Non-cured rubber asphalt waterproof coating as well as preparation method and application thereof

A technology of asphalt waterproof coating and non-curing rubber, which is applied in the direction of asphalt coating, unspecified rubber coating, coating, etc., which can solve the problem of simultaneous improvement of high temperature resistance and low temperature flexibility, difficulty in fully processing smoke, and complex production process and other issues, to achieve the effect of improving the product's excellent performance, good skin-like waterproof effect, and improving circular economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

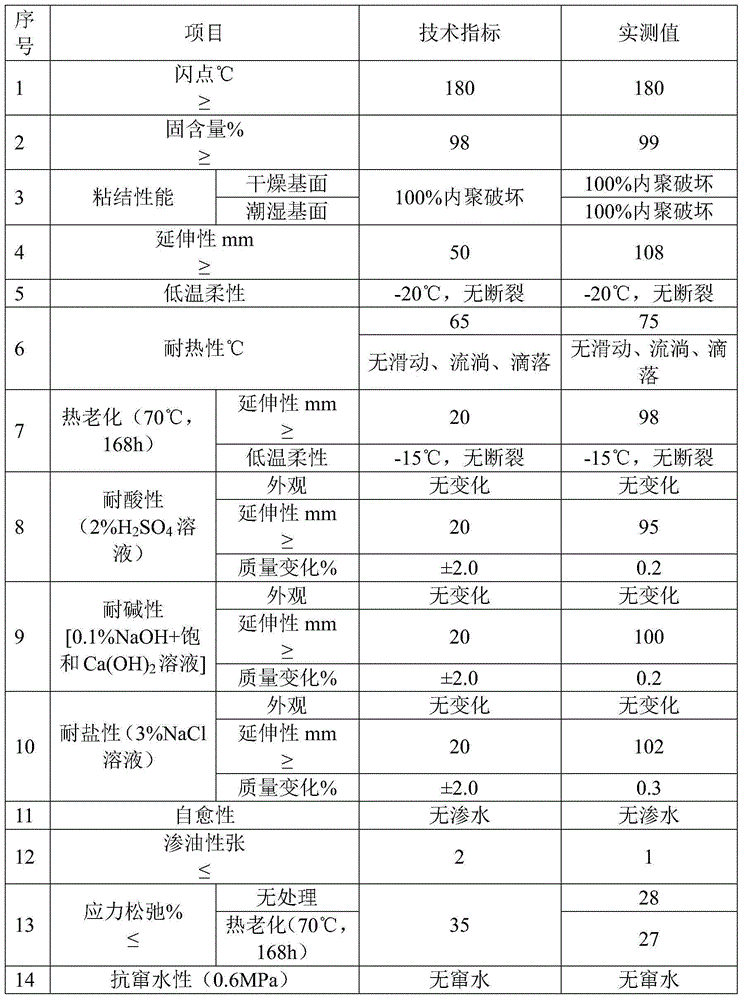

[0038] 32 parts of petroleum asphalt, 28 parts of waste rubber powder, 16 parts of waste engine oil, 5 parts of styrene-butadiene block copolymer, 8 parts of styrene-butadiene rubber SBR, 6 parts of recycled plastic particles, 10 parts of terpene resin, Guma 5 parts of Long resin, 2 parts of surfactant, and 0.8 parts of ionic liquid were added in sequence, and mixed uniformly by high-speed shearing machine at 170°C to prepare non-curing rubber asphalt waterproof coating. According to the 2014 publicity draft of the non-curing rubber asphalt coating industry standard, the technical requirements for the non-curing rubber asphalt waterproof coating are tested, see Table 1.

[0039] Table 1 Test results of non-cured rubber asphalt waterproof coating

[0040]

