosity grade is 100, castor oil and poly-alpha-olefin PAO15 according to mass ratioof 10:2:1, the lubricant oil is high in fuel oil saving rate; and 3) the anti-rust agent is a mixture of petroleum sodium sulfonate, triethanolamine borate and amide according to the mass ratio of 5:3:1, so that the lubricant oil has excellent anti-rust performance.

Owner:刘建忠

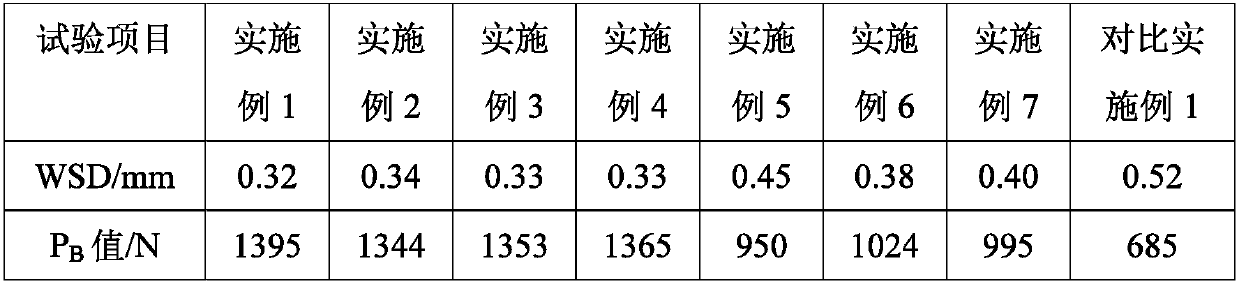

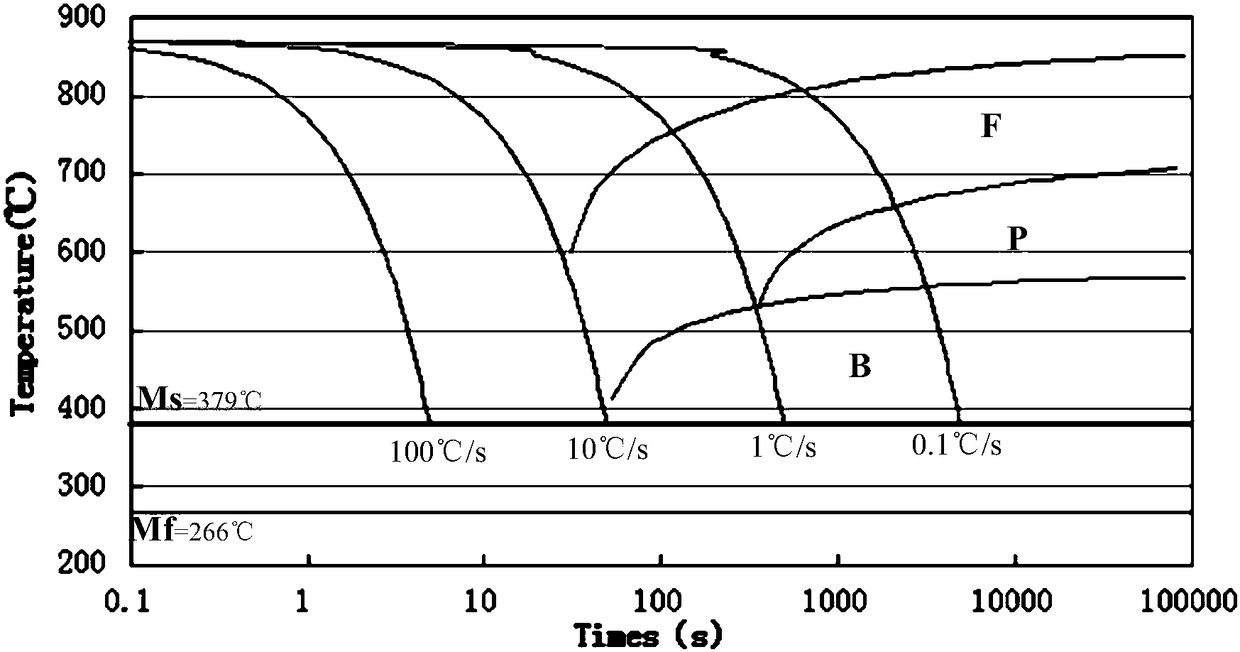

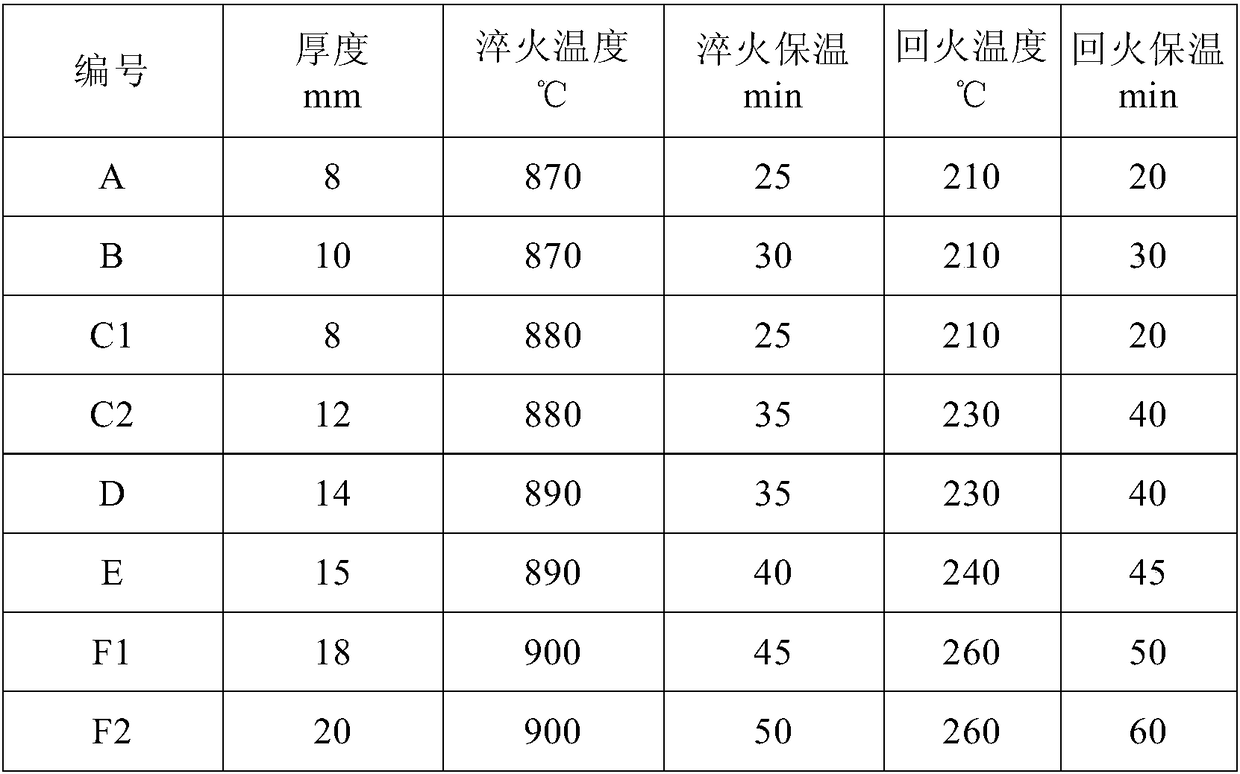

High-hardness wear-resistant corrosion-resistant steel plate for slurry dredging and production method thereof

ActiveCN108930001AGood abrasion resistanceImprove corrosion resistanceSteel platesCorrosion resistant

The invention provides a high-hardness wear-resistant corrosion-resistant steel plate for slurry dredging and a production method thereof. The steel plate comprises, by weight, 0.18 to 0.24% of C, nomore than 0.01% of Si, 1.3 to 1.6% of Mn, no more than 0.015% of P, no more than 0.005% of S, 0.2 to 1.0% of Al, 0.3 to 1.2% of Cr, 0.001 to 0.002% of B, no more than 0.005% of N, and one or more selected from a group consisting of 0.01 to 0.03% of Nb and 0.01 to 0.025% of Ti, with the balance being Fe and unavoidable impurity elements, wherein the sum of Nb and Ti is more than 6.65 N and no morethan 0.045. The composition design of the wear-resistant corrosion-resistant steel plate allows the steel plate to have both corrosion resistance and wear resistance; and the steel plate is mainly applied to manufacturing of dredging pipelines applied to reclamation of land from water, navigation channel dredging and other fields and has wear and corrosion resistance two times higher than the wearand corrosion resistance of conventional common pipes, so dredging efficiency is greatly improved and operation cost is lowered.

Owner:BAOSHAN IRON & STEEL CO LTD

Abrasion-resistant durable hoisting steel wire rope

InactiveCN103541252AGood flexibilityGood abrasion resistanceTextile cablesArchitectural engineeringAramid

The invention discloses an abrasion-resistant durable hoisting steel wire rope which comprises a center strand. A plurality of inner-layer strands are uniformly twisted on the outside of the center strand in a wrapping manner, a plurality of outer-layer strands are uniformly twisted on the outside of each inner-layer strand in a wrapping manner, each inner-layer strand is made of a plurality of inner abrasion-resistant mild steel wires, each inner abrasion-resistant mild steel wire comprises a mild steel wire base and an inner abrasion-resistant layer arranged on the outer surface of the mild steel wire base, each outer-layer strand is made of a plurality of outer abrasion-resistant steel wires, each outer abrasion-resistant steel wire comprises a steel wire base and an outer abrasion-resistant layer arranged on the outer surface of the steel wire base, and the center strand is made of aramid fibers. Owing to the mode, the abrasion-resistant durable hoisting steel wire rope has the advantages of good flexibility, abrasion resistance and durability and long service life.

