Degradable odor generation element for non-burned cigarette and cigarette product

A non-combustible, odor-free technology, applied to smokers’ products, applications, tobacco, etc., can solve the problem of small volatilization area, achieve the effect of large specific surface area, control volatilization, and increase the sense of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

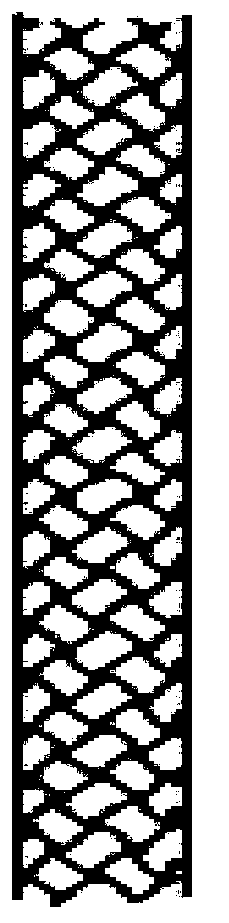

[0047] Use polylactic acid monofilament with a circular cross section of 0.15mm in diameter, use 8 strands of braided netting wire, wear 1 strand and press 1 strand, each strand contains 1 monofilament arranged in parallel with each other, and use a braiding machine to weave into a rope , 45 ropes are arranged in parallel to form an odor generating element. The polylactic acid monofilament is treated by soaking in a dilute polylactic acid solution containing a perfume additive, wherein the polylactic acid dilute solution has a mass fraction of 5% polylactic acid, a mass fraction of a perfume of 2%, and the perfume additive is menthol. The overall outer diameter of the odor generating element is 7mm and the length is 15mm. Its structural diagram is as figure 1 Shown:

Embodiment 2

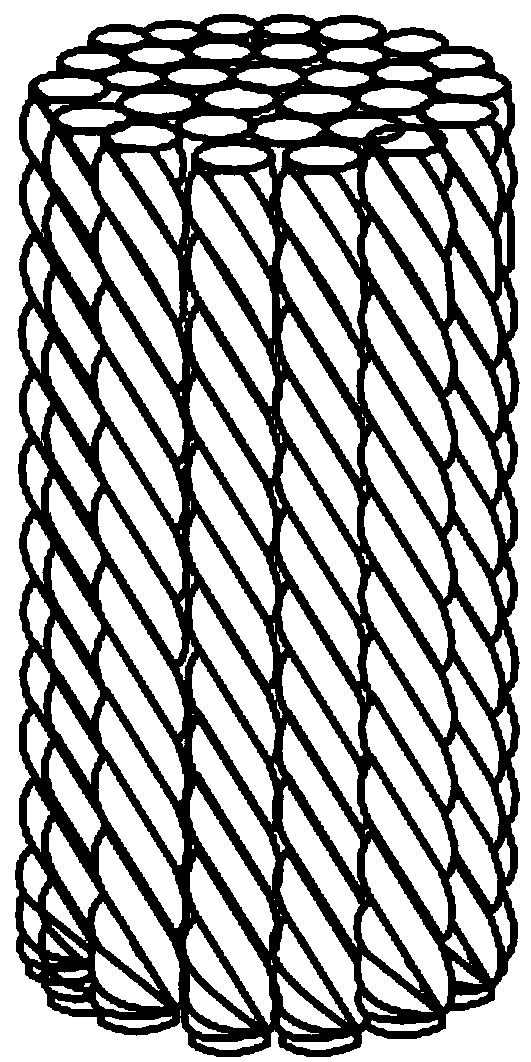

[0049] Use polylactic acid monofilaments with an oval cross-section of 0.2 mm in diameter, use 3 monofilaments to twist in the Z direction, and twist the twist to 300 to form a strand 1, and then twist the 3 strands 1 in an S direction, The twist is 220 and twisted into 9 monofilaments to form a ZS-twisted strand-like rope, and 36 strand-like ropes are arranged in parallel to form an odor generating element. The polylactic acid monofilaments do not need to be treated by soaking in a dilute polylactic acid solution containing fragrance additives. The overall outer diameter of the odor generating element is 7mm and the length is 17mm. Its structural diagram is as figure 2 Shown:

