Heat-conductive pipe and mfg. method

一种制造方法、热导管的技术,应用在半导体/固态器件制造、半导体器件、间接换热器等方向,能够解决热导管性能变异、不能工作介质充填量量化、未能提供真空度及注液量等问题,达到控制充填量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

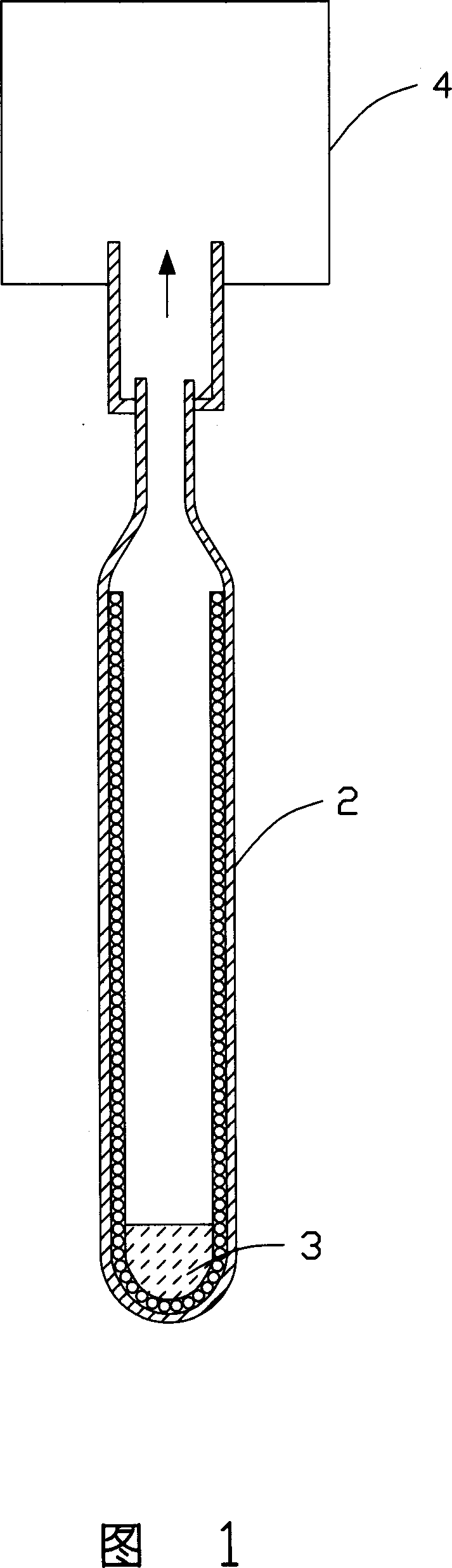

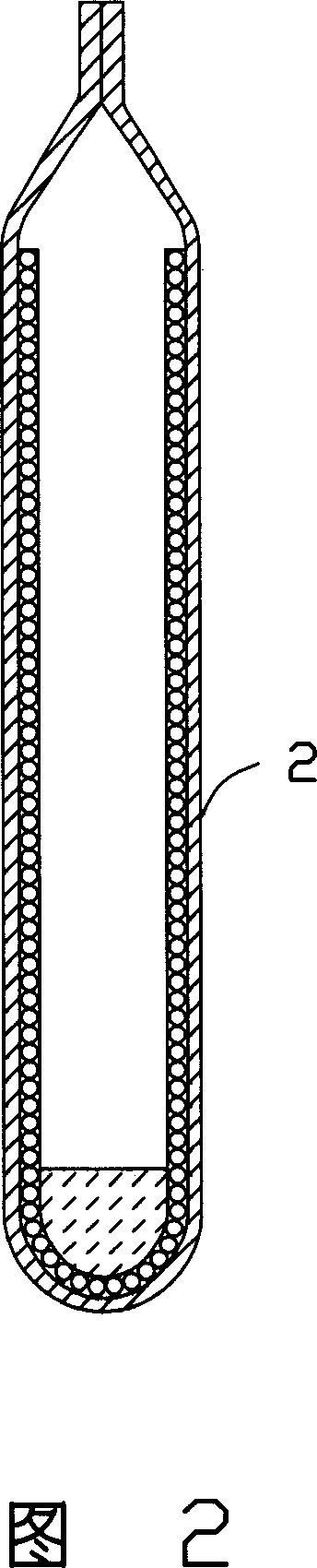

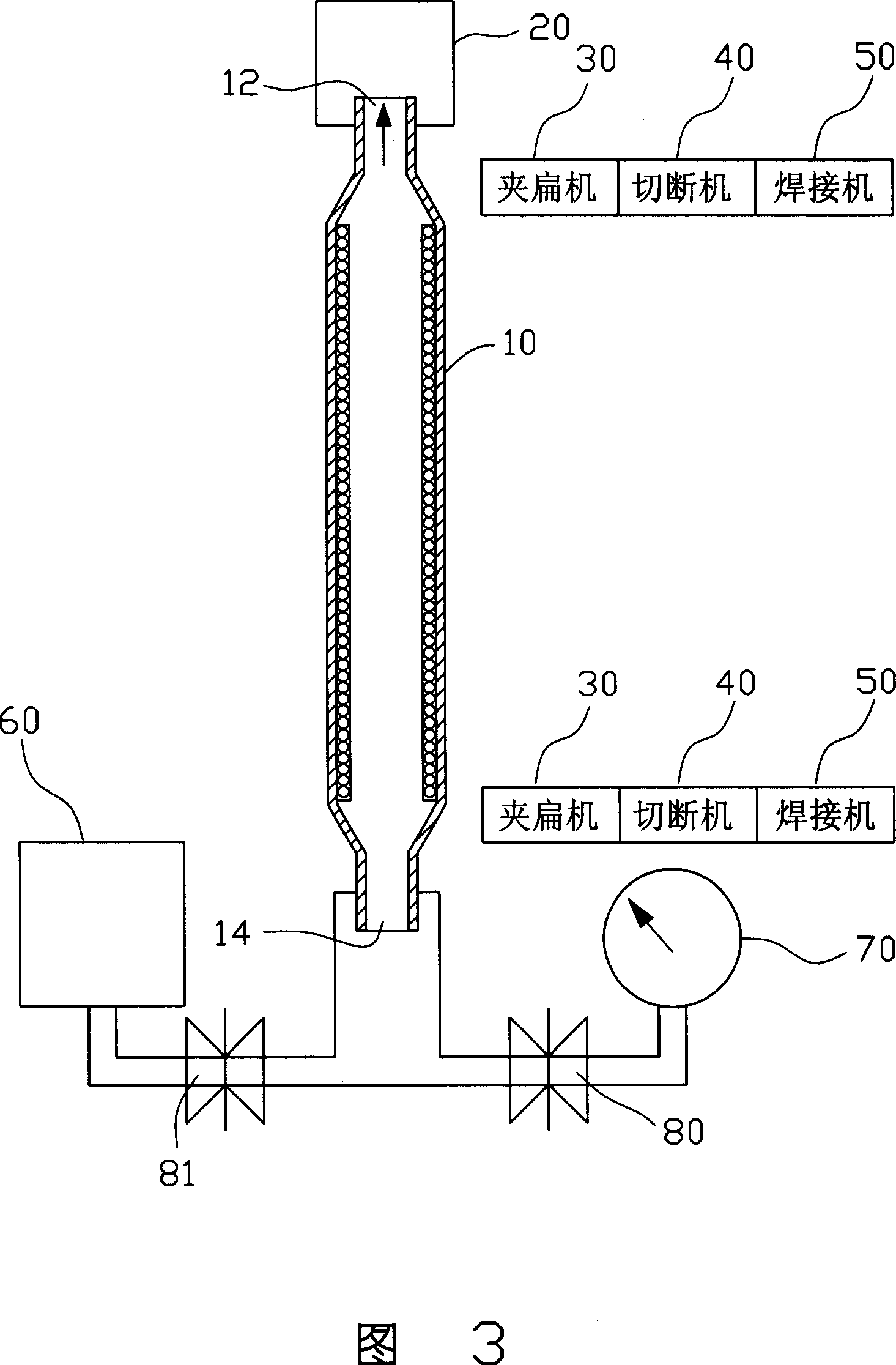

[0017] Please refer to FIG. 3 to FIG. 4 , which are schematic diagrams of the manufacturing device and sealing structure of the heat pipe of the present invention. The manufacturing device of the heat pipe includes a vacuum pump 20 , a clamping machine 30 , a cutting machine 40 , a welding machine 50 , a liquid injection tank 60 , a vacuum gauge 70 and a pair of valves 80 and 81 .

[0018] The operating principle of the manufacturing device of the heat pipe is as follows: firstly, the tube body 10 with the first opening 12 and the second opening 14 is placed in the vacuum suction tube and fixed with a base (not shown). The tube body 10 is provided with a capillary structure. Open the vacuum valve 80, close the liquid injection valve 81 and start the vacuum pump 20 to extract the gas in the tube body 10 from the first opening 12. The second opening 14 of the tube body 10 is equipped with a vacuum gauge 70, which shows the vacuum at the end of the tube body 10. Spend. When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com