Owner:无锡市内河装卸机械有限公司

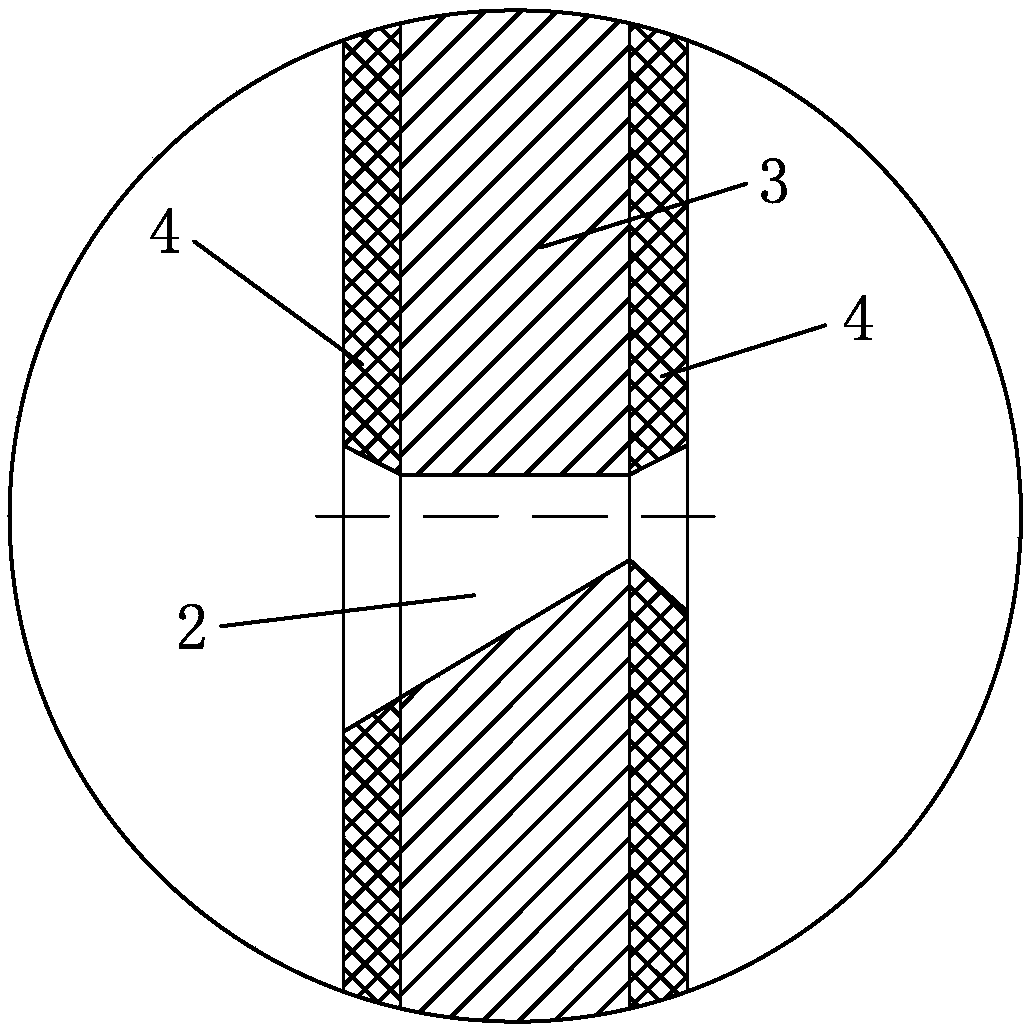

Steel wire rope winding drum used for hoisting machinery

InactiveCN103332619ASimple structureGood abrasion resistanceWinding mechanismsArchitectural engineeringFlange

The invention discloses a steel wire rope winding drum used for hoisting machinery. The steel wire rope winding drum comprises a winding drum body, wherein the two ends of the winding drum body are respectively provided with a flange, a steel wire rope spiral groove is formed in the outer surface of the winding drum body, a first wear-proof layer is arranged on the outer surface of the steel wire rope spiral groove, and a second wear-proof layer is arranged on the outer surface of the first wear-proof layer. Through the method, the steel wire rope winding drum is simple in structure, has good wear-proof and durable performance and is long in service life.

