Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Control vacuum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

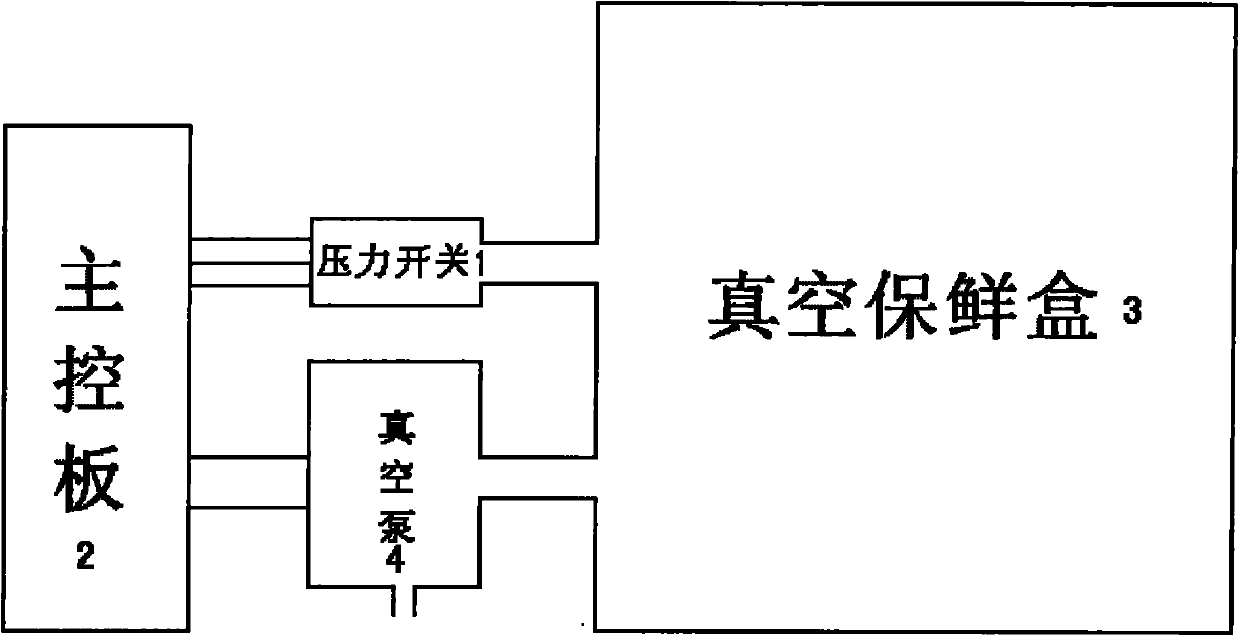

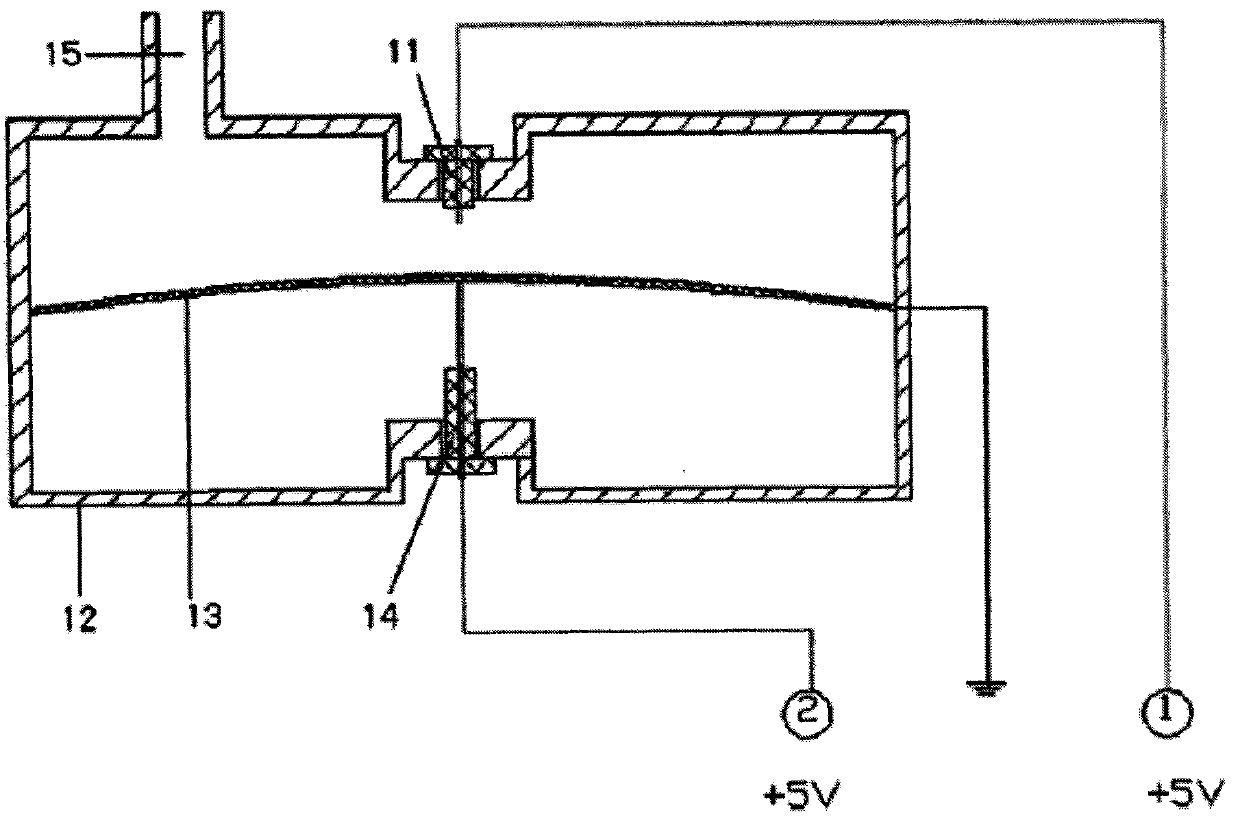

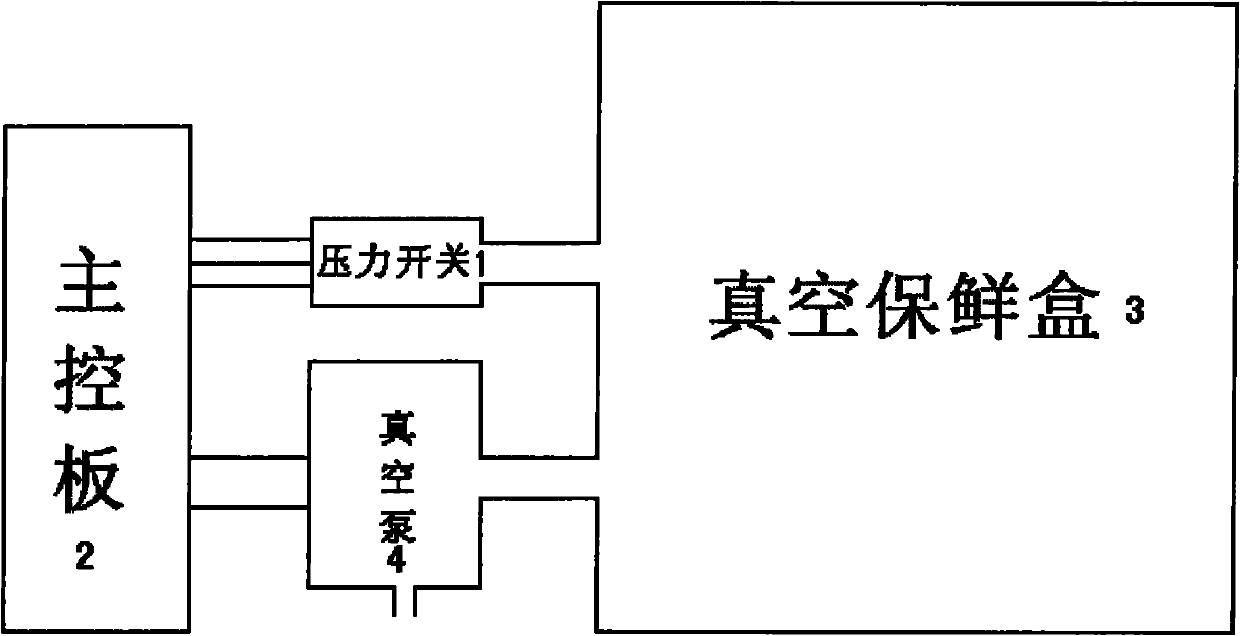

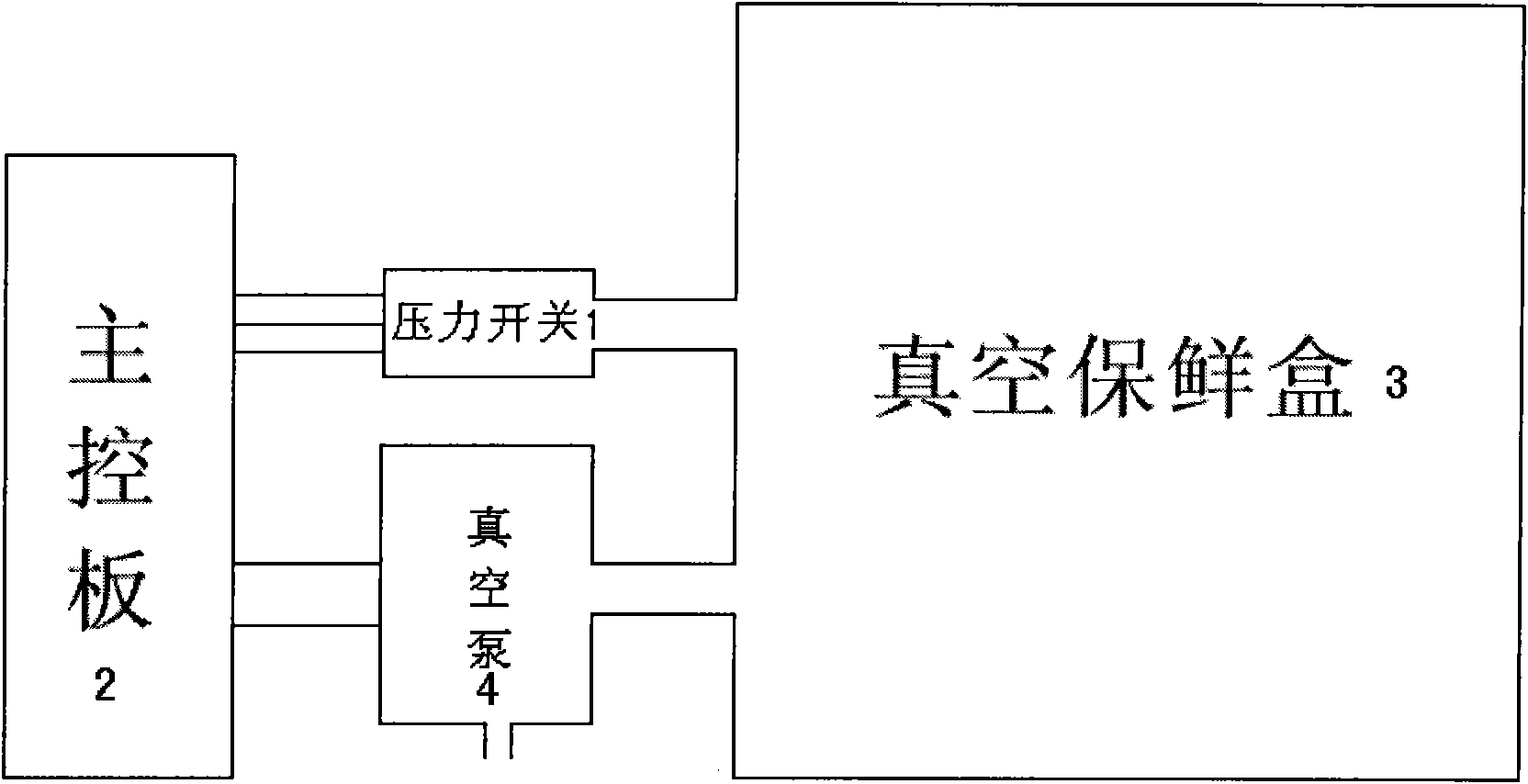

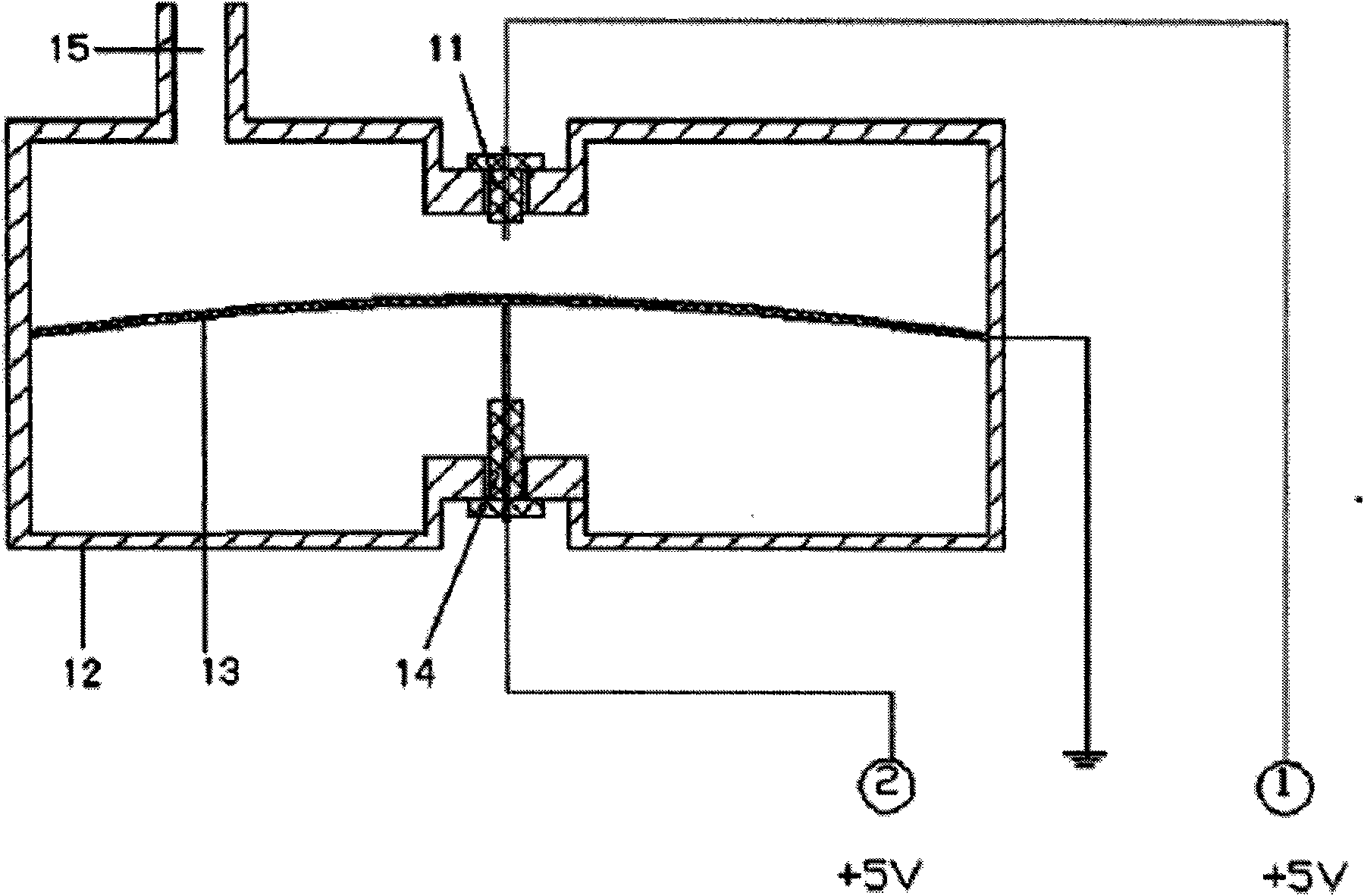

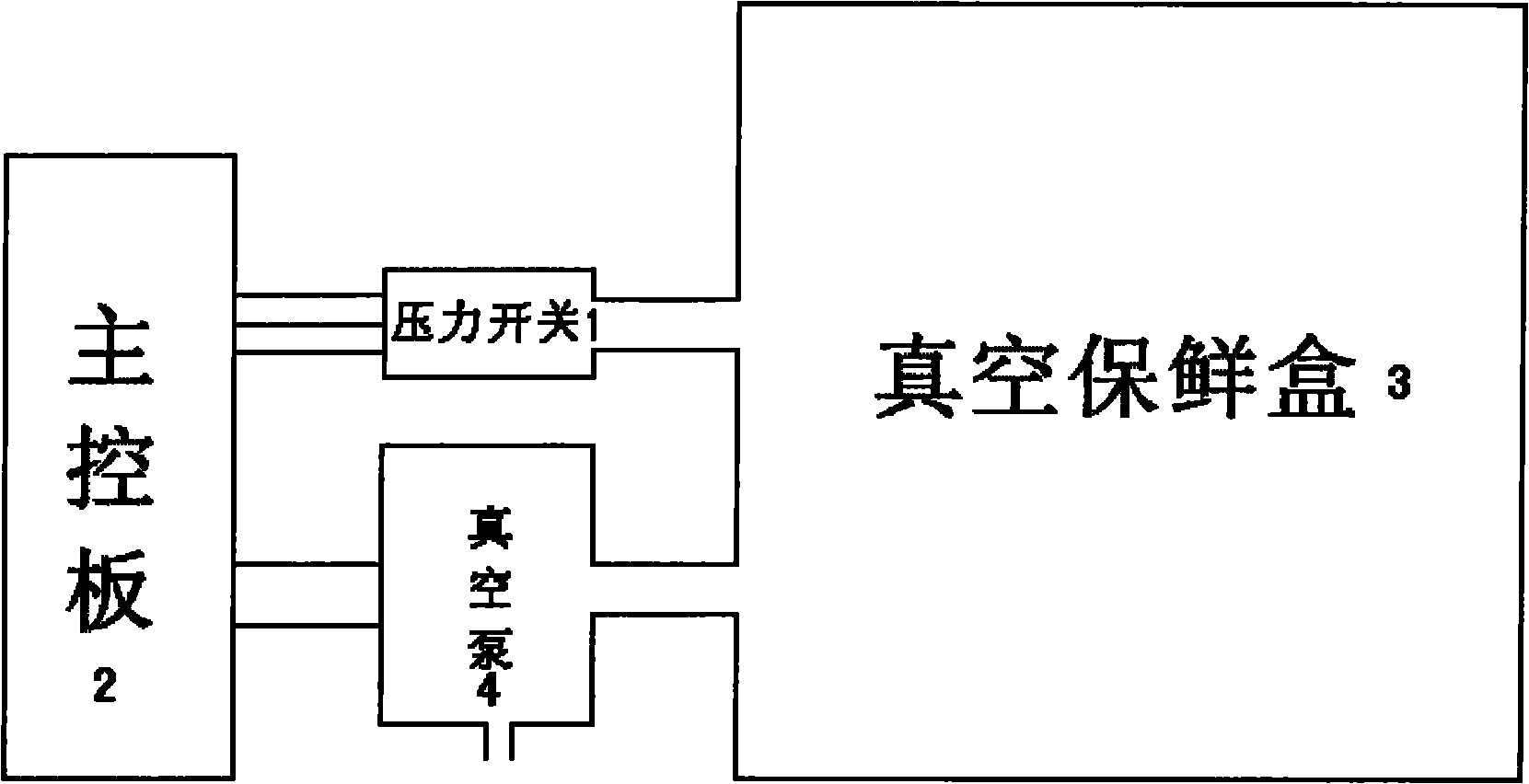

Device and method for controlling vacuum degree of vacuum refreshing refrigerator

ActiveCN101995142ASimple structureLow costDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigerated temperature

The invention relates to the technical field of refrigerators, in particular to a device and a method for controlling the vacuum degree of a vacuum refreshing refrigerator, which comprises a vacuum refreshing box, a vacuum pump, a pressure switch and a master control board, wherein the vacuum pump is communicated with the vacuum refreshing box, a pressure detection end of the pressure switch is communicated with the vacuum refreshing box, a pressure signal output end of the pressure switch is connected with the master control board, and a control signal output end of the master control board, which controls the action of the vacuum pump according to a pressure signal of the pressure switch, is connected with a signal input end of the vacuum pump electrically. In the control method, the pressure switch is used for detecting the air pressure of the vacuum refreshing box and outputting the pressure signal according to the air pressure to control the action of the vacuum pump. In the invention, the pressure switch is added to control the vacuum degree inside the refreshing box to be kept in a certain range all the time, and the control range is adjustable; moreover, the pressure switch has the advantages of simple structure and low cost and is safe and reliable.

