High overload ablation resistant EPDM (Ethylene-Propylene-Diene Monomer) elastic heat insulation material

A technology of EPDM rubber and thermal insulation material, applied in the field of EPDM rubber (hereinafter referred to as EPDM rubber) thermal insulation material, can solve the problems of reducing the engine loading coefficient, complex implementation process, reducing the range of weapons, etc. High temperature particle erosion resistance, improved carbonization strength, and increased range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) The composition of the anti-high overload ablation EPDM thermal insulation material is as follows:

[0031] EPDM rubber: 100; Aramid fiber: 20; Asbestos fiber: 8; Silica: 25;

[0032] Zinc oxide: 3; liquid paraffin: 5; ammonium polyphosphate: 5; decabromodiphenyl ether: 20;

[0033] Antimony trioxide: 10; Dicumyl peroxide: 2.

[0034] Preparation method: weigh the above components in proportion, mix the weighed components with an open mill according to the general rubber mixing process, and then vulcanize and mold them under the condition of (150-160) ° C × 5 MPa × 60 min .

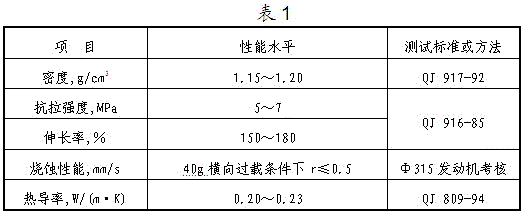

[0035] (2) See Table 1 for the properties of EPDM thermal insulation materials resistant to high overload ablation.

[0036]

Embodiment 2

[0038] (1) The composition of the anti-high overload ablation EPDM thermal insulation material is as follows:

[0039] EPDM rubber: 100; heterocyclic aramid fiber: 15; asbestos fiber: 5;

[0040] Silicon dioxide: 12; Zinc oxide: 5; Liquid paraffin: 10; Ammonium sulfate: 15;

[0041] Decabromodiphenyl ether: 30; Antimony trioxide: 15; Dicumyl peroxide: 3.

[0042] Preparation method, with embodiment 1.

[0043] (2) See Table 2 for the properties of the high overload ablation EPDM thermal insulation material.

[0044]

Embodiment 3

[0046] (1) The composition of the anti-high overload ablation EPDM thermal insulation material is as follows:

[0047] EPDM rubber: 100; Aramid fiber: 18; Asbestos fiber: 12; Silica: 20;

[0048] Zinc oxide: 5; liquid paraffin: 10; ammonium polyphosphate: 10; decabromodiphenyl ether: 10; antimony trioxide: 5; dicumyl peroxide: 1; 2,5-dimethyl 2,5 -(di-tert-butylperoxy)hexane: 2.

[0049] Preparation method, with embodiment 1.

[0050] (2) The properties of EPDM thermal insulation material against high overload ablation are shown in Table 3.

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com