Grease special for plastic and preparation method thereof

A grease and plastic technology, applied in the field of plastic grease, can solve the problems of lack of protection and poor high temperature resistance of plastic materials, and achieve the effect of stable colloidal stability and strong high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

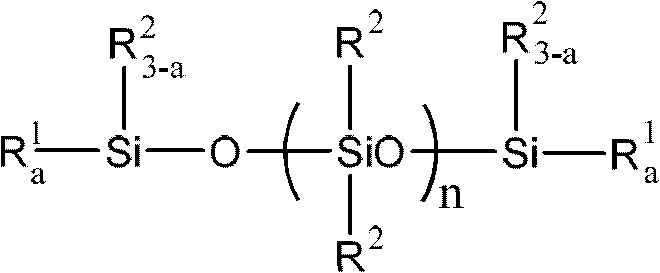

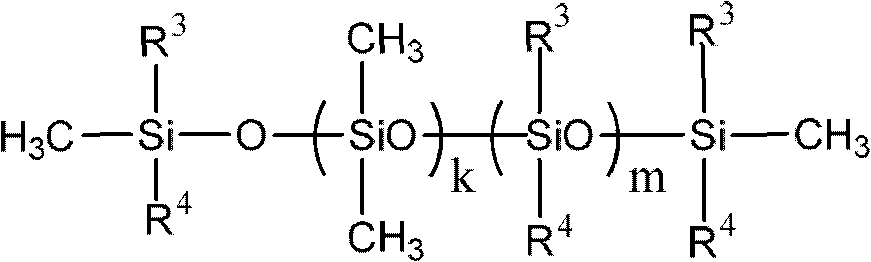

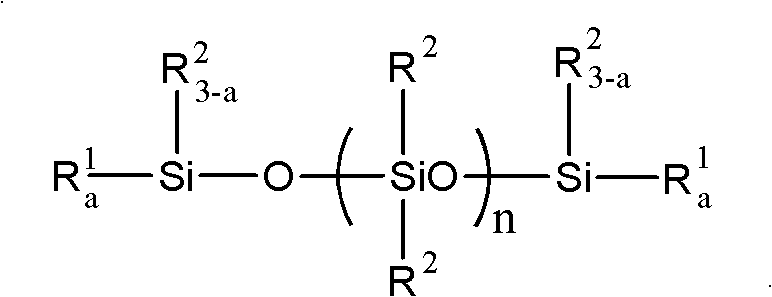

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: a kind of special lubricating grease for plastics, its preparation steps are as follows:

[0034] 1. Add 40kg of polydimethylsiloxane with a polymerization viscosity of 50mPa.s at 25°C and 10kg of polymethylphenylsiloxane with a polymerization viscosity of 150mPa.s at 25°C into the reactor, and stir evenly.

[0035] 2. Add 1kg of polytetrafluoroethylene, 0.5kg of 2,6-di-tert-butyl-p-cresol, and 0.5kg of ethylene glycol, and stir evenly.

[0036] 3. Add 6kg and the specific surface area is 230m 2 / g dehydrated hydrophobic silica treated with chlorosilane, stir well.

[0037] 4. Raise the temperature of the reaction kettle to 140°C and stir at a constant temperature for 2 hours to form the base material.

[0038] 5. Grind the base material 2 times with a three-roll mill to form fat.

[0039] 6. Carry out defoaming treatment on the obtained grease, vacuumize for 2 hours under the condition of absolute vacuum greater than 0.08MPa, stop the vacuum, and pack ...

Embodiment 2

[0040] Embodiment 2: a kind of special lubricating grease for plastics, its preparation steps are as follows:

[0041] 1. Add 70kg of polydibutylsiloxane with a polymerization viscosity of 20000mPa.s at 25°C and 40kg of polymethylphenylsiloxane with a polymerization viscosity of 150mPa.s at 25°C into the reactor, and stir evenly.

[0042] 2. Add 3kg of polytetrafluoroethylene, 1kg of 4,4'-thiobis(3-methyl-6-tert-butyl)phenol, and 2kg of polyethylene glycol, and stir evenly.

[0043] 3. Adding 14kg specific surface area is 230m 2 / g dehydrated hydrophobic silica treated with chlorosilane, stir well.

[0044] 4. Raise the temperature of the reaction kettle to 140°C and stir at a constant temperature for 2 hours to form the base material.

[0045] 5. Grind the base material 2 times with a three-roll mill to form fat.

[0046] 6. Carry out defoaming treatment on the obtained grease, vacuumize for 2 hours under the condition of absolute vacuum greater than 0.08MPa, stop the vacu...

Embodiment 3

[0047] Embodiment 3: a kind of special lubricating grease for plastics, its preparation steps are as follows:

[0048] 1. Add 40kg of polymethylvinylsiloxane with a polymerization viscosity of 2000mPa.s at 25°C and 40kg of polymethylphenylsiloxane with a polymerization viscosity of 150mPa.s at 25°C into the reactor, and stir evenly.

[0049]2. Add 2 kg of molybdenum disulfide, 0.75 kg of 2,6-di-tert-butyl-p-cresol, and 1 kg of glycerin, and stir evenly.

[0050] 3. Adding 10kg specific surface area is 230m 2 / g dehydrated hydrophobic silica treated with silazane, stir evenly.

[0051] 4. Raise the temperature of the reaction kettle to 140°C and stir at a constant temperature for 2 hours to form the base material.

[0052] 5. Grind the base material 2 times with a three-roll mill to form fat.

[0053] 6. Carry out defoaming treatment on the obtained grease, vacuumize for 2 hours under the condition of absolute vacuum greater than 0.08MPa, stop the vacuum, and pack into cans....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com