Owner:HISENSE HOME APPLIANCES GRP CO LTD +1

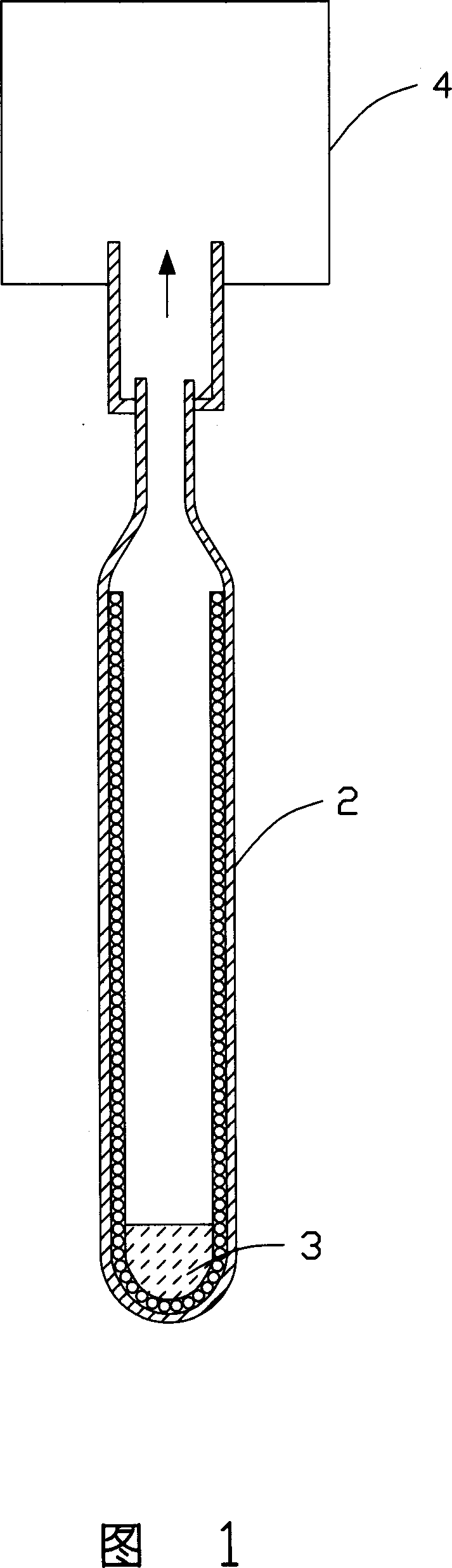

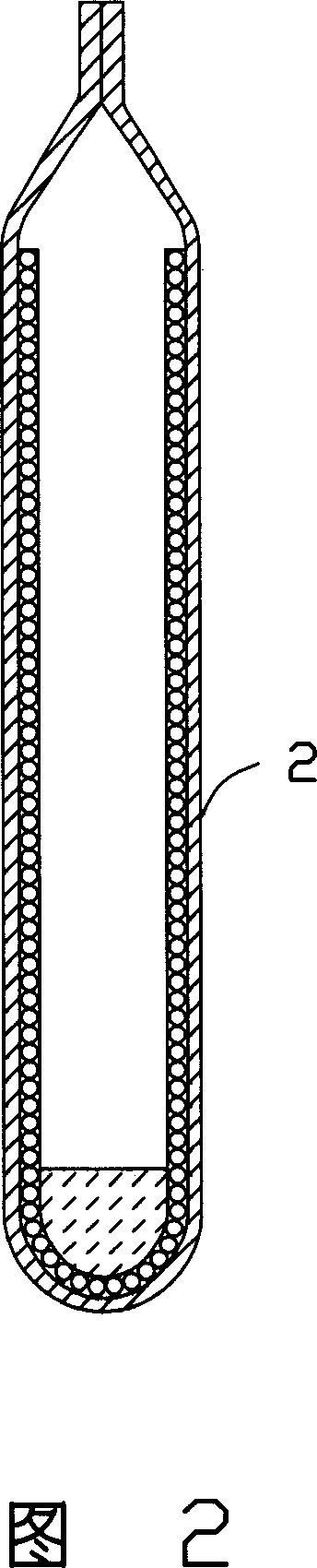

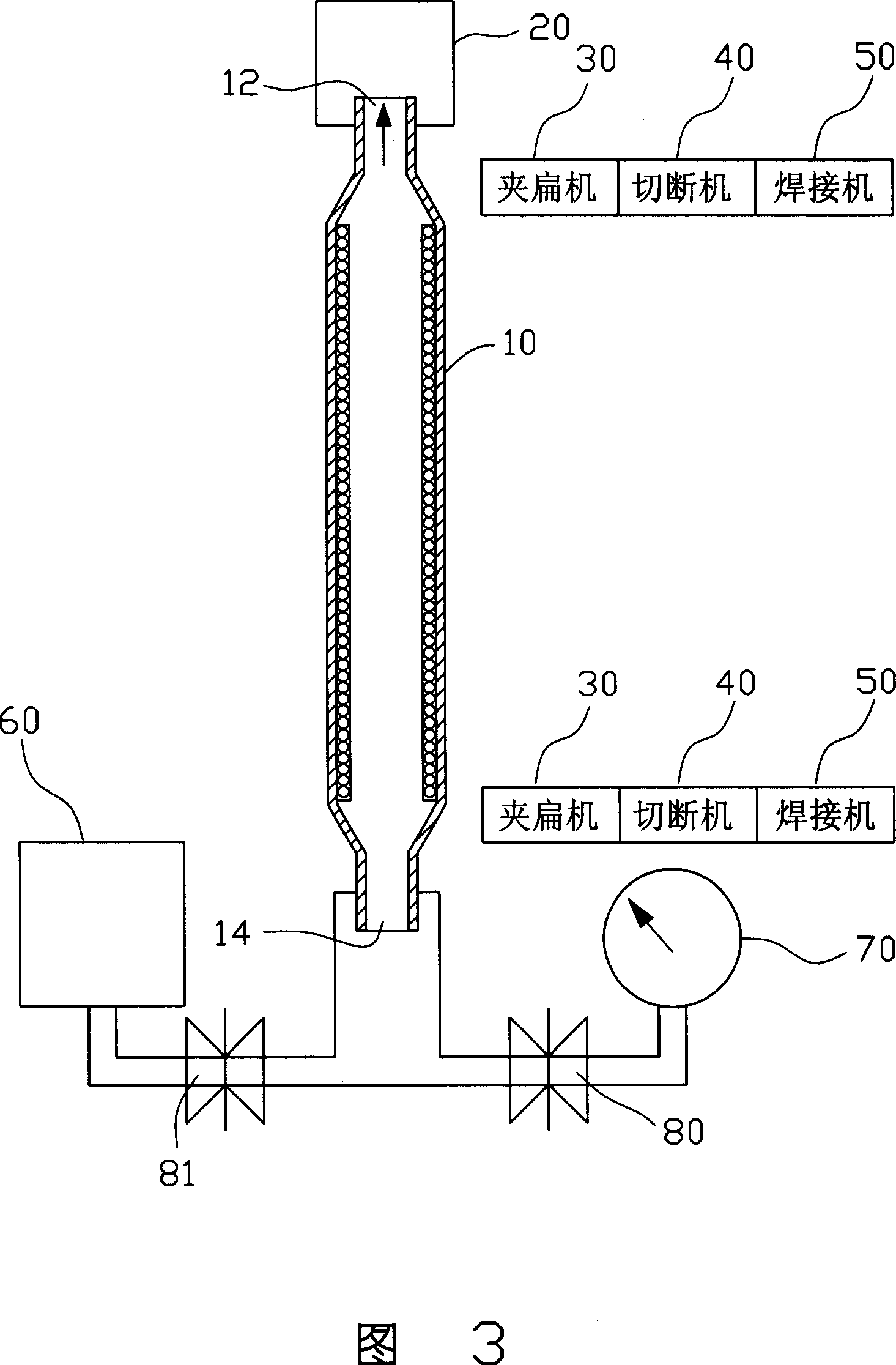

Heat-conductive pipe and mfg. method

InactiveCN1936479AControl vacuumControl filling volumeSemiconductor/solid-state device detailsSolid-state devicesGuide tubeBiomedical engineering

Owner:FU ZHUN PRECISION IND SHENZHEN +1

Food processing method of food processor and food processor

InactiveCN108652478ALower oxygen levelsReduce churnVessels with intergral heatingVacuum pumpingStopped work

The invention discloses a food processing method of a food processor and the food processor, and relates to the field of food processing. The food processor comprises a machine base provided with a motor and a circuit board, a vacuum pump, a mixing cup, a grinding cutter, a pressure relief module used for pressure relief of the mixing cup and a sealing module used for sealing the mixing cup. The circuit board is provided with a control circuit. The food processing method at least comprises the steps that a intermittent vacuum extraction step is performed, specifically, the sealing module sealsthe mixing cup, then the vacuum pump works to extract air in the mixing cup to enable the mixing cup to be in a negative pressure state and then the vacuum pump stops working, then the pressure relief module performs pressure relief on the mixing cup, and the intermittent vacuum pumping step is executed repeatedly; and a crushing step is performed, specifically, the motor drives the grinding cutter to rotate to crush materials in the mixing cup. According to the food processing method, no burnt bottom and less foam are achieved, and the noise is low.

Owner:JOYOUNG CO LTD

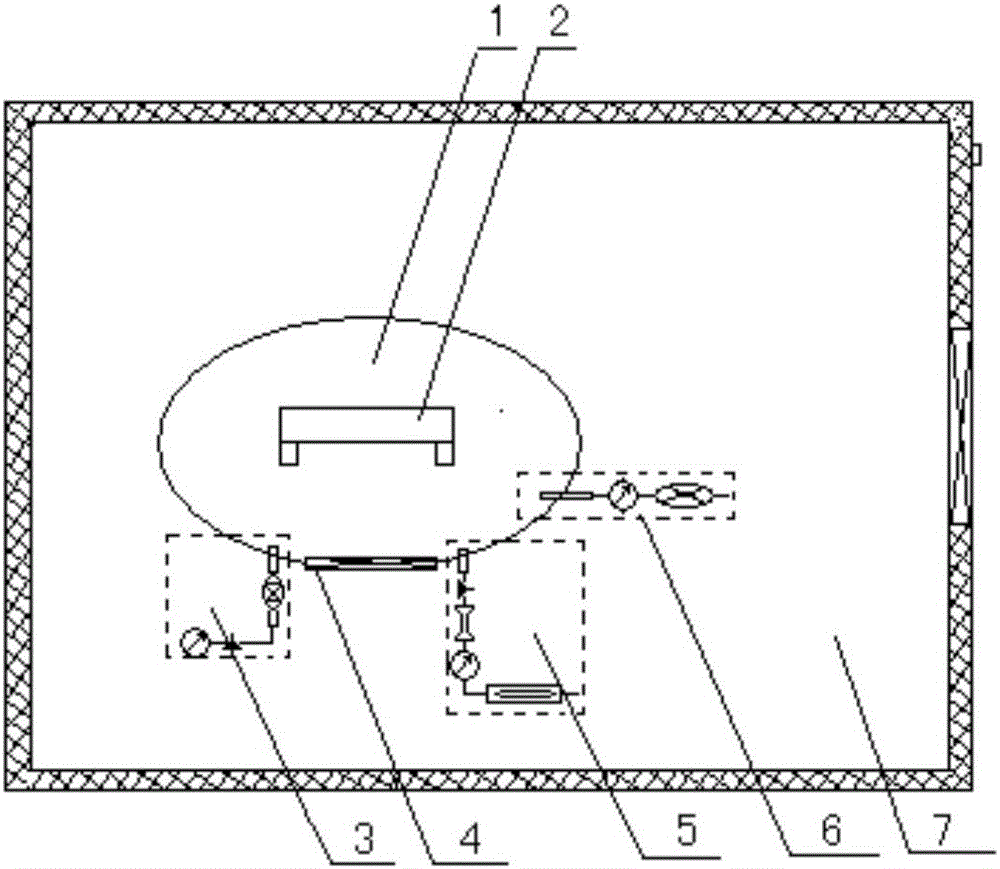

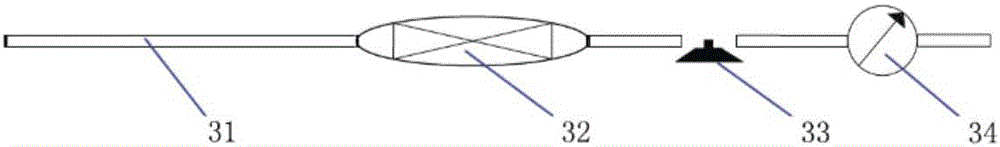

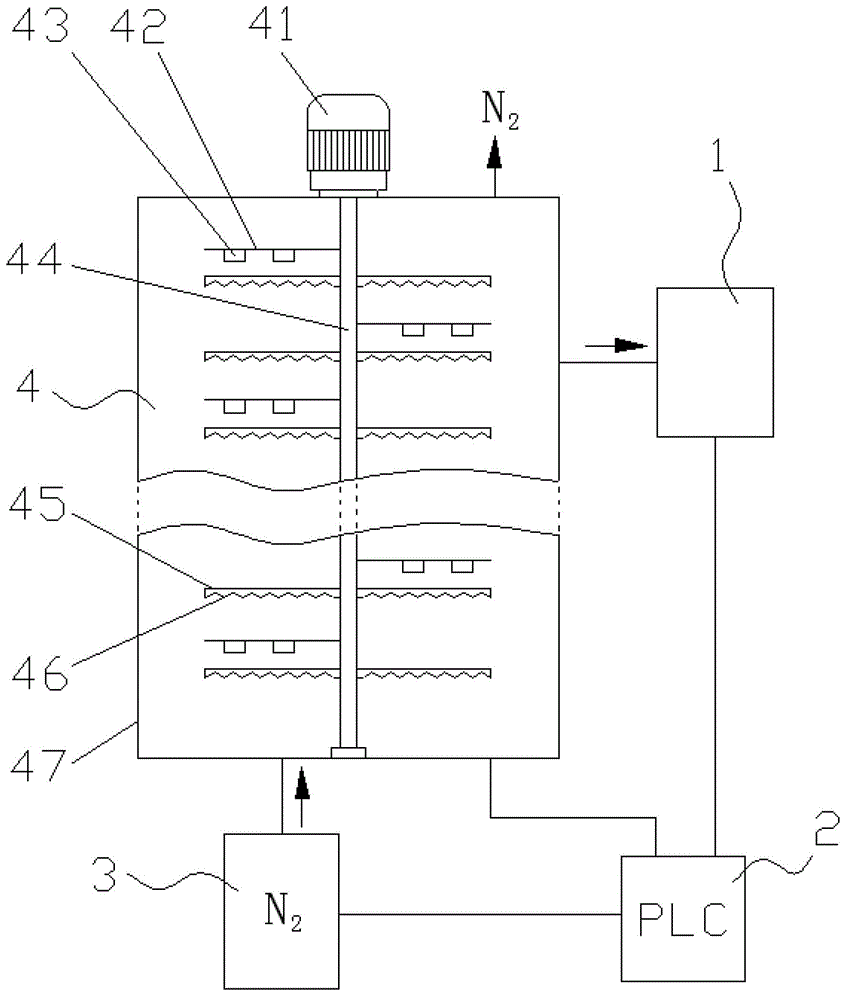

Device and method for testing formaldehyde and VOCs (volatile organic compounds) from furniture and decorative materials by bag method

ActiveCN106814163AMeet the test requirementsGuaranteed Material/Volume Load RatioWithdrawing sample devicesAir quality improvementControl systemTest sample

The invention relates to a device for testing formaldehyde and VOCs (volatile organic compounds) from furniture and decorative materials by bag method; the device mainly comprises a test bag, an air purification system, a vacuum control system and an air sampling system; a sample chamber of the device uses the test bag, a test sample is put in the test bag via a test bag opening / door and is locked and sealed via the test bag opening / door; the vacuum control system and the air purification system are communicated with the front end of the test bag; the air sampling system is communicated with the rear end of the test bag for sampling air. The device and method have the advantages of high test data accuracy, good repeatability, small error and the like, and are suitable for popularization and application.

