UV conductive silver paste formula and preparation method thereof

A technology of conductive silver paste and formula, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., and can solve the problems of conductive paste falling off, conductive circuit scrapping, and uneven volatilization of organic carrier solvents, etc. problems, to achieve the effect of strong adhesion, good environmental protection, and superior electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

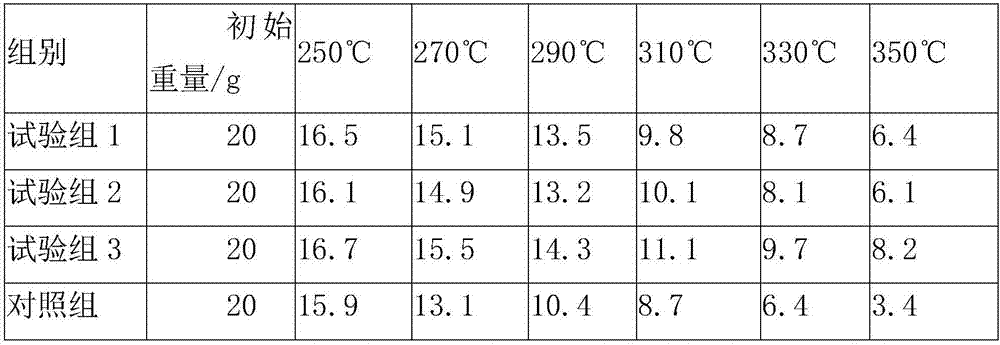

Embodiment 1

[0022] A UV conductive silver paste formula, comprising the following raw materials in parts by weight: 5 parts of diethylene glycol ether acetate, 8 parts of dimethyl nylon acid, 3 parts of white paste, 1.2 parts of polyethylene glycol, 5.5 parts of citric acid, 1.1 parts of ethyl cellulose, 8.8 parts of vinyl neodecanoate, 9 parts of epoxy resin, 10 parts of polyester acrylate, 3 parts of modified polysiloxane, 2 parts of polyethylene oxide, 0.5 parts of photoinitiator, modified 30 parts of silver powder;

[0023] For the modified silver powder, take 1.2 parts of KH-560 in parts by weight, add water 1.2 times its weight and stir evenly, then add concentrated hydrochloric acid to adjust the pH value to 4, then add 30 parts of nano-silver powder and mix evenly, mix The solution was ultrasonically dispersed in a constant temperature water bath at 40°C for 15 minutes while being mechanically stirred, then 1 part of titanium dioxide was added, stirred for 15 minutes, filtered, an...

Embodiment 2

[0030] A UV conductive silver paste formula, comprising the following raw materials in parts by weight: 7 parts of diethylene glycol ethyl ether acetate, 10 parts of dimethyl nylon acid, 5 parts of white paste, 2.2 parts of polyethylene glycol, 6.5 parts of citric acid , 2.3 parts of ethyl cellulose, 10.5 parts of vinyl neodecanoate, 11 parts of epoxy resin, 15 parts of polyester acrylate, 5 parts of modified polysiloxane, 3 parts of polyethylene oxide, 1.5 parts of photoinitiator, 40 parts of modified silver powder;

[0031] The modified silver powder, according to parts by weight, takes 2.4 parts of KH-560, adds 1.2 times its weight of water and stirs evenly, then adds concentrated hydrochloric acid to adjust the pH value to 5, then adds 40 parts of nano-silver powder and mixes evenly, mixes The solution was ultrasonically dispersed in a constant temperature water bath at 45°C for 15-20min while being mechanically stirred, then 1.5 parts of titanium dioxide was added, stirre...

Embodiment 3

[0038] A UV conductive silver paste formula, comprising the following raw materials in parts by weight: 6 parts of diethylene glycol ethyl ether acetate, 9 parts of dimethyl nylon acid, 4 parts of white paste, 1.7 parts of polyethylene glycol, 6 parts of citric acid , 1.8 parts of ethyl cellulose, 9.5 parts of vinyl neodecanoate, 10 parts of epoxy resin, 13 parts of polyester acrylate, 4 parts of modified polysiloxane, 2.5 parts of polyethylene oxide, 1 part of photoinitiator, 35 parts of modified silver powder;

[0039] Described modified silver powder, take 1.8 parts of KH-560 in parts by weight, add water 1.2 times its weight and stir evenly, then add concentrated hydrochloric acid to adjust the pH value to 4.5, then add 35 parts of nano-silver powder and mix evenly, mix The solution was ultrasonically dispersed in a constant temperature water bath at 42°C for 18 minutes while being mechanically stirred, then 1.3 parts of titanium dioxide was added, stirred for 15 minutes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com