Method for producing high-arene environment-friendly rubber oil

A technology for environmentally friendly rubber oil and production method, which is applied in the refining hydrocarbon oil, petroleum industry and other directions to achieve the effects of simple and economical process, increasing density difference and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

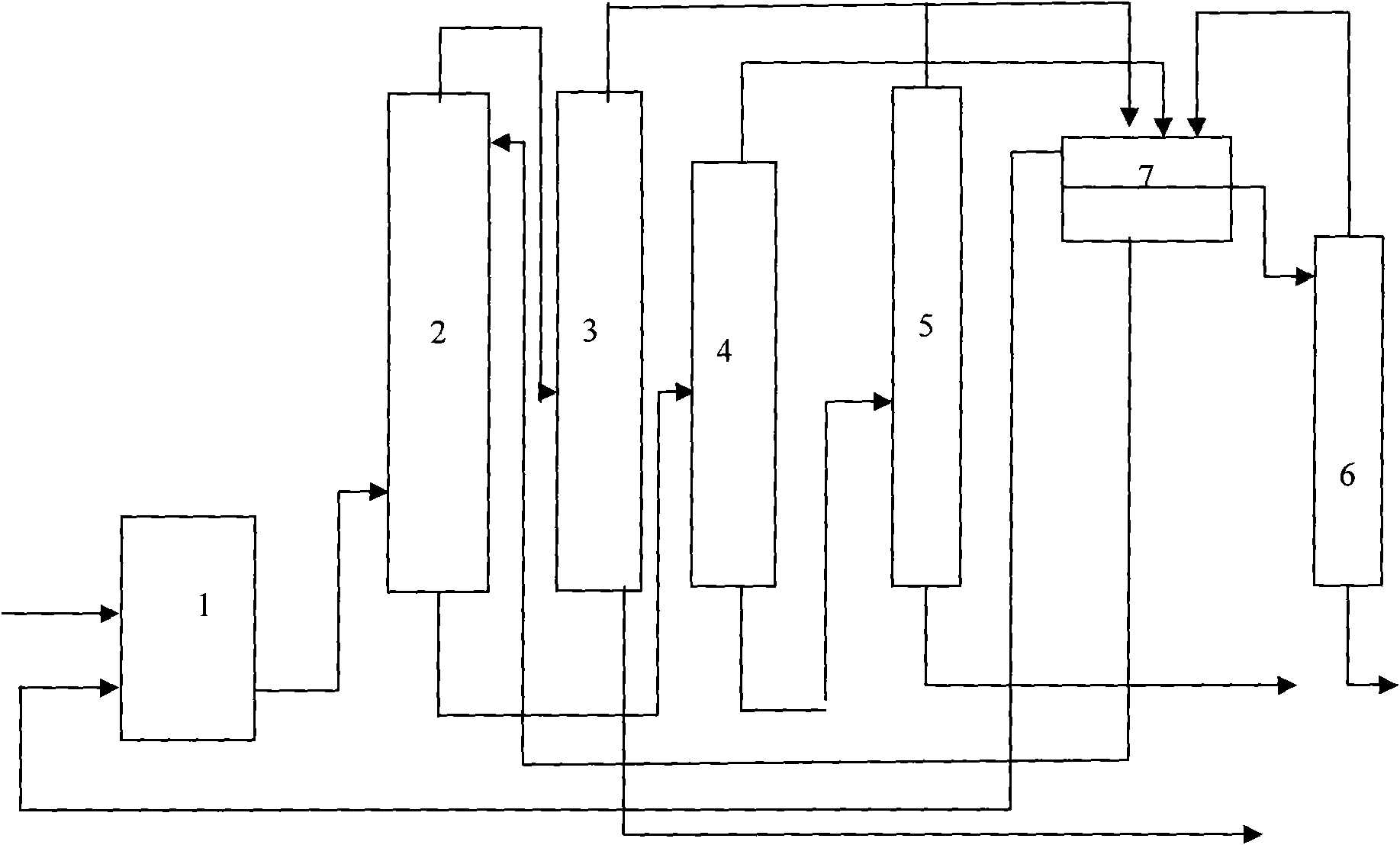

Method used

Image

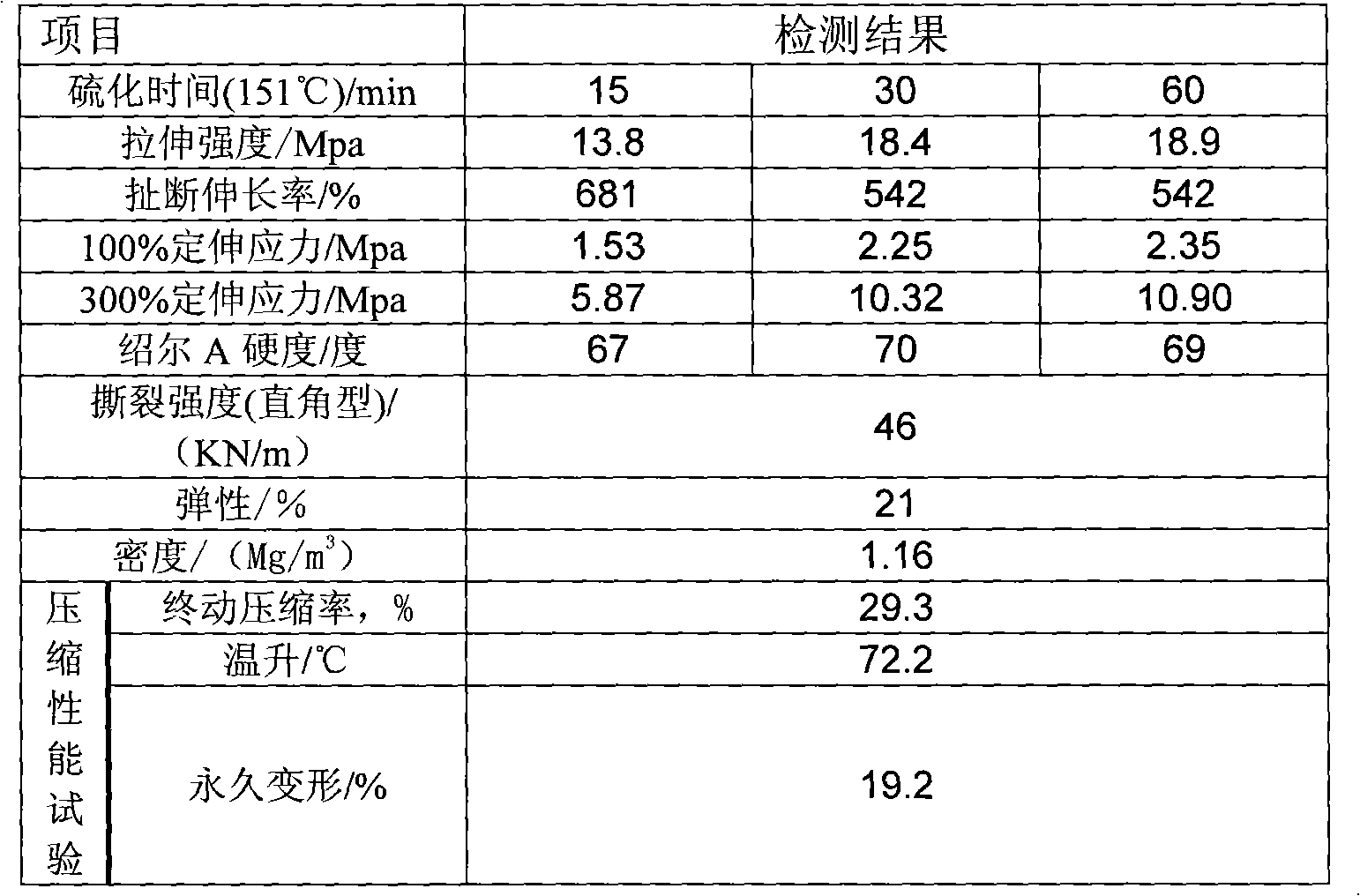

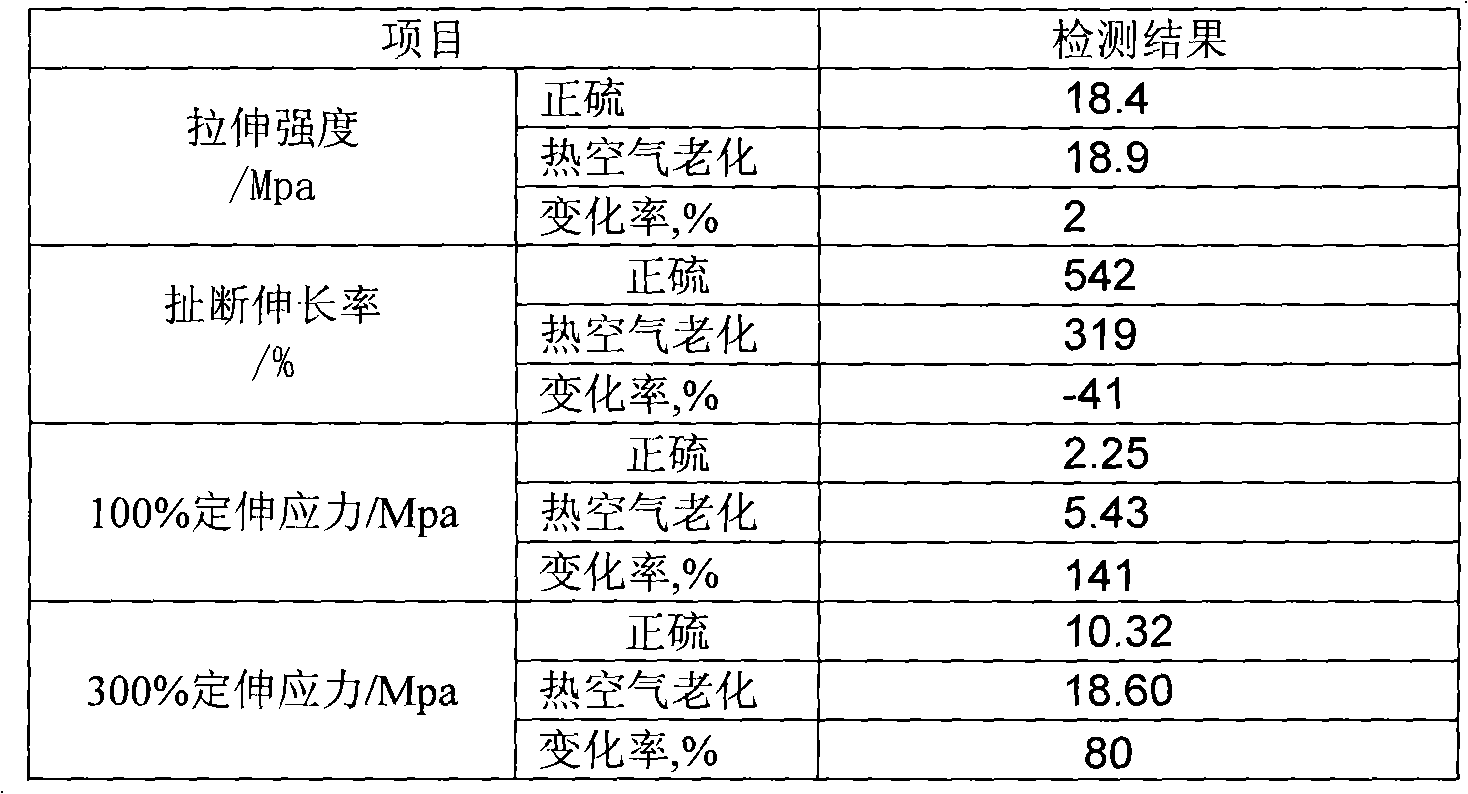

Examples

Embodiment 1

[0017] Using the four-line paraffin-based furfural extract oil produced by Dalian No. 7 Plant as raw material, use light hydrocarbons with a distillation range of 180°C-300°C as additives and furfural as a refining solvent in the laboratory pilot extraction device , under the refining conditions of agent-oil ratio 2.0-4.0 (mass ratio), tower top temperature 50-80°C, tower bottom temperature 30-50°C, the yield is 56.8%, the CA value is 22.8%, and the PCA is 2.6 % high aromatics environmental protection rubber oil.

Embodiment 2

[0019] Using Liaohe reduced third-line cycloalkylfurfural extracted oil as raw material, on the laboratory pilot extraction device, with light hydrocarbons with a distillation range of 180°C-300°C as additives and furfural as a refined solvent, in the agent oil Under the refining conditions of ratio 2.0-4.0 (mass ratio), tower top temperature 50-80°C, and tower bottom temperature 30-50°C, a high aromatic hydrocarbon with a yield of 35.0%, a CA value of 19.4%, and a PCA of 2.3% was obtained Environmentally friendly rubber oil.

Embodiment 3

[0021] Using the four-line paraffin-based furfural extracted oil produced by Dalian No. 7 Plant as raw material, a simple hydrocarbon with a boiling point of about 130°C as an auxiliary agent and furfural as a refining solvent in a pilot extraction device in the laboratory. Under the refining conditions of oil ratio 2.0-4.0 (mass ratio), tower top temperature 50-80°C, and tower bottom temperature 30-50°C, a high yield of 56.0%, CA value of 25.0%, and PCA of 2.5% was obtained. Aromatic environmental protection rubber oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com