Electrostatic spinning device for preparing nano-fibers on large scale

A technology for large-scale preparation of micro-nano fibers, applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve problems such as uneven thickness of non-woven fabrics, volatile solvents, and limited jet flow from a single needle. Improve the efficiency of electrospun fibers, improve the efficiency of fiber collection, and guide the effect of fiber deposition range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

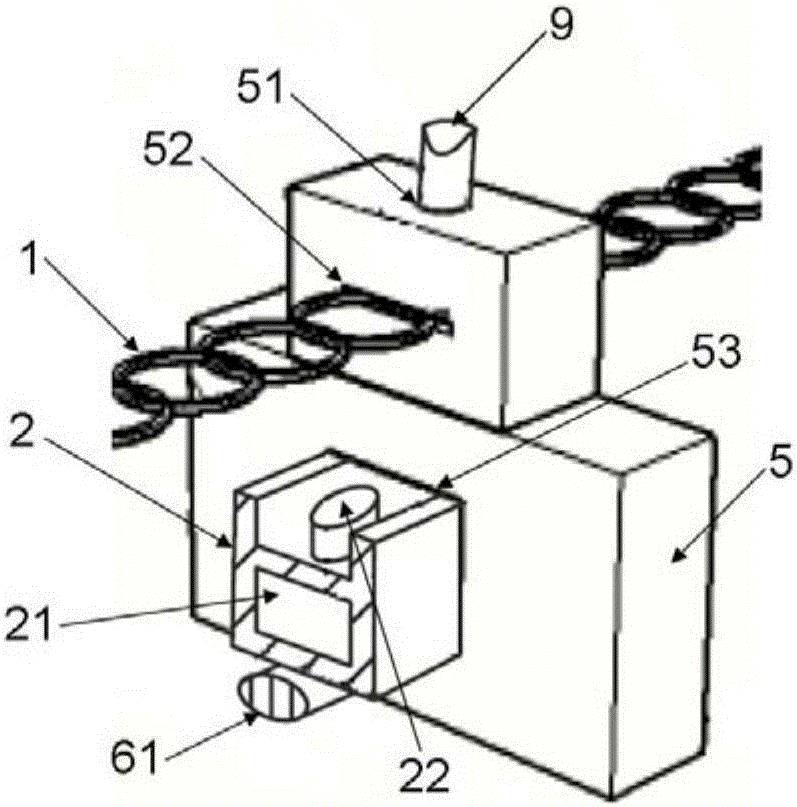

[0034] like Figures 1 to 4 As shown, an electrospinning device for preparing micro-nano fibers on a large scale, the electrospinning device uses a straight metal chain 1 as a fiber emitter, and the metal chain is connected to the positive pole of a high-voltage direct current power supply 10, and the metal chain 1 A collecting pole is arranged directly above, and the collecting pole is connected to the negative pole of the high-voltage direct current power supply 10 or grounded, and an air supply system for upwardly jetting airflow is arranged directly below the metal chain 1, and a device for applying spinning to the metal chain 1 is also arranged on the metal chain 1. Precursor liquid supply system.

[0035] Specifically, the metal chain 1 is formed by interlocking a plurality of identical thin metal rings. The air supply system includes an air supply pipe 2 arranged directly below the metal chain 1 . Gas injection port 22, described gas injection port 22 is communicated w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com