Preparation technique of high-purity hydroxyethyl acrylate

A preparation technology of hydroxyethyl acrylate, which is applied in the field of preparation technology of high-purity hydroxyethyl acrylate, can solve problems such as difficult polymer handling, and achieve the effects of improving polymerization inhibition, preventing polymerization reaction, and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

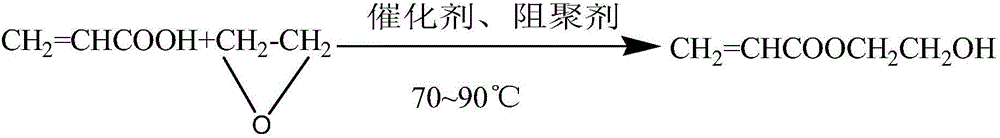

Method used

Image

Examples

Embodiment 1

[0029] Under vacuum conditions, 2000kg of acrylic acid, chromium acetate with a mass fraction of 2.0%, 13×10 -4 Hydroquinone and p-hydroxyanisole, after the completion, ensure that the vacuum is 0.75Mpa, add ethylene oxide after the metering tank is replaced by nitrogen, ensure that the oxygen / nitrogen volume ratio is 0.25%, and drop it under the condition of steam heating to 80°C Add ethylene oxide, ensure the pressure ≤ 60KPa by controlling the drop rate of ethylene oxide, the molar ratio of ethylene oxide to acrylic acid is 1.02:1, control the reaction temperature at 90°C by cooling with cooling water, and the reaction time is 1.5 hours; drop After the addition is completed, turn off the cooling water and raise the temperature naturally. After the temperature drops, take a sample to detect that the mass percentage of acrylic acid is less than 0.5%, which is considered as the completion of the addition reaction;

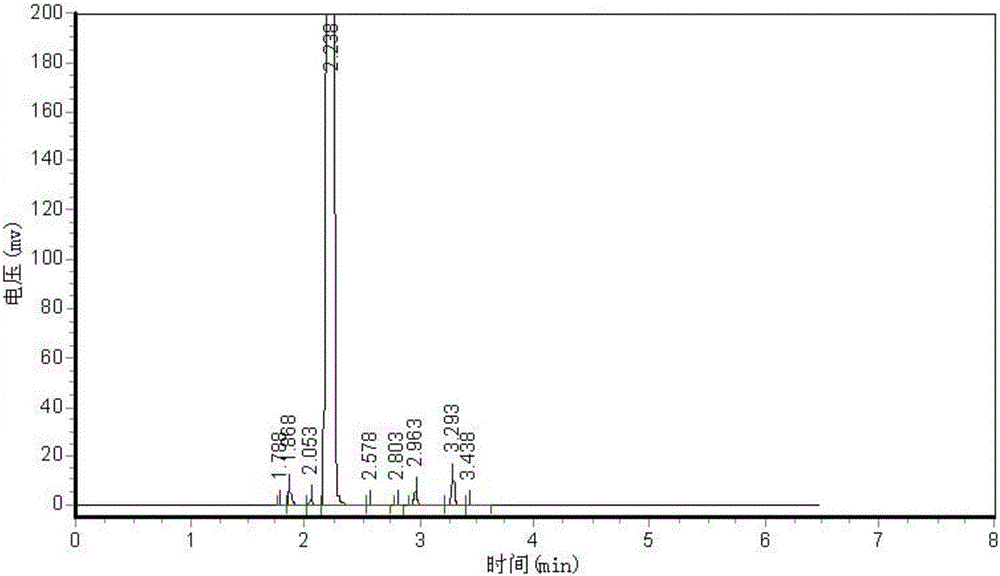

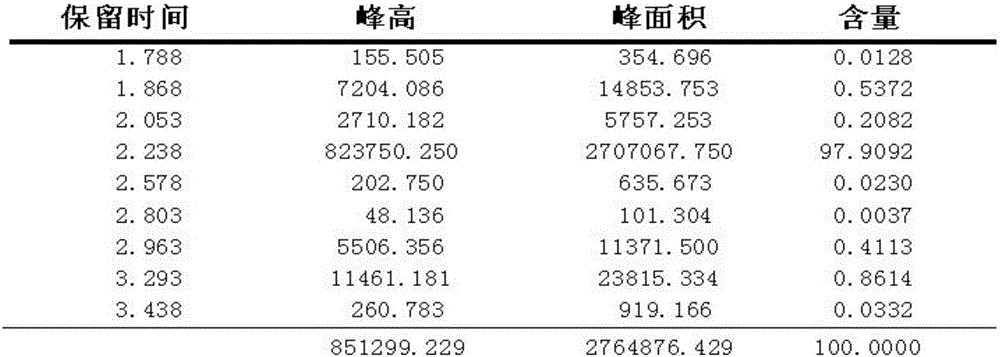

[0030] Thin-film evaporator is used for weight removal under ...

Embodiment 2

[0035] Under vacuum conditions, 2000kg of acrylic acid, chromium acetate with a mass fraction of 5.0%, 13×10 -4 of hydroquinone and paraben and 5 x 10 -3 After completion, ensure that the vacuum is at 0.75Mpa, fill in nitrogen to ensure that the oxygen / nitrogen volume ratio is 0.25%, add ethylene oxide dropwise under the condition of steam heating to 80°C, and ensure that the pressure is ≤ 60KPa by controlling the drop rate of ethylene oxide , the molar ratio of ethylene oxide to acrylic acid is 1.06:1, the reaction temperature is controlled at 90°C by cooling with cooling water, and the reaction time is 1.5 hours; after the addition is completed, the cooling water is turned off and the temperature rises naturally. After the temperature drops, the mass percentage of acrylic acid is less than 0.5% is regarded as the completion of the addition reaction;

[0036]Thin-film evaporator is used for weight removal under vacuum conditions to obtain primary distillation products. Catal...

Embodiment 3

[0038] Under vacuum conditions, 2000kg of acrylic acid, chromium acetate with a mass fraction of 2.0%, 13×10 -4 of hydroquinone and paraben and 5 x 10 -3 After completion, ensure that the vacuum is at 0.75Mpa, fill in nitrogen to ensure that the oxygen / nitrogen volume ratio is 0.25%, add ethylene oxide dropwise under the condition of steam heating to 85°C, and ensure that the pressure is ≤ 60KPa by controlling the drop rate of ethylene oxide , the molar ratio of ethylene oxide to acrylic acid is 1.02:1, the reaction temperature is controlled at 90°C by cooling with cooling water, and the reaction time is 1.5 hours; after the addition is completed, the cooling water is turned off and the temperature rises naturally. 0.5% is regarded as the completion of the addition reaction;

[0039] Thin-film evaporator is used for weight removal under vacuum conditions to obtain primary distillation products. Catalyst and heavy components enter the raffinate tank from the bottom of thin-fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com