Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

114results about How to "Meet the requirements of technical indicators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing high-arene environment-friendly rubber oil

The invention relates to a method for producing high-arene environment-friendly rubber oil. The method comprises the steps of taking heavy-solvent extract oil of a lubricating-oil solvent-refining device as raw material, adding an auxiliary agent to the raw material and then refining solvent, wherein the heavy-solvent extract oil has the flash point higher than 200 DEG C, the kinematic viscosity greater than 15.0 mm<2> / s at 100 DEG C and the CA value greater than 35.0 percent; the auxiliary agent is single-hydrocarbon or light-hydrocarbon oil with low density, low viscosity and boiling point between 80 and 300 DEG C; the solvent is N-methyl pyrrolidone, phenol or furfural; a refining tower has the temperature between 50 and 100 DEG C on the top and has the temperature between 30 and 100 DEG C on the bottom; and the mass ratio of the raw material to the auxiliary agent to the solvent is 1.0:0.1-0.5:2.0-5.0. Refined oil is high in arene content; the CA value of the refined oil is above 19.0 percent; the arene content of the refined oil is greater than 50.0 percent; the PCA content of the refined oil determined by an IP346 method is less than 3.0 percent; the benzopyrene of the refined oil is less than 1 PPM; and the total content of eight specific polyaromatic hydrocarbon is less than 10 PPM.

Owner:PETROCHINA CO LTD

Paint with spectral selectivity, preparation method, and application

ActiveCN101092533AStrong reflexesWith thermal insulationLiquid surface applicatorsCoatingsReflectivityChemistry

This invention relates to a method for preparing spectrum-selective coating. The spectrum-selective coating is composed of acrylate copolymer or silicone acrylate copolymer as the matrix, titanium dioxide powder, heavy calcium powder, wollastonite and talcum powder as the fillers, hollow microbeads as the additive, and preservative, emulsifier and dofoamer as the auxiliary materials. Both the reflectivity of the spectrum-selective coating in 0.2-2.8 mu.m wave band and the emissivity in 8-13.5 mu.m wave band are higher than 80%. The spectrum-selective coating can cool the surface of the coated object by using the space coating energy, and has good heat insulating function. The spectrum-selective coating has such advantages as simple process, and good radiation cooling effect.

Owner:北京北洋华诚新能源科技发展有限公司

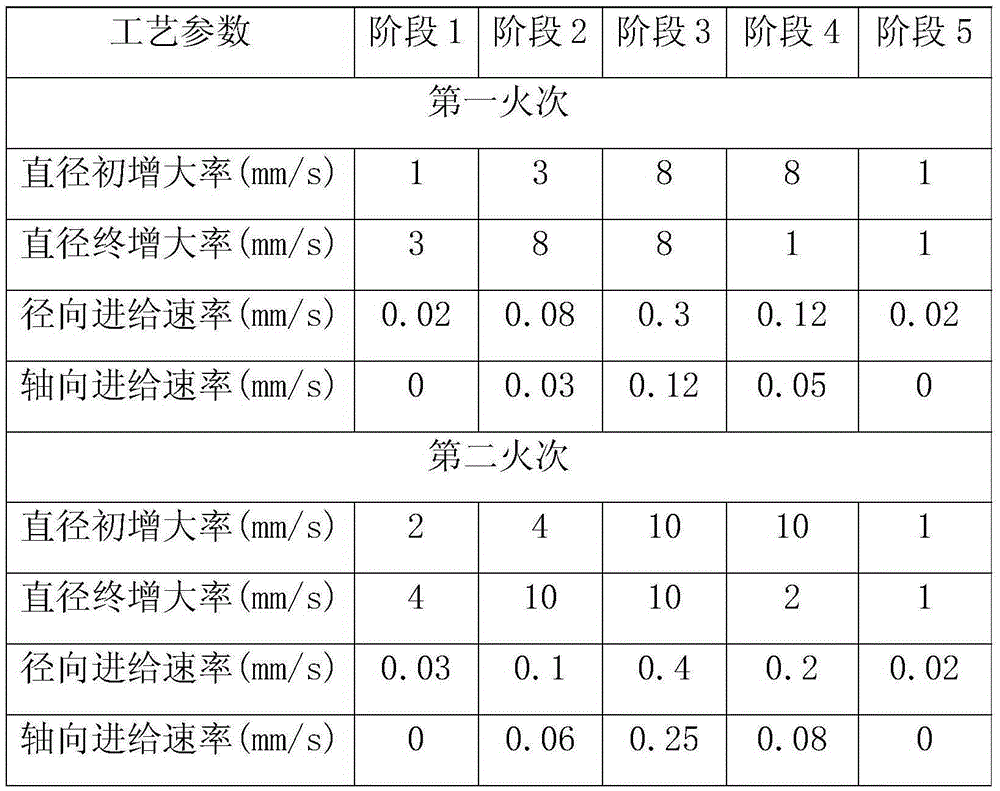

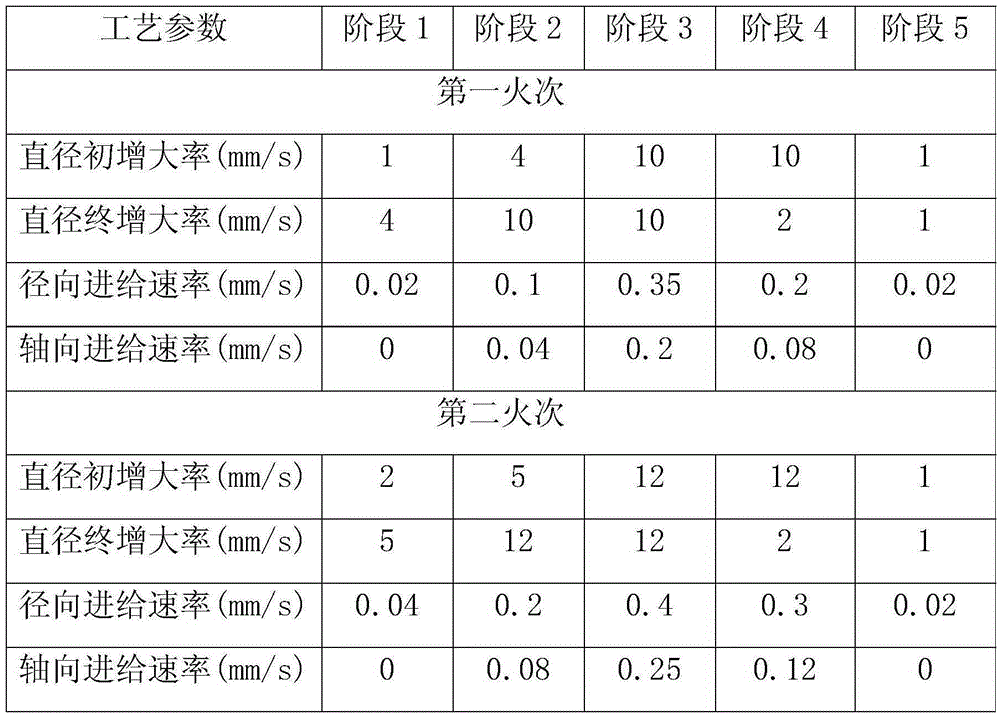

Rolling production method for integral aluminum alloy ring of super-large diameter

The invention belongs to the technical field of ring rolling forming and particularly relates to a rolling production method for an integral aluminum alloy ring of the super-large diameter. According to the technical scheme of the invention, a ring rolling forming technology is adopted, and through control over the rolling deformation temperature, the diameter increasement rate, the radial and axial feed rates, the radial and axial rolling reductions, the rolling ratio, the core roller diameter and the ring rolling heating number of an aluminum alloy ring piece of the super-large specification, the stable and continuous rolling process of the integral aluminum alloy ring of the super-large diameter is achieved, the size precision, the ovality and the radial and axial deformation quantities of the ring piece are effectively controlled, the product quality consistency is improved, the product percent of pass is increased, and technical index requirements of products are met.

Owner:CAPITAL AEROSPACE MACHINERY +1

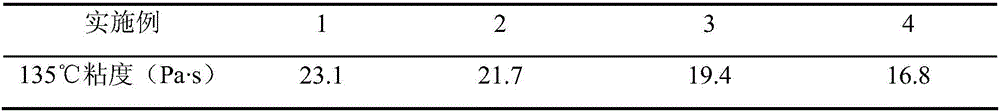

High-permeability anti-aging modifier and preparation method thereof

The invention is applied to the field of road engineering materials, and discloses a high-permeability anti-aging modifier which is prepared from the following raw materials in parts by mass: 35-45 parts of a light component, 4-6 parts of a permeation promoting component, 20-25 parts of a plastification component, 4-5 parts of a tolerance component, 5-10 parts of an anti-aging component, 4-8 parts of water and 18-25 parts of an SBS component. The permeation effect of the high-permeability anti-aging modifier on aged asphalt is improved by virtue of polarization treatment of the light component, the regeneration effect is improved, meanwhile secondary aging of regenerated alphabet in the mixing and service process, and moreover the adhesion and toughness property of alphabet is improved. The Marshall stability of an anti-aging regenerated alphabet mixed material is up to 12KN, the flexural-tensile strain of the anti-aging regenerated alphabet mixed material is up to 2568mu epsilon, the anti-aging property of the anti-aging regenerated alphabet mixed material is remarkably improved, and application of a high-volume regenerated alphabet mixed material in a road surface layer structure is possible.

