High-permeability anti-aging modifier and preparation method thereof

An anti-aging modifier and high-penetration technology, applied in the field of road engineering materials, can solve the problems of accelerating the aging of recycled asphalt, increasing the cost of recycling again, and the expected effect is quite different, so as to increase the proportion of structural asphalt and improve the utilization rate of recycling. , The effect of reducing leakage and oil flooding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

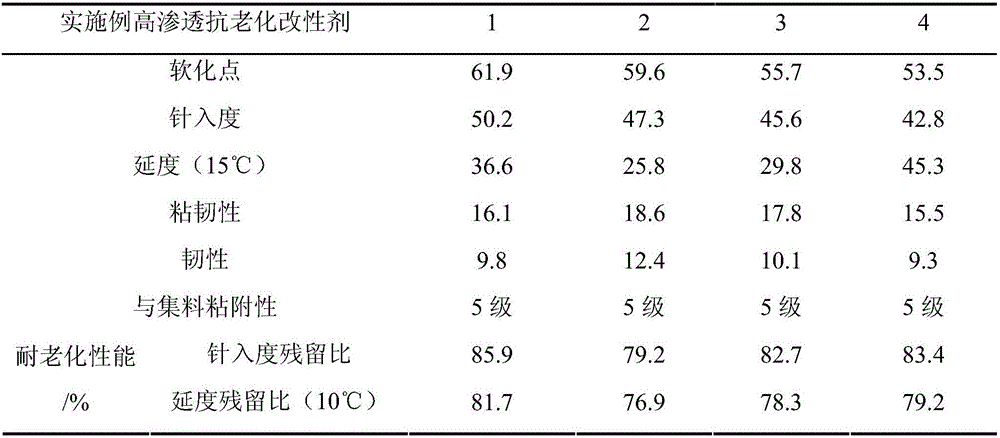

Embodiment 1

[0040] A high-permeability anti-aging modifier, the parts by mass of each raw material are: 35 parts of light components, 4 parts of permeation-enhancing components, 25 parts of plasticizing components, 4 parts of compatibility components, anti-aging components Divide into 10 parts, 4 parts of deionized water, 18 parts of SBS components. The light component is the third-line oil reduction (or the third-line extraction oil), the penetration-enhancing component is sodium bromide, the plasticizer is C5 petroleum resin, and the compatibility component is dimethyl Dioctadecyl ammonium chloride, the mass percentage of nano-montmorillonite and anti-heat oxygen agent B225 in the antiaging agent component is 95%: 5%, and the SBS component is styrene-butadiene-styrene embedded Segment copolymer (SBS, hereinafter the same).

[0041] The preparation method of above-mentioned a kind of high permeability anti-aging modifier, comprises the following steps:

[0042] 1) According to the abov...

Embodiment 2

[0049] A high-permeability anti-aging modifier, the parts by mass of each raw material are: 35 parts of light component, 5 parts of permeation-enhancing component, 20 parts of plasticizing component, 5 parts of compatibility component, anti-aging component Divided into 7 parts, 8 parts of deionized water, 20 parts of SBS components. The light component is the third-line oil reduction (or the third-line extraction oil), the penetration-enhancing component is sodium bromide, the plasticizer is C5 petroleum resin, and the compatibility component is dimethyl Dioctadecyl ammonium chloride, nano-montmorillonite and anti-heat oxygen agent B225 mass percent are 90:10 in the antiaging agent component,

[0050] The preparation method of above-mentioned a kind of high permeability anti-aging modifier, comprises the following steps:

[0051] 1) According to the above, select raw materials;

[0052] 2) Dissolving the compatibility component and the anti-aging component in deionized water...

Embodiment 3

[0058] A high-permeability anti-aging modifier, the parts by mass of each raw material are: 35 parts of light weight component, 6 parts of permeation-enhancing component, 20 parts of plasticizing component, 4 parts of compatibility component, anti-aging component Divide into 5 parts, 5 parts of deionized water, 25 parts of SBS component. The light component is the third-line oil reduction (or the third-line oil extraction), the penetration-increasing component is sodium bromide, the plasticizer is C5 petroleum resin, and the solubilizer is acrylamide. The modifying agent is SBS, and the antioxidant is organic montmorillonite and anti-heat oxygen agent B225 mass percent is 90:10,

[0059] The preparation method of above-mentioned a kind of high permeability anti-aging modifier, comprises the following steps:

[0060] 1) According to the above, select raw materials;

[0061] 2) Dissolving the compatibility component and the anti-aging component in deionized water, and stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com