Owner:沈阳紫微恒检测设备有限公司

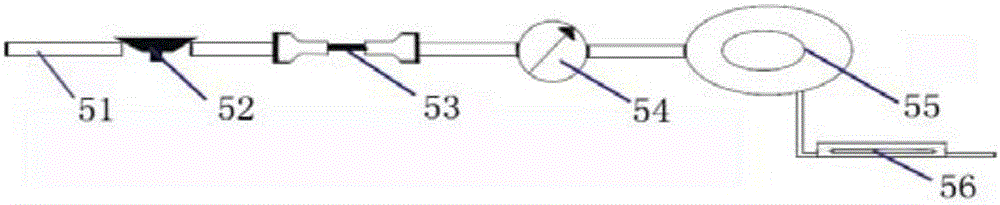

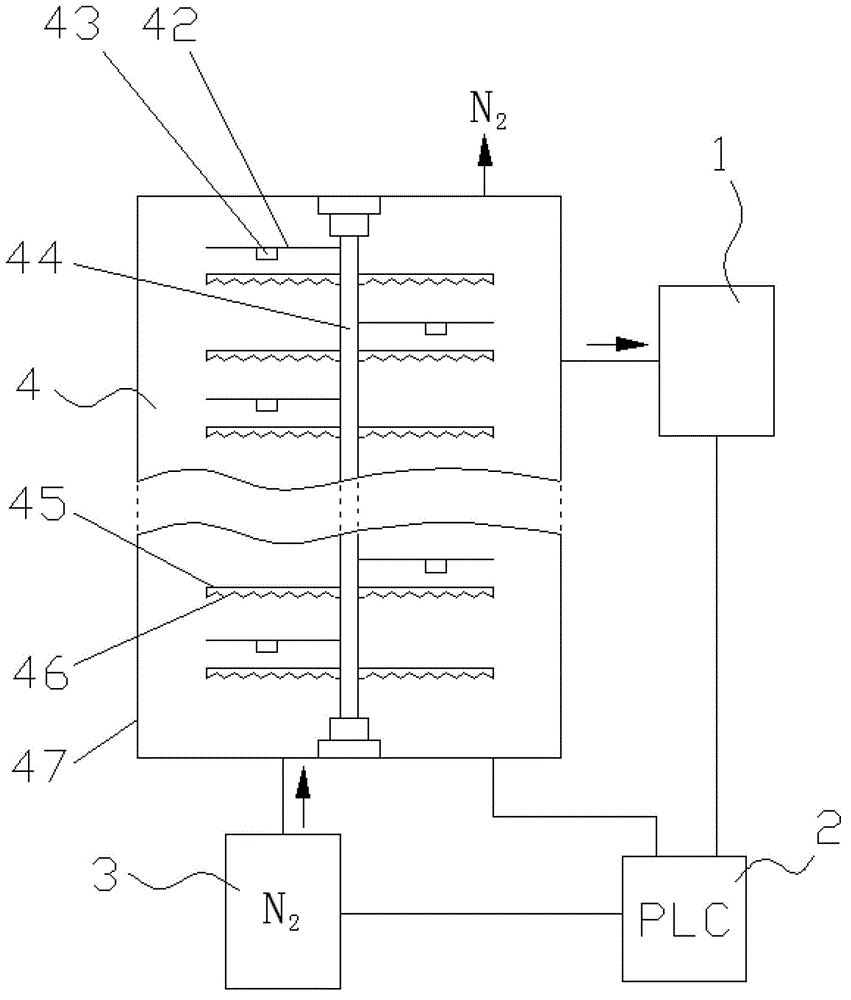

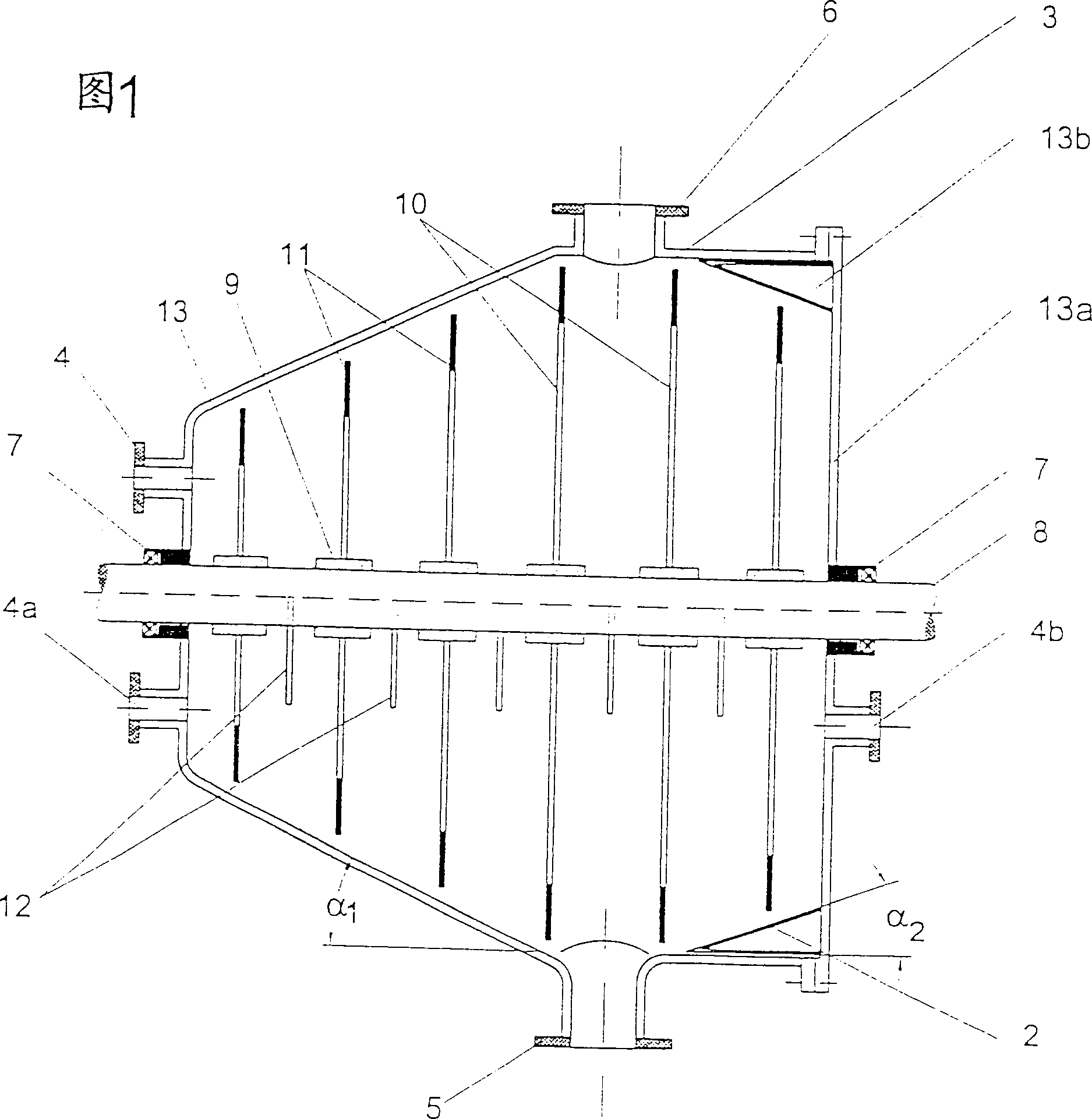

Liquid nitrogen refrigeration micro-wave heating vacuum drier

InactiveCN102721269AEvenly heatedExtended temperature rangeDrying using combination processesDrying machines with progressive movementsFreeze-dryingHigh energy

The invention relates to the technical field of vacuum freeze drying, and provides a liquid nitrogen refrigeration micro-wave heating vacuum drier, which includes a refrigeration drying part connected with a water circulation vacuum pump and a liquid nitrogen refrigeration system, as well as a PLC main-control system connected with the water circulation vacuum pump, the liquid nitrogen refrigeration system and the refrigeration drying part, wherein the refrigeration drying part includes a sealed freeze-dry box; a rotating main shaft is vertically arranged in the freeze-dry box; the rotating main shaft is connected with a plurality layers of freeze-dry pallets from the top down; a micro-wave heating system is arranged above each layer of freeze-dry pallet; and the micro-wave heating system include microwave generators. The liquid nitrogen refrigeration micro-wave heating vacuum drier provided by the invention adopts the liquid nitrogen refrigeration manner and the microwave rotary heating manner, effectively enlarges the refrigeration temperature reach of the freeze-dry box, improves the freeze-dry efficiency, and reduces the freeze-dry time and energy consumption; besides, the water circulation vacuum pump adopted by the liquid nitrogen refrigeration micro-wave heating vacuum drier requires no water catching system, and effectively controls the degree of vacuum of the freeze-dry box, thereby avoiding the problems such as high energy consumption caused by the adoption of the water catching system.

Owner:HAINAN WEI KANG PHARMA QIANSHAN

Vacuum refreshing device for refrigerator

InactiveCN102706082AControl vacuumExtend freshnessDomestic cooling apparatusLighting and heating apparatusPulp and paper industryRefrigerated temperature

Owner:YIXING SITONG HOUSEHOLD ELECTRICAL APPLIANCE FITTINGS

Method for producing ultrafine zirconium powder

The invention discloses a method for producing ultrafine zirconium powder. The method comprises the following steps: mixing firearm zirconium sponge and electrolyzed zirconium serving as raw material zirconium, adding the mixture into a material receiving crucible of a hydrogenation reactor, igniting the raw material zirconium and hydrogenating to obtain zirconium hydride; putting the zirconium hydride into a ball-milling tank loaded with a ball-milling medium, and performing ball milling till the granularity of the zirconium hydride is smaller than or equal to 400 meshes; putting the smashed zirconium hydride into a vacuum drying oven for drying, loading the smashed and dried zirconium hydride into a dehydrogenating furnace for dehydrogenating, putting the dehydrogenated zirconium hydride into the ball-milling tank loaded with the ball-milling medium for performing ball-milling, sieving, washing and drying to obtain ultrafine zirconium powder. The method has the advantages that the raw materials are readily available, the technological process is stable, the phenomena of self-ignition and explosion are avoided, and the technical index and safety production requirements of the ultrafine zirconium powder can be met.

Owner:CITIC JINZHOU METAL

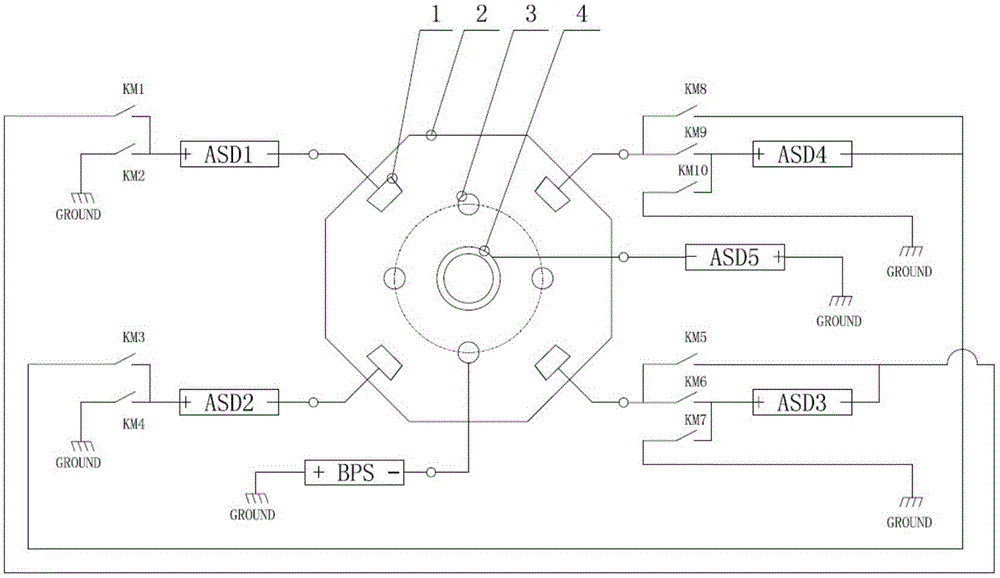

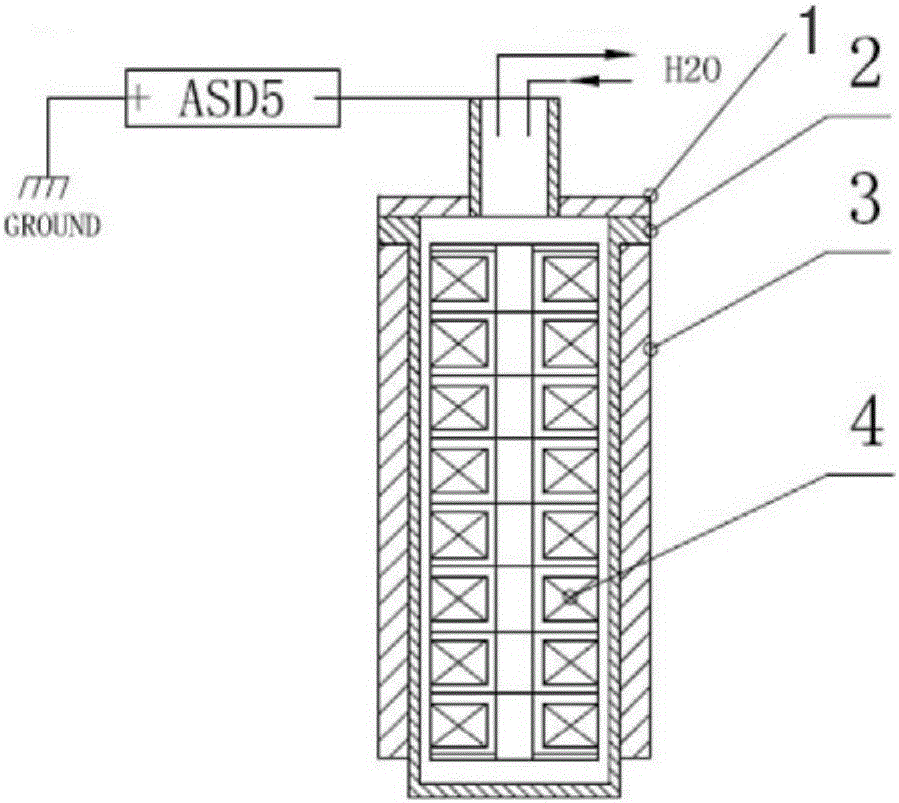

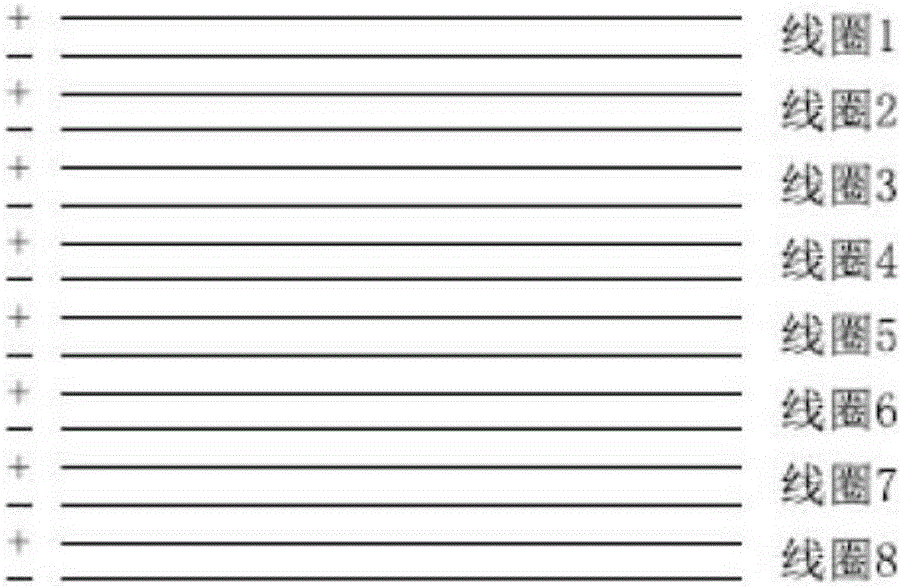

Additive manufacturing system capable of achieving rapid deposition on surface of workpiece through vacuum plasma

ActiveCN105970160ASolve the low efficiency of coating depositionImprove adhesionAdditive manufacturing apparatusVacuum evaporation coatingControl systemElectromagnetic field

The invention relates to an additive manufacturing system capable of achieving rapid deposition on the surface of a workpiece through vacuum plasma. The additive manufacturing system comprises a vacuum obtaining and measuring device and a vacuum chamber; and a plurality of side wall cathode target pairs are installed on the side wall of the vacuum chamber. The additive manufacturing system is characterized in that a columnar cathode target and a rotary type bearing mechanism are installed at the center of the vacuum chamber; the columnar cathode target is connected with a high-power arc power source so as to output large currents; the power input end of the columnar cathode target is connected with the output end of a PLC control system; the PLC control system repeatedly conducts positive and negative pole input switching change to act in the electromagnetic field direction of the target face of the columnar cathode target, so that arc spots located on the target face upwards and spirally move along the target face and are transferred from one end to the other end; and the arc spots conduct repeated spiral transferring movement on the target face of the columnar cathode target to form a workpiece surface rapid circular deposition structure, and finally a thick coating is obtained on the surface of the workpiece rapidly. The additive manufacturing system has the beneficial effects of being high in deposition efficiency of the coating on the surface of the workpiece and the like.

Owner:GUANGDONG STRONG METAL TECH

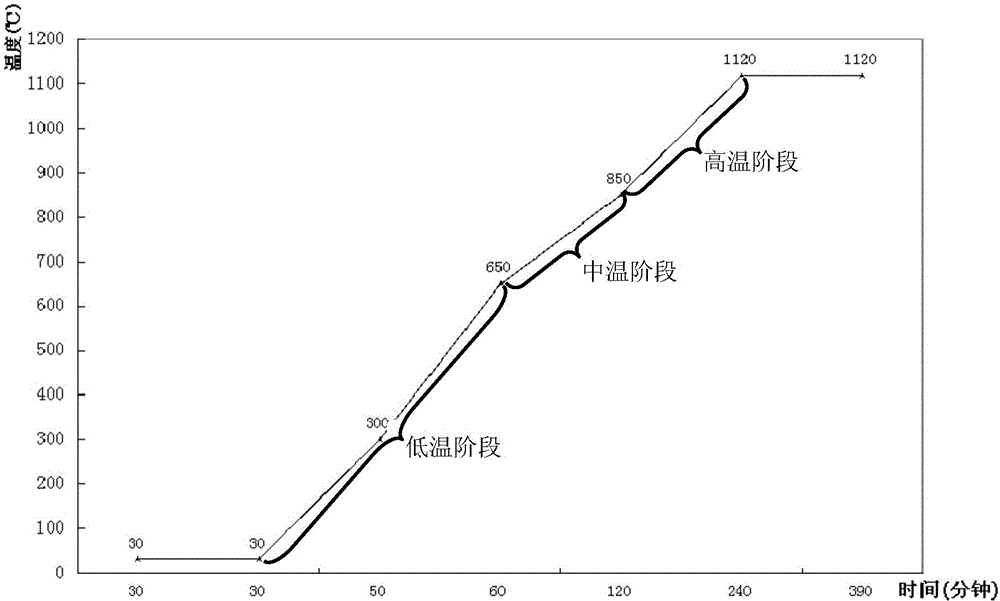

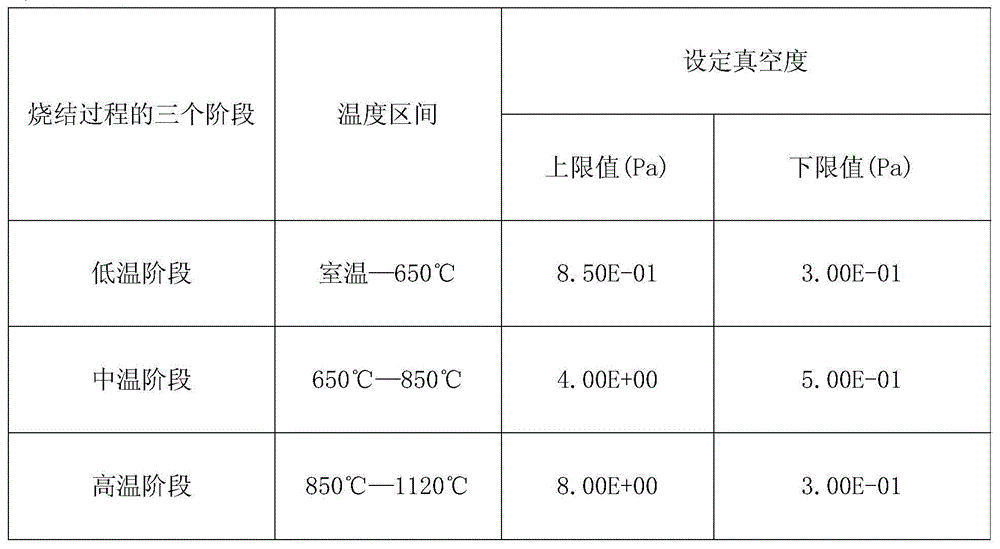

Method for controlling atmosphere of sintering furnace

The invention discloses a method for controlling atmosphere of a sintering furnace. The method includes the steps of 1, dividing a heating zone of the sintering furnace to obtain a low temperature phase, a medium temperature phase and a high temperature phase; 2, setting corresponding upper and lower limits of vacuum degrees according to the low temperature phase, the medium temperature phase and the high temperature phase obtained in the step 1, and inputting the upper and lower limits of the vacuum degrees of the phases into a programming controller used in the step 1; 3, starting a vacuum pump to evacuate a body of the sintering furnace, acquiring actual vacuum degree of the sintering furnace, and allowing the programming controller to adjust a heating speed according to whether or not the acquired actual interior vacuum degree is between the upper and lower limits of the corresponding set vacuum degree. Heating speed of every phase is controlled via the programming controller.