Owner:WUHAN UNIV OF TECH +1

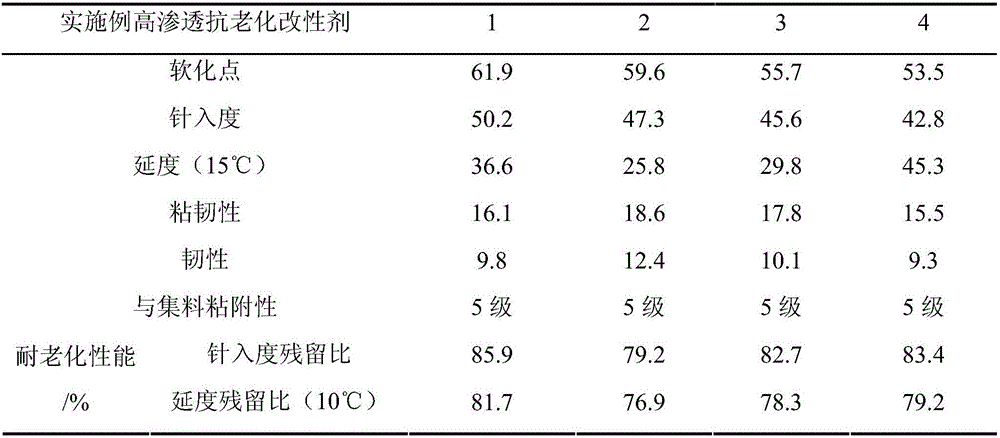

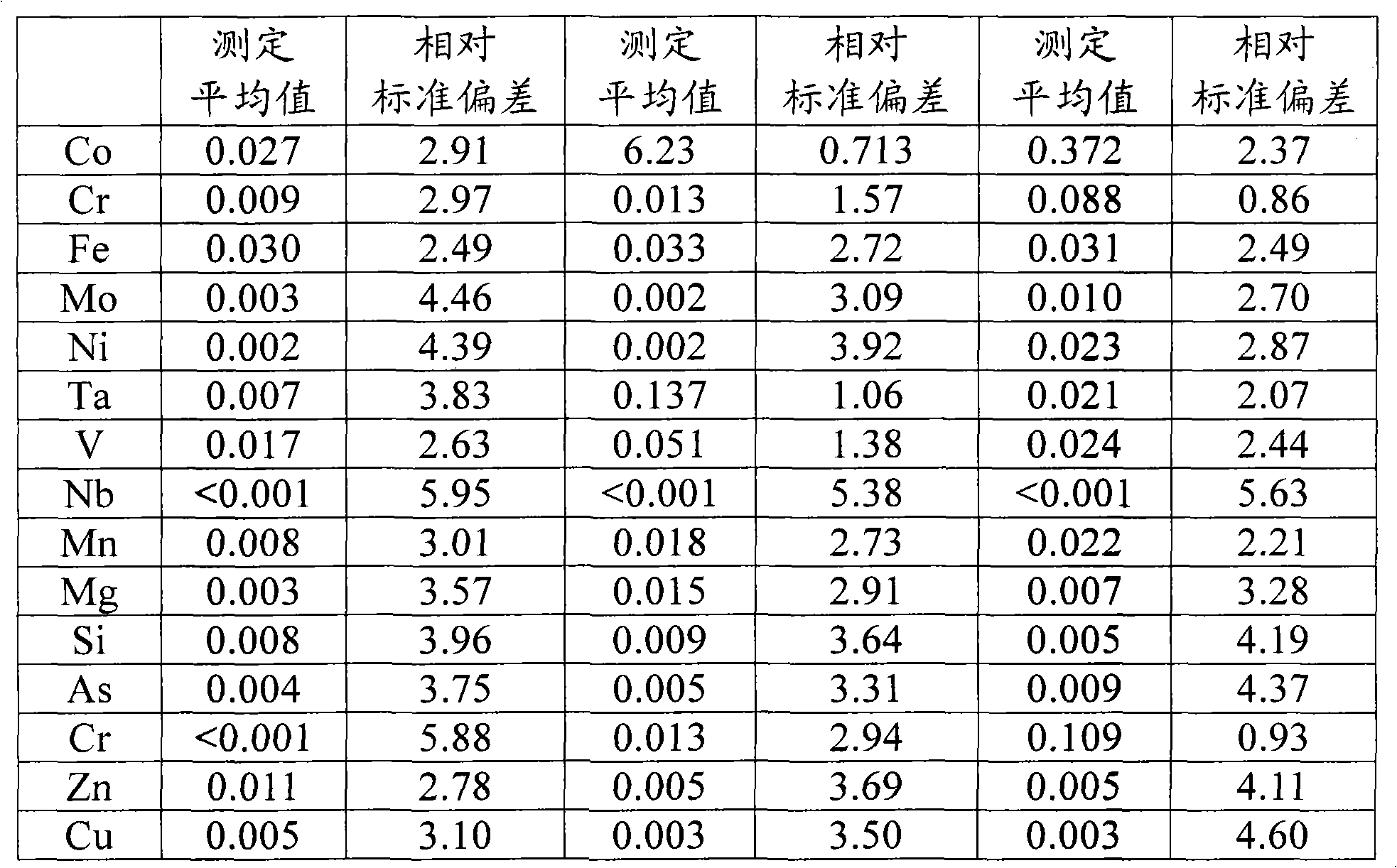

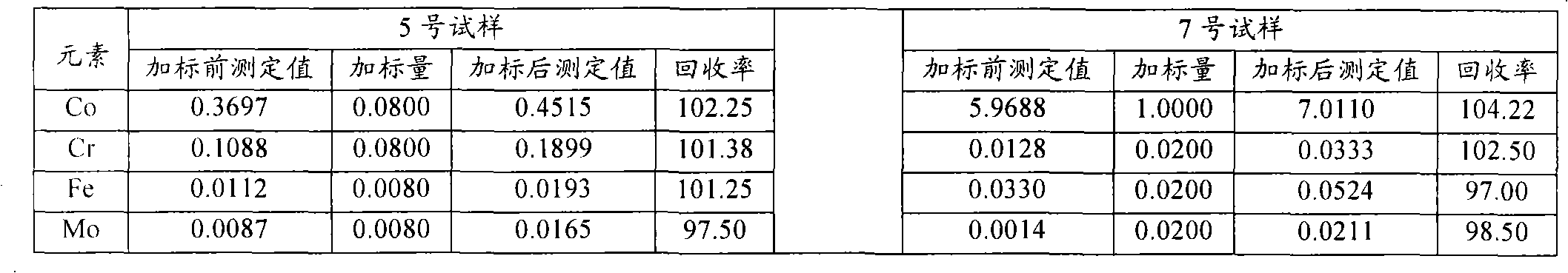

Digestion method and detection method of Tungsten-base class sample

InactiveCN102213657AMeet the requirements of technical indicatorsMeet the test requirementsPreparing sample for investigationMaterial analysis by electric/magnetic meansMicrowavePhosphoric acid

The invention discloses a digestion method of a Tungsten-base class sample, wherein the digestion method comprises the following steps: weighting and putting the tungsten-base class sample in a container, rinsing the wall of the container with a right amount of water; adding nitric acid and phosphoric acid, and then carrying out sample digestion and complex reaction by virtue of microwaves withinthe closed container; and after microwave processing is finished, cooling and diluting until an appropriate volume is achieved, thereby obtaining a sample solution used for detection. In addition, inductive coupling plasma atomic emission spectrum method and other detection methods are chosen to determine elements.

Owner:PANZHIHUA IRON AND STEEL +1

Processing method for superimposed riveting pressing pieces automatically

InactiveCN101049624ASave man hoursMeet the requirements of technical indicatorsShaping toolsPunchingEngineering

An automatically overlapping and riveting technology for at most 8 punched workpieces features use of a cascade die set with the first working position for alternatively punching hole and lug, and the second working position for blanking. Its technological steps includes punching hole on the raw band, punching lug, punching for blanking while pressing it in riveting die, and so on.

Owner:TIANJIN JINRONG TIANYU PRECISION MACHINERY CO LTD

Manufacturing method for titanium and titanium alloy products by coating and forming

The invention discloses a manufacturing method for titanium and titanium alloy products by coating and forming, wherein the needed devices during a production process comprise an electric furnace, a forming machine and an infrared thermometer. The manufacturing method comprises the following steps of coating by choosing steel or pure titanium; selecting single-layer coating or double-layer coating; performing blank verification, oxidation resistance, lubrication and heating before forming, and preheating a die to be about 200 DEG C before forming; rapidly transferring the heated coated blanks onto a pressure machine for forming, and forming by 1-2 heating numbers; and measuring the temperatures of the surfaces of the blanks by the infrared thermometer during the forming process, so as to ensure that the temperatures of the blanks are always kept in a titanium alloy hot-forming temperature range during forming, and finally obtaining the titanium and titanium alloy products. Hemispherical shells manufactured by the manufacturing method disclosed by the invention meet requirements on various technical indexes with low manufacturing cost; the forming heating numbers are reduced to be 1-2 from the previous 2-3, so that the production efficiency is improved and the production cost is reduced; and the thinning rate of the material is reduced, and the utilization ratio of the material is increased.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Fluorine-containing acrylic acid super-hydrophobic resin for oil-water separation and preparation method thereof

ActiveCN104829766AThe reaction process is simpleReduce manufacturing costLiquid separationFunctional monomerOil water

The invention discloses a fluorine-containing acrylic acid super-hydrophobic resin for oil-water separation and a preparation method thereof. The super-hydrophobic resin is prepared from the following raw materials: hard monomers, soft monomers, fluorine-containing functional monomers, organic bentonite, and fullerene through radical polymerization reactions in a solution. The technology process is simple, the production cost is low, and the prepared fluorine-containing acrylic acid super-hydrophobic resin has stable properties and meets the technical requirements. The super-hydrophobic, anti-aging, and high / low temperature resistant properties of the resin are excellent, and the resin has an excellent performance on separating oil and water, can be used to produce the separating filter core of automobile engine filter, is capable of effectively removing water (in various forms) in oil, and can be widely applied to automobile separation filters.

Owner:SHANXI FUNUOOU NEW MATERIAL TECH CO LTD

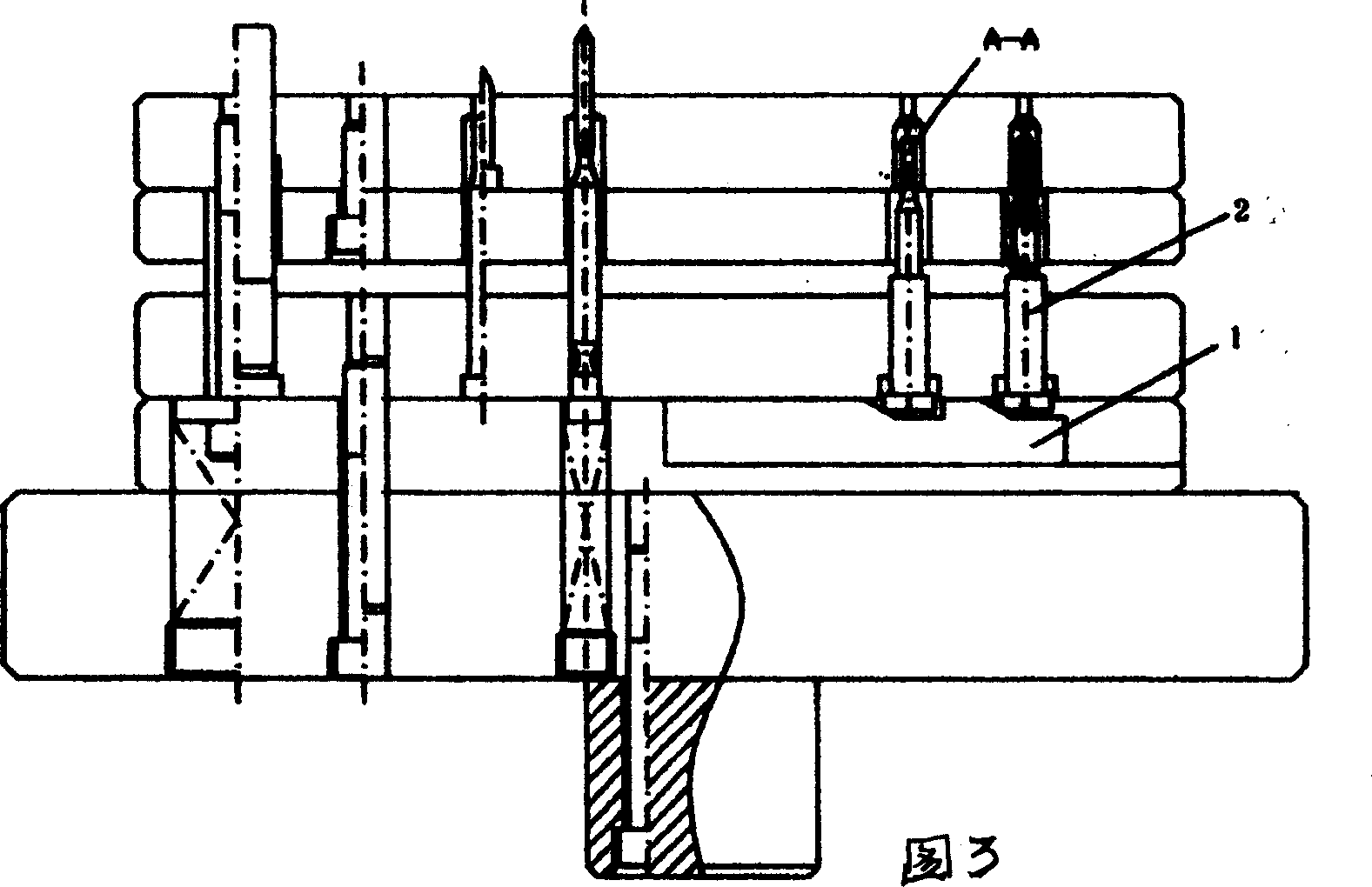

Preparing method of magnetic ring for reactor

InactiveCN101710535AOvercoming technical deficienciesImprove shielding effectInductances/transformers/magnets manufactureEpoxyMaterials science

The invention relates to a reactor, in particular to a preparing method of a magnetic ring for a reactor. The method is characterized by comprising the following steps of: a, mixing soft magnetic powder and epoxy resin glue into a mixture at the weight ratio of 1: 4; b, uniformly stirring the mixture; c, putting the stirred mixture into a forming mold to be formed by pressing on a press machine; d, putting a formed magnetic ring (1) and the forming mold into a drying oven to be continuously dried for 3-4 hours at 120 to 130 DEG C, and then controlling the temperature to be uniformly reduced to normal temperature within 1 to 1.5 hours; and e, taking out the magnetic ring (1), and then demolding. After the magnetic ring is treated with the method, the surface of the magnetic ring is smooth and bubble-free, the possibility of the crack of the magnetic ring can be reduced; and when the magnetic ring is applied to a reactor, the anti-saturation property of the iron core of the reactor can be improved, and the shielding property can be enhanced, therefore, the reactor meets the requirement of technical index, and the use property of the reactor is improved.

Owner:NINGXIA YINLI ELECTRICAL CO LTD

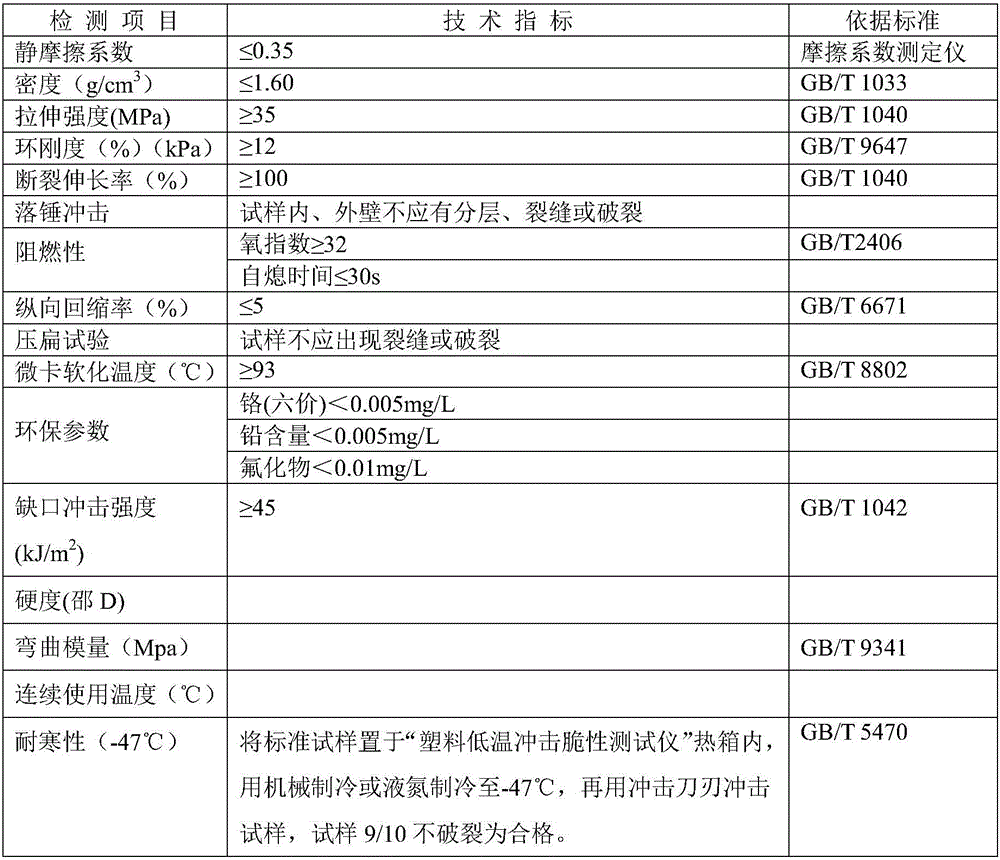

Toughened power cable CV environmentally-friendly pipe and preparation method thereof

The invention discloses a polyvinyl chloride composite material, which is prepared from the following components in parts by weight: 50 to 150 parts of polyvinyl chloride polymer and 5 to 20 parts of thermoplastic polyester elastomer, wherein the thermoplastic polyester elastomer is prepared from chlorinated polyvinyl chloride and polyvinyl chloride; the weight ratio of the chlorinated polyvinyl chloride to the polyvinyl chloride is 1 : (0.2 to 1.5). The invention also provides application of the polyvinyl chloride composite material in preparing a cable protection pipe. A toughened power cable CV environmentally-friendly pipe provided by the invention can well meet the application requirement when serving as the cable protection pipe, is not only suitable for being used as a protection pipe when an electric power and communication cable is paved underground, but also suitable for being used as a protection pipe when a cable is directly buried in a carriageway, paved in a vital communication line crossing, crosses a bridge and a river and in other special environments, is also applicable in the engineering construction fields such as power grid construction and renovation, and city municipal renovation, and has a very wide market prospect.

