Porous polymer whole separating material and preparation method thereof

A technology of porous polymers and monolithic materials, applied in chemical instruments and methods, and other chemical processes, can solve the problems of narrow monomer selection range, inconvenient operation, and high condition requirements, and achieve wide monomer selection range, pore The effect of high rate and good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Preparation of embodiment 1, poly(GMA-co-EDMA) porous polymer monolithic material

[0017] 0.37mL glycidyl methacrylate (GMA), 0.20mL ethylene glycol methacrylate (EDMA), 0.38mL cyclohexanone, 0.76mL dodecanol, 0.012g azobisisobutyronitrile (AIBN), 0.076g poly(BMA) 70 -b-(GMA) 10 The mixed solution was ultrasonically dissolved into a transparent homogeneous solution, and nitrogen gas was passed for 15 minutes to remove oxygen. Then put the mixed solution into a dry stainless steel empty column tube, seal it and place it in a water bath at 55°C for 24 hours, then take it out, connect it to a high-pressure pump, wash out the porogen and unreacted monomer with tetrahydrofuran, and obtain the porous Polymer monolithic materials.

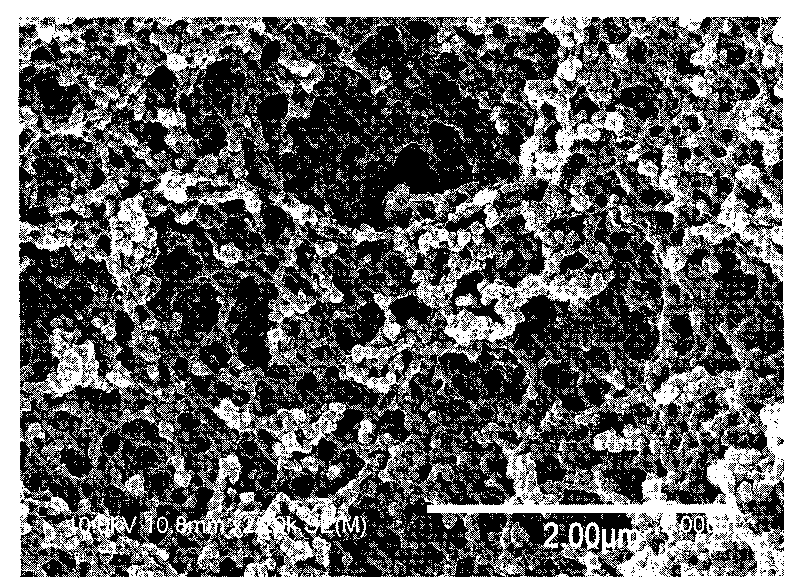

[0018] The microscopic morphology of the pillars of the porous polymer monolith prepared above was observed with a scanning electron microscope, and the results are shown in the attached figure 2 shown. It can be seen from the figure that th...

Embodiment 2

[0019] Embodiment 2, the preparation of poly(BMA-co-EDMA) porous polymer monolithic material

[0020] 0.37mL n-butyl methacrylate (BMA), 0.20mL ethylene glycol methacrylate (EDMA), 0.17mL cyclohexanone, 1.54mL dodecanol, 0.012g azobisisobutyronitrile (AIBN), 8.5mg poly(BMA) 70 -b-(GMA) 20 The mixed solution was ultrasonically dissolved into a transparent homogeneous solution, and nitrogen gas was passed for 15 minutes to remove oxygen. Then put