Oil shielding volatilization device

An oil shielding and oil supply pipe technology is applied in the field of metallized film evaporation oil shielding devices, which can solve the problems of shielding oil vapor affecting the effect of the blank area, difficult to control the shielding oil vapor, affecting the quality of the finished film capacitor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

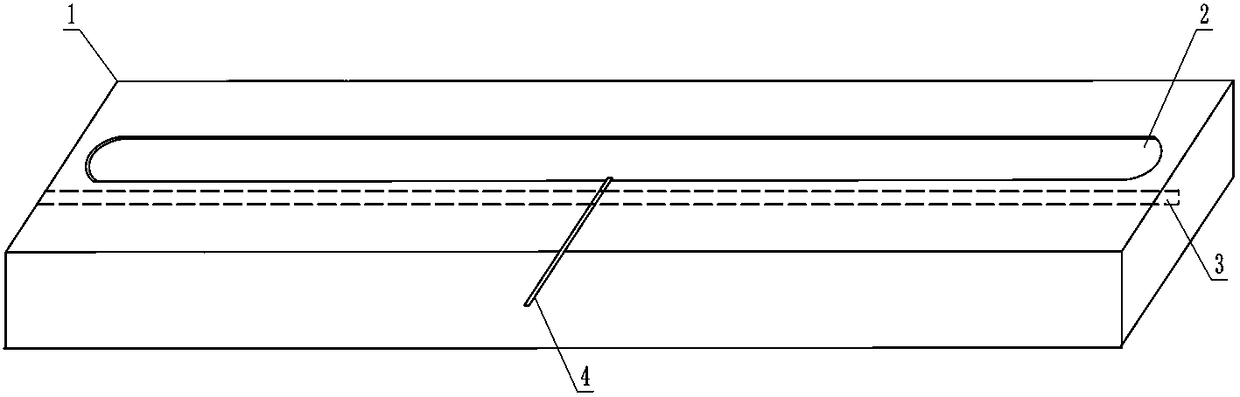

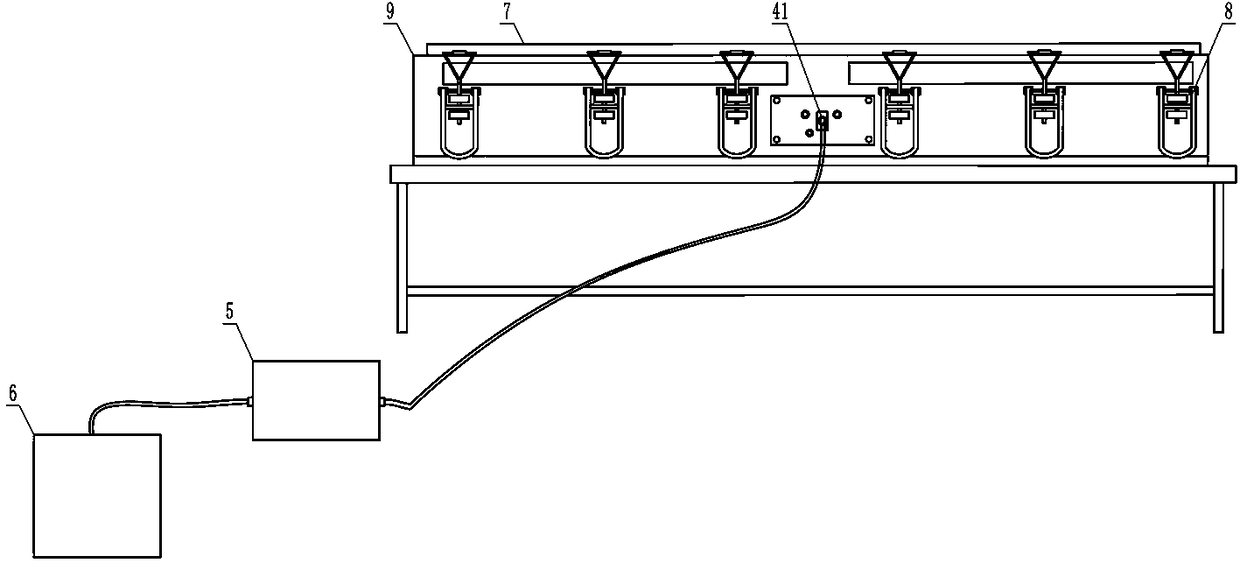

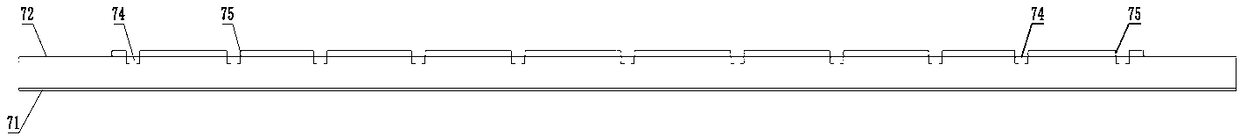

[0024] Such as Figure 1-4 As shown, an oil shielding volatilization device includes a boat-type heating plate 1, an electric heating tube 3, an oil supply pipe 4 and a micro-flow control pump 5, and the upper surface of the boat-type heating plate 1 is provided with a shallow evaporation groove 2, so that The bottom surface of the shallow evaporation tank 2 is a horizontal and straight structure, the electric heating tube 3 is embedded in the boat heating plate 1, the electric heating tube 3 is arranged below the shallow evaporation tank 2, and the supply The oil inlet end 41 of the oil pipe 4 is connected to the oil outlet of the micro-flow control pump 5 , and the oil outlet end of the oil supply pipe 4 is connected to the evaporation shallow tank 2 . The shape of the shallow evaporation groove 2 is specifically a horizontal strip shape, and the shallow evaporation groove 2 includes two sides arranged in parallel and an arc-shaped transition portion connecting the ends of t...

Embodiment 2

[0030] The difference between this embodiment and Embodiment 1 is that the depth of the evaporation shallow groove 2 is preferably set to 1 mm, and the height of the vertical barrier wall 75 is set to 1 cm.

[0031] After testing, the average thickness of the oil film in the blank area of the shielding oil using the original technology and equipment is 60 nanometers, the deviation range: 60%, and there is a flowing oil film between the film layers. After adopting the oil shielding volatilization device in this embodiment, the average thickness of the oil film in the blank area of the shielding oil is 30 nanometers, and the deviation range is 10%. By comparison, the oil shielding volatilization device in this embodiment has the characteristics of strong consistency and more uniform oil film thickness, which provides convenience for effectively cleaning the oil film during metal vapor deposition, and makes the oil residue of the finished metallized film reach a trace amount, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com