Owner:四川鑫森管业有限公司

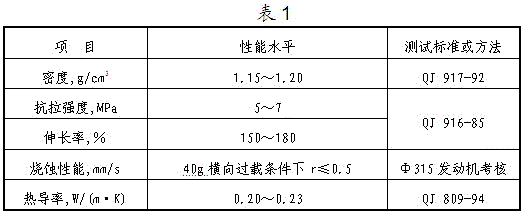

High overload ablation resistant EPDM (Ethylene-Propylene-Diene Monomer) elastic heat insulation material

The invention provides a high overload ablation resistant EPDM (Ethylene-Propylene-Diene Monomer) elastic heat insulation material which is prepared from 100 of EPDM, 15 to 20 of aromatic polyamide organic fiber, 5 to 12 of inorganic fiber, 12 to 25 of a silicon dioxide strengthening agent, 3 to 5 of zinc oxide, 5 to 15 of a petroleum based softener, 5 to 20 of an ammonium salt flame retardant, 10 to 30 of deca-brominated diphenyl ether, 5 to 15 of antimonous oxide and 2 to 4 of a peroxide vulcanizing agent, wherein the aromatic polyamide organic fiber is aramid fiber or heterocyclic aramid fiber; the inorganic fiber is asbestos fiber or ceramic fiber; the petroleum based softener is one of liquid paraffin and naphthenic oil. The high overload ablation resistant EPDM elastic heat insulation material is excellent in overload ablation resistance and relatively high in mechanical property and processing property, is applicable to the requirement of a high overload engine for the erosion resistance of an inner heat insulation material; therefore, effective heat insulation is guaranteed, the thickness of a heat insulation layer can be reduced, and the packing factor of the engine is increased.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

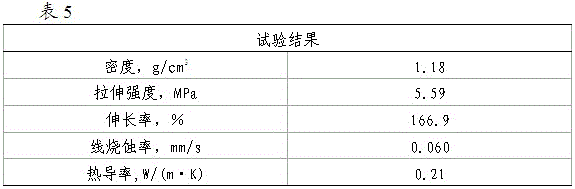

Decoloring method for recovering cutting fluids through multilineal cutting

InactiveCN102061215ASimple stepsSimple and fast operationLubricant compositionRecovery methodFiltration

The invention discloses a decoloring method for recovering cutting fluids through multilineal cutting, comprising the following steps of: 1, reducing viscosity: heating coloured cutting fluids to 40-75 DEG C; 2, flocculating and decoloring: adding hydrogen peroxide, sufficiently stirring, then adding carclazyte, sufficiently stirring, and then standing so as to obtain a solid-liquid mixture with flocculates; 3, carrying out multistage filtration; 4, carrying out ion exchange processing: removing inorganic foreign ions by adopting an ion exchange column or an ion exchange bed so as to obtain defecated filter liquor with conductivity of less than 5 microseconds / centimeter under the temperature condition of 25 DEG C; and 5, carrying out negative-pressure vacuum distillation. The method has reasonable design, high practical value, good decoloring effect and low recovery cost, adopts simple step, is easy and convenient to operate, ensures that chroma of processed cutting fluids is less than 15 and various indexes all meet the requirements of technical indexes and can solve multiple practical problems of high recovery cost, unstable processed cutting fluid quality, difficult processing procedure mastering, and the like of the traditional cutting fluid recovery method.

Owner:XIAN HUAJING ELECTRONICS TECH

Method for manufacturing seamless ring and special heat treatment system thereof

ActiveCN101831537AInconsistent quality performanceConsistent quality performanceFurnace typesHeat treatment furnacesHardnessContinuous flow

The invention discloses a method for manufacturing a seamless ring and a special heat treatment system thereof. The manufacturing method comprises four continuous flows of ring rolling, metal working, heat treatment and finish machining, wherein the heat treatment flow comprises three processes of heating, quenching and tempering. The quenching process of the heat treatment flow comprises the steps of: (1) opening a vortex generator which is positioned at the bottom of a quenching tank, wherein the quenching liquid in the quenching tank forms stable vortex; and (2) lifting the seamless ring out of a split track furnace and putting the seamless ring into the quenching tank for quenching. In the method for manufacturing the seamless ring and the special heat treatment system, the vortex generator is opened first before the seamless ring is quenched, and when stable vortex which moves at a constant speed is formed in the quenching tank, a heated workpiece is put into the quenching tank, so that inconsistent quality performance of the seamless ring due to the inconsistency of the concentration and temperature of the quenching liquid is avoided. Therefore, the consistency of the surface hardness and core hardness of the seamless ring and the consistency of the overall hardness can be guaranteed.

Owner:CHANGZHOU SHUANGQIANG MASCH MFG CO LTD

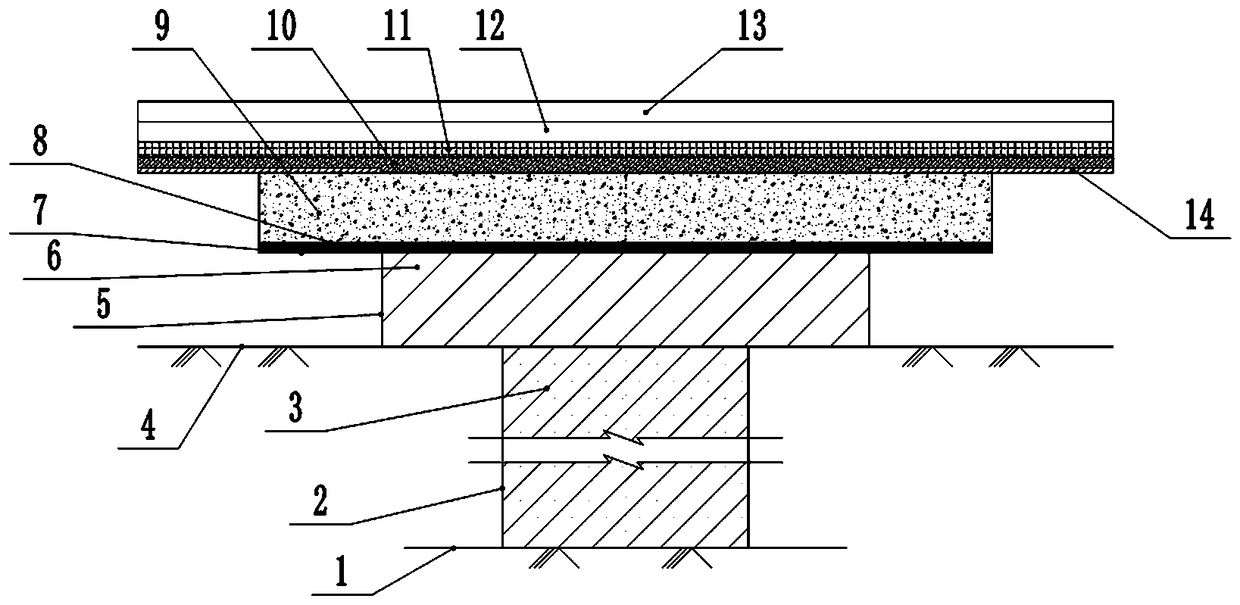

Method for repairing pavement by using plain concrete and reinforced concrete

PendingCN108316089ASimple construction methodGuarantee the construction qualityIn situ pavingsPaving detailsRebarReinforced concrete

Owner:HUALAN DESIGN GRP CO LTD

Preparation method for IC10 alloy low-pressure-turbine guide vane thermal barrier coating

InactiveCN108118278AExtended service lifeImprove corrosion resistanceMolten spray coatingAviationSuperalloy

The invention belongs to the technical field of aviation engine thermal barrier coatings and particularly relates to a preparation method for an IC10 alloy low-pressure-turbine guide vane thermal barrier coating. A matrix material is an IC10 directional solidified high temperature alloy, and the preparation process procedure comprises the steps of supplied part checking, preparing before spraying,spraying process parameter confirming, cleaning, protecting before grit blasting, grit blasting, protecting before spraying, a NiCrAlYSi metal bonding bottom layer supersonic spraying, a nano zirconium oxide coating atmospheric plasma spraying, clearing, final checking and respraying and repairing. According to the preparation method for the IC10 alloy low-pressure-turbine guide vane thermal barrier coating, the NiCrAlYSi metal bonding bottom layer supersonic spraying and the nano zirconium oxide coating atmospheric plasma spraying are adopted, so that the high temperature oxidation resistance and heat insulation capacities of the coating are improved, the preparation of low-pressure-turbine guide vane surface thermal barrier coating of an aviation engine of some type is realized, and bymeans of the preparation of coating, the service life of hot end components can be effectively prolonged.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