Embodiment 3

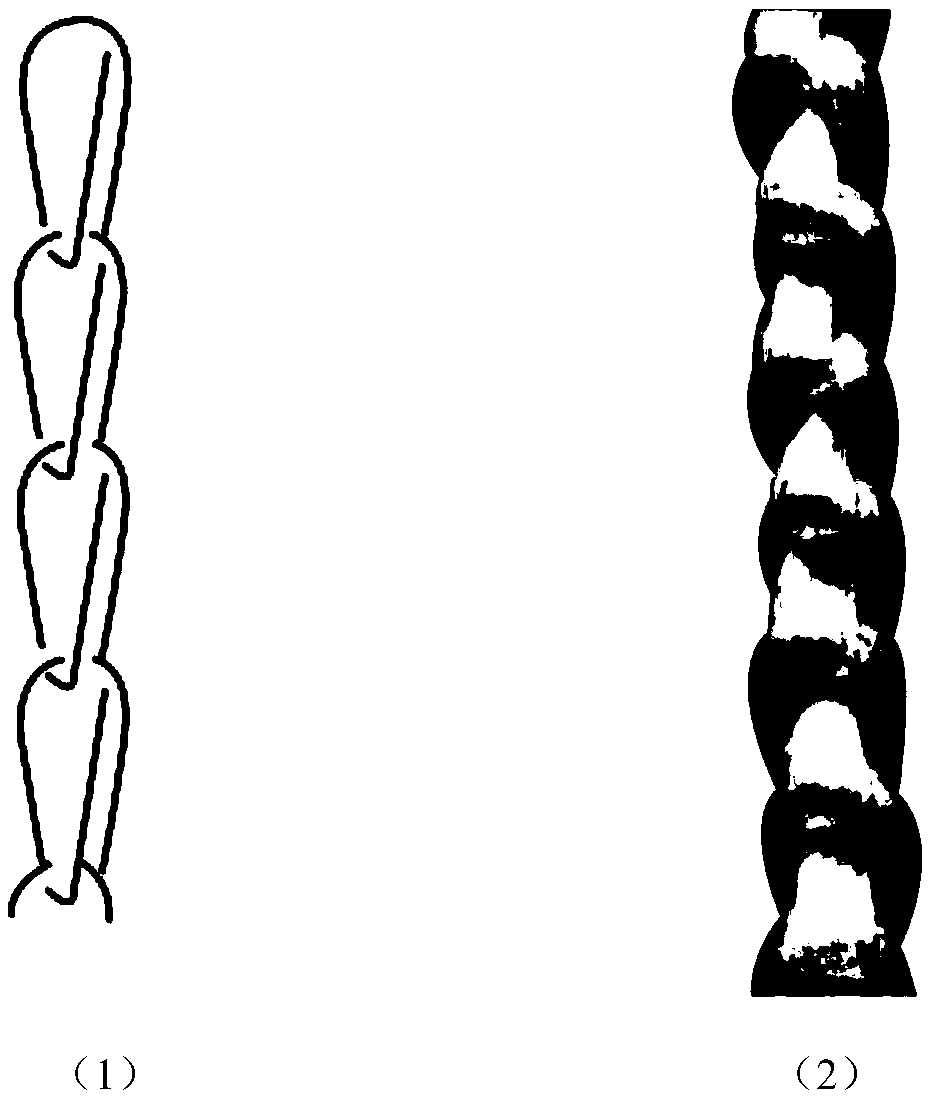

[0051] Use polylactic acid monofilaments with a triangular cross-section of 0.5 mm in diameter, so that the yarn carried by each guide needle is always lapped on the same knitting needle to form a knitted chain structure knitted fabric. Use 1 guide needle, One monofilament uses the warp knitting machine in the knitting field to weave a closed-end chain structure to form a chain-like rope, and 50 ropes are arranged in parallel to form the odor generating element. The polylactic acid monofilament is treated by soaking in a dilute polylactic acid solution containing a perfume additive, wherein the polylactic acid dilute solution has a mass fraction of 1% polylactic acid, a mass fraction of a perfume of 1%, and the perfume additive is menthol. The overall outer diameter of the odor generating element is 7mm, and the length is 20mm. Its structural diagram is as image 3 Shown:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com