Owner:SINO MAGNETICS TECH

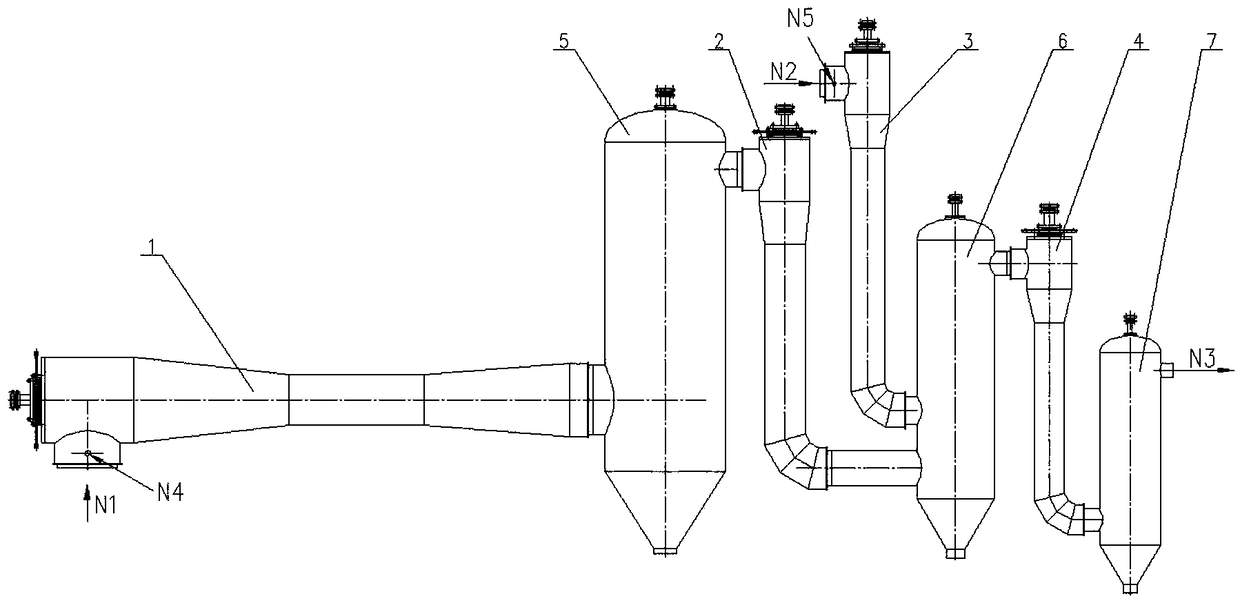

Phenol steam injection vacuum system

InactiveCN108916128AExtend continuous use timeReduce maintenance frequency and maintenance costsJet pumpsSteam/vapor condensersPolycarbonateEngineering

The invention belongs to the technical field of polycarbonate devices, and particularly relates to a phenol steam injection vacuum system which is applicable to the polycarbonate devices. According tothe system, a first-level ejector 1, a first-level condenser 5, a second-level ejector 2, a third-level ejector 4 and a third-level condenser 7 are sequentially connected, and a second B-level ejector 3 is connected to a second-level condenser 6. The phenol steam injection vacuum system meets requirements in the polycarbonate production process, novel equipment with vacuum degrees needed by finalpolycondensation and pre-condensation reactors can be provided, the phenol steam injection vacuum system is reasonable in structural design and safe to use and can continuously and stably run, environmental pollution in the production process is low, and excellent-quality products can be produced by the polycarbonate devices.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

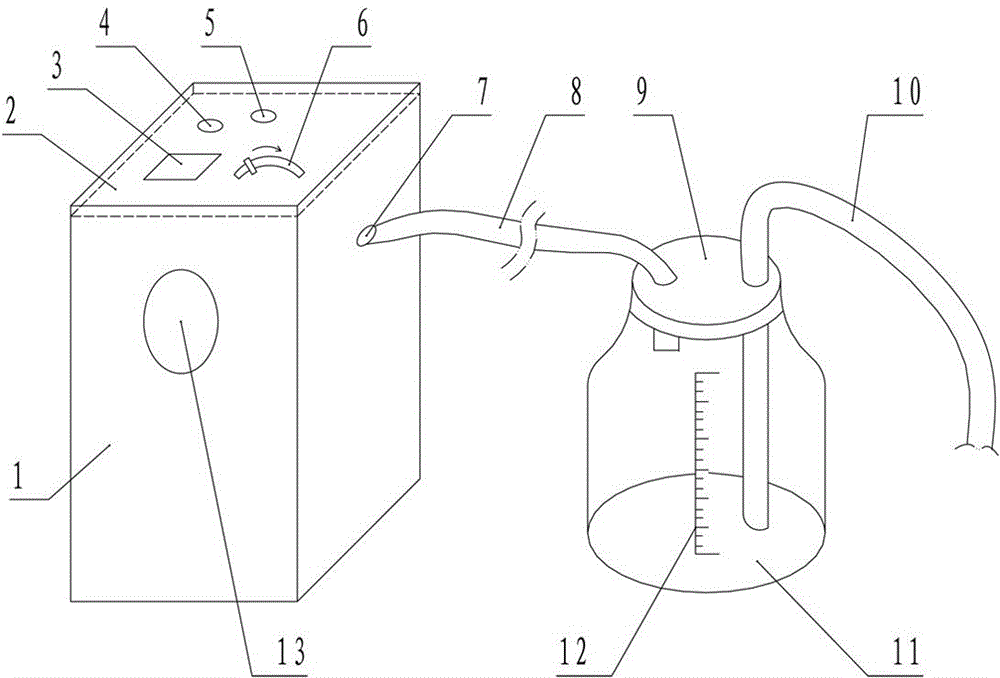

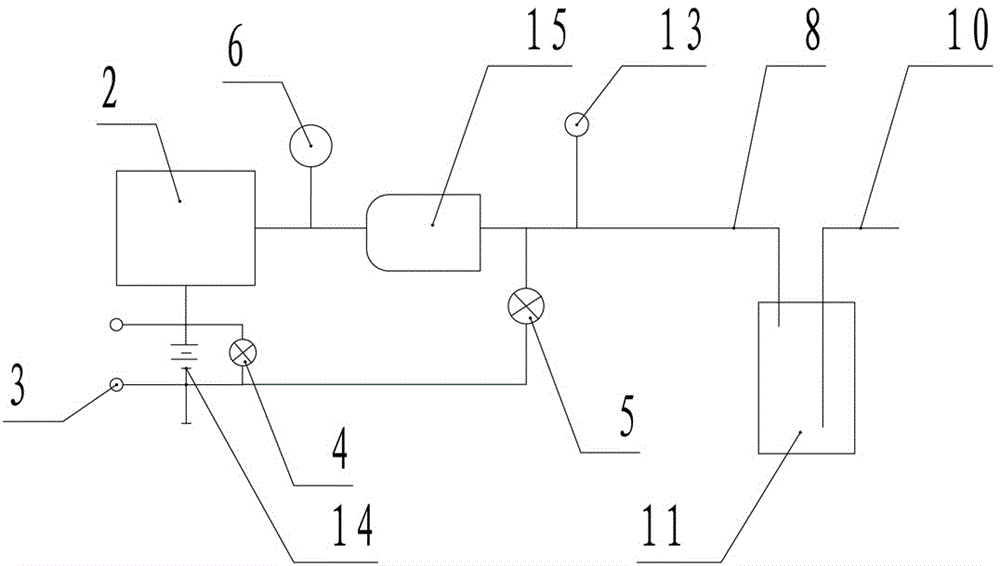

Portable continuous negative-pressure suction instrument

InactiveCN105963810AControl vacuumFine control of vacuum degreeWound drainsIntravenous devicesMedical equipmentEngineering

The invention discloses a portable continuous negative-pressure suction instrument, and relates to the technical field of medical equipment. The portable continuous negative-pressure suction instrument comprises an instrument box internally provided with a vacuum pump and a lithium battery pack. A circuit control mainboard is arranged on the top face of the instrument box, and the side face of the instrument box is provided with a negative-pressure outputting opening and a vacuum meter; the pressure of the vacuum pump is controlled by a negative-pressure adjusting key, the vacuum meter is connected to an outputting pipe of the vacuum pump, and a negative-pressure connector of the vacuum pump is communicated with a drainage bottle through a negative-pressure connecting pipe extending out of the negative-pressure outputting opening; a drainage pipe is connected to the drainage bottle; the circuit control mainboard is further provided with a charging opening, a charging indicating lamp and a working indicating lamp. By means of the portable continuous negative-pressure suction instrument, the various problems that in an existing negative-pressure suction instrument, the pressure is unstable, a machine body is heavy, the size is large, convenience and fastness are not suitable, power supplying with a direct current is not achieved, and individual instruments need to artificially and manually extrude to carry out negative-pressure treatment can be solved.