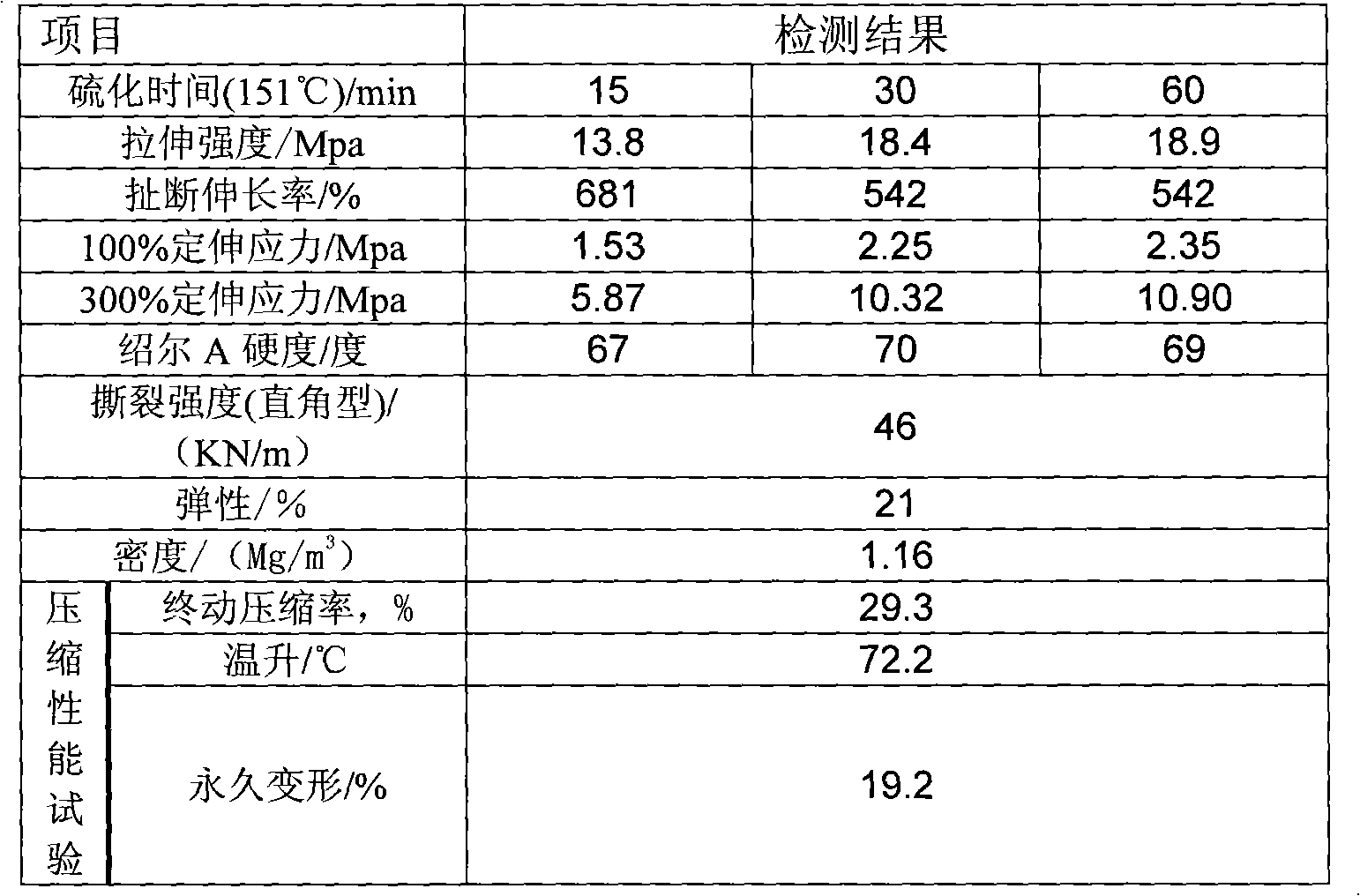

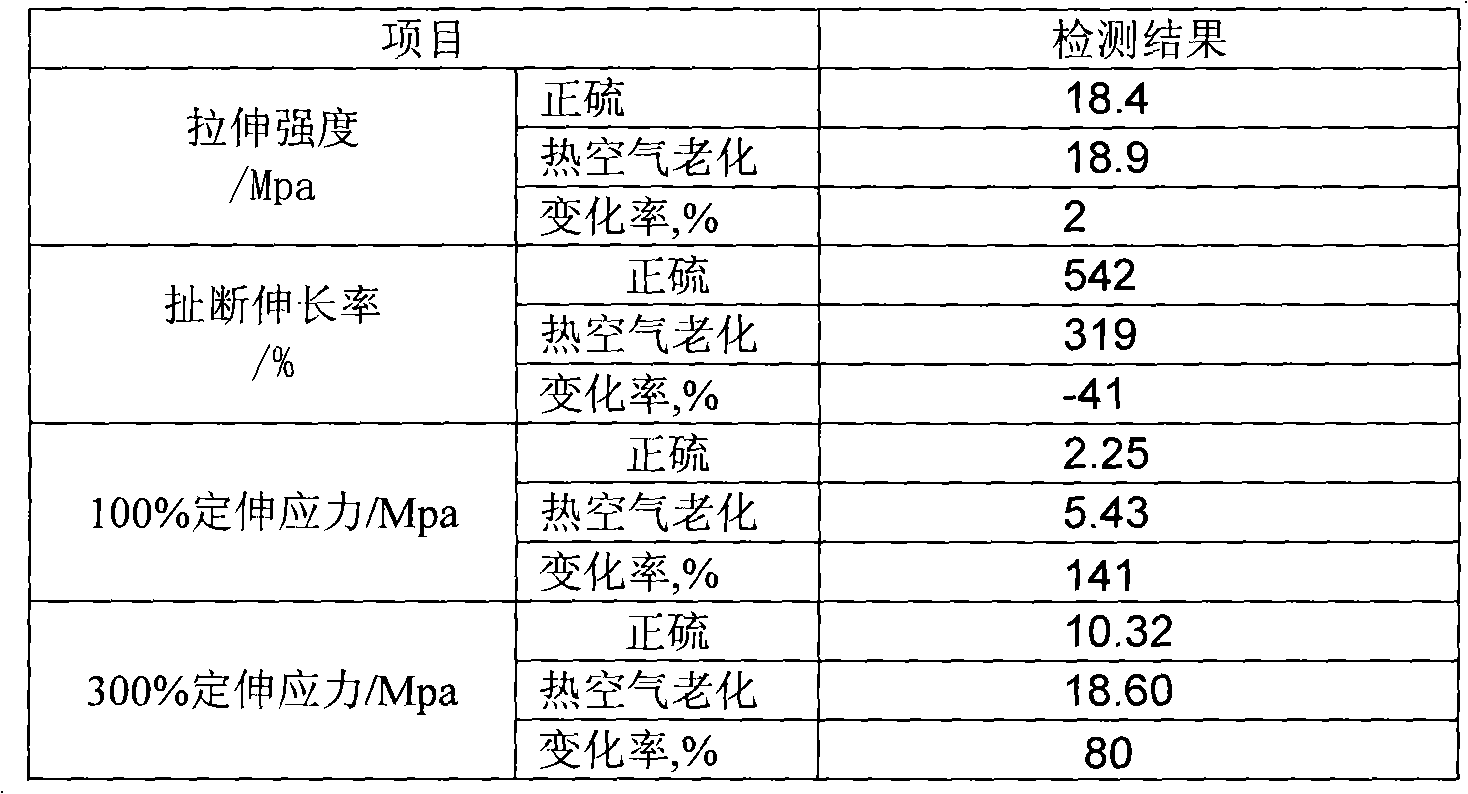

Low-pressure variation ethylene acrylate rubber material resistant to ultra-low temperature and high-temperature oil, and preparation method thereof

The invention discloses a low-pressure variation ethylene acrylate rubber material resistant to ultra-low temperature and high-temperature oil, and a preparation method thereof, and belongs to the technical field of rubber sealing pieces. The ethylene acrylate rubber material comprises 100 parts of ethylene acrylate rubber Vamac GLS, 1.5 to 2.5 parts of 4,4'-bis(phenyl isopropyl) diphenylamine, 0.3 to 0.7 part of a processing aid 18D, 0.5 to 1.5 parts of stearic acid, 0.5 to 1.5 parts of a processing aid VAM, 85 to 115 parts of carbon black ST1120, 5 to 20 parts of a softening plasticizer EK-70, 0.8 to 1.6 parts of a cross-linking aid HMDC-1 and 2 to 2.4 parts of vulcanizing agent 1,8-diazabicyclo[5.4.0]undec-7-ene. The preparation method of the ethylene acrylate rubber material comprises the steps of mixing of a master batch, post vulcanization of the master batch and vulcanization. The prepared ethylene acrylate rubber material can meet requirements of VW TL52329 technical indexes, and has the characteristics of ultra-low temperature resistance, high-temperature oil resistance, low pressure variation and low cost.

Owner:南京金三力高分子科技有限公司

B4C-based ceramic material with TiH2 as sintering aid and preparation method of B4C-based ceramic material

The invention discloses a B4C-based ceramic material with TiH2 as a sintering aid and a preparation method of the B4C-based ceramic material, belonging to a preparation method of a ceramic material and being used for solving the problem that the densification is inhibited by an oxidation environment easily generated when B4C is prepared by taking Ti powder as the sintering aid and also solving the problems of great density increase and great hardness reduction of composite ceramics prepared by reacting between large addition amounts of TiH2 and B4C and sintering so as to meet the requirement for preparing light-weight high-strength materials. The B4C-based ceramic material disclosed by the invention is prepared by sintering after mixing B4C powder and TiH2 powder, wherein the components are weighted according to the mass percentage: 90-99% of B4C powder and 1-10% of TiH2 powder. The preparation method disclosed by the invention comprises the steps of mixing and sintering. The ceramic material prepared by the invention is high in hardness, low in density and electrical resistivity, high in bending strength and fracture toughness, and capable of well meeting the requirements for various technical indexes of a protective material, improving the protection reliability and realizing electrical discharge machining, and has the potential of mass production.

Owner:WUHAN UNIV OF TECH

Method for producing ultrafine zirconium powder

The invention discloses a method for producing ultrafine zirconium powder. The method comprises the following steps: mixing firearm zirconium sponge and electrolyzed zirconium serving as raw material zirconium, adding the mixture into a material receiving crucible of a hydrogenation reactor, igniting the raw material zirconium and hydrogenating to obtain zirconium hydride; putting the zirconium hydride into a ball-milling tank loaded with a ball-milling medium, and performing ball milling till the granularity of the zirconium hydride is smaller than or equal to 400 meshes; putting the smashed zirconium hydride into a vacuum drying oven for drying, loading the smashed and dried zirconium hydride into a dehydrogenating furnace for dehydrogenating, putting the dehydrogenated zirconium hydride into the ball-milling tank loaded with the ball-milling medium for performing ball-milling, sieving, washing and drying to obtain ultrafine zirconium powder. The method has the advantages that the raw materials are readily available, the technological process is stable, the phenomena of self-ignition and explosion are avoided, and the technical index and safety production requirements of the ultrafine zirconium powder can be met.

Owner:CITIC JINZHOU METAL

Preparation method of diisobutyl adipate

InactiveCN102911048ALight colorMeet the requirements of technical indicatorsOrganic compound preparationCarboxylic acid esters preparationDiisobutyl AdipateAlcohol

The invention relates to a preparation method of diisobutyl adipate. The method includes following steps of an esterification reaction step, a washing step, a dealcoholizing step, a refining step and a filtering step, wherein the dealcoholizing step is that refining agents are added to dealcoholized coarse products to be stirred and refined for one hour, and the filtering step is that refined mixed liquids are filtered to obtain a diisobutyl adipate product. According to the preparation method of the diisobutyl adipate, the refining agents are used in the refining step so that the color of the final obtained product is shallow, the product can be sold without high vacuum refining processing, and the quality of the prepared product completely fits with technical indicator requirements. According to the preparation method, a high vacuum refining step is omitted during production, investment for high vacuum pump devices is avoided, accordingly, device investment is saved, production costs are reduced, and market competition of the product is improved.

Owner:TIANJIN CHEM REAGENT RES INST

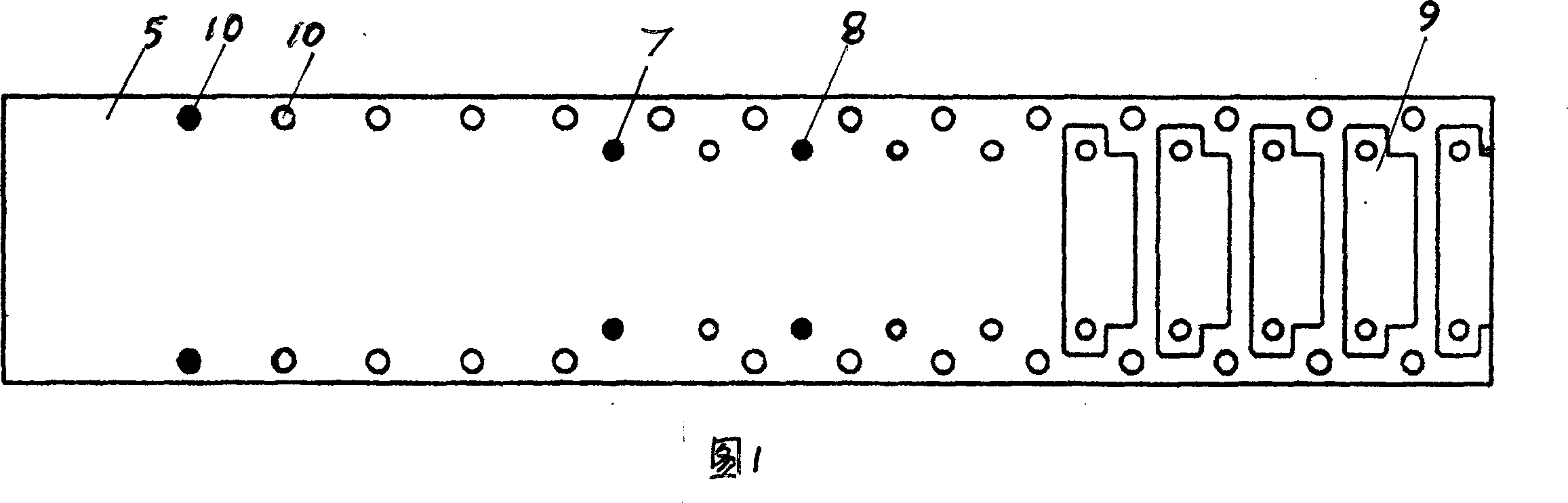

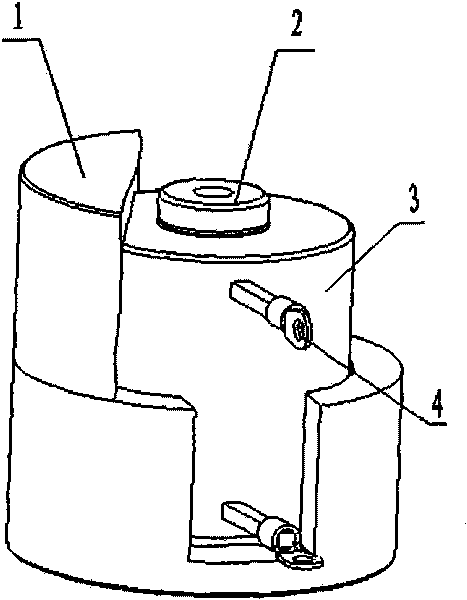

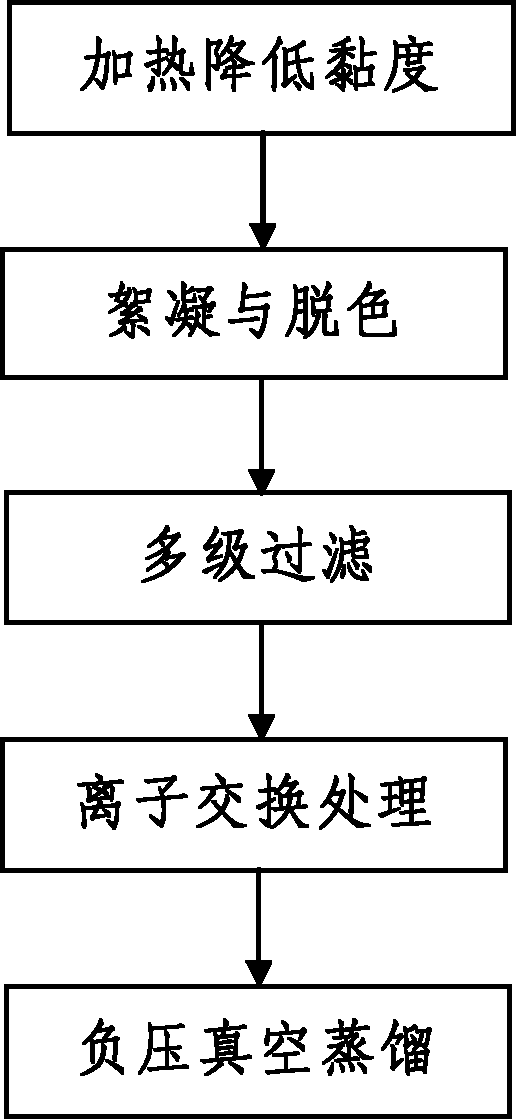

Noise insulation hood with sound insulation volume thereof being intelligently controlled

InactiveCN101635144ASound insulation monitoring and controlStrong practical valueSound producing devicesAutomatic controlIntermediate frequency