Owner:无锡市顺凯机械制造厂

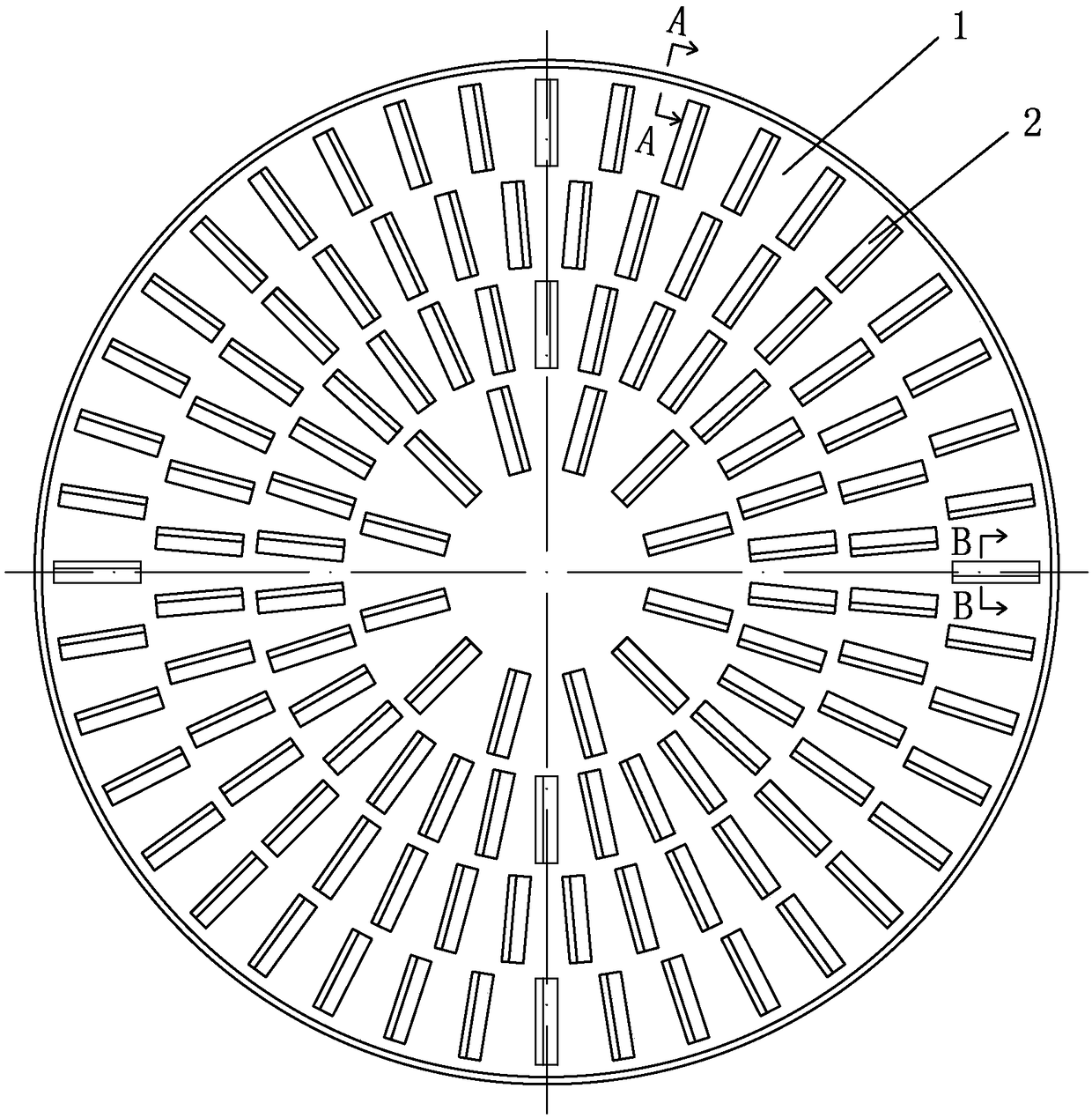

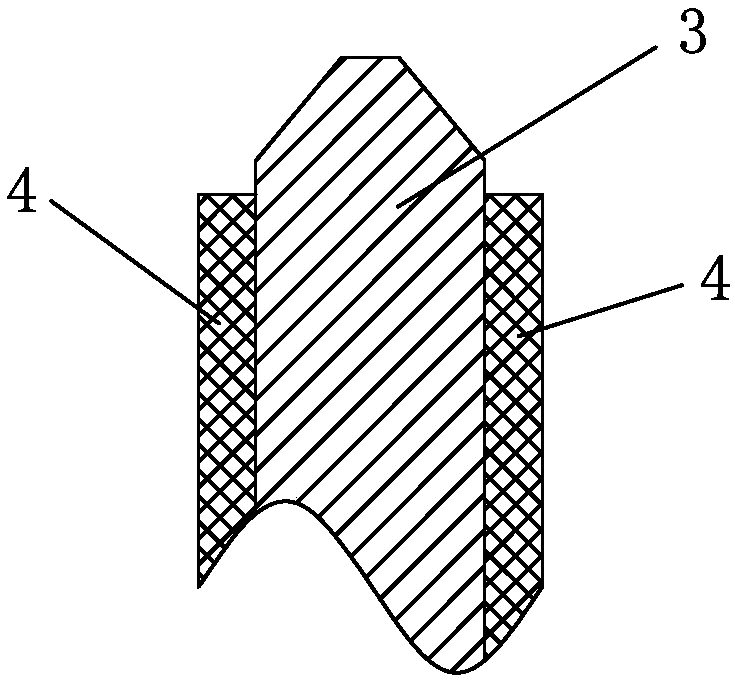

Compartment grid plate of large-volume low-energy continuous ball mill for ceramic industry

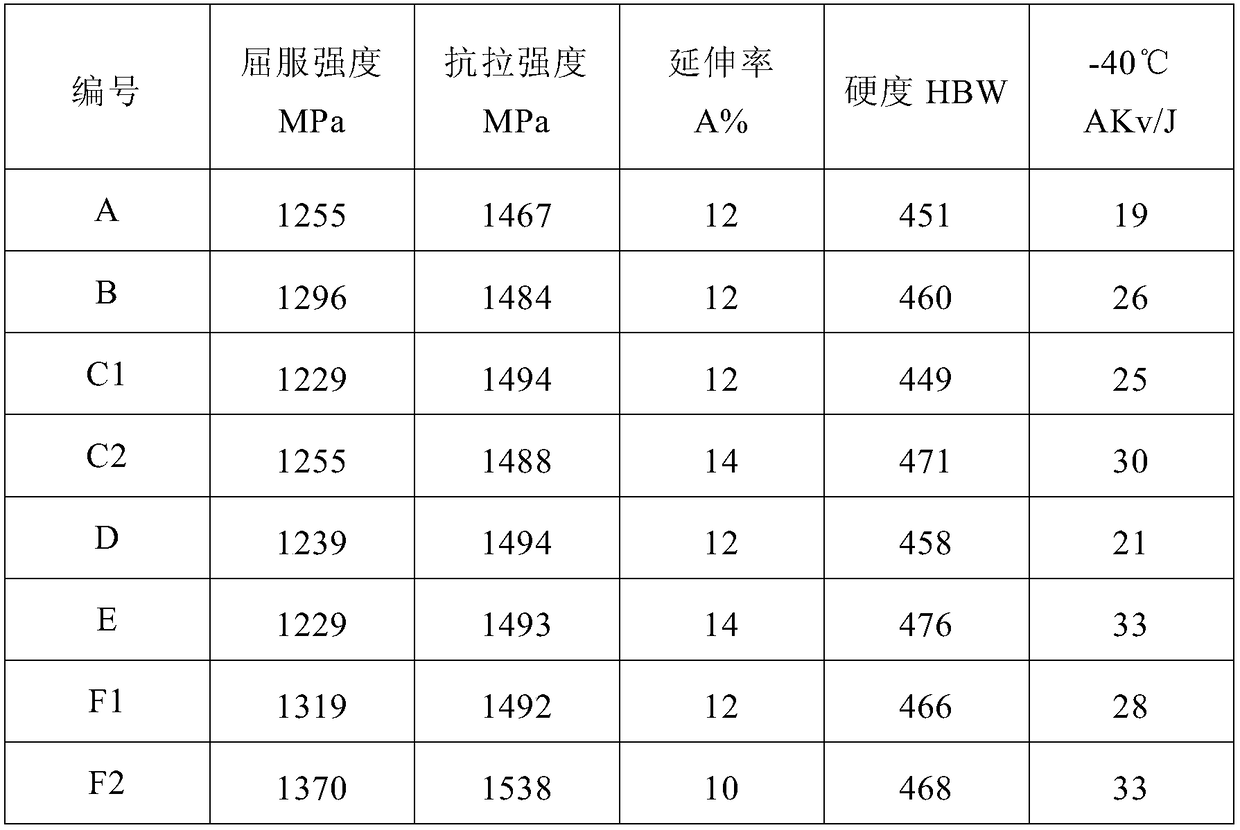

PendingCN109317262AImprove efficiencyHigh strengthGrain treatmentsWear resistantUltimate tensile strength

The invention relates to a compartment grid plate of a large-volume low-energy continuous ball mill for ceramic industry. The compartment grid plate comprises a grid plate and grid seams, the grid plate is circular, the size of the grid plate is the same as the inner diameter of a ball mill compartment body, the grid plate is made of a metal layer and wear-resistant layers, the middle layer is provided with a framework of a steel plate structure, the two faces are wear-resistant metal layers, compared with a rubber sieve plate and a rubber grid plate where wear-resistant ceramic is inlaid, thewear resistance and durability are better, the strength is high, four rings of grid seams are arranged on the grid plate with the circle center of the grid plate as the center, each ring is providedwith several grid seams, the distances between two adjacent grid seams on each ring are the same, an opening in one edge of each grid seam is large, an opening in the other edge of each grid seam is small, the openings have certain angles, the angle directions are set according to the rotating direction of the grid plate, and the grid seams are effectively prevented from being blocked by ball stone.