Owner:WUZHOU RED CROSS HOSPITAL

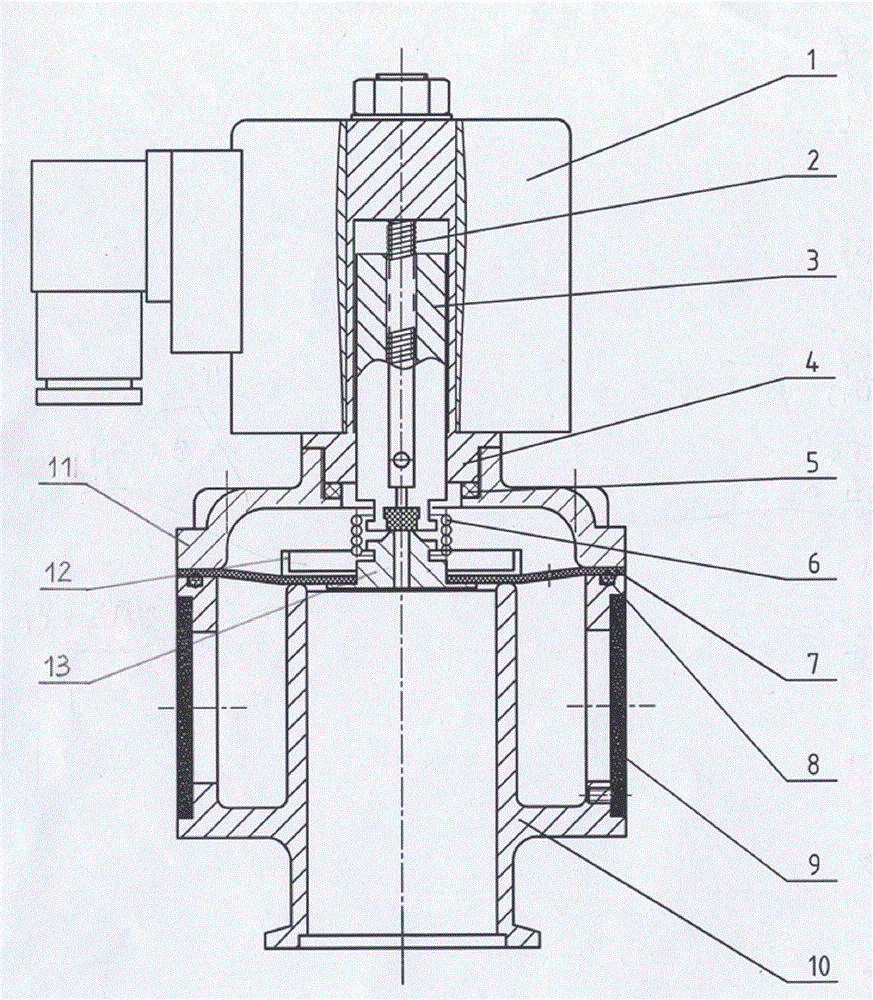

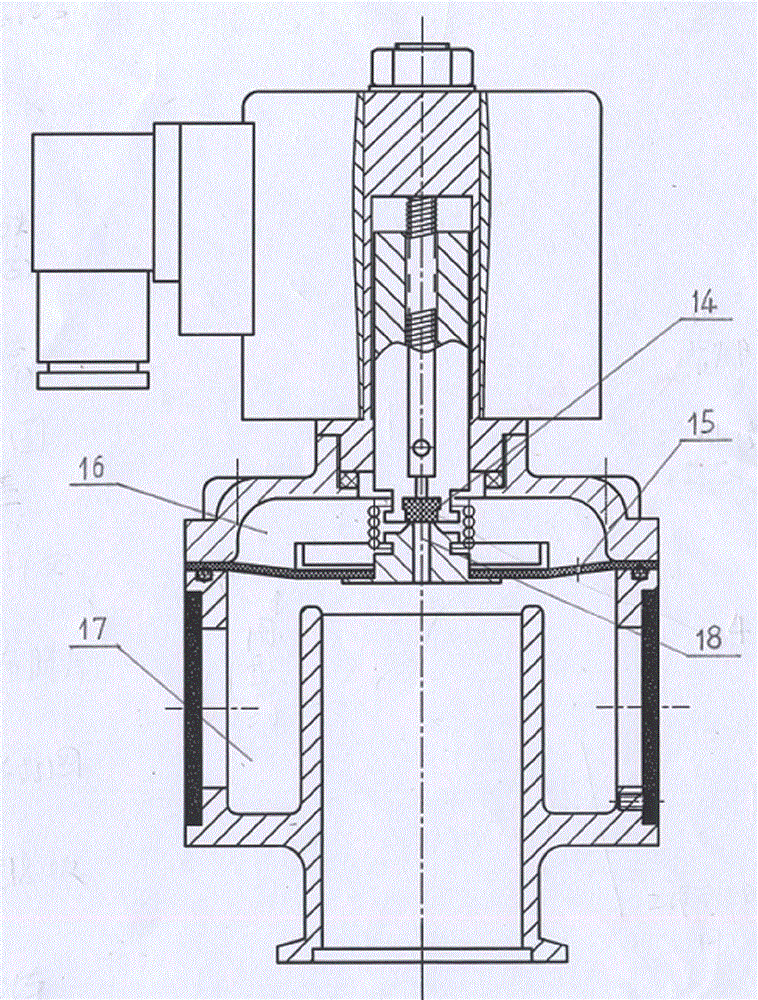

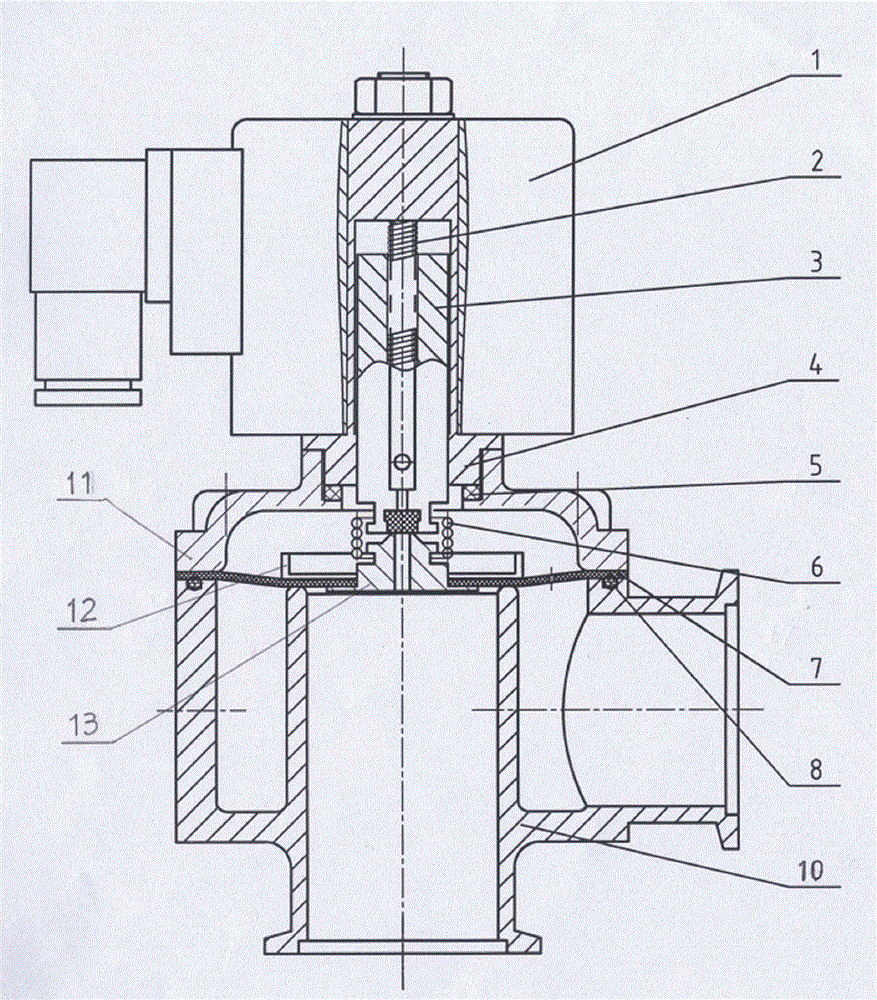

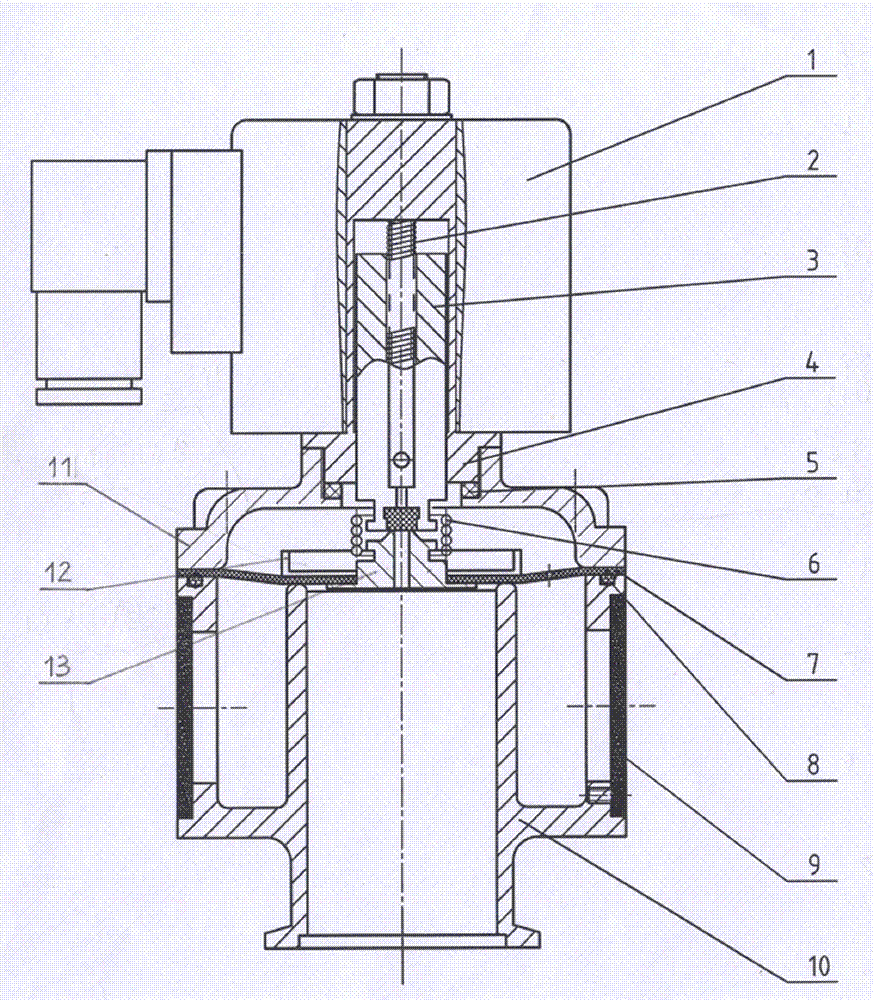

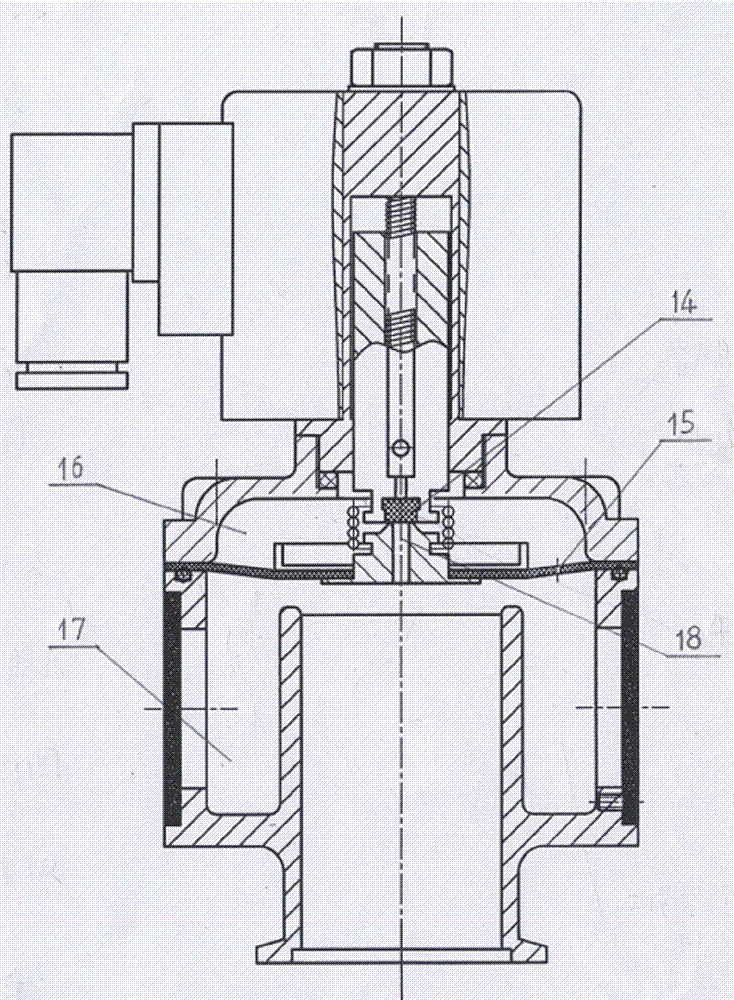

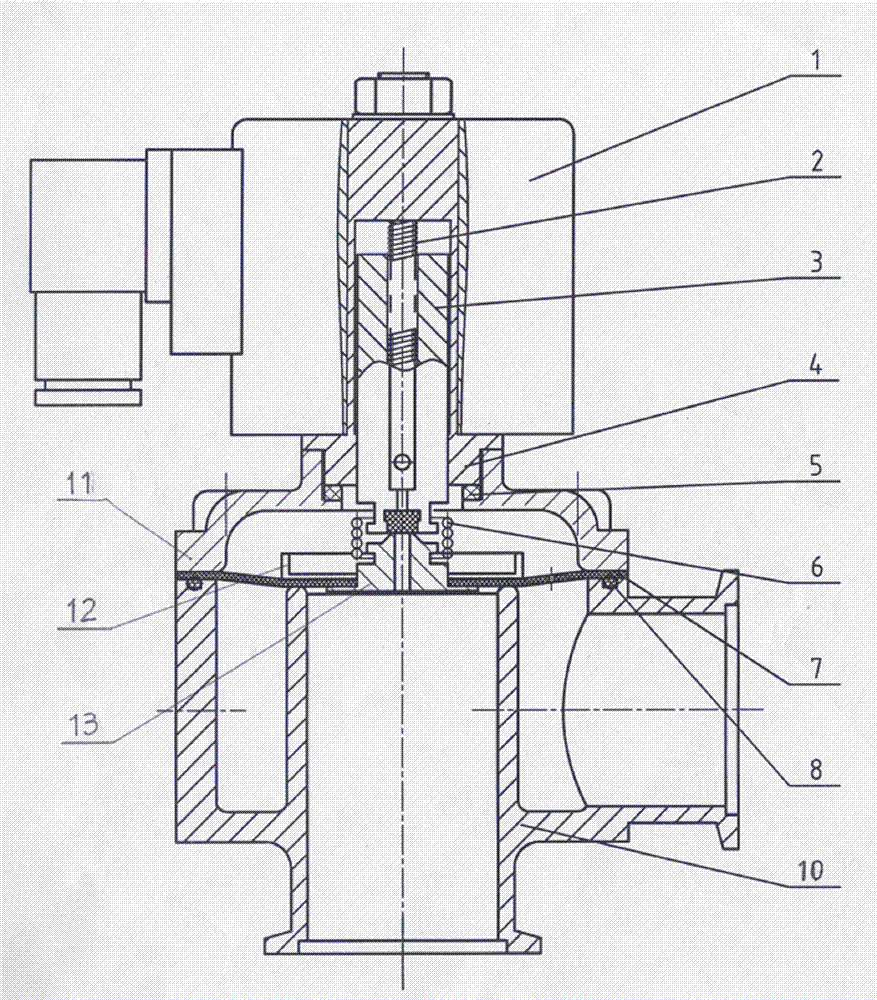

Electromagnetic high-vacuum inflation valve

ActiveCN104930225AControl vacuumSolve efficiency problemsOperating means/releasing devices for valvesDispersed particle filtrationAir filterElectromagnetic shielding

The invention relates to an electromagnetic high-vacuum inflation valve. The electromagnetic high-vacuum inflation valve comprises an electromagnetic assembly, an armature, a valve element, an upper cover, a cloth clamping membrane, a membrane pressing plate, a membrane base, a filter plate, a body and the like. When the vacuum state of a vacuum system needs to be damaged and air is injected, the electromagnetic assembly is powered on, the valve element sucks the armature upwards, the gas pressure in a back pressure chamber and the gas pressure in a working gas chamber are changed, the membrane base and the cloth clamping membrane are disengaged from a pipeline opening in the body, and air entering the filter plate or an air filter is injected into the vacuum system. When the vacuum degree of the vacuum system decreases to a preset value, the electromagnetic assembly is powered off, force of an upper spring is downward, the cloth clamping membrane presses the pipeline opening in the body, and the vacuum system is closed. The electromagnetic high-vacuum inflation valve is connected into a vacuum pipeline, and the vacuum degree of the vacuum system can be damaged or controlled in time according to presetting.

Owner:SHANGHAI LEIHANG MASCH MFG CO LTD

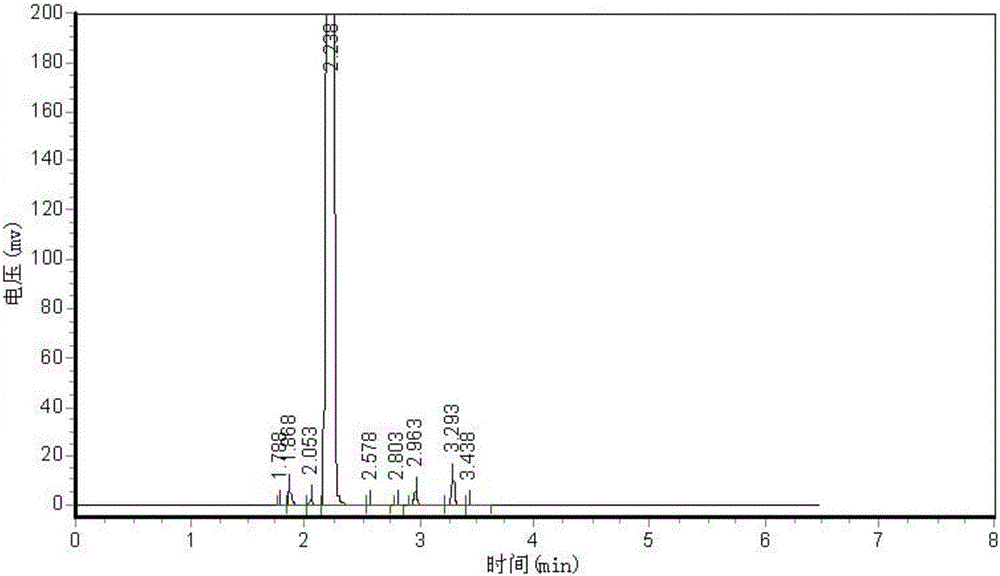

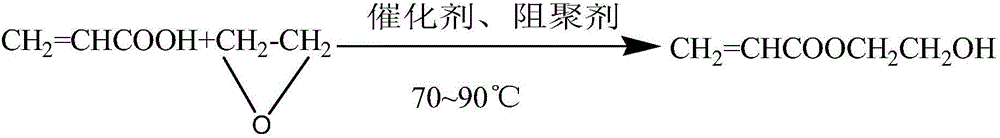

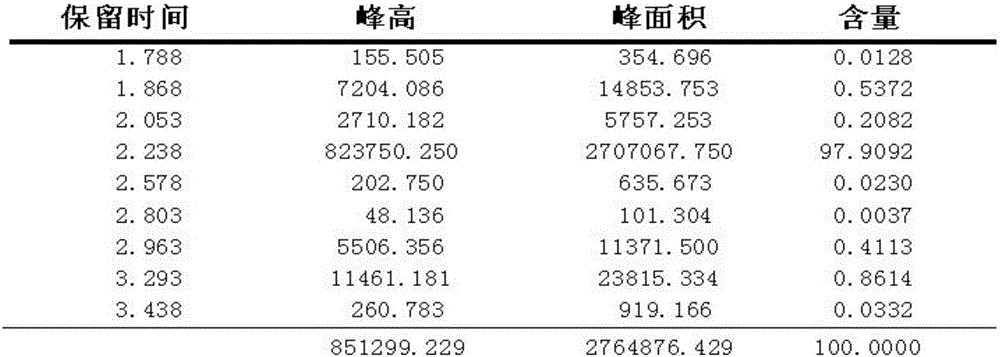

Preparation technique of high-purity hydroxyethyl acrylate

InactiveCN105968010AEfficient recyclingGood dispersionOrganic compound preparationCarboxylic acid esters preparationWorking temperaturePolymerization

The invention provides a preparation technique of high-purity hydroxyethyl acrylate. A rectification process is added in a purification process; a polymerization inhibitor is replenished through a spraying way in a phase transformation process of the rectification process; meanwhile, the vacuum degree and the working temperature of a tower top are controlled; the flash polymerization, in a rectifying tower, of hydroxyethyl acrylate is avoided, so as to achieve the purposes of being stable in operation, being capable of effectively preventing polymerization and improving product quality, thereby improving the purity of a hydroxyethyl acrylate product.

Owner:CHANGZHOU HICKORY CHEM

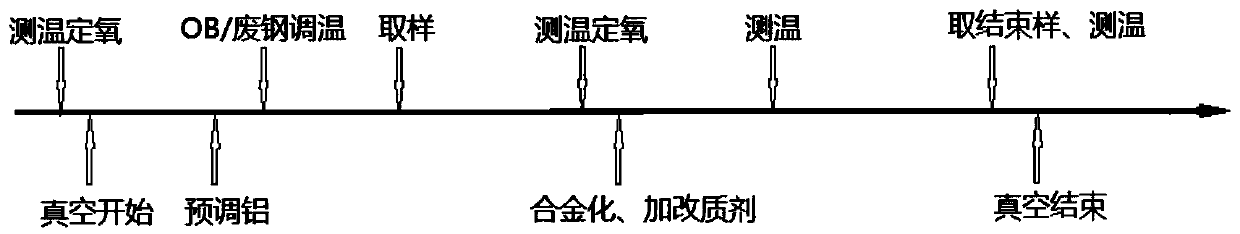

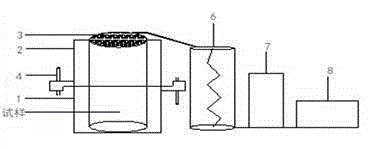

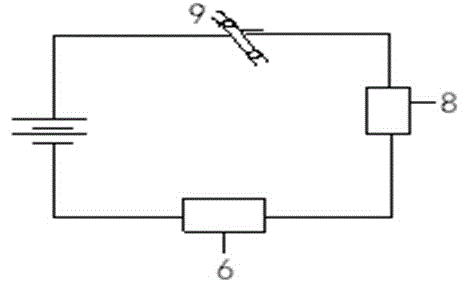

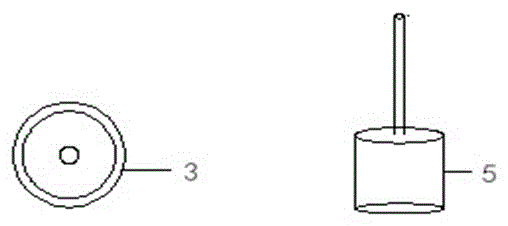

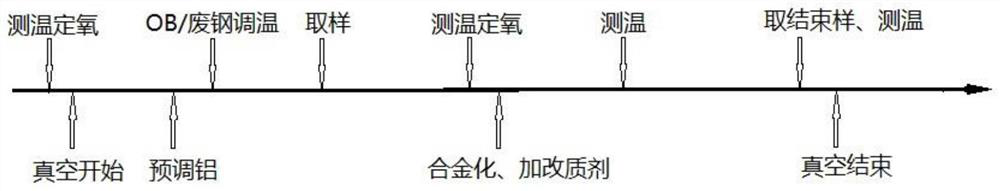

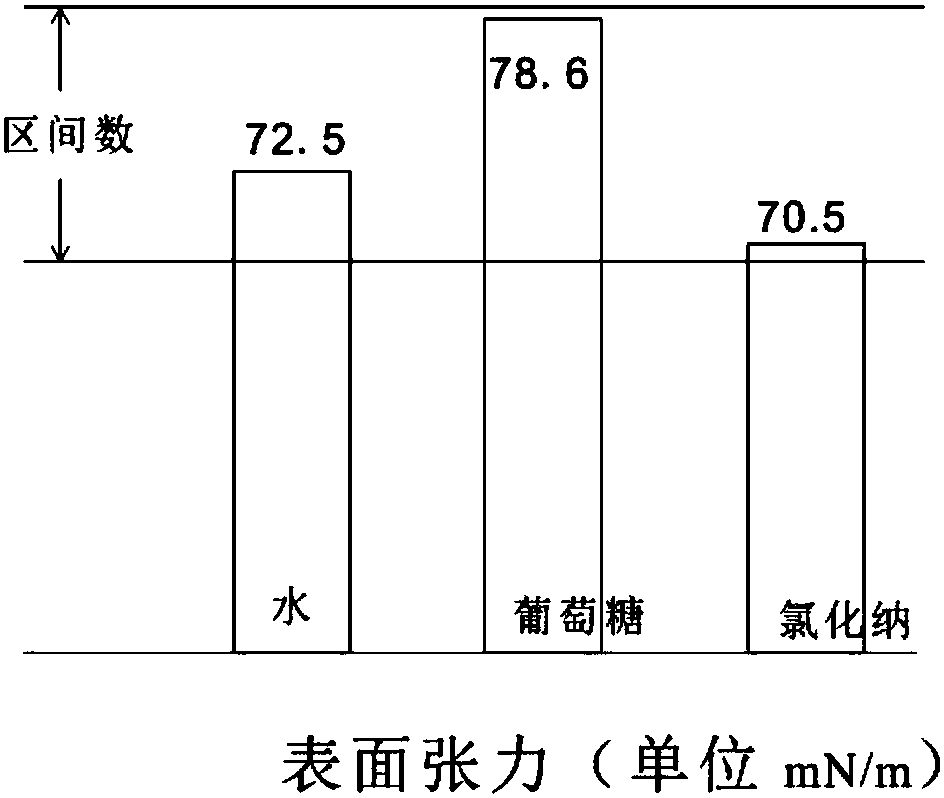

RH refining method for controlling wettability of inclusions in low-carbon aluminum killed steel

The invention provides an RH refining method for controlling wettability of inclusions in low-carbon aluminum killed steel. Through controlling the components, the adding time, the adding amount and the adding mode of an inclusion modifier, and in cooperation of the vacuum degree control and process adjustment in the RH refining process, so that the surface of the aluminum oxide inclusions is completely covered or partially covered with 2Al-2 O-3.CaO and 6Al-2 O-3.CaO, and the modified form of the inclusions is surface modification or local surface modification. On the basis of controlling thevacuum degree of RH refining, the yield of the modifier can be improved, and the problem of molten steel pollution caused by the modifier is reduced. On the basis that the refining process and the period are not influenced, the surface wettability of the aluminum oxide inclusions in the molten steel is improved. The problem of water opening nodulation in the continuous casting process can be relieved, and the problem of liquid level abnormal fluctuation caused by the water opening nodulation is avoided; and the problem of aggregation of the aluminum oxide inclusions in the solidification process of the molten steel is relieved, so that the cleanliness of the molten steel is improved, and the product quality of the low-carbon aluminum killed steel is improved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

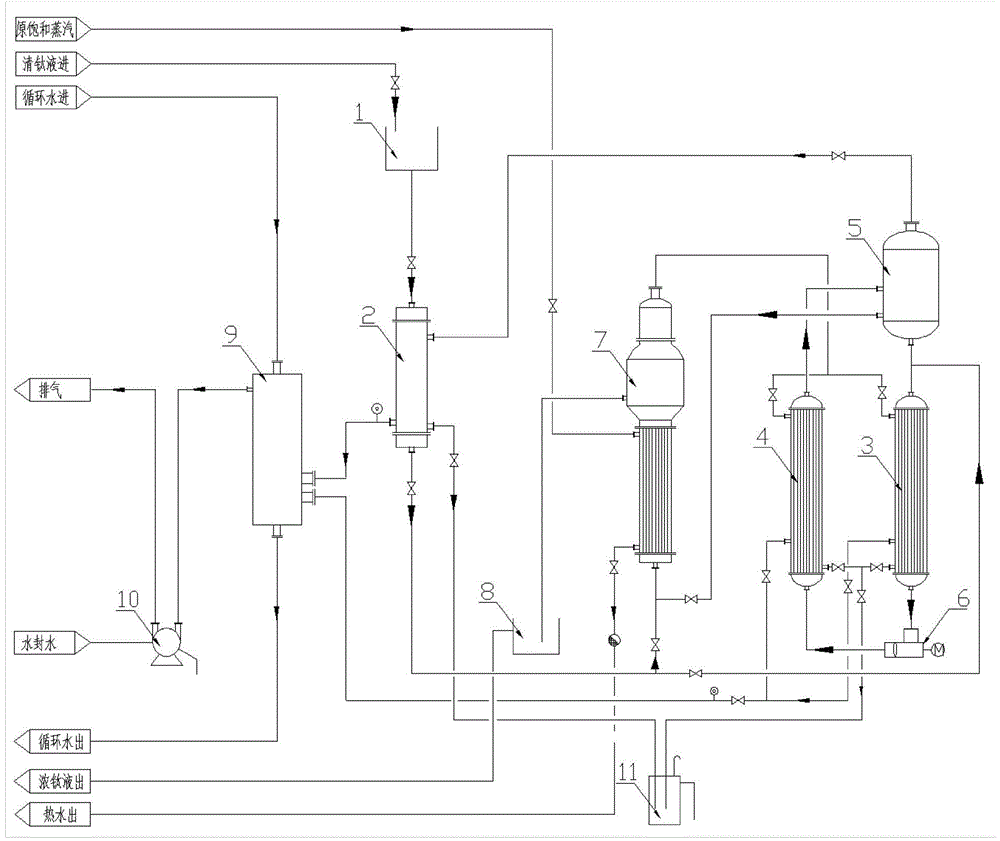

Two-effect titanium liquid concentration device and concentration process

InactiveCN104368166AAvoid fouling and cloggingImprove overall heat transfer coefficientFlash distillationMultiple-effect evaporationEvaporatorTitanium

The invention discloses a two-effect titanium liquid concentration device and a concentration process. The concentration device comprises a preheater, a primary heat exchanger, a secondary heat exchanger, a flash tank, a film evaporator and an atmospheric condenser, wherein a solution outlet of the preheater is connected with a solution inlet of the primary heat exchanger; a solution outlet of the primary heat exchanger is connected with a solution inlet of the secondary heat exchanger by virtue of a circulating pump; a solution outlet of the secondary heat exchanger is connected with a solution inlet of the flash tank; a steam outlet of the flash tank is connected with a steam inlet of the preheater; a steam outlet of the preheater is connected to a first steam inlet of the condenser; a first solution outlet of the flash tank is connected with a solution inlet of the primary heat exchanger; and a second solution outlet of the flash tank is connected with a solution inlet of the film evaporator. According to the concentration device disclosed by the invention, the flow velocity of titanium liquid in the primary heat exchanger and the secondary heat exchanger is controlled by virtue of the circulating pump, the problem of scaling and blockage of heat exchange tubes in the heat exchangers in large area is solved, the total heat transfer coefficient of the heat exchangers is greatly improved, and the heat exchange area of the heat exchangers is reduced.

Owner:NANTONG JINGTONG GRAPHITE EQUIP

Grain direct shear test sample preparation device and sample preparation method

InactiveCN105115804AControl vacuumGuaranteed compactionPreparing sample for investigationEngineeringStorage tank

The invention discloses a grain direct shear test sample preparation device and a sample preparation method. The grain direct shear test sample preparation device comprises a lower cutting box, an upper cutting box, a box cover, an inserting pin, an impacting hammer and an air exhaust device (a motor, an air pump, an air storage tank and a switch). The problems of sample preparation devices and sample preparation technology for grain bulk direct shear tests are solved; through the sample preparation device and the sample preparation method, grain sample forming is guaranteed, height, flatness and compactness of a whole grain sample are ensured, and sample preparation efficiency is improved. The sample preparation device and the sample preparation method are simple to operate and suitable for direct shear sample preparation of different grain varieties.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Cationic dyeable PET and composite elastic fiber prepared from same

ActiveCN111499853AAchieve Transition ReunionRealize settlement and other issuesTextile/flexible product manufactureConjugated synthetic polymer artificial filamentsFiberPolymer science

The invention provides a cationic dyeable PET and a composite elastic fiber prepared from the same. A preparation method of the cationic dyeable PET comprises the following steps: mixing titanium dioxide, terephthalic acid and ethylene glycol, and pulping to obtain slurry; respectively carrying out esterification and pre-polycondensation on the slurry, adding dihydroxypropyl isophthalate-5-sodiumsulfonate into a pre-polycondensation product, and carrying out preliminary melt blending to obtain a primary product of cationic dyeable PET ; and carrying out solid-phase tackifying treatment on theprimary product of the cationic dyeable PET to obtain the cationic dyeable PET. The cationic dyeable PET / PTT composite elastic fiber is prepared from cationic dyeable PET and PTT through melt composite spinning. The problem that complete extinction and deep dyeing of PET fibers are difficult to unify at present is effectively solved, and the prepared product is good in performance, high in additional value, easy in process implementation and beneficial to large-scale production, and has a wide application prospect in elastic fabrics for clothing, home textiles and the like.