Embodiment 2

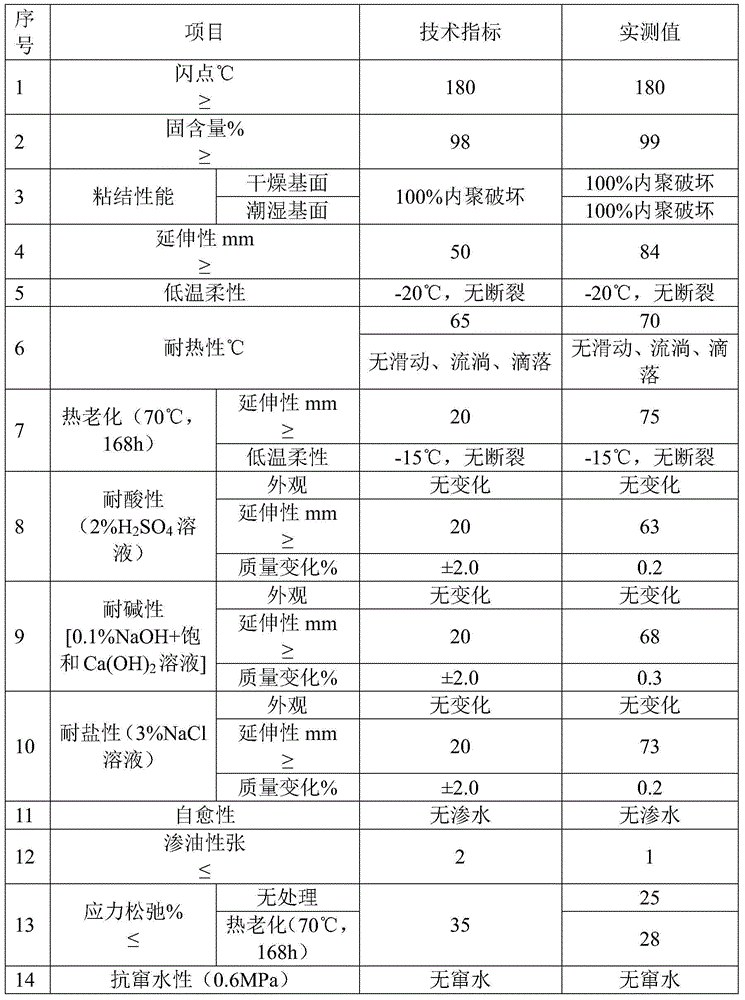

[0042] 25 parts of petroleum asphalt, 15 parts of waste engine oil, 30 parts of 80 mesh waste rubber powder, 6 parts of SBS, 3.5 parts of SBR, 3.5 parts of recycled plastic particles, 8 parts of terpene resin, 4 parts of coumarone resin, and 2 parts of surfactant Parts, 0.5 parts of ionic liquid were added in sequence, and mixed uniformly by high-speed shearing machine at 170 ° C to prepare non-curing rubber asphalt waterproof coating. According to the 2014 publicity draft of the non-curing rubber asphalt coating industry standard, the technical requirements for the non-curing rubber asphalt waterproof coating are tested, see Table 2.

[0043] Table 2 Test results of non-cured rubber asphalt waterproof coating

[0044]

Embodiment 3

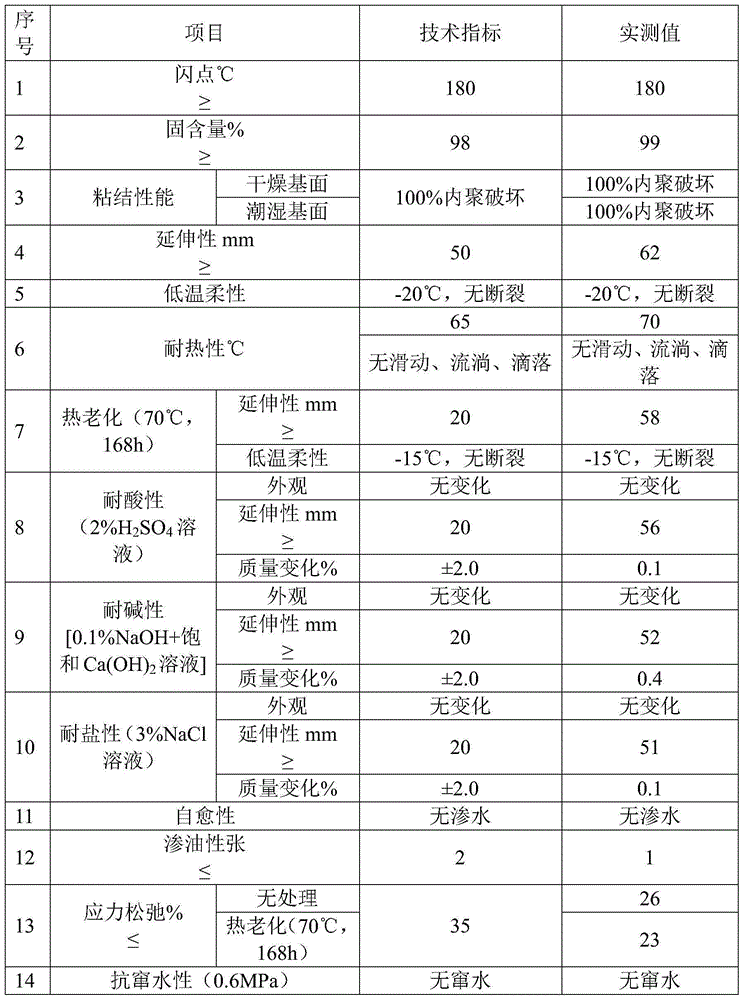

[0046] Add 30 parts of petroleum asphalt, 10 parts of waste engine oil, 20 parts of 120-mesh waste rubber powder, 3 parts of SBS, 2 parts of SBR, 4 parts of recycled plastic particles, 1.5 parts of surfactant, and 1 part of ionic liquid in sequence, and pass through a high-speed shearing machine Mix evenly at 160°C to prepare non-cured rubber asphalt waterproof coating. According to the 2014 publicity draft of the non-curing rubber asphalt coating industry standard, the technical requirements for the non-curing rubber asphalt waterproof coating are tested, see Table 3.

[0047] Table 3 Test results of non-cured rubber asphalt waterproof coating

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com