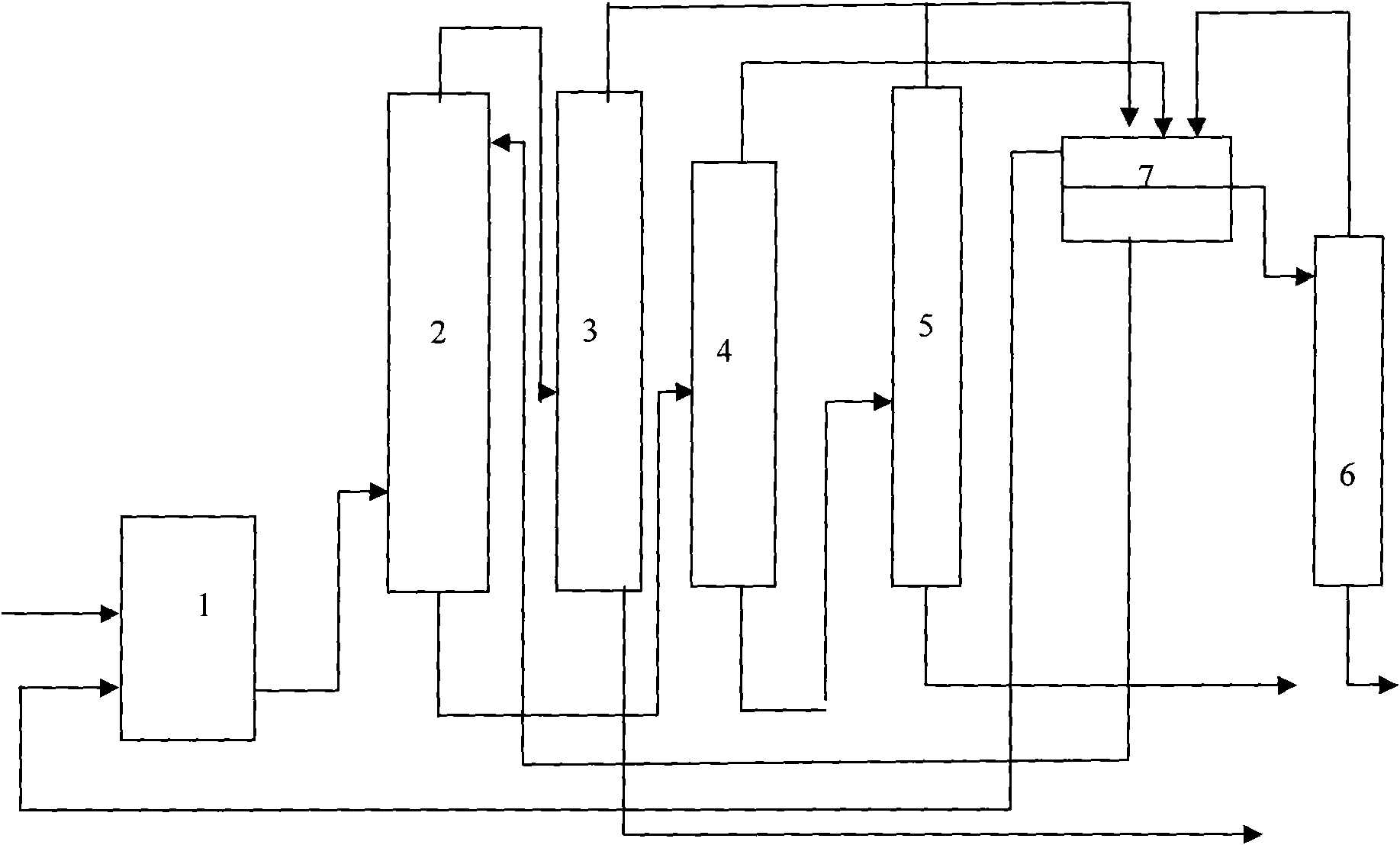

The design of current domestic noise insulation hood is still of a pure mechanical structure, and once the noise insulation hood is manufactured, the sound insulation volume thereof is determined, but in fact, as the change of operation load and conditions, the noise energy radiated by a noise source also changes, therefore, the prior noise insulation hood is purely mechanical noise insulation and lacks function of intelligent and automatic control. The noise insulation hood with the sound insulation volume thereof being intelligently controlled is developed and investigated on account of the defect, and is specifically designed for large-scale noise source, such as large-scale gas compressors. The invention combines modern control theory, computer technology and noise control theory to invent a novel noise insulation hood with intelligently controlled sound insulation volume (for the arrangement diagraph of the specific device, see the abstract attached diagraph 1) which solves the above problems completely and can meet different user requirements. The characteristic of the invention lies in the automatic processing of the two problems of noise source heat dissipation and the sound insulation volume of noise source in different frequency range (comprising high, low and intermediate frequencies), thus solving the problem of ventilation and heat dissipation of compressors, realizing comprehensive intelligent and automatic control of the sound insulation volume of sound insulation devices simultaneously, and having the advantages of humanization and intellectualization.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

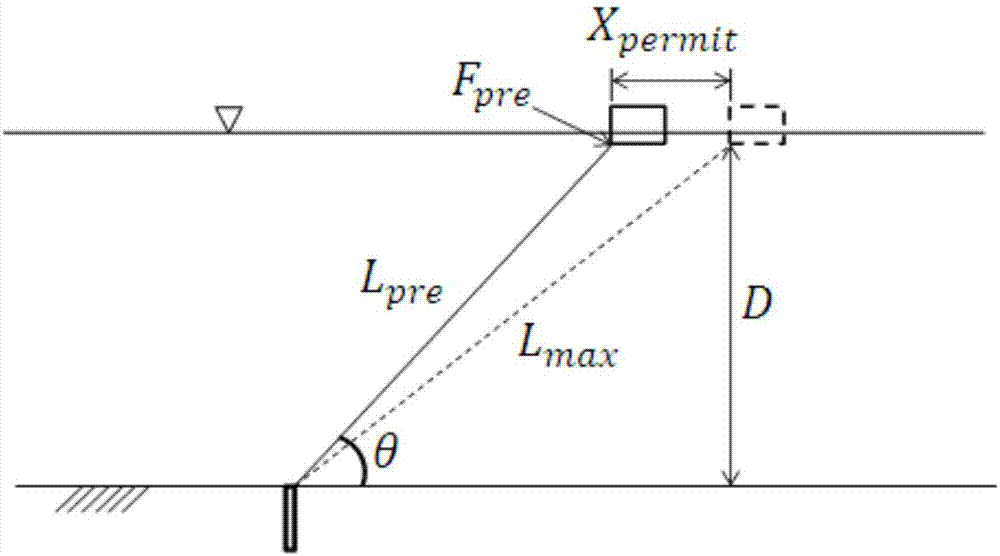

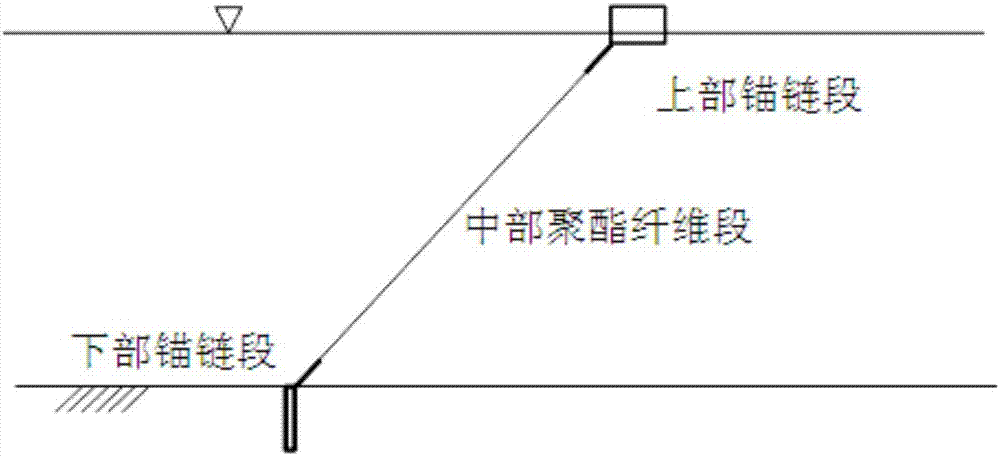

Planning and design method for polyester fiber tension type mooring system

ActiveCN107358000AReduce workloadMeet the requirements of technical indicatorsGeometric CADSpecial data processing applicationsPolyesterFiber

The invention relates to a planning and design method for a polyester fiber tension type mooring system. The method is characterized by comprising the following steps that 1, a polyester fiber cable and anchor chain of certain specification are selected as materials of segments of each cable in the mooring system, and the segmental structure of each cable in the mooring system is determined; 2, initial mooring system general arrangement of an offshore platform is given, and a return stiffness curve of the offshore platform in the horizontal offset direction is obtained according to the determined segmental structure of each cable; 3, inspection is conducted on the given initial mooring system general arrangement under the extreme environment according to the obtained return stiffness curve, and then mooring system general arrangement meeting the technical requirements is obtained. Accordingly, the workload that when the initial scheme is designed, multiple design parameters of the mooring system are subjected to trial calculation and adjustment repeatedly can be reduced, and the method can be widely applied to the field of deep-water marine engineering.