Owner:广东鼎汇能科技股份有限公司

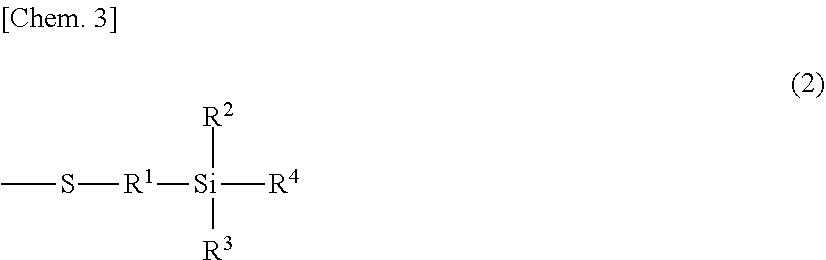

Heavy-duty tire rubber compositions and tires

InactiveUS20200332090A1Excellent low heat generate propertyGood abrasion resistanceHeavy duty tyresHeavy duty vehicleComposite materialPolymer chemistry

The invention provides a heavy-duty tire rubber composition capable of giving heavy-duty tires which exhibit low heat generation properties and have good abrasion resistance, and also provides a tire tread, a bead filler, a tire belt and a heavy-duty tire which each partially include the composition. The heavy-duty tire rubber composition includes 100 parts by mass of a solid rubber (A), 0.1 to 50 parts by mass of a modified liquid diene rubber (B) having a functional group derived from a silane compound with a specific structure, and 20 to 200 parts by mass of a filler (C), the modified liquid diene rubber (B) satisfying the following (i) and (ii): (i) the weight average molecular weight (Mw) is not less than 1,000 and not more than 120,000, and (ii) the vinyl content is less than 30 mol %.

Owner:KURARAY CO LTD

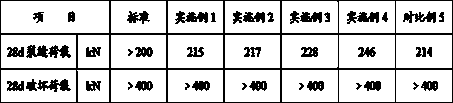

Steam-curing-free ultrahigh-performance concrete manhole cover as well as preparation method thereof

The invention discloses a steam-curing-free ultrahigh-performance concrete manhole cover as well as a preparation method thereof. The steam-curing-free ultrahigh-performance concrete manhole cover comprises an ultrahigh-performance concrete body and a reinforcement framework, wherein the ultrahigh-performance concrete body is prepared from the following stepsraw materials: river sand, high-activity low-shrinkage admixture, mineral powder, cement, a high-activity molecular activated catalyst, awater reducer, steel fibers and water. The invention also discloses a method for preparing the steam-curing-free ultrahigh-performance concrete manhole cover. By adopting a normal-temperature maintenance way, the process is simple, and the production cost and energy consumption can be reduced. The ultrahigh-performance concrete manhole cover prepared by adopting the normal-temperature maintenance way is excellent in performance, excellent in anti-permeability, anti-frozen-molten performance, corrosion resistance, high temperature resistance, erosion resistance and the like.

Owner:常州绿玛特建筑科技有限公司

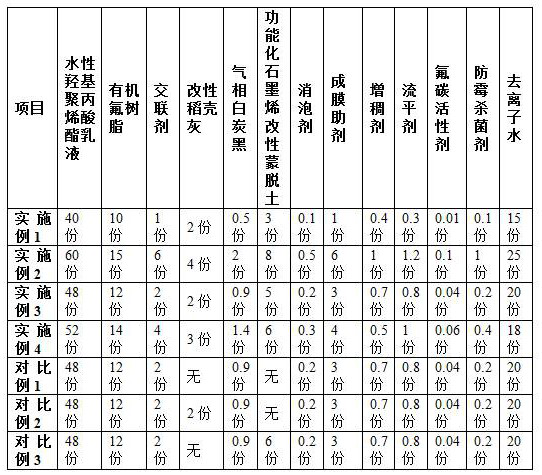

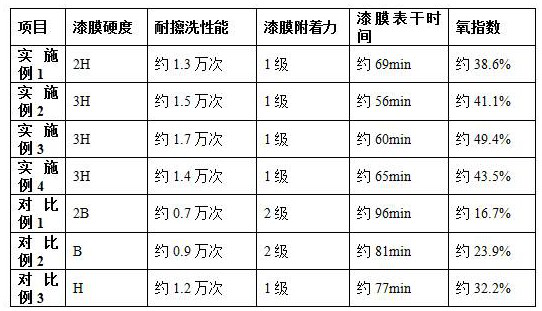

Flame-retardant anti-fouling water-based paint for woodware, and preparation method thereof

InactiveCN112094552AGood film forming stabilityImprove stain resistanceFireproof paintsAntifouling/underwater paintsActive agentCross linker

The invention relates to a flame-retardant anti-fouling water-based paint for woodware, and a preparation method thereof The water-based paint is prepared from, by weight, 40-60 parts of a water-basedhydroxyl polyacrylate emulsion, 10-15 parts of organic fluorine resin, 1-6 parts of a cross-linking agent, 2-4 parts of modified rice hull ash, 0.5-2 part of fumed silica, 3-8 parts of functionalizedgraphene modified montmorillonite, 0.1-0.5 part of an antifoaming agent, 1-6 parts of a coalescing agent, 0.4-1 part of a thickener, 0.3-1.2 parts of a leveling agent, 0.01-0.1 part of a fluorocarbonactivator, 0.1-1 part of a mildew-proof bactericide and 15-25 parts of deionized water. Compared with paints in the prior art, the water-based paint disclosed by the invention has the advantages of strong adhesive force to wood products, and good flame-retardant and heat-insulating effects, and apaint film of the paint has the advantages of high hardness, good abrasion resistance, good weather resistance, good fullness and distinctness of image, good stain resistance, easiness in construction, no pollution to environment and human bodies, no toxicity and no harm, and is green and environment-friendly.