Owner:ZHANGJIAGANG GLORY CHEM IND CO LTD +1

A rh refining method to control the wettability of inclusions in low carbon aluminum killed steel

The invention provides an RH refining method for controlling wettability of inclusions in low-carbon aluminum killed steel. Through controlling the components, the adding time, the adding amount and the adding mode of an inclusion modifier, and in cooperation of the vacuum degree control and process adjustment in the RH refining process, so that the surface of the aluminum oxide inclusions is completely covered or partially covered with 2Al-2 O-3.CaO and 6Al-2 O-3.CaO, and the modified form of the inclusions is surface modification or local surface modification. On the basis of controlling thevacuum degree of RH refining, the yield of the modifier can be improved, and the problem of molten steel pollution caused by the modifier is reduced. On the basis that the refining process and the period are not influenced, the surface wettability of the aluminum oxide inclusions in the molten steel is improved. The problem of water opening nodulation in the continuous casting process can be relieved, and the problem of liquid level abnormal fluctuation caused by the water opening nodulation is avoided; and the problem of aggregation of the aluminum oxide inclusions in the solidification process of the molten steel is relieved, so that the cleanliness of the molten steel is improved, and the product quality of the low-carbon aluminum killed steel is improved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

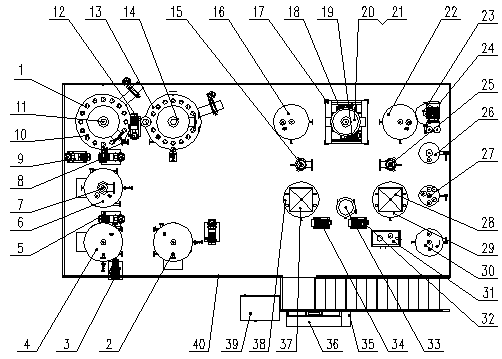

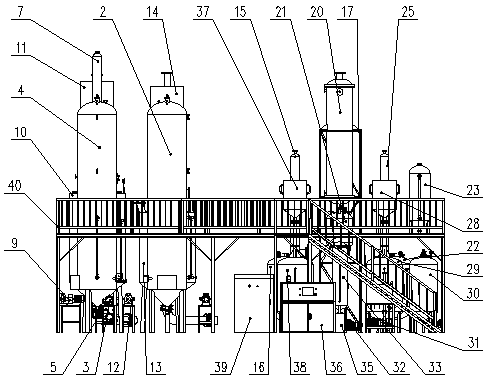

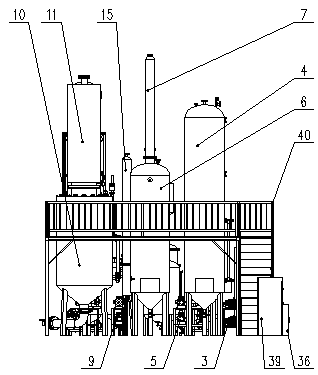

Complete rectifying device for regeneration of waste oil

PendingCN107815328ANot easy to scaleExtended service lifeTreatment with plural serial stages onlyCooling towerFiltration

The invention provides a complete rectifying device for regeneration of waste oil, and relates to an oil purifier. According to the complete rectifying device for regeneration of the waste oil, a pretreatment tank, a reaction kettle, a fractionating tower, a distillation tower, a catalytic tower, a reboiling tower, a rectifying tower, a cooling tower, a gas-liquid separator, a semi-finished product tank, a desulfurizing tower, a light oil storage tank, a distillation vacuum pump unit, a filtration vacuum pump unit, a steam-water separator, a buffer tank, a filter tank, a fire isolating tank, an oil spill tank, a pneumatic valve box, a console and a power cabinet are sequentially installed on the ground and a mounting rack of the device, wherein vertical electric heating tubes are arrangedin the reaction kettle, the distillation tower, the catalytic tower, the reboiling tower and the rectifying tower. The device has a scientific and reasonable structure, and the defects in an existingpyrolysis rectifying system for regeneration of the waste oil can be overcome; the vertical electric heating tubes do not scale and get damaged easily, so that types of oil are adjusted and controlledat will, the effect of distillation of the waste oil is improved significantly, and the production cost of waste oil regeneration is reduced; therefore, the device has a promotion value.

Owner:CHONGQING FANGSHENG CLEANING EQUIP CO LTD

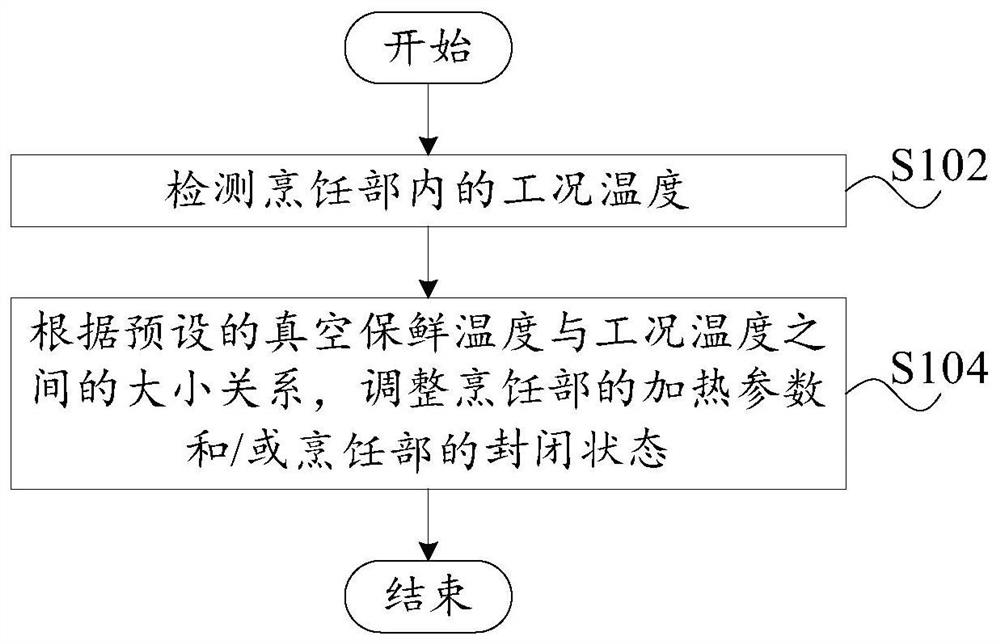

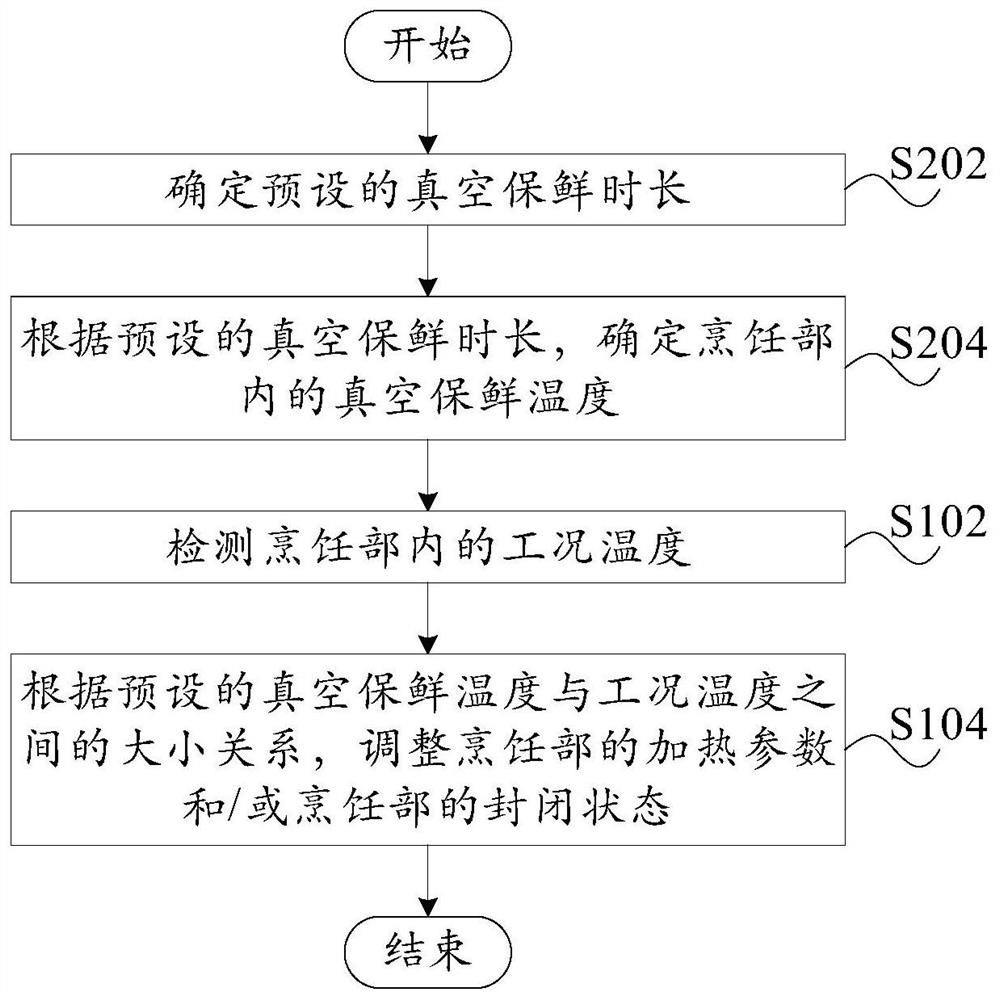

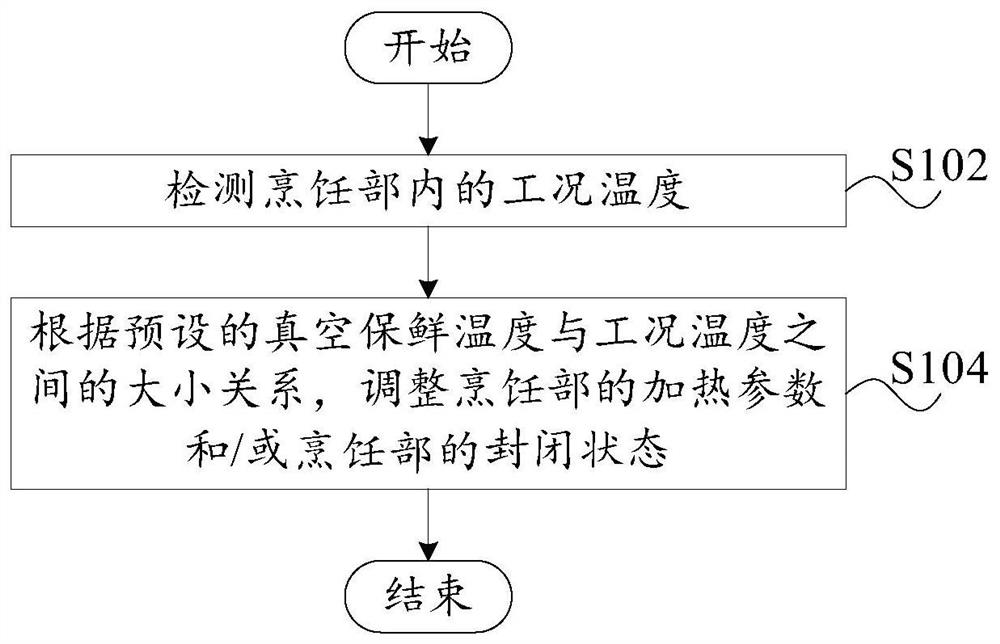

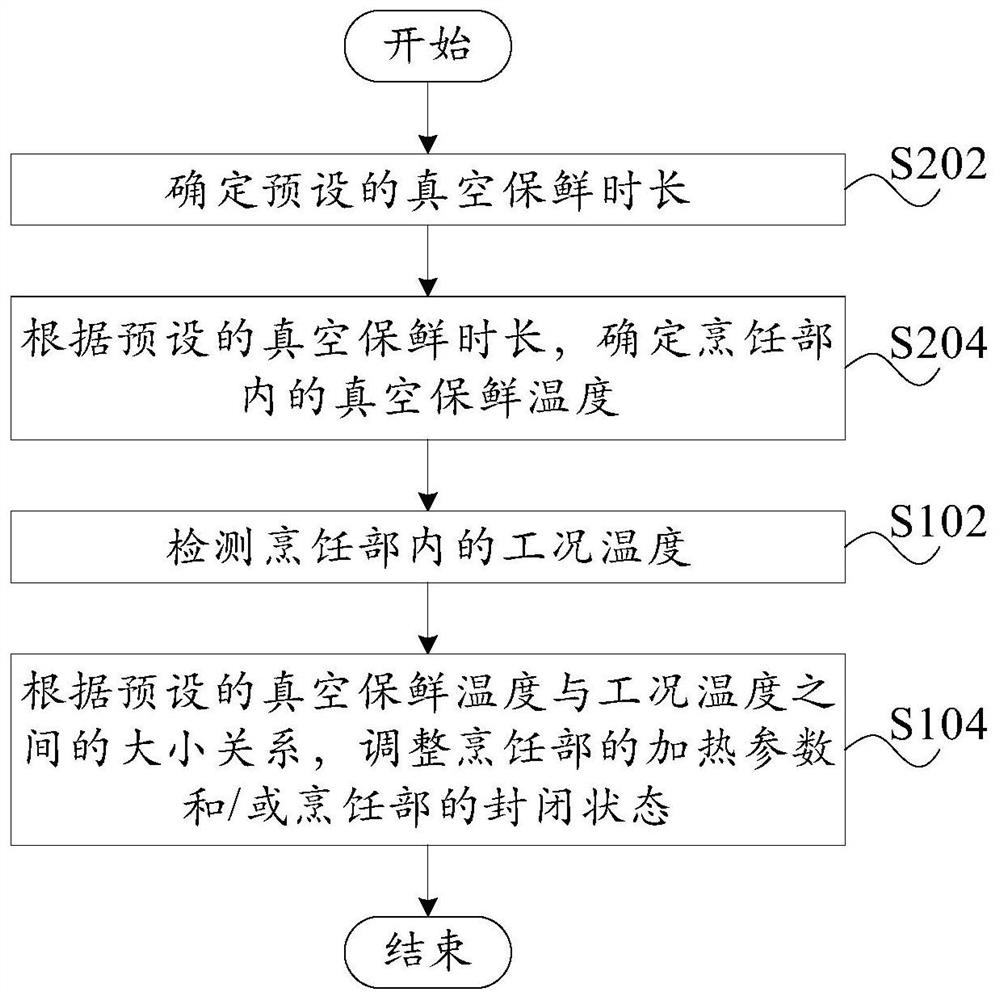

Cooking control method, device, cooking appliance and computer-readable storage medium

ActiveCN112568694BControl vacuumReduce manufacturing costAuxillary controllers with auxillary heating devicesPressure-cookersWorking temperatureProcess engineering

The invention provides a cooking control method, device, cooking utensil and computer-readable storage medium, wherein the cooking control method includes: detecting the operating temperature of the cooking part; size relationship, adjust the heating parameters and / or closed state of the cooking section. Through the technical solution of the present invention, when the cooking part is used to vacuum-preserve the contained materials, based on the corresponding relationship between the steam temperature and the degree of vacuum, the heating parameters and / or the heating parameters of the cooking part are adjusted according to the obtained operating temperature of the cooking part or a closed state to realize the control of the vacuum degree of the cooking part. Since it is only necessary to detect the working temperature of the cooking part during the control process, there is no need to set a pressure sensor or a pressure switch. Therefore, not only the manufacturing cost of the cooking appliance is effectively reduced, Moreover, the heating parameters and / or the sealing state of the cooking portion can be quickly adjusted to improve the reliability of the vacuum function of the cooking appliance.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