Owner:CHINA NAT OFFSHORE OIL CORP +1

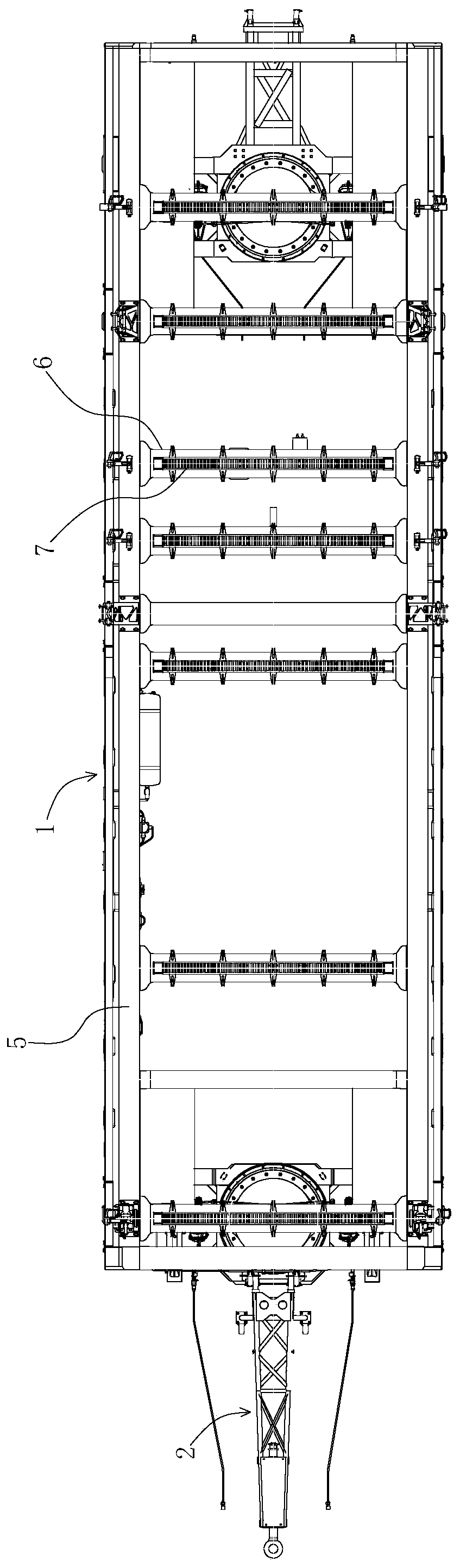

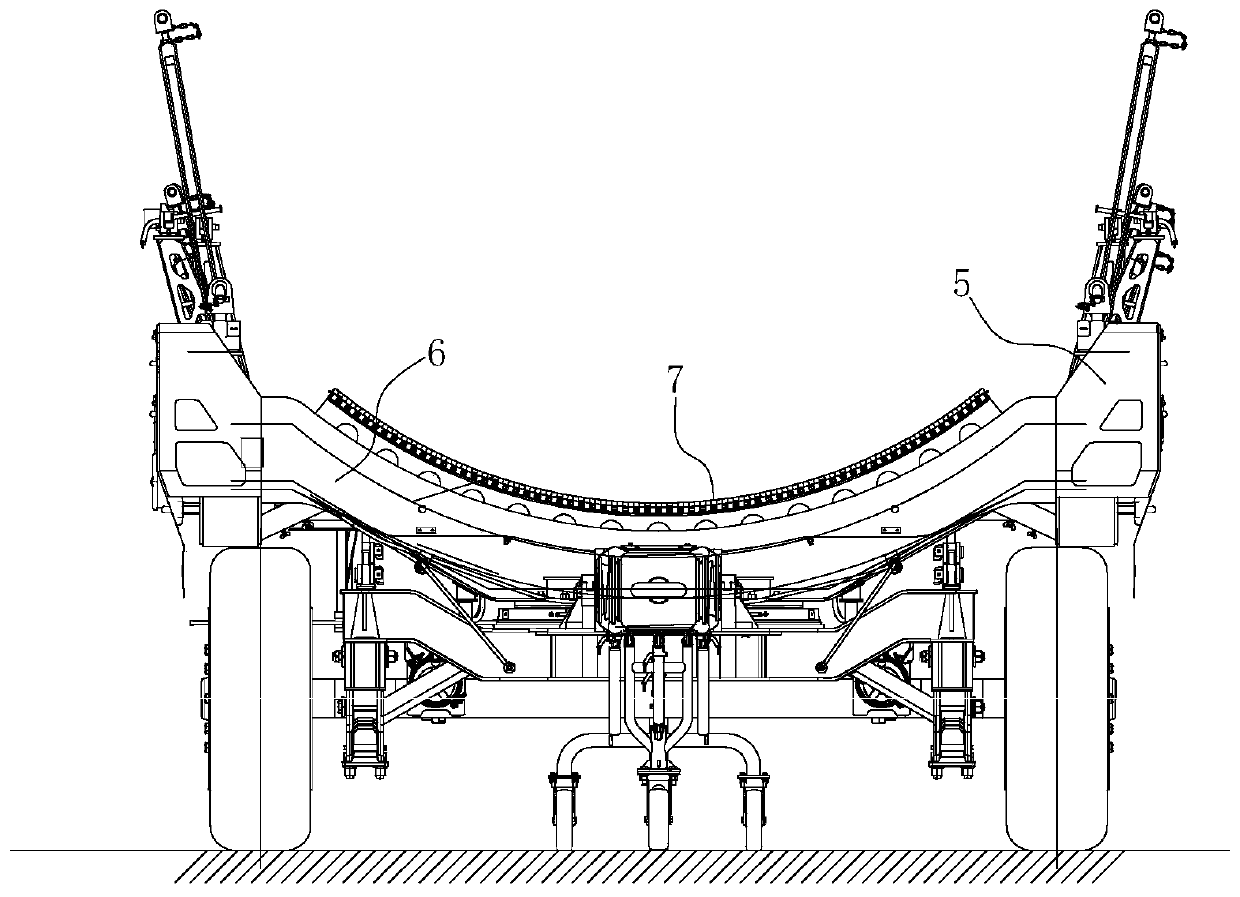

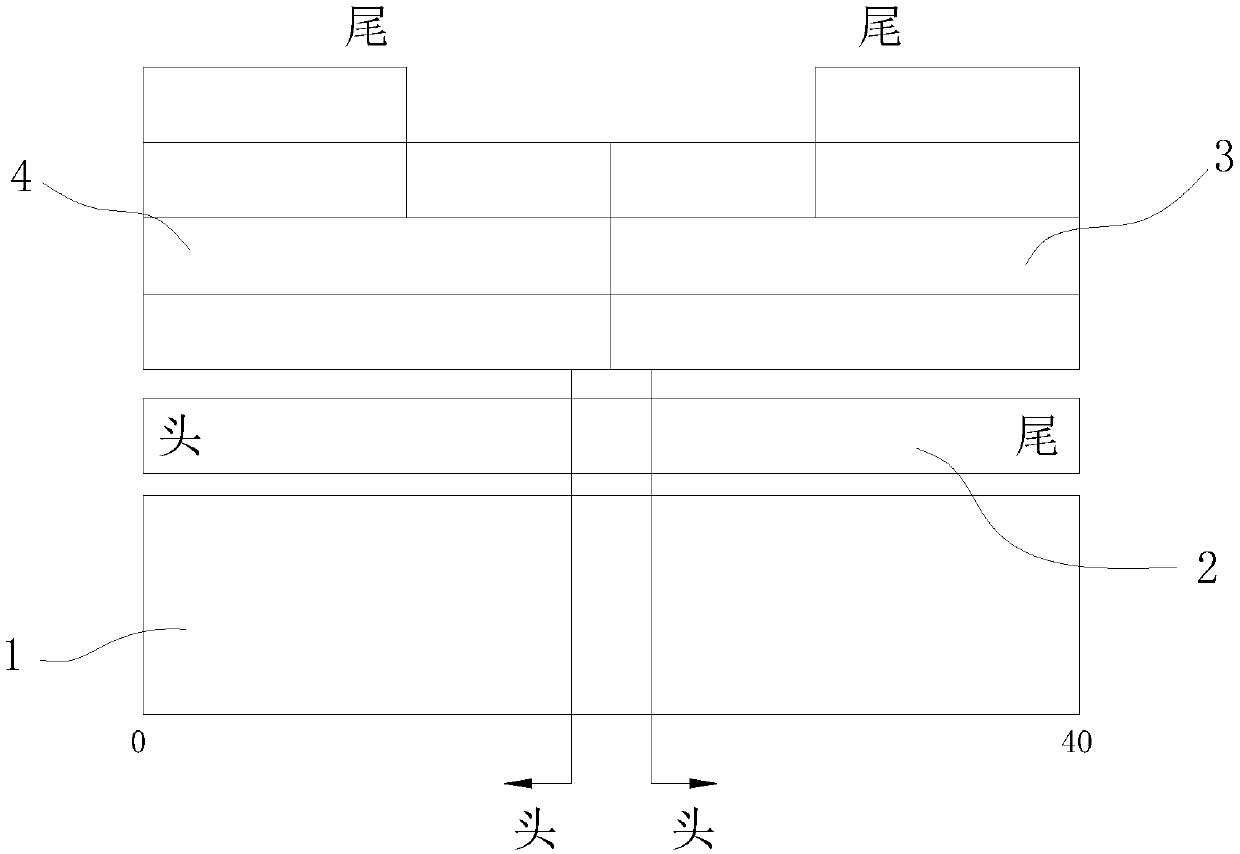

Universal-type arrow body highway transporting vehicle

ActiveCN110103803AReduce the overall heightImprove stabilityLoad securingVehicle carriersVehicle frameCoupling

The invention discloses a universal-type arrow body highway transporting vehicle. The universal-type arrow body highway transporting vehicle includes a vehicle frame assembly, a front wheel set, a rear wheel set, a braking system and a traction arm, wherein the vehicle frame assembly includes two longitudinal beams and a plurality of cross beams connected between the two longitudinal beams, the cross beams are in a downward concave arc shape, a plurality of moving brackets are arranged between the two longitudinal beams and mounted on the cross beams, mounting seats are arranged on the longitudinal beams, couplings are arranged on the mounting seats, the front wheel set is mounted at the bottom of the front end of the vehicle frame assembly, the rear wheel set is mounted at the bottom of the rear end of the vehicle frame assembly, and the traction arm is connected to the front wheel seat or the rear wheel set. The purpose is to provide the universal-type arrow body highway transportingvehicle to meet the using requirements of multiple models and bases, through an overall optimization layout and lightweight design, on the premise of meeting the requirements of the technical index,the structure is simplified, and reliability, maintainability and supportability are improved.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

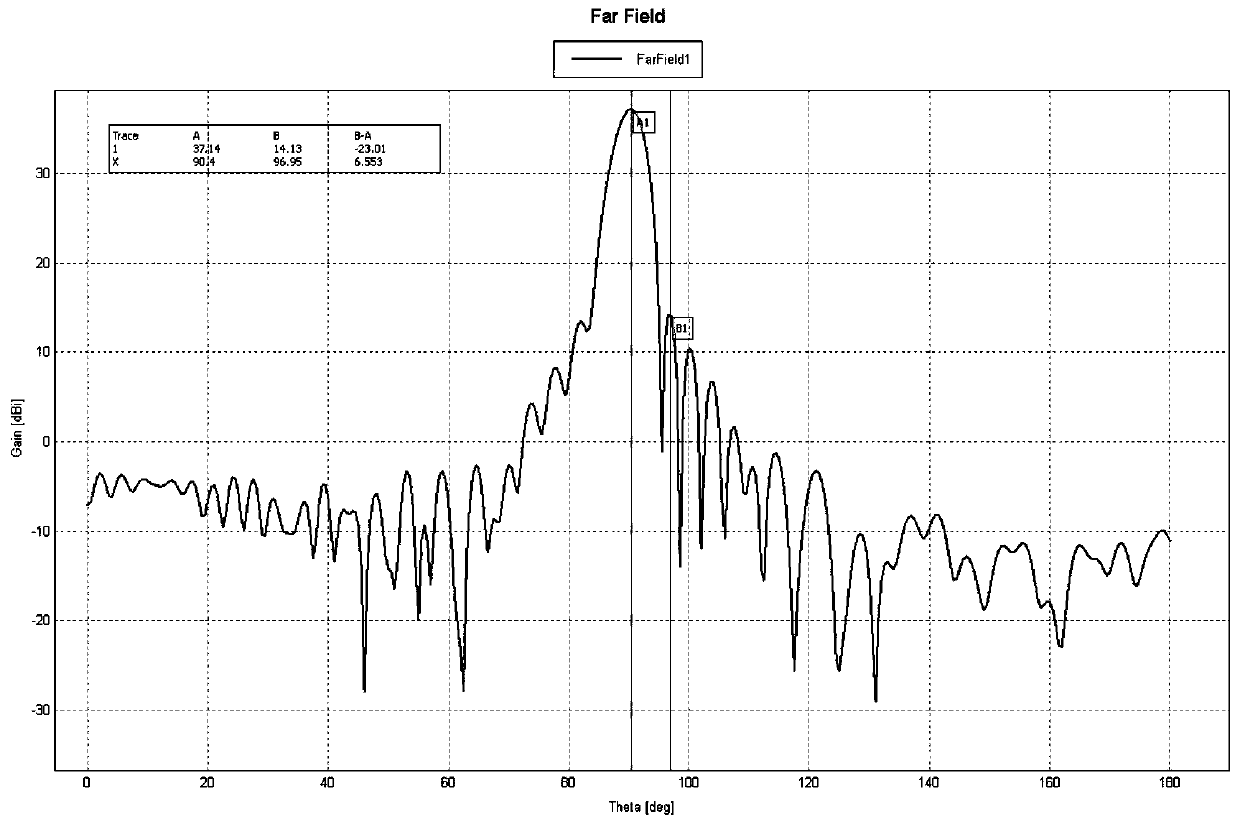

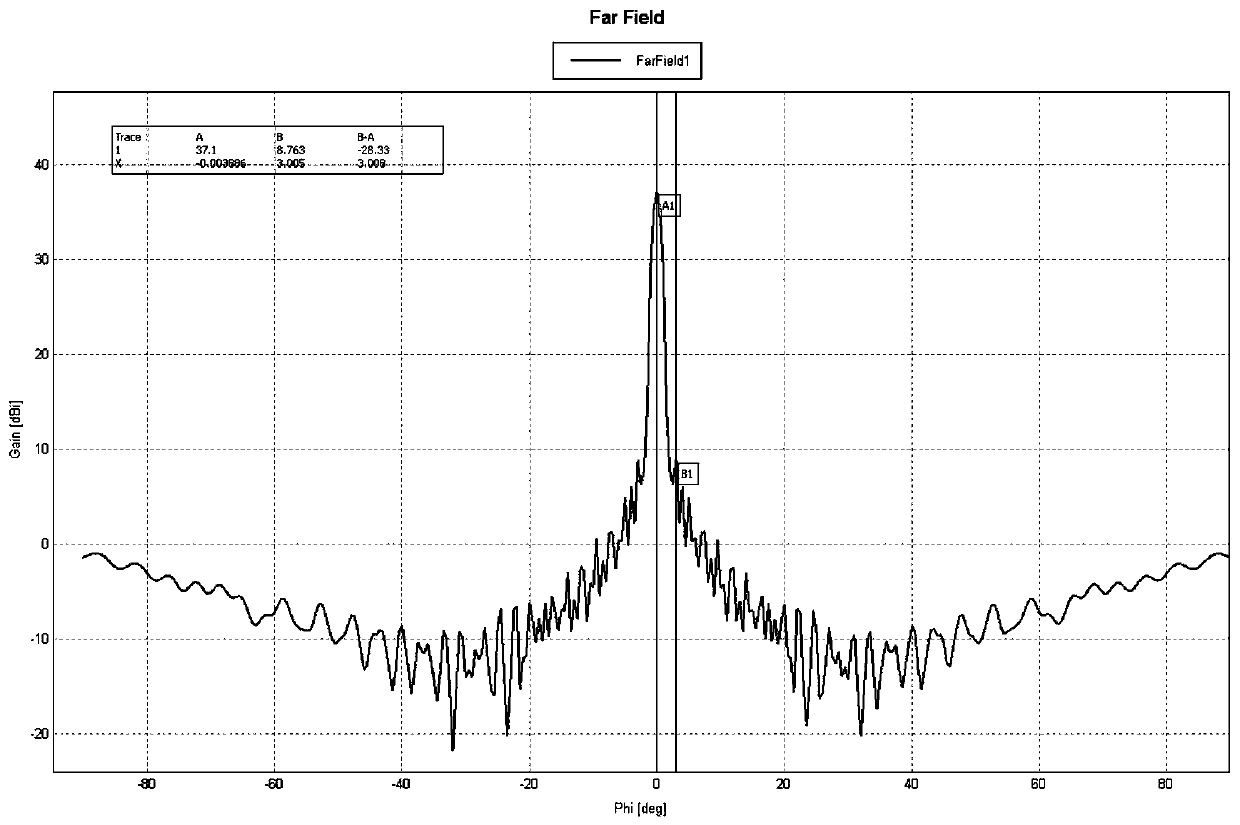

FOD detection radar system

PendingCN110231622AStrong real-time processingReduce volumeRadio wave reradiation/reflectionCommunication interfaceRadar systems

The invention relates to an FOD detection radar system. The FOD detection radar system comprises an antenna feeder subsystem, an intermediate frequency subsystem, a digital subsystem, a power subsystem and an auxiliary debugging system, wherein the antenna feeder subsystem comprises an antenna and a receiving-transmitting front-end; the antenna comprises an antenna support, a transmitting antennaand a receiving antenna; the intermediate frequency subsystem mainly comprises a transmitting frequency synthesizer, a local oscillation frequency synthesizer and a receiver / LFM source; the receiver / LFM source provides a homogenous LFM signal for the transmitting frequency synthesizer and the local oscillation frequency synthesizer, meanwhile receives an output signal of a receiving link of the receiving-transmitting front-end and outputs the output signal to a signal processor after frequency conversion; the digital subsystem comprises the signal processor and a communication interface module; the signal processor is a core component of the system, is connected with an upper computer system of an airport and receives control information of the upper computer system; and the communicationinterface module is used for converting the signal of the signal processor and performing communication between an FOD detection radar and the upper computer system. The FOD detection radar system hasthe advantages of being small in size, stable in performance, high in practicability and high in anti-interference capability.