Owner:JIANGXI LONGZHENG SCI & TECH DEV

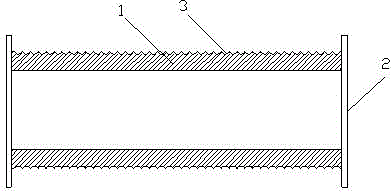

Novel durable corrugated roller structure

The invention discloses a novel durable corrugated roller structure, which comprises a metal roller body, and roller shafts arranged on two ends of the metal roller body, wherein a plurality of corrugated teeth are arranged on an outer part of the metal roller body, and are integrally arranged with the metal roller base body; and a composite wear-resisting coating is coated on outer surfaces of the corrugated teeth, and sequentially comprises a titanium nitride hard coating, an aluminium oxide hard coating and a tungsten carbide hard coating from inside to outside. Through the mode, the novel durable corrugated roller structure has better wear-resisting and durable performance.

Owner:虞伯林

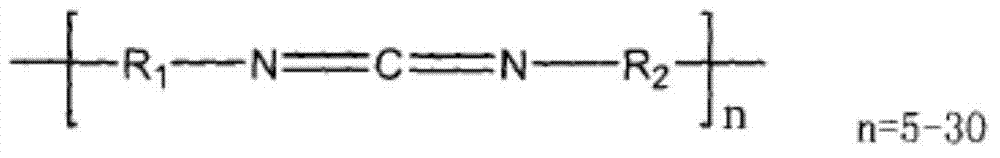

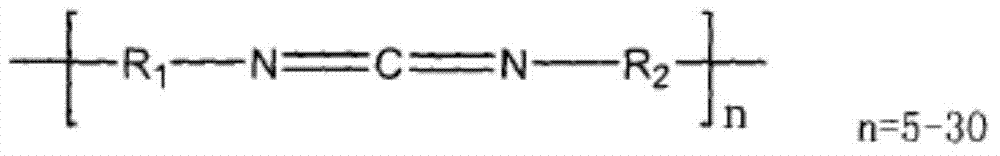

Tail end-capped polylactic acid fiber with high heat resistance and water resistance and preparation method thereof

InactiveCN103484969AImprove hydrolysis resistanceGood abrasion resistanceMelt spinning methodsMonocomponent polyesters artificial filamentPolylactic acidWater resistance

The invention discloses a polylactic acid fiber which has high hydrolysis resistance and friction resistance. The polylactic acid fiber comprises a polylactic acid ingredient, wherein the group at the tail end of a polylactic acid molecular chain is capped, glycidyl ester is used as an epoxy capping agent, and the polylactic acid ingredient is mixed with fatty acid diamide and / or an alkyl substituted type fatty acid monoamide ingredient and a polycarbodiimide ingredient.