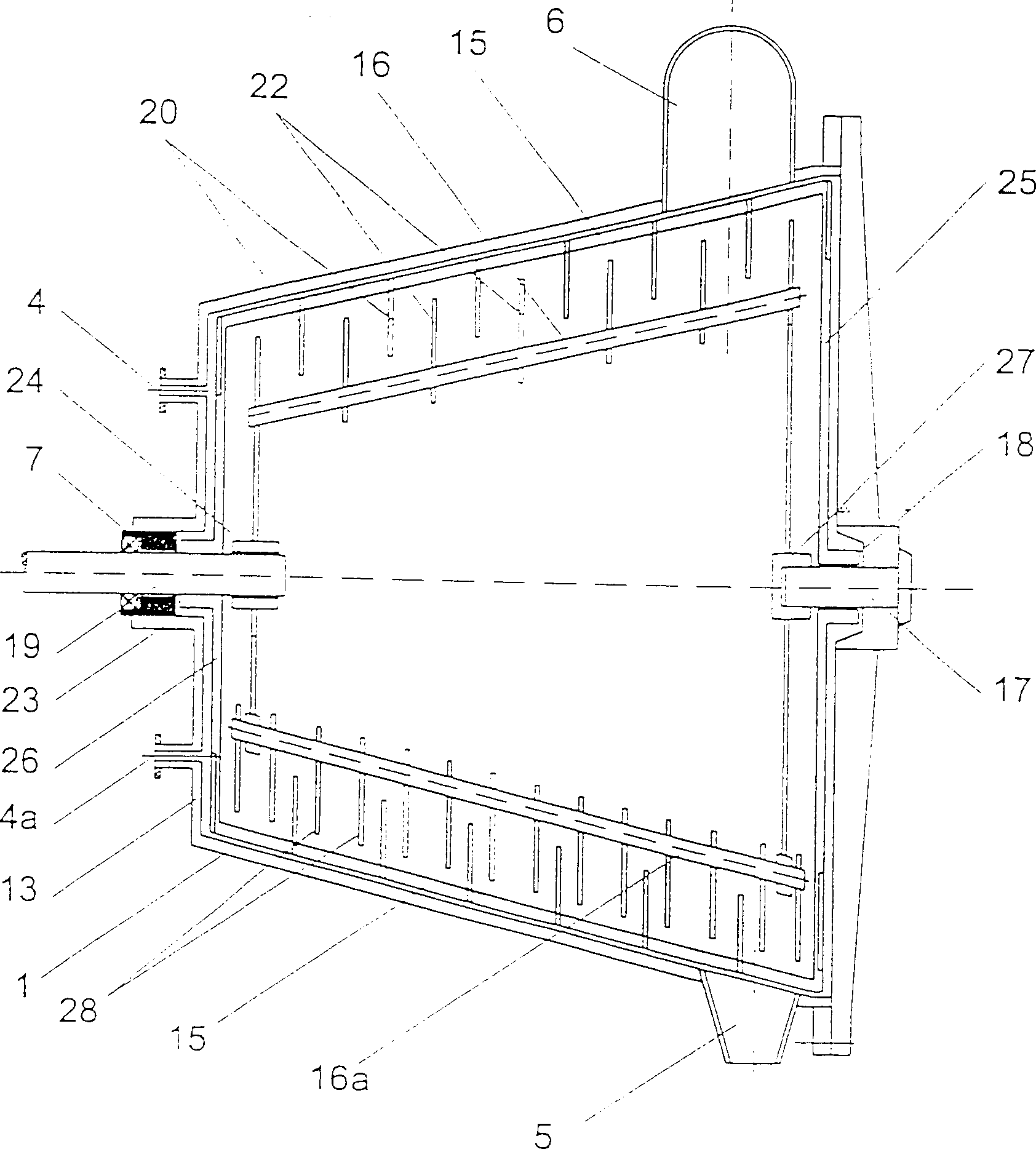

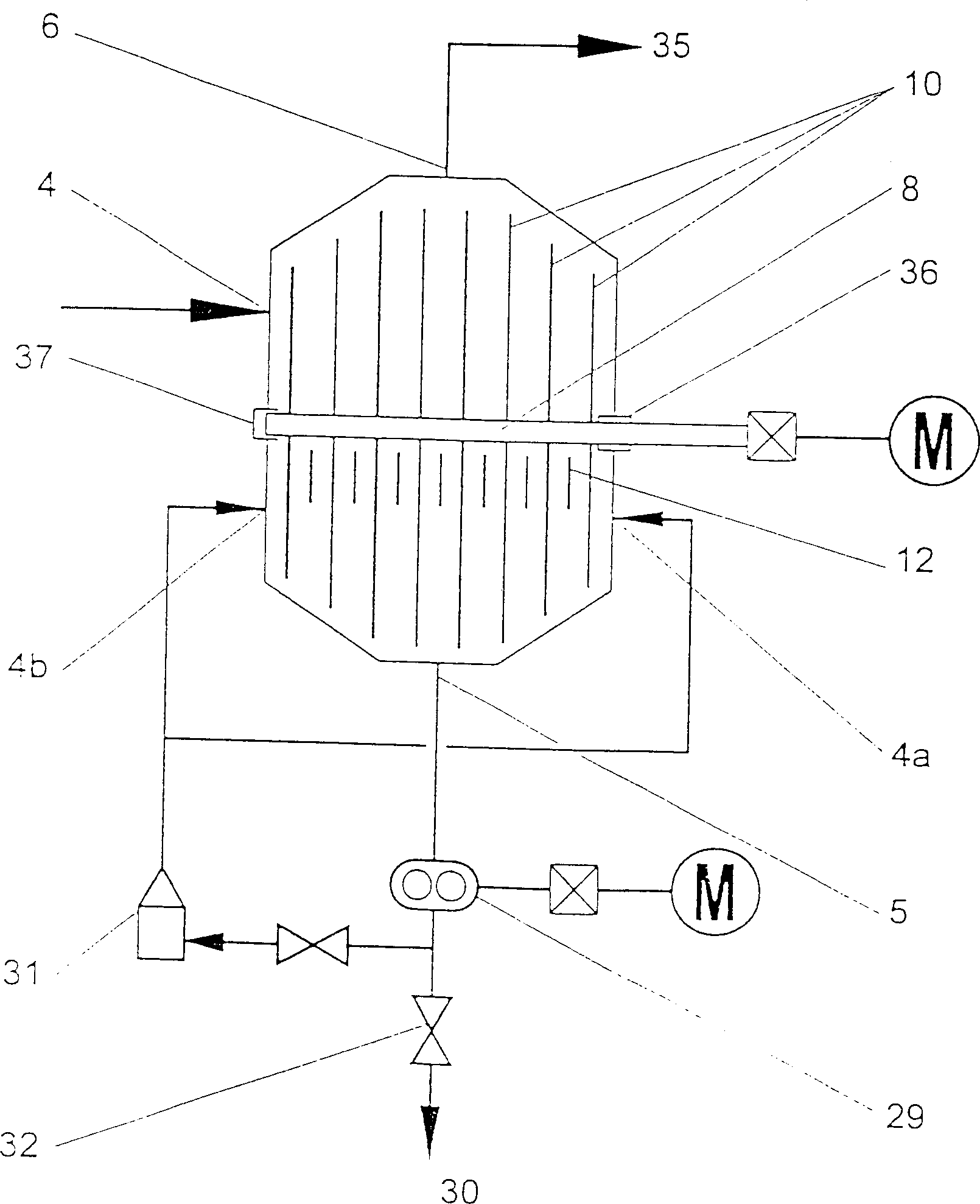

Batch polycondensation method and rotating disc reactor therefor

InactiveCN1239250CQuality improvementReduce heat loadRotary stirring mixersTransportation and packagingOligomerNuclear engineering

Owner:LURGI ZIMMER GMBH

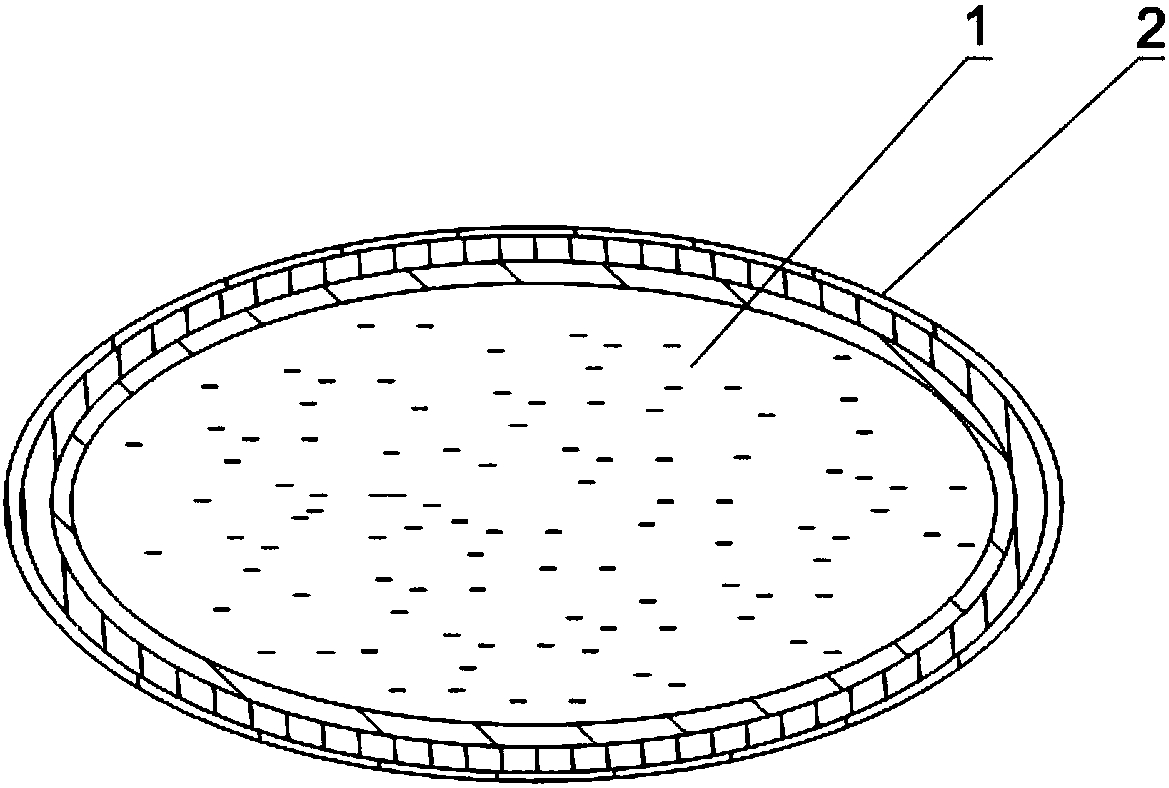

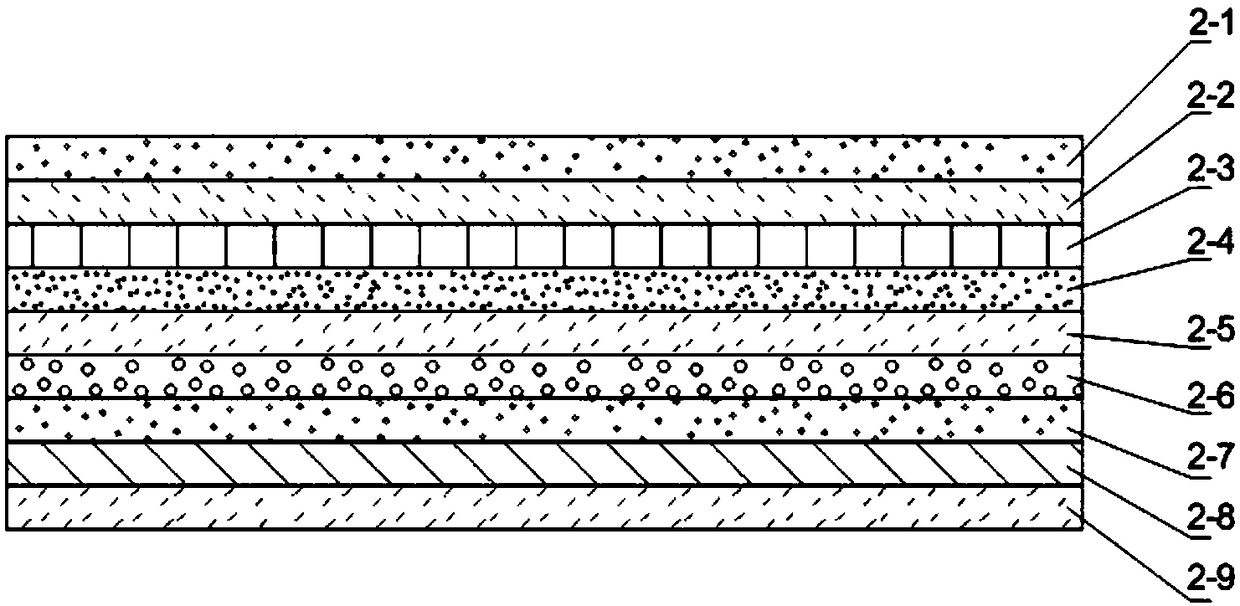

Outer barrier bag flushing liquid bag

PendingCN108498328ALeaked in timeBreak the tensionSynthetic resin layered productsPharmaceutical containersMedical unitPass rate

The invention provides an outer barrier bag flushing liquid bag which is constituted by a package and flushing liquid in the package. The package comprises a liquid medicine layer, a leakage observinglayer and a gas barrier layer, and is particularly and sequentially provided with PP resin serving as a thermal-bonding layer, POE resin serving as a diaphragm layer, POE resin serving as a strengthlayer, POE resin serving as a bonding layer, thermoplastic resin serving as a thermal-resisting layer, negative pressure gas serving as the leakage observing layer, PP resin serving as a thermal sticky layer, nylon resin serving as a reinforcing layer, and PET resin serving as a barrier layer. The integration of the outer barrier bag flushing liquid bag and the flushing liquid and the high barrierproperty to liquid are achieved; if the liquid medicine layer generates micro pores, the leakage observing layer can absorb the micro-leakage flushing liquid, and water spots are generated on the leakage observing layer, so that the micro-leakage flushing liquid is advantageously removed through quality testing; and the pass rate of factory finished products of the flushing liquid packing bag isincreased, the more guaranteed flushing liquid is provided for a medical unit, and the medication safety of patients is ensured.

Owner:张杰 +1

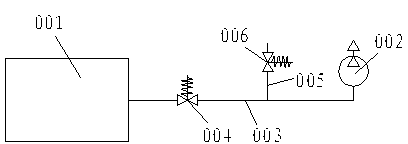

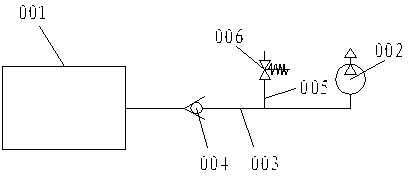

Device and method for controlling vacuum degree of vacuum refreshing refrigerator

ActiveCN101995142BControl vacuumSimple structureDomestic cooling apparatusLighting and heating apparatusControl signalVacuum pump

The invention relates to the technical field of refrigerators, in particular to a device and a method for controlling the vacuum degree of a vacuum refreshing refrigerator, which comprises a vacuum refreshing box, a vacuum pump, a pressure switch and a master control board, wherein the vacuum pump is communicated with the vacuum refreshing box, a pressure detection end of the pressure switch is communicated with the vacuum refreshing box, a pressure signal output end of the pressure switch is connected with the master control board, and a control signal output end of the master control board,which controls the action of the vacuum pump according to a pressure signal of the pressure switch, is connected with a signal input end of the vacuum pump electrically. In the control method, the pressure switch is used for detecting the air pressure of the vacuum refreshing box and outputting the pressure signal according to the air pressure to control the action of the vacuum pump. In the invention, the pressure switch is added to control the vacuum degree inside the refreshing box to be kept in a certain range all the time, and the control range is adjustable; moreover, the pressure switch has the advantages of simple structure and low cost and is safe and reliable.

Owner:HISENSE HOME APPLIANCES GRP CO LTD +1

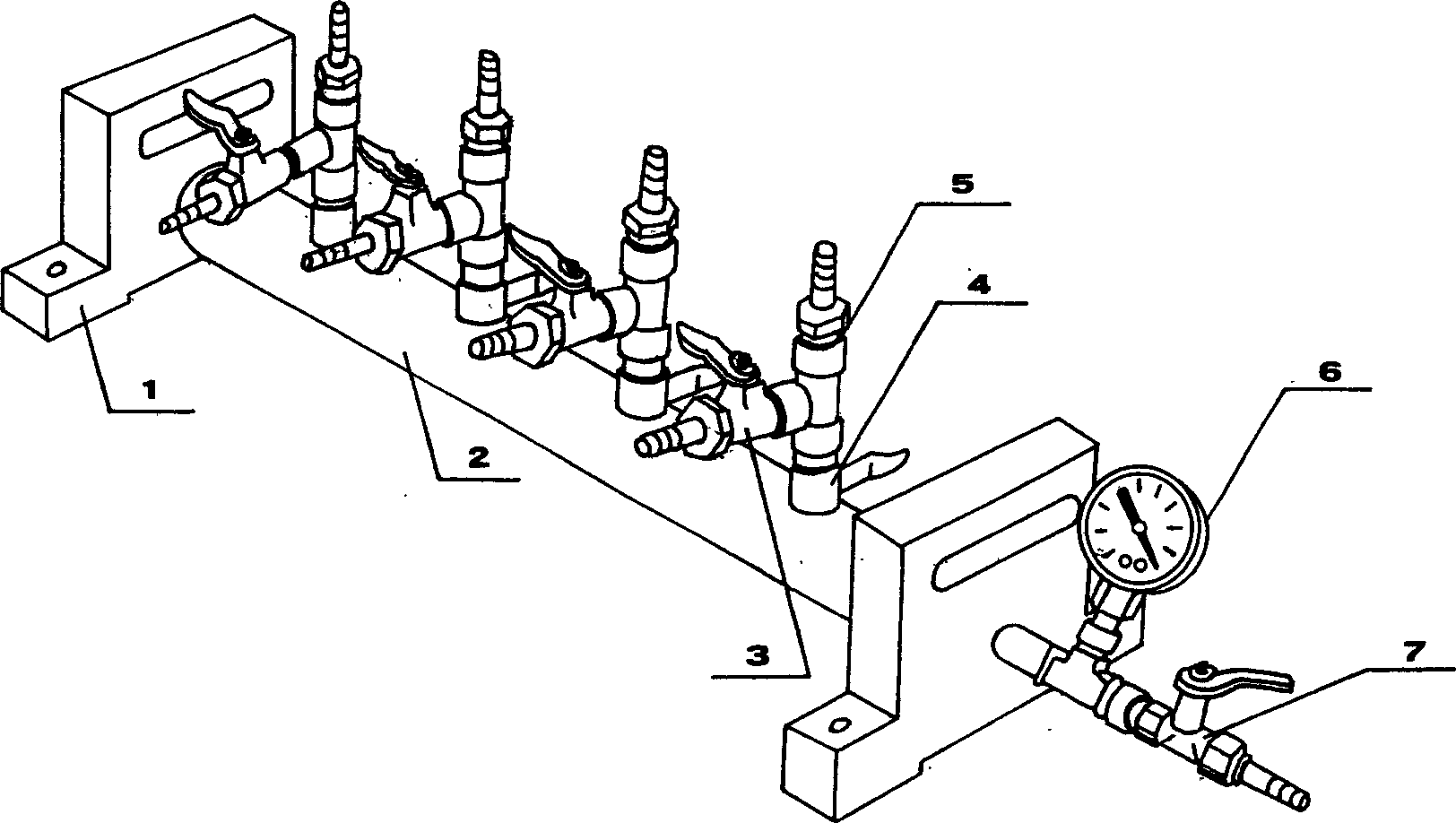

Filtering device with multiple head

InactiveCN1631484ALightweight and cheapControl vacuumFiltration circuitsStationary filtering element filtersEngineeringFast speed

The invention unfurls a kind of filter of many heads. It include main tube, trestle for fixing main tube, the main tube has an open side a close side fixed switch. On the main tube, there are many other tubes, the side close to the main tube fixed switch. The invention's advantages are many operations at one time, separated switch, no effect to others, owning high effect, fast speed features. In the tube there is vacuum watch; tubes and trestle are made of plastic, so it also has the advantages of light and cheap.

Owner:OCEAN UNIV OF CHINA

Cooking control method and device, cooking utensil and computer readable storage medium

ActiveCN112568694AControl vacuumFast and reliable heatingAuxillary controllers with auxillary heating devicesPressure-cookersProcess engineeringManufacturing engineering

The invention provides a cooking control method and device, a cooking utensil and a computer readable storage medium, and the cooking control method comprises the steps: detecting the working condition temperature of a cooking part; and adjusting the heating parameters and / or the closed state of the cooking part according to the size relationship between the preset vacuum fresh-keeping temperatureand the working condition temperature. According to the technical scheme, when the cooking part is used for carrying out vacuum fresh keeping on the contained materials, the heating parameters and / orthe closed state of the cooking part are / is adjusted according to the obtained working condition temperature of the cooking part on the basis of the corresponding relation between the steam temperature and the vacuum degree, so that control over the vacuum degree of the cooking part is achieved; in the control process, only the working condition temperature of the cooking part needs to be detected, and a pressure sensor or a pressure switch does not need to be arranged, so that the manufacturing cost of the cooking utensil is effectively reduced, the heating parameters and / or the closed stateof the cooking part are / is quickly adjusted, and the reliability of the vacuum function of the cooking utensil is improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