Owner:西安大合智能科技有限公司

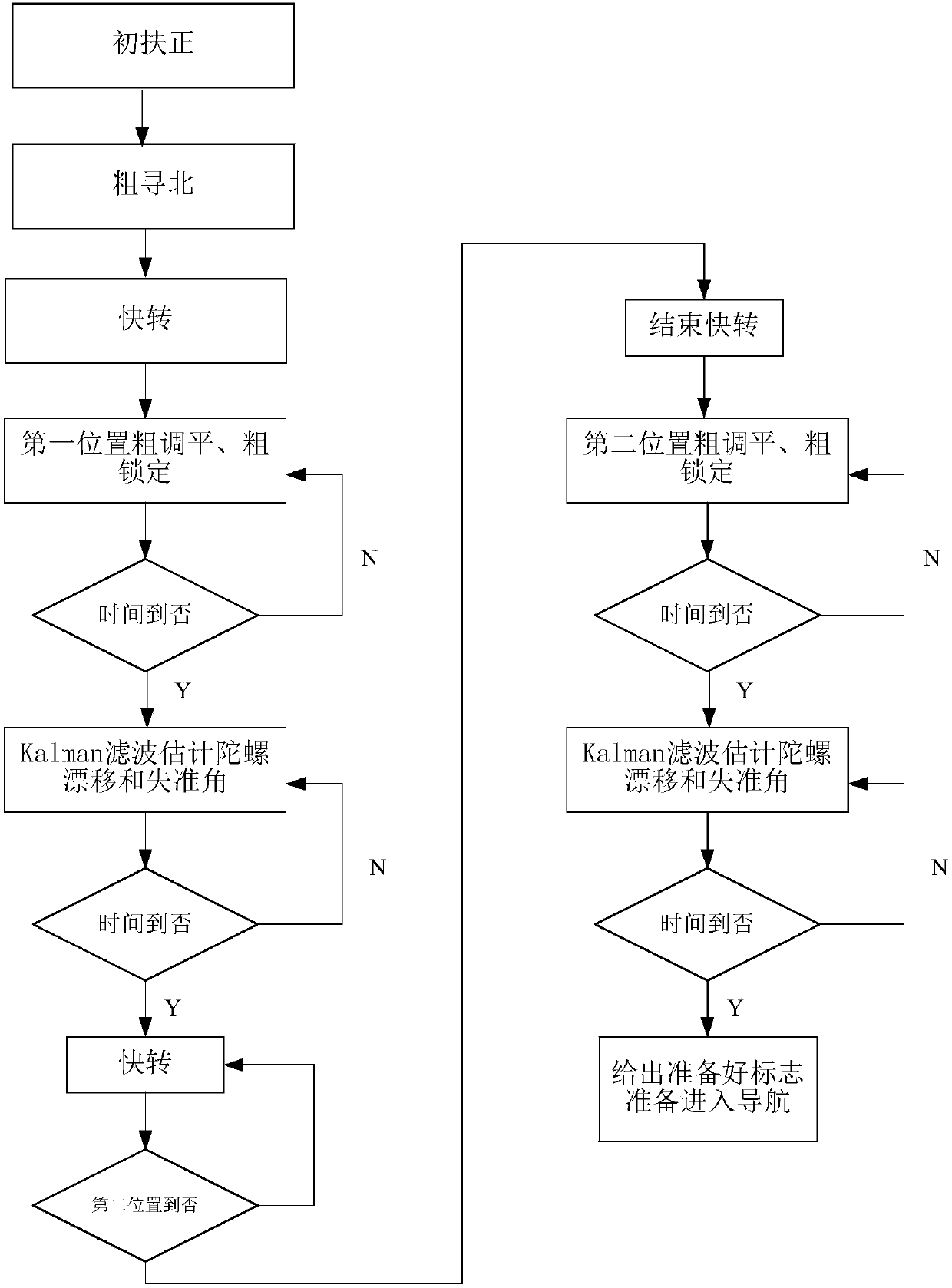

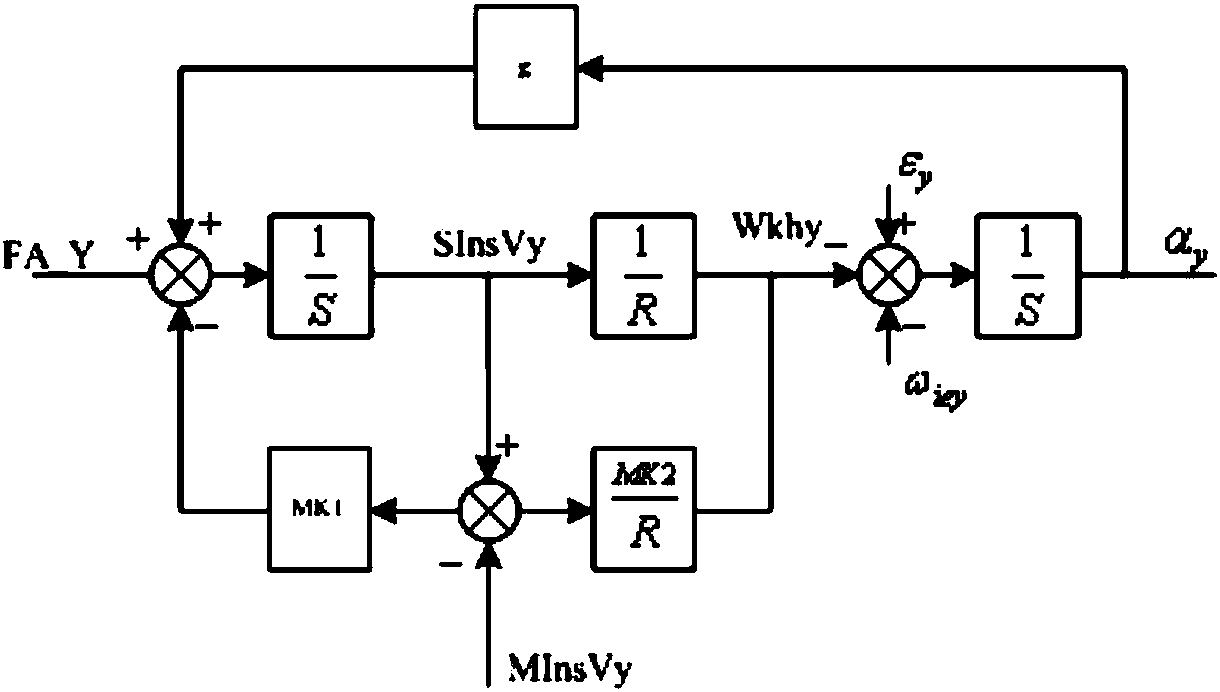

Self-alignment method of gravity meter on shaking condition

ActiveCN107797156AImproved self-alignment accuracyMeet the requirements of technical indicatorsGravitational wave measurementEarth's rotationComputer science

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

Small-stroke proportional output LVDT compensation coil process

InactiveCN109616313AIncrease winding lengthIncrease the lengthTransformers/inductances coils/windings/connectionsCoils manufactureEngineeringConductor Coil

The invention relates to a small-stroke proportional output LVDT compensation coil process. The process comprises the following steps that step 1, the number of turns and the number of layer of primary coils are designed according to technical indexes for performing horizontal winding; step 2, a compensation coil WE is horizontally wound from left to right on the primary coils; and step 3, a secondary coil WA and a secondary coil WB are horizontally wound on the compensation coil WE according to a layer winding process. After the compensation coil is added, the wire winding length L and the length of an iron core can be increased, so that the performance of the LVDT can be improved; and the voltage value can be regulated, so that the requirements of technical indexes can be met.

Owner:安徽感航电子科技有限公司

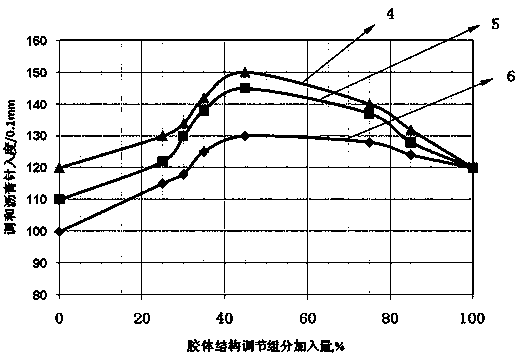

Polymer modified asphalt, and preparation method thereof

ActiveCN110437630AStrong penetrating powerChange the penetrationBuilding insulationsNeedle penetrationPolymer modified

The invention discloses a polymer modified asphalt, and a preparation method thereof. The polymer modified asphalt is prepared from a specific blended asphalt, so that the obtained polymer modified asphalt contains no compatibilizer. According to the specific blended asphalt, a specific matrix asphalt and a colloid structure are selected to adjust the components; the colloid structure is adopted to adjust the components, so that matrix asphalt needle penetration is changed, and in composition, mutual complementation with the matrix asphalt is realized, the obtained blended asphalt is reasonable in component matching, and modification is convenient to realize. The polymer modified asphalt is excellent in compatibility, high and low temperature performance, aging resistance, fatigue resistance, and road using performance, and the performance is capable of satisfying technical index requirements of polymer modified asphalt.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing N,N-diethyl M-Methyl Benzoyl amide

InactiveCN101914034AHigh purityLight colorOrganic compound preparationCarboxylic acid amides preparationDiamineSolvent

The invention relates to a method for preparing N,N-diethyl M-Methyl Benzoyl amide. The method comprises the steps of: orderly adding ethidene diamine, water and benzol in a reactor, stirring and adding M-Methyl Benzoyl formyl chloride and acid absorbing fine preparation, maintaining reaction under a room temperature, stirring and reacting for 1 to 5 hours after completely adding materials, adding water to wash after finishing reaction, stirring, layering, removing water layer, distilling, removing solvent benzol so as to obtain the products of N,N-diethyl M-Methyl Benzoyl amide. In the amidation step of the method, sodium hydroxide is used as acid absorbing fine preparation so as to obtain the produces with high purity and shallow color. The product can be sold without high vacuum refining. The quality of the product totally meets the demand of technical index.

Owner:TIANJIN CHEM REAGENT RES INST

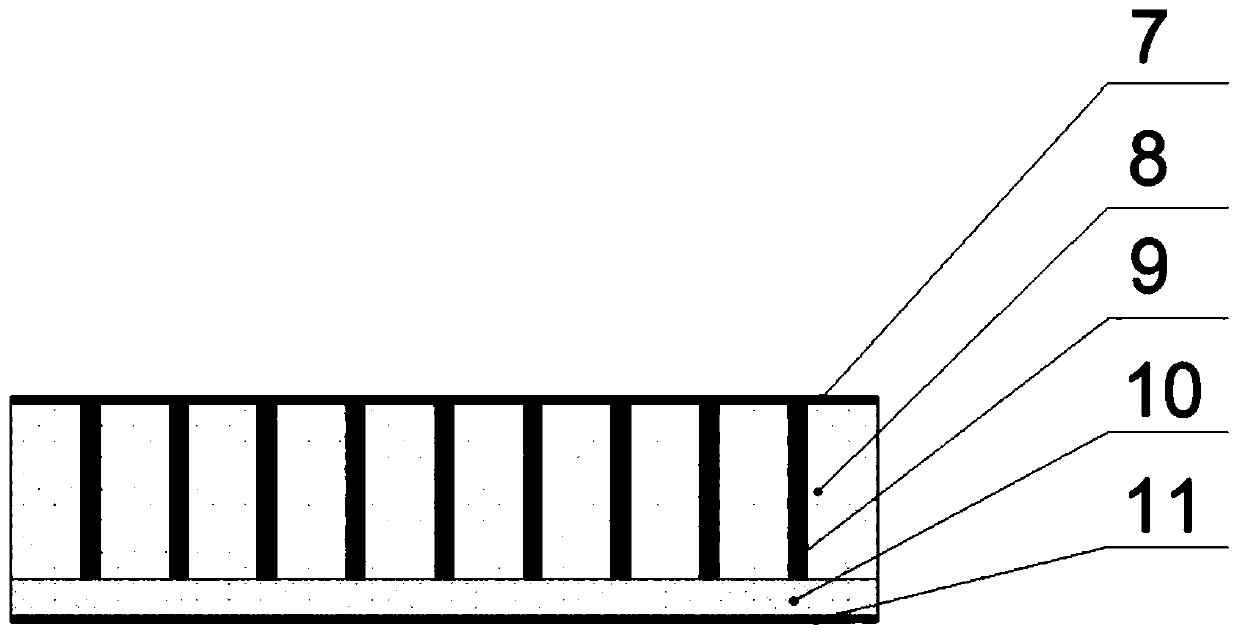

High-frequency broadband underwater acoustic transducer and manufacturing method thereof

InactiveCN110493698AMeet the requirements of technical indicatorsLarge amount of informationPiezoelectric/electrostrictive transducersCeramic compositeOperating frequency

The invention belongs to and relates to a high-frequency broadband underwater acoustic transducer device, in particular to a high-frequency broadband underwater acoustic transducer and a manufacturingmethod thereof. The underwater acoustic transducer comprises a matching layer, a wafer backing layer and an acoustic transmission coating layer which are sequentially installed in the shell in parallel from top to bottom, wherein the wafer is of a 1-3-2 type piezoelectric ceramic composite material structure and comprises a ceramic substrate, a plurality of ceramic elements grow on the ceramic substrate, and every two ceramic elements are connected through a high-molecular polymer; an upper electrode is arranged above the ceramic element; a lower electrode is arranged below the ceramic substrate, a watertight cable or a watertight connector is led out from the lower electrode through the backing layer and the shell, and received or transmitted electric signals are input or output. According to the technical requirements of working frequency and bandwidth characteristics, the wafer and the matching layer are optimally designed, and when the method is applied to underwater speed measurement sonar and detection sonar, broadband signal processing can be carried out to increase the information amount, improve the detection precision, increase the detection range and the like.

