Laser-surface carburization process for metal materials and carbon coating device thereof

A metal material and surface carburizing technology, which is applied in the field of metal material laser surface carburizing process and its carbon coating device, can solve the problems of affecting the metal alloying process, uneven thickness, adhesion of nano carbon powder, etc. Defects, simple carburizing process, weak bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 metal material laser surface carburizing process

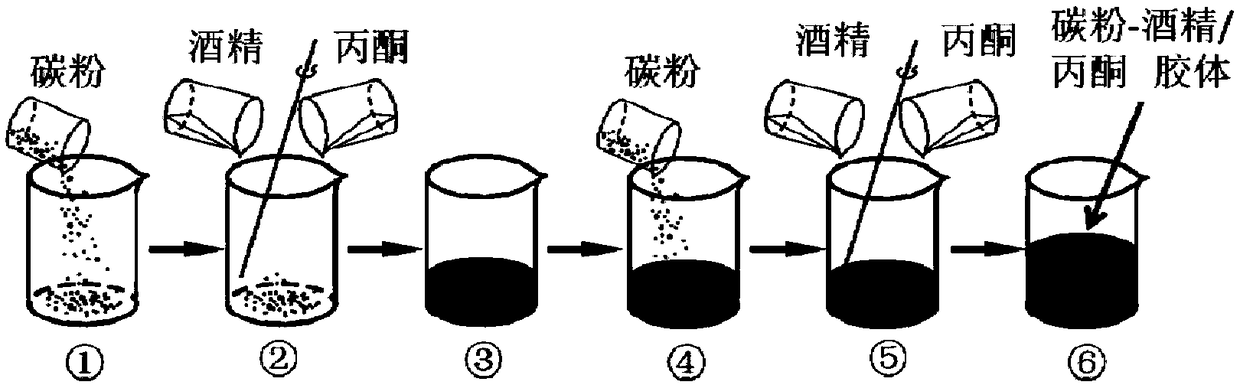

[0034] Colloid preparation. Choose toner with an average particle size of 10nm. In order to disperse the toner more evenly in alcohol and acetone, take such as figure 1 The method of compound adding of carbon powder and organic solvent shown. First, add 25g of carbon powder into the beaker, then add 50mL of alcohol and 10mL of acetone in turn, and stir with a glass rod when adding alcohol and acetone until the carbon powder has no obvious agglomeration. Then, after standing for 5 minutes, add 10g of carbon powder, then add 30mL of alcohol and 10mL of acetone in turn, and stir with a glass rod until a relatively uniform colloid is formed, and finally stand for 5 minutes to obtain a uniform "carbon powder-alcohol / acetone colloid "In the process of adding carbon powder and organic solvent twice, the purpose of the first time is to obtain a colloid with high viscosity, and the purpose of the second time is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com