High/low-temperature-resistant lubricating crease and preparation method for same

A lubricating grease and low temperature technology, which is applied in the field of high and low temperature resistant lubricating grease and its preparation, can solve the problems of lubricating grease thinning and loss, destroying the structure of lubricating grease, poor lubrication, etc., to prevent high temperature deterioration, excellent adhesion performance, Reduce the effect of protecting the bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

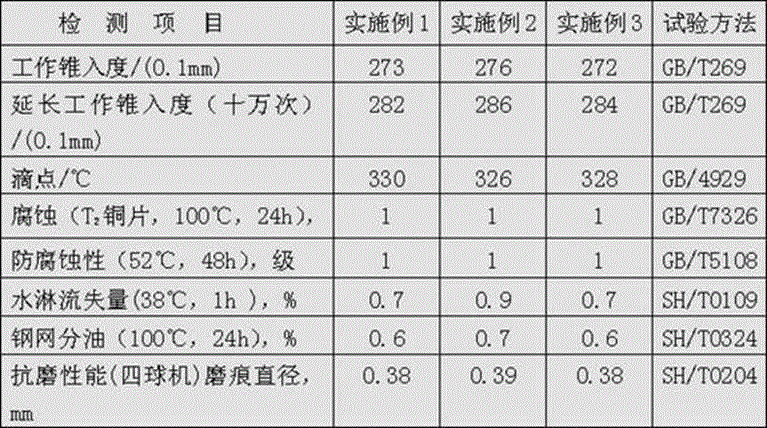

Examples

Embodiment 1

[0023] The high and low temperature resistant grease of the present embodiment is made from the raw materials of following components:

[0024] (1) C 18 h 34 o 3 : 100kg, (2) PA0 40 : 500kg, (3) TAB: 260kg, (4) C 18 h 36 o 3 : 70kg, (5)CH 4 O: 30kg, (6)H 2 O: 30kg, (7)H 3 BO 3 : 5kg, (8)C 12 h 11 N: 3kg, (9) BN: 20kg, (10) Ca(OH) 2 : 7kg.

[0025] The preparation method of the high and low temperature grease of the present embodiment is as follows:

[0026] The first step: the glyceride C 18 h 34 O100kg, poly R olefin PA0 40 500kg, synthetic sulfonate TAB 260kg, sequentially added to the saponification kettle, start the agitator, heat to 50°C, and mix for 35 minutes;

[0027] The second step: add fatty acid C to the saponification kettle 18 h 36 o 3 70kg, low molecular alcohol CH 4 O30kg and H equivalent to low molecular weight alcohol 2 O30kg, constant temperature 55°C, stirring for 130min;

[0028] Step 3: When the temperature of the saponification ket...

Embodiment 2

[0033] The high and low temperature resistant grease of the present embodiment is made from the raw materials of following components:

[0034] (1) C 18 h 34 o 3 : 150kg, (2) PA0 8 : 450kg, (3) MOS 2 : 6kg, (4) 531W: 4kg, (5) C 18 h 36 o 2 : 60kg, (6)C 2 h 6 o 2 : 50kg, (7)H 2 O: 50kg, (8) T107: 300kg, (9) TM-A: 10kg, (10) LiOH: 10kg

[0035] The preparation method of the high and low temperature grease of the present embodiment is as follows:

[0036] The first step: the glyceride C 18 h 34 o 3 150kg, poly R olefin PA0 8 450kg, synthetic sulfonate T107220kg, add to the saponification kettle one by one, start the agitator, heat to 60°C, and mix for 30 minutes;

[0037] The second step: add fatty acid C to the saponification kettle 18 h 36 o 2 60kg, low molecular weight alcohol C 2 h 6 o 2 50kg and the same amount of H as low molecular alcohol 2 O50kg, constant temperature 65 ℃, stirring transformation 110min;

[0038] Step 3: When the temperature of the...

Embodiment 3

[0043] The high and low temperature resistant grease of the present embodiment is made from the raw materials of following components:

[0044] (1) C 5 h 98 o 6 : 130kg, (2) V50: 470kg, (3) H 3 BO 3 : 10kg, (4) AF: 6kg, (5) C 18 h 36 o 3 : 70kg, (6)C 2 h 4 o 3 : 40kg, (7)H 2 O: 40kg, (8) T106: 200kg, (9) BN: 15kg, (10) Ca(OH) 2 : 5kg.

[0045] The preparation method of the high and low temperature grease of the present embodiment is as follows:

[0046] The first step: the glyceride C 5 h 98 o 6 Add 130kg, poly R olefin V50470kg, and synthetic value sulfonate T106230kg into the saponification kettle in turn, start the agitator, heat to 55°C, and mix for 30 minutes;

[0047] The second step: add fatty acid C to the saponification kettle 18 h 36 o 3 70kg, low molecular weight alcohol C 2 h 4 o 3 40kg and the same amount of H as low molecular alcohol 2 O40kg, constant temperature 60 ℃, stirring transformation for 2 hours;

[0048] Step 3: When the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com