Owner:SUZHOU LONGJIE SPECIAL FIBER

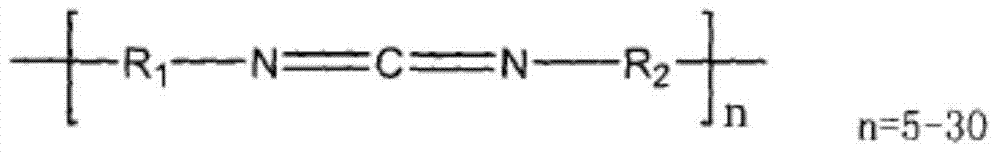

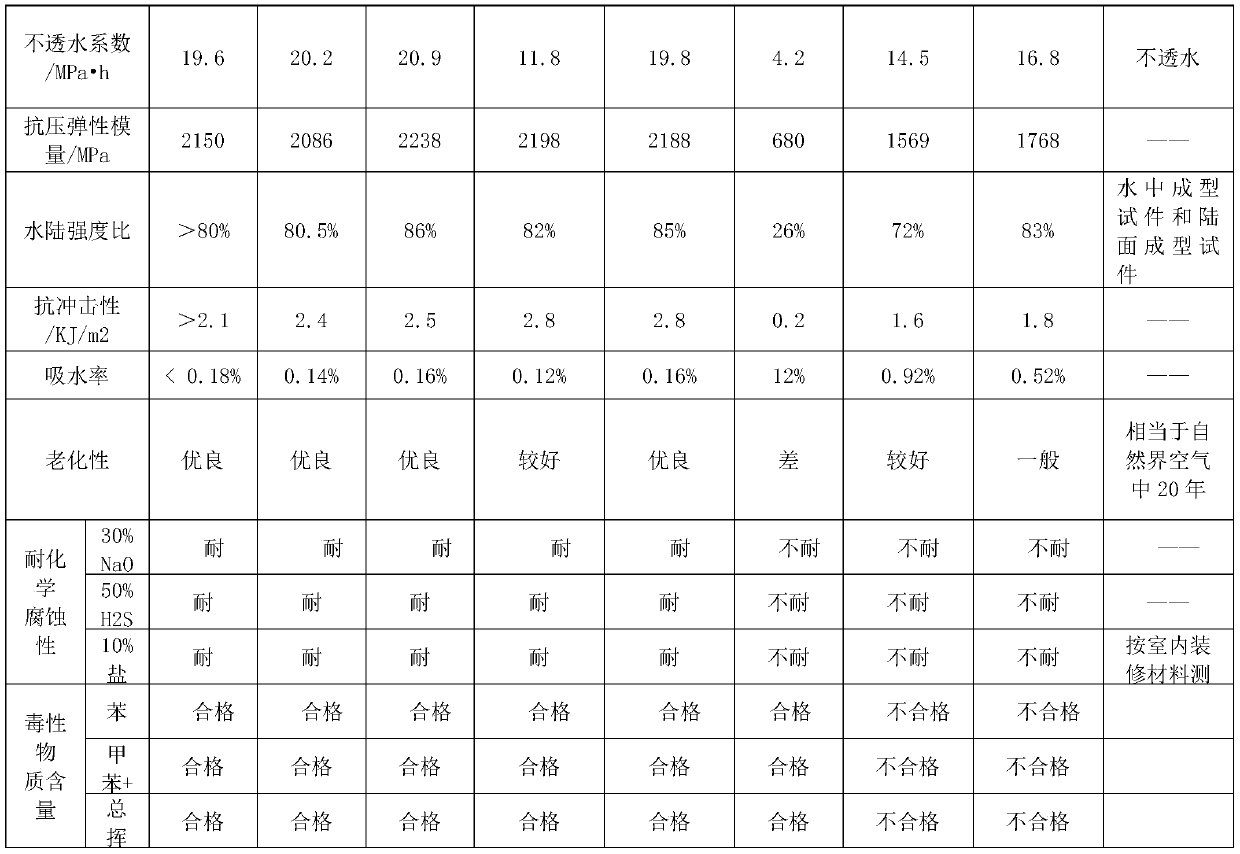

Underwater repairing coating material for concrete structure

The invention discloses an underwater repair coating material for a concrete structure, and belongs-the technical field of coatings. The coating material comprises 25-45 wt% of tetrafunctional epoxy resin, 3-8 wt% of auxiliary agents, 0.3-2 wt% of short fibers, 40-65 wt% of a powder filler, 4-15 wt% of a curing agent and 0-12 wt% of a reactive diluent; the sum of the percentages of the above raw materials is 100 wt%; the auxiliary agents comprise a leveling agent, a water reducer and a plasticizer; the short fibers are basalt fibers; the powder filler is a combination of river sands, cement and silicon powder; the curing agent is modified epoxy resin containing an imidazoline structure; and the reactive diluent is trimethylolpropane triglycidyl ether. The underwater repairing coating material can meet underwater wet construction, can be rapidly cured underwater, and has the main advantages of excellent dispersion resistance, excellent fluidity, excellent compressive strength, good bonding strength with old concrete, and good mechanical strength. No organic solvents or heavy metals are added, so that the coating material is safe, environment-friendly and sanitary.

Owner:CHENGDU PRESSTER NEW MATERIALS

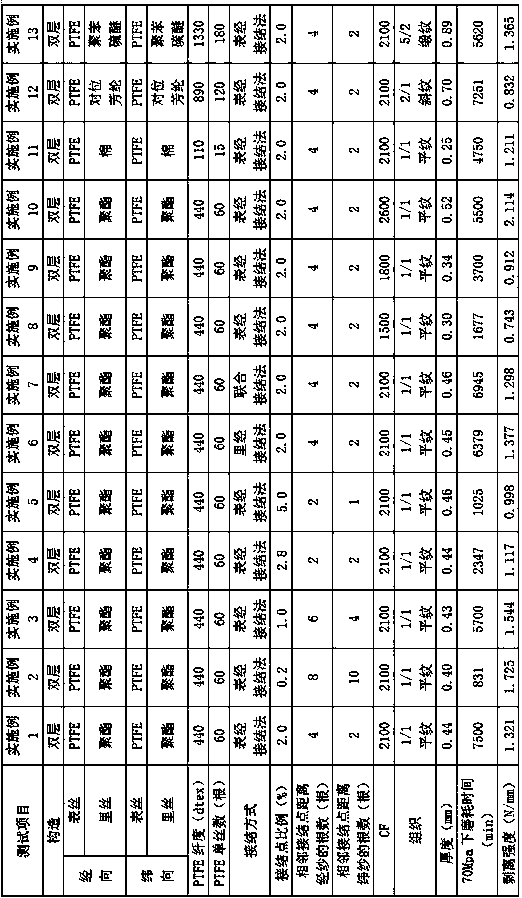

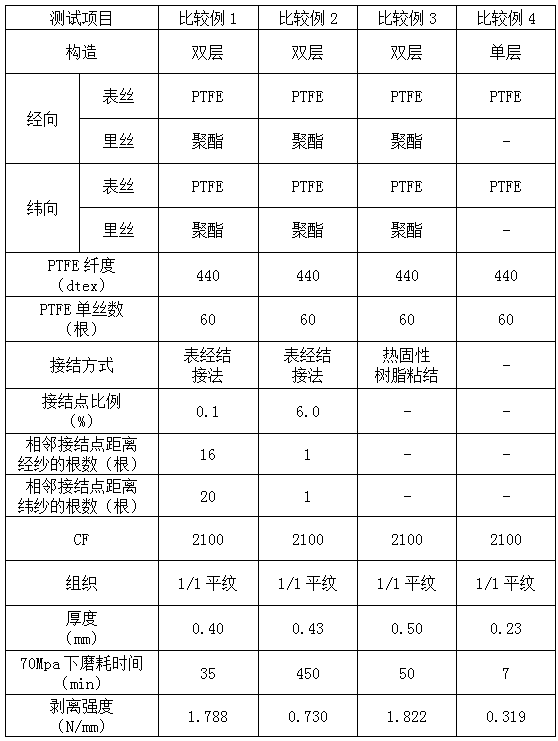

Self-lubricating double-layer fabric and application thereof

ActiveCN108070940AGood abrasion resistanceHigh peel strengthOrnamental textile articlesMulti-ply fabricsFiber layerPolytetrafluoroethylene

The invention discloses a self-lubricating double-layer fabric and application thereof. The double-layer fabric is formed by connecting a polytetrafluoroethylene fiber layer with a fiber layer formedby other fibers through bonding points, and the number of the binding points in one complete circulation structure in the double-layer fabric accounts for 0.2-5.0% of the total structure number. The self-lubricating double-layer fabric has the advantages of good abrasion resistance and high peel strength, and can be applied to plane or curved surface or linear motion parts.