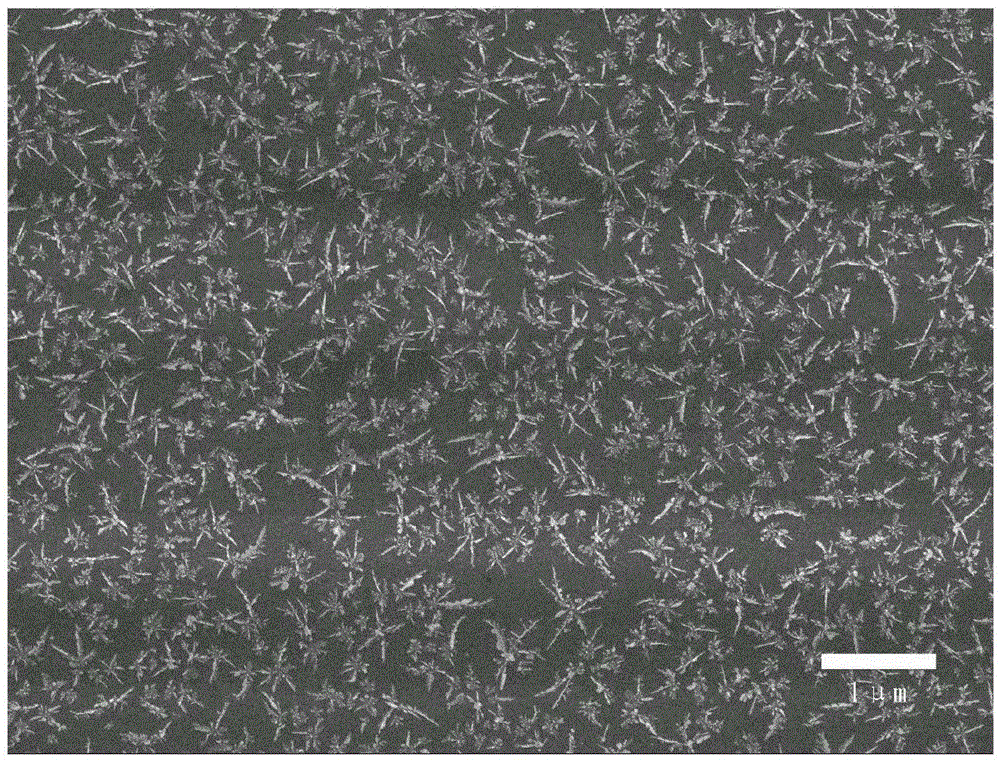

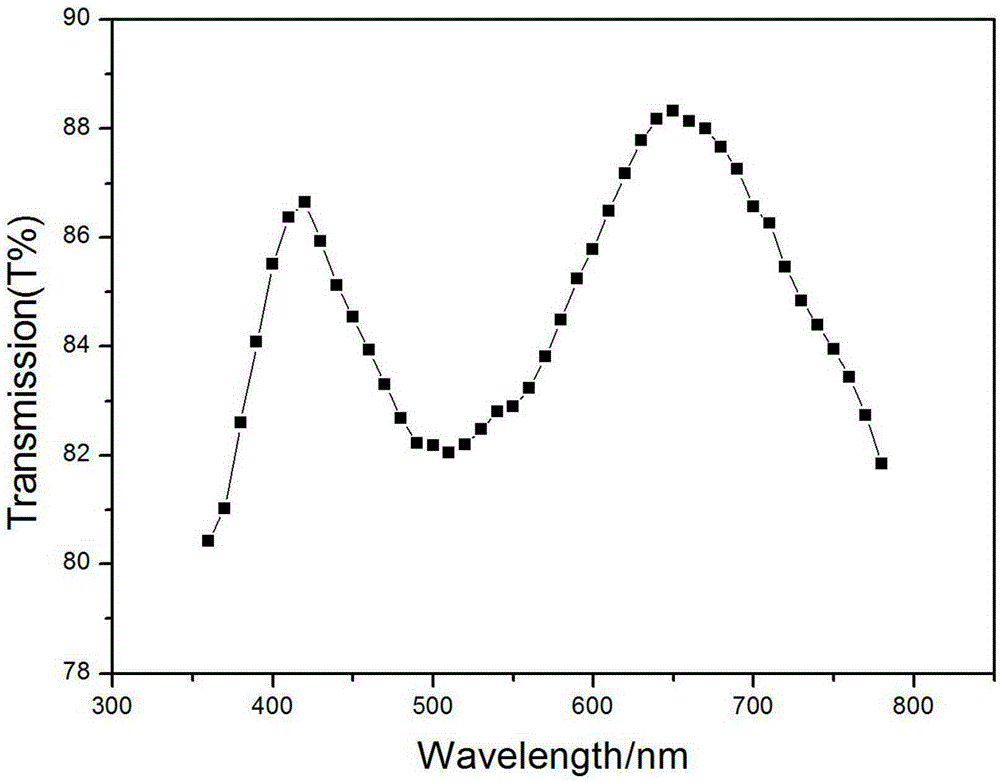

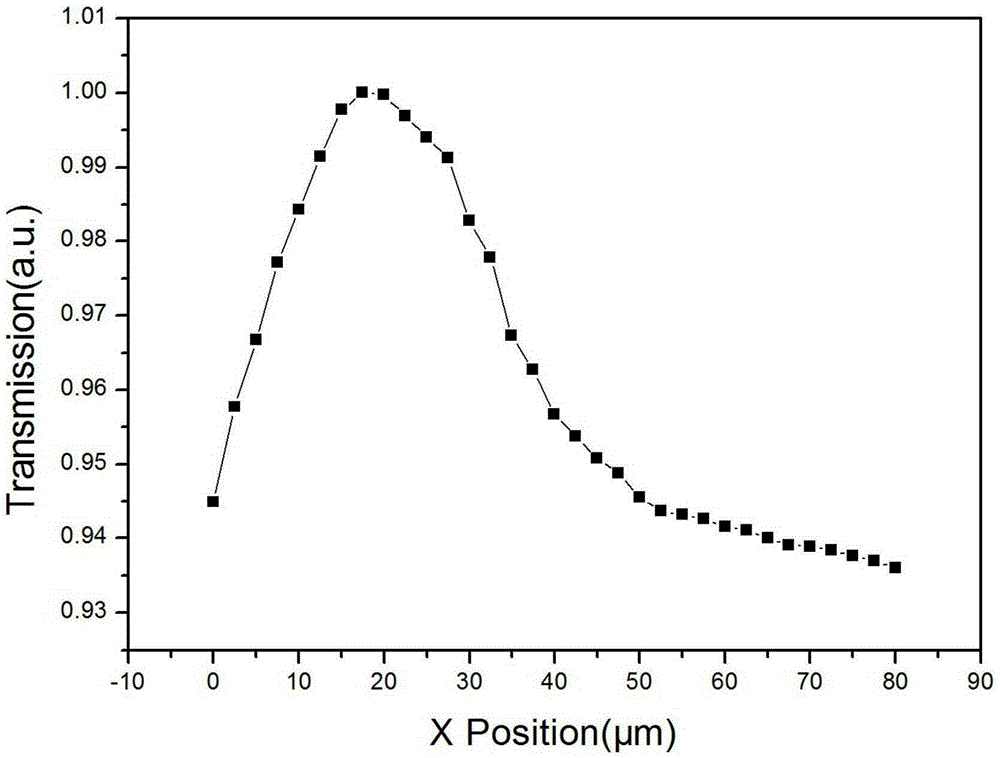

A preparation method of optical frequency band metamaterial based on gold branched unit

InactiveCN104191734BControl distribution densityControl shapeGlass/slag layered productsMonolayerMetamaterial

The invention relates to a preparation method of an optical frequency band metamaterial based on gold-branch-shaped units and particularly relates to a preparation method of a metamaterial. The preparation method of the metamaterial comprises the following steps: firstly preparing the gold-branch-shaped units in an aqueous solution by using dodecyltrimethylammonium bromide as a template by virtue of a nano self-assembly method, then assembling the prepared gold-branch-shaped units into a single-layer array on a glass substrate, coating the surface of the single-layer array with a PVA (Poly Vinyl Alcoho) film and overlapping the single-layer array and a sheet of ITO (Indium Tin Oxide) conductive glass to form the metamaterial of a composite structure. The metamaterial shows relatively strong transmission passband peak in a visible light frequency band and has obvious plate focusing effect on light with corresponding wavelengths.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

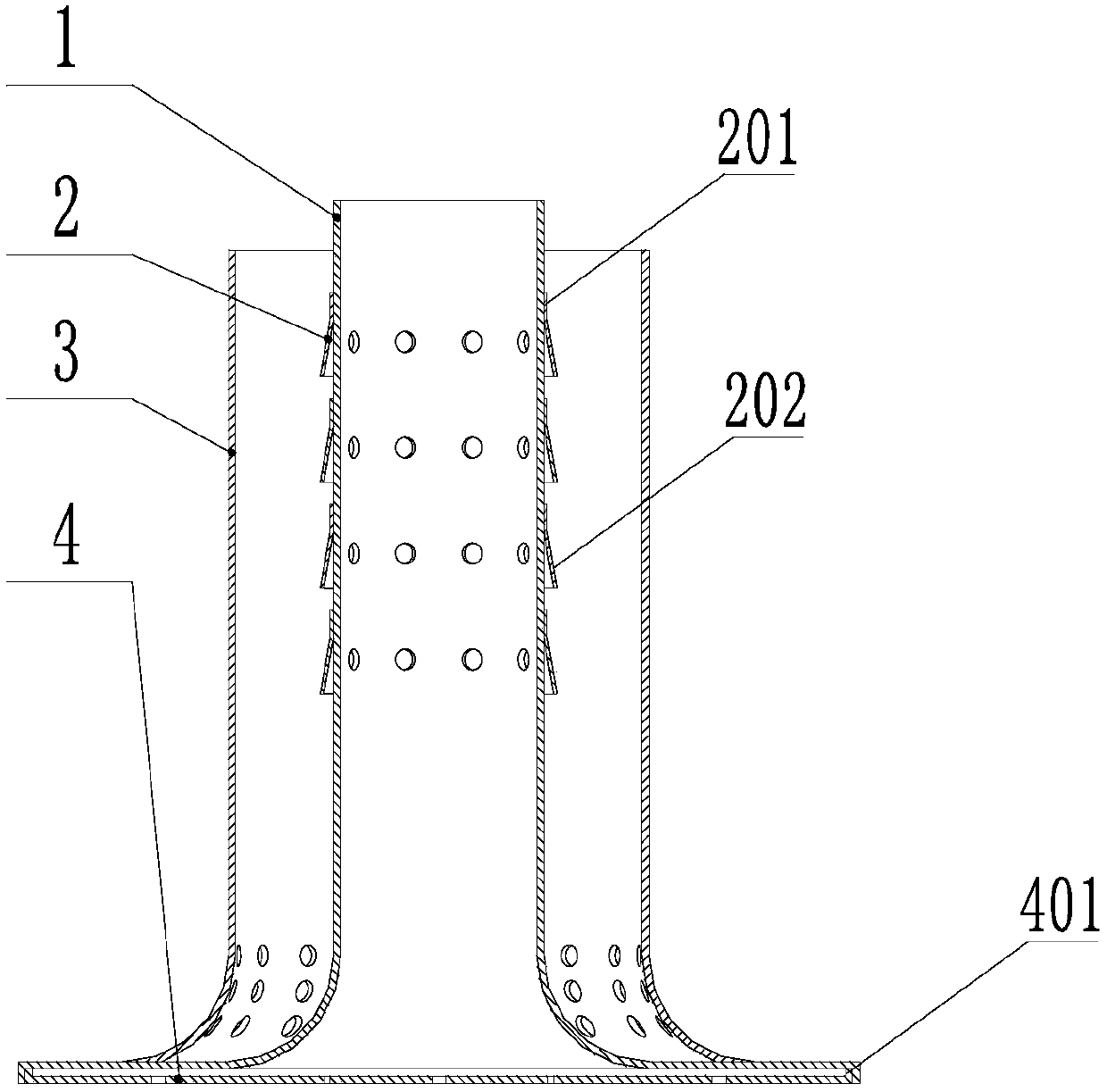

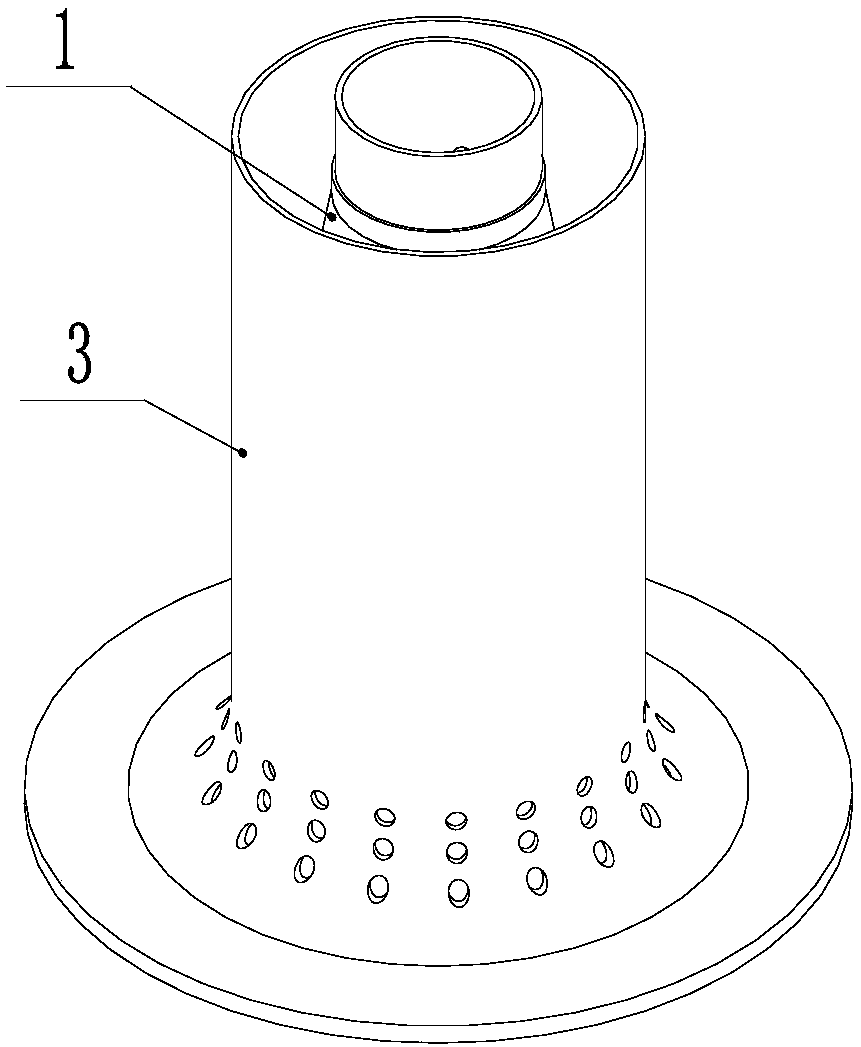

Blow-type vacuum suction cup and vacuum adsorption equipment with the blow-type vacuum suction cup

ActiveCN106219234BNovel structureReduce upfront investmentConveyor partsPulp and paper industryEngineering

The invention discloses an air blowing type vacuum sucking disc and a vacuum adsorption device with the air blowing type vacuum sucking disc. The air blowing type vacuum sucking disc comprises an inner barrel, an adsorption disc which is arranged at the bottom of the inner barrel and covers an opening in the bottom of the inner barrel, and an outer barrel which is arranged outside the inner barrel in a sleeving manner, wherein negative pressure holes are formed in the side wall of the inner barrel; the inner barrel is provided with unidirectional sealing elements used for unidirectionally sealing the negative pressure holes; the unidirectional sealing elements prevent airflow from flowing from the outer side of the inner barrel into the inner barrel through the negative pressure holes; the adsorption disc is provided with suction holes; exhaust holes are formed in the side wall of the outer barrel; the exhaust holes are positioned below the negative pressure holes; and the bottom of the outer barrel and the bottom of the inner barrel are hermetically connected. According to the novel-structure vacuum sucking disc provided by the invention, ordinary vacuum sucking discs are made vacuum through extracting air with a vacuum machine; and in the air blowing type vacuum sucking disc, an air compressor is adopted to generate compressed air, the compressed air flows directionally at a high speed, and a vacuum state is achieved, namely, the vacuum state is achieved through adopting an air blowing method.

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

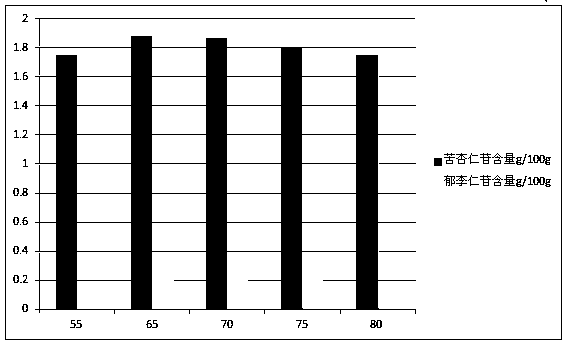

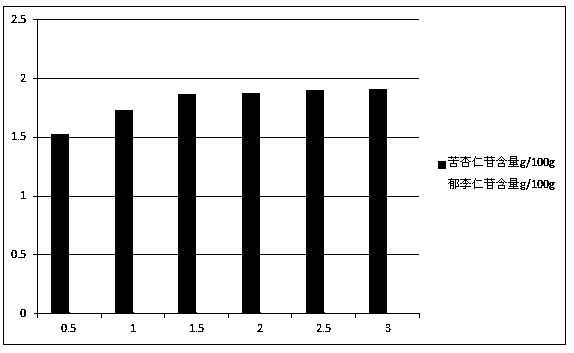

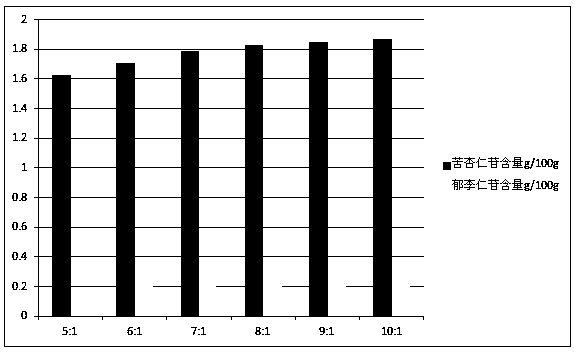

Process for extracting health-care bunge cherry seeds

The invention discloses a process for extracting health-care bunge cherry seeds. The process comprises the following steps: S1, pretreating raw materials to obtain raw material powder; S2, extractingraw material powder by adopting an ethanol solution reflux extraction method to obtain an extracting solution; S3, filtering the extracting solution to obtain filtrate; S4, concentrating the extracting solution to obtain concentrated paste; S5, determining the content of amygdalin and tulip in the concentrated paste; S6, performing alcohol precipitation treatment on the concentrated paste to obtain clear liquid; S7, filtering the clear liquid; S8, drying the filtered clear liquid to obtain dry tulip kernel powder; S9, determining the content of amygdalin and bunge cherry seed glucoside; S10, executing packaging and warehousing and storing the finished product. A decompression reflux extraction technology is adopted, so that the stability of the bunge cherry seeds is guaranteed at low temperature and low pressure; preliminarily filtering is executed by adopting an oscillating sieve to remove the large-particle residues of the bunge cherry seeds, insoluble substances are removed by adopting a diatomite vacuum filtration technology, the bunge cherry seed residues are recycled, and energy saving and environment protection are achieved.

Owner:WUHAN YIYUANTANG BIOTECH

A cationic dyeable pet and composite elastic fiber made therefrom

ActiveCN111499853BOvercome Difficult Dispersion ProblemsAdd evenlyTextile/flexible product manufactureConjugated synthetic polymer artificial filamentsFiberSulfonate

The invention provides a cationic dyeable PET and a composite elastic fiber prepared therefrom. The preparation method of cationic dyeable PET includes: mixing titanium dioxide, terephthalic acid and ethylene glycol and beating to obtain a slurry; performing esterification and precondensation on the slurry respectively, and adding dihydroxyisophthalic acid to the precondensation product Propyl ester-5-sodium sulfonate is initially melt-blended to obtain the primary product of cationic dyeable PET; the primary product of cationic dyeable PET is subjected to solid-phase viscosity increasing treatment to obtain cationic dyeable PET. Cationic dyeable PET / PTT composite elastic fiber is prepared by melt composite spinning of cationic dyeable PET and PTT. The technical solution provided by the invention effectively solves the problem that the current PET fiber is difficult to unify with full extinction and deep dyeing. The prepared product has good performance, high added value, easy process realization, and is conducive to large-scale production. It is suitable for elastic fabrics such as clothing and home textiles Wide application prospects.

Owner:ZHANGJIAGANG GLORY CHEM IND CO LTD +1

Electromagnetic high vacuum inflation valve

ActiveCN104930225BControl vacuumOperating means/releasing devices for valvesDispersed particle filtrationAir filterPneumatic valve

The invention relates to an electromagnetic high-vacuum inflation valve. The electromagnetic high-vacuum inflation valve comprises an electromagnetic assembly, an armature, a valve element, an upper cover, a cloth clamping membrane, a membrane pressing plate, a membrane base, a filter plate, a body and the like. When the vacuum state of a vacuum system needs to be damaged and air is injected, the electromagnetic assembly is powered on, the valve element sucks the armature upwards, the gas pressure in a back pressure chamber and the gas pressure in a working gas chamber are changed, the membrane base and the cloth clamping membrane are disengaged from a pipeline opening in the body, and air entering the filter plate or an air filter is injected into the vacuum system. When the vacuum degree of the vacuum system decreases to a preset value, the electromagnetic assembly is powered off, force of an upper spring is downward, the cloth clamping membrane presses the pipeline opening in the body, and the vacuum system is closed. The electromagnetic high-vacuum inflation valve is connected into a vacuum pipeline, and the vacuum degree of the vacuum system can be damaged or controlled in time according to presetting.

Owner:SHANGHAI LEIHANG MASCH MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com