Owner:CHINA ELECTRONICS TECH GRP NO 26 RES INST

Alcoholization and mildew prevention method for tobacco leaves

The invention discloses an alcoholization and mildew prevention method for tobacco leaves. The alcoholization and mildew prevention method for the tobacco leaves comprises the following steps: sealinga tobacco box / tobacco stack by films, introducing one or more gases of nitrogen, ozone or carbon dioxide, reducing the oxygen content in the tobacco box / tobacco stack to be below 2% , and carrying out treatment for 5 to 10 days; then opening the tobacco box / tobacco stack, putting into an anti-mildew curing agent, arranging temperature-humidity collecting equipment, and oxygen-content measuring equipment; monitoring the temperature and humidity and oxygen content of the tobacco box / tobacco stack, adjusting the use amount of the anti-mildew curing agent, and keeping the oxygen content at 6 to 12%, the humidity at 50 to 65%, the temperature at 20 to 28 DEG C for more than 40 days and the like. The technology of the invention can be better applied to mildewproof maintenance of the tobacco leaves in the alcoholification period, and the operation is good under the conditions that the oxygen content is 6 to 12%, the humidity is 50 to 65% and the temperature is 20 to 28 DEG C, and the oxygenand humidity reduction speeds are moderate, so that tobacco leaf products are good in grade, and meet requirements of various technical indexes, furthermore, the cost and use amount are lowered.

Owner:四川金叶生物防治有限公司

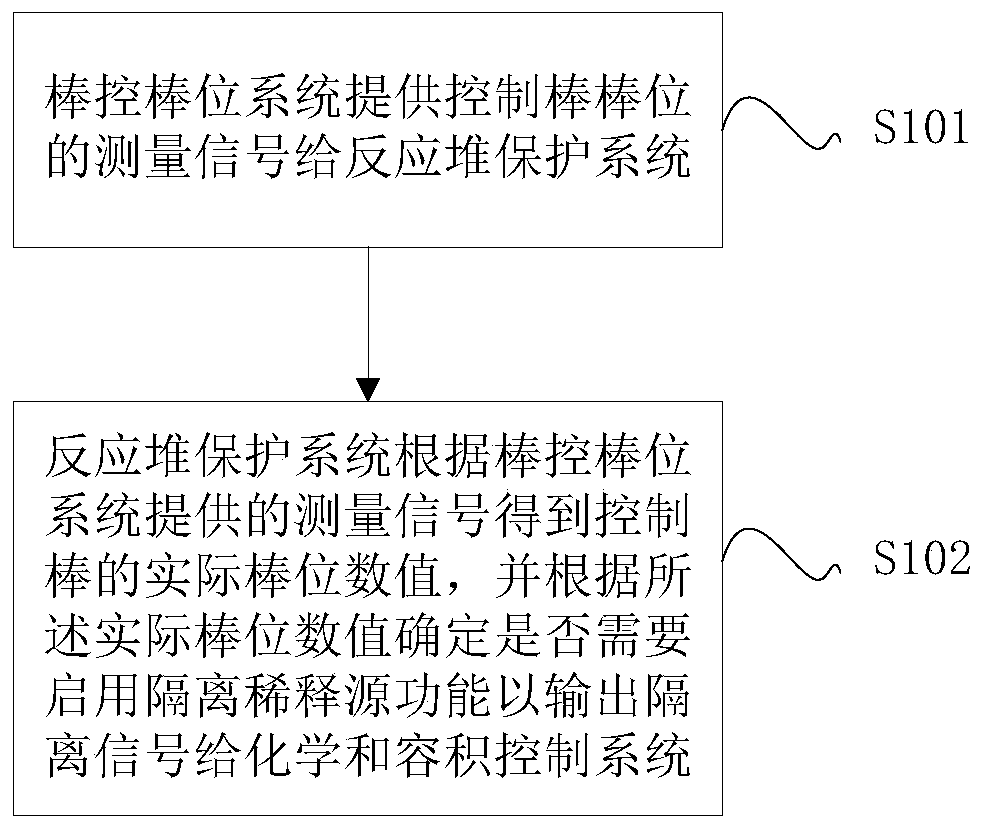

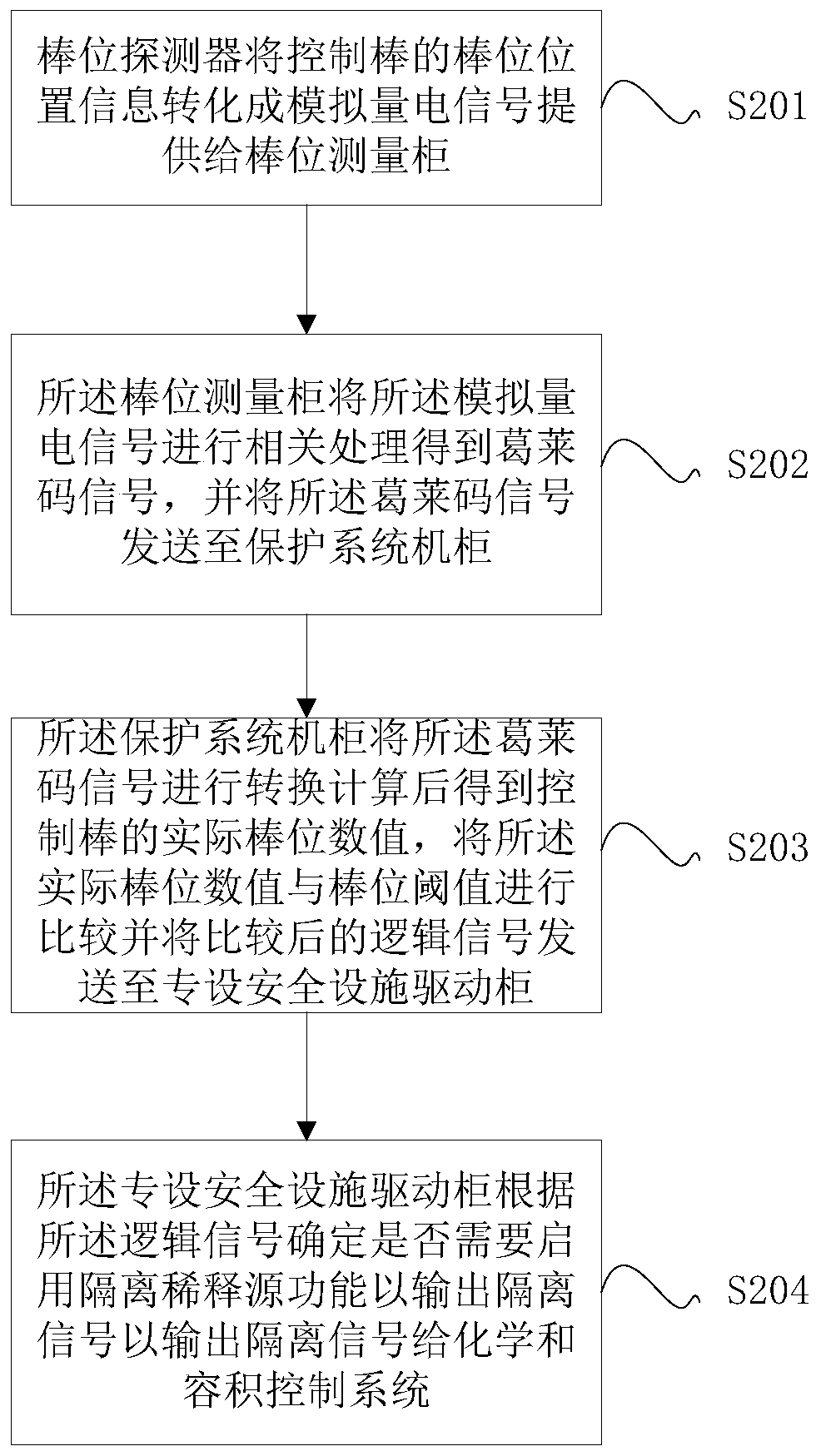

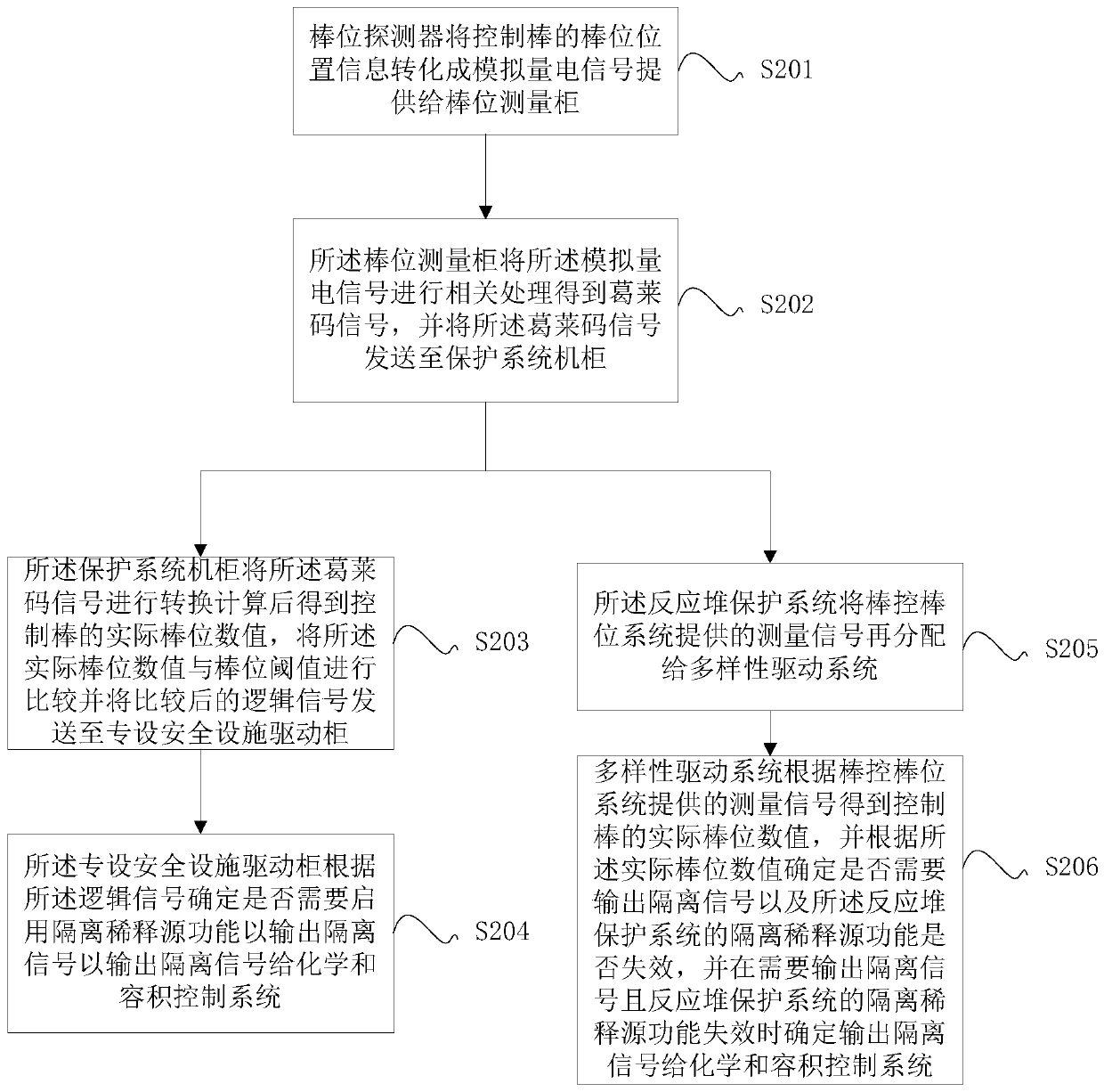

Nuclear power station boron dilution accident handling method and system

ActiveCN109785980AImprove safety performance and automationMeet the non-intervention acceptance requirementsNuclear energy generationNuclear reaction controlAutomatic controlNuclear engineering

The invention discloses a nuclear power station boron dilution accident handling method and system. The nuclear power station boron dilution accident handling method and system are suitable for poweroperation automatic control conditions. The nuclear power station boron dilution accident handling method comprises the steps that a rod control and rod position system provides a measuring signal ofa control rod position for a reactor protection system; and the reactor protection system obtains an actual rod position value of a control rod according to the measuring signal provided by the rod control and rod position system and determines whether a dilution source isolation function needs to be started or not according to the actual rod position value to output an isolation signal to a chemical and volume control system so as to automatically isolate a dilution source when a boron dilution accident occurs under the power operation automatic control condition; and therefore, an acceptancerequirement, for example, a time requirement that no intervention within 30 minutes in the Hualong project, of longer-time no intervention of an operator is satisfied, the safety performance and automation level of a unit are obviously enhanced, safety requirements of a third generation of reactor type are satisfied, and technical index requirements of the third generation of reactor type are satisfied.

Owner:中广核工程有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com