Owner:TORAY IND INC

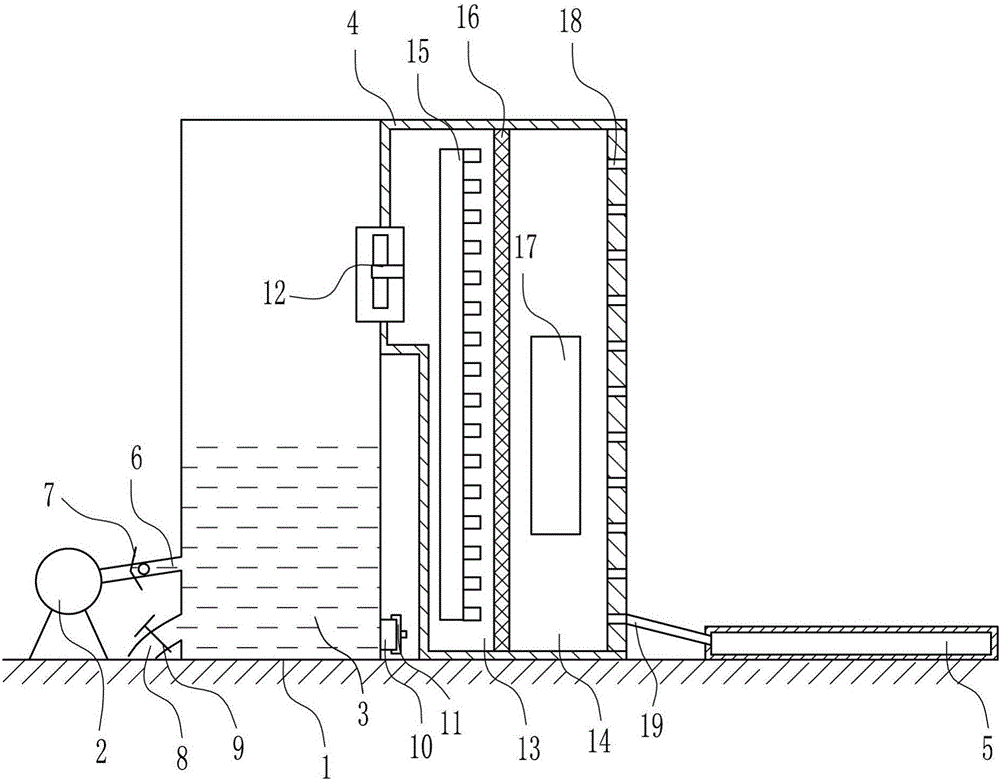

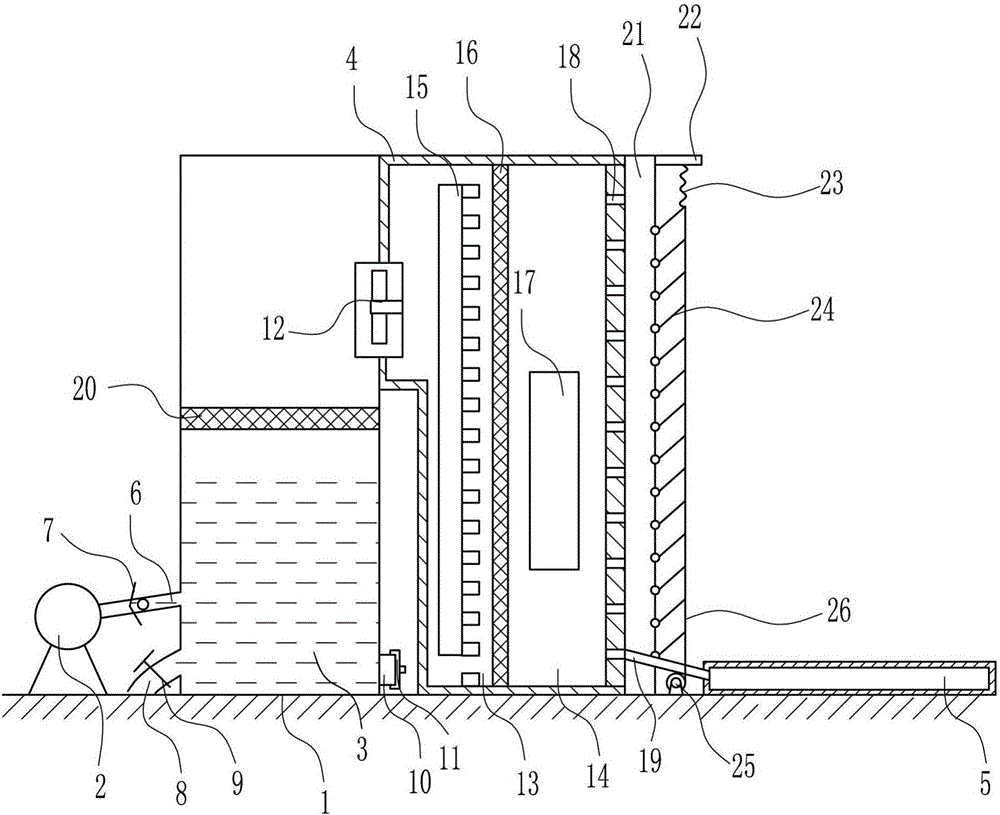

Heating device for warm-keeping room for animal husbandry in winter

The invention relates to a heating device for a warm-keeping room in winter, in particular to a heating device for a warm-keeping room for animal husbandry in winter.Therefore, the technical problems are solved by providing the heating device for the warm-keeping room for animal husbandry in winter. Animal-living places can be directly heated. Heating equipment has good effect and is safe and reliable. Therefore, animals can be fed and takes rest normally and can smoothly get through the winter. Considerable economic benefit can be provided for poultry feeders. In order to solve the above technical problem, the eating device for the warm-keeping room in winter comprises an air pump, an air purification box, a box body, a hollow plate, a first air inlet pipe, a check valve, a water outlet pipe, a drawing fan, a heating plate, a filter screen, a heat radiator, a second air inlet pipe and the like. The heating device for the warm-keeping room for animal husbandry in winter has following beneficial effects: animal-living places can be directly heated; heating equipment has good effect and is safe and reliable; and therefore, animals can be fed and takes rest normally and can smoothly get through the winter.

Owner:杨国锋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com