Potato dried rice noodles and preparation method thereof

A technology of dried potato and whole potato powder, applied in the field of food processing, can solve the problems of sticky soup, easy sticking, broken strips, etc., and achieves the effects of balanced water distribution, rich nutrition, and reducing the broken strip rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

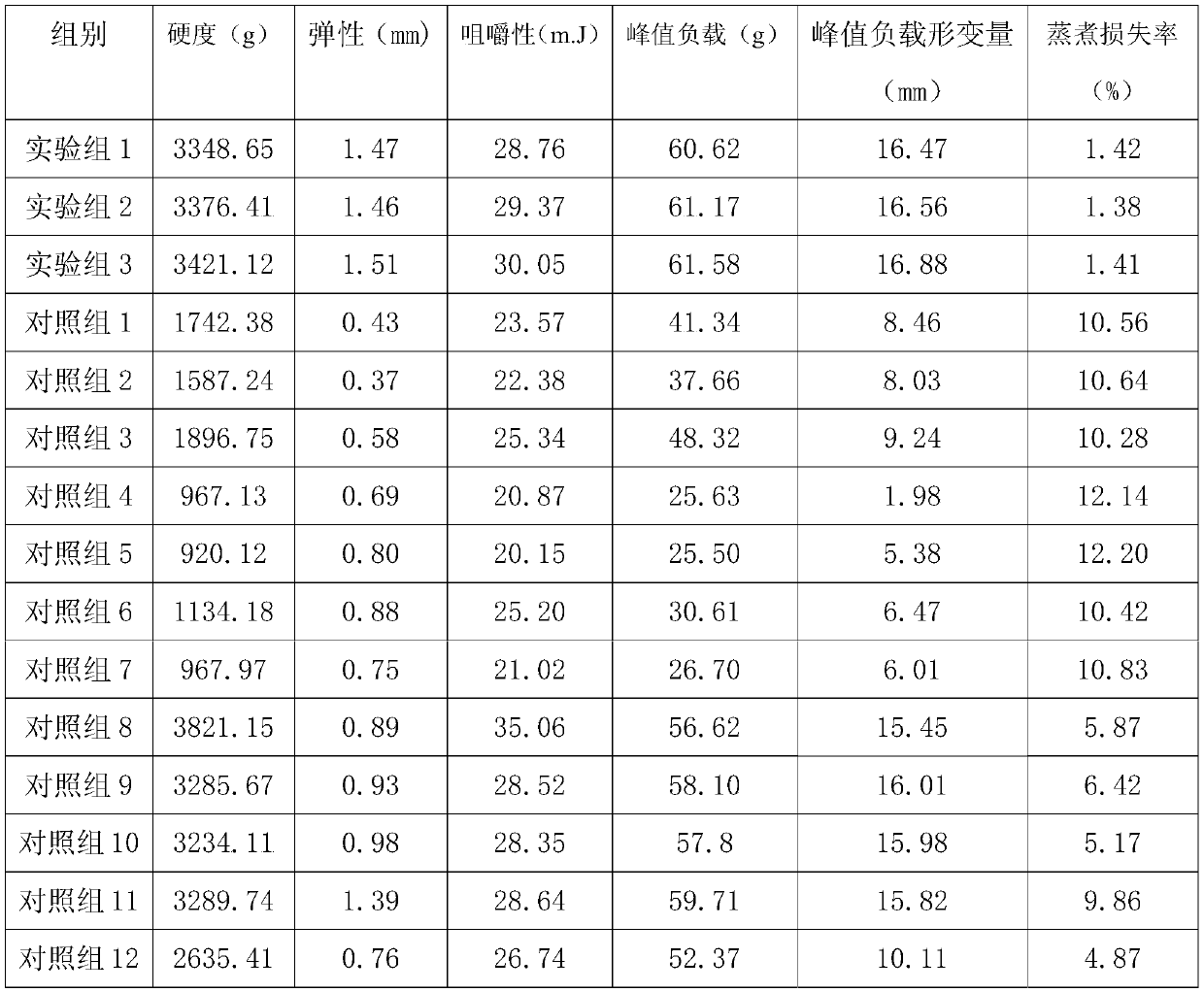

Examples

Embodiment 1

[0047] 1. Preparation of whole potato flour

[0048](a) Potato raw material selection: choose fresh potatoes with good color, no rot and mildew, no peculiar smell, no germination, no symptoms of diseases and insect pests, no mechanical damage and green skin;

[0049] (b) cleaning: washing the silt and impurities of the potato skin;

[0050] (c) peeling and rinsing: after removing the potato epidermis with a mechanical friction peeling machine, rinse with clear water immediately;

[0051] (d) Trimming and slicing: After manually inspecting and removing the remaining skin and bud eyes on the surface of the potato, send it into a slicer for slicing to obtain potato slices with a thickness of 2.0 mm;

[0052] (e) Draining for color protection: Soak the potato slices in the color protection solution for 10 minutes, then lay them flat on a hollowed-out stainless steel tray, and drain the moisture on the surface of the potato chips; the color protection solution contains 0.05% of s...

Embodiment 2

[0072] 1. Preparation of whole potato powder

[0073] (a) Potato raw material selection: choose fresh potatoes with good color, no rot and mildew, no peculiar smell, no germination, no symptoms of diseases and insect pests, no mechanical damage and green skin;

[0074] (b) cleaning: washing the silt and impurities of the potato skin;

[0075] (c) peeling and rinsing: after removing the potato epidermis with a mechanical friction peeling machine, rinse with clear water immediately;

[0076] (d) Trimming and slicing: After manually inspecting and removing the remaining skin and bud eyes on the surface of the potato, send it into a slicer for slicing to obtain potato slices with a thickness of 2.5mm;

[0077] (e) Draining for color protection: Soak the potato slices in the color protection solution for 15 minutes, then spread them flat in hollowed-out stainless steel trays, and drain the moisture on the surface of the potato chips; the color protection solution contains 0.08% of...

Embodiment 3

[0097] 1. Preparation of whole potato powder

[0098] (a) Potato raw material selection: choose fresh potatoes with good color, no rot and mildew, no peculiar smell, no germination, no symptoms of diseases and insect pests, no mechanical damage and green skin;

[0099] (b) cleaning: washing the silt and impurities of the potato skin;

[0100] (c) peeling and rinsing: after removing the potato epidermis with a mechanical friction peeling machine, rinse with clear water immediately;

[0101] (d) Trimming and slicing: After manually inspecting and removing the remaining skin and bud eyes on the surface of the potato, send it into a slicer for slicing to obtain potato slices with a thickness of 3.0mm;

[0102] (e) Draining for color protection: Soak the potato slices in the color protection solution for 20 minutes, then lay them flat on a hollowed-out stainless steel tray, and drain the moisture on the surface of the potato chips; the color protection solution contains 0.1% of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com