Insulating and heat-conducting silicone grease and preparation method thereof

A technology of insulating thermal conductivity and silicone grease, applied in chemical instruments and methods, materials for heat exchange, etc., can solve the problems of neglecting the stability of non-Newtonian fluid colloids, not examining the huge influence of thermal conductivity and coating performance, etc., to achieve excellent Colloidal stability, effects of improved colloidal stability, good coatability and lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

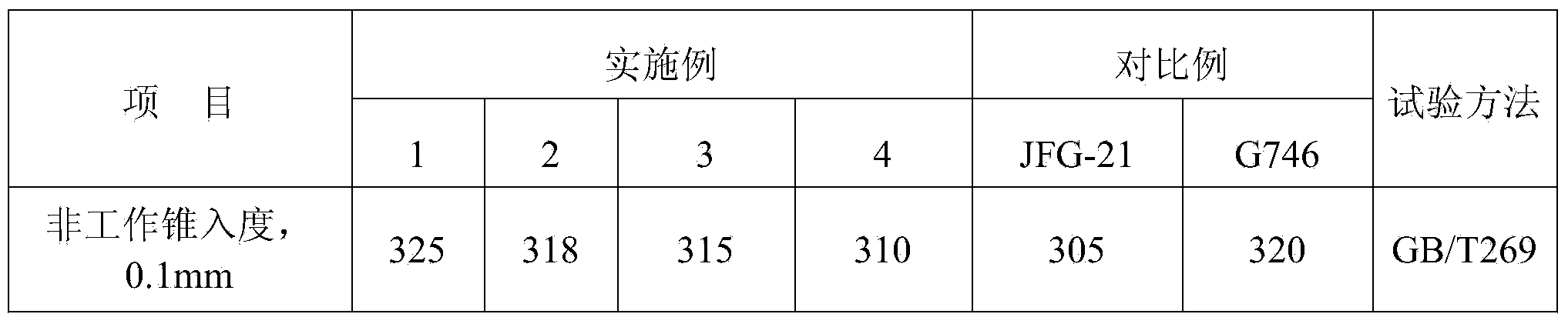

[0024] 10 parts of phenylmethyl silicone oil with a kinematic viscosity of 500cst at 25°C, 10 parts of dimethyl silicone oil with a kinematic viscosity of 60000cst at 25°C, 40 parts of modified zinc oxide, 25 parts of spherical alumina, 1 part of fumed silica, 1 part PTFE, 0.5 parts of BYK310, 0.2 parts of L135, 0.3 parts of L57 are mixed evenly and then ground three times by a three-roller mill, then transferred to a stainless steel kettle, adding 12 parts of benzyl silicone oil with a kinematic viscosity of 500cst at 25°C, and heating Keep warm at 110°C, filter with 120-mesh copper wire mesh, reflow and shear for 1 hour, the shear pressure is 0.04MPa, degas with a pump for 30 minutes, and then pack to obtain the finished product. The physical and chemical indicators are shown in Table 1.

Embodiment 2

[0026] 15 parts of phenylmethyl silicone oil with a kinematic viscosity of 1000cst at 25°C, 15 parts of dimethyl silicone oil with a kinematic viscosity of 60000cst at 25°C, 45 parts of modified zinc oxide, 10 parts of boron nitride, 2 parts of fumed silica, 1.5 parts Liquid benzotriazole fatty amine salt, 1 part of BYK161, 0.3 part of L135, 0.2 part of L01 are mixed evenly and then ground three times with a three-roll mill, then transferred to a stainless steel kettle, and 10 parts of benzyl with a kinematic viscosity of 500cst at 25°C are added Silicone oil, heat up to 90°C and keep it warm, filter with 120-mesh copper wire mesh, reflow and shear for 1 hour, shear pressure 0.04MPa, degas with a pump for 30 minutes, and then pack to obtain the finished product. The physical and chemical indicators are shown in Table 1.

Embodiment 3

[0028] 15 parts of simethicone oil with a kinematic viscosity of 100cst at 25°C, 15 parts of simethicone oil with a kinematic viscosity of 60000cst at 25°C, 30 parts of spherical alumina, 20 parts of boron nitride, 10 parts of nano-alumina, 2 parts of polytetrafluoroethylene Vinyl fluoride, 2 parts of organic bentonite, 0.5 parts of BYK390, 0.2 parts of L135, 0.3 parts of L57 are mixed evenly and then ground three times with a three-roll mill, then transferred to a stainless steel kettle, and 5 parts of dimethyl Silicone oil, heat up to 90°C and keep it warm, filter with 120-mesh copper wire mesh, reflow and shear for 1 hour, shear pressure 0.04MPa, degas with a pump for 30 minutes, and then pack to obtain the finished product. The physical and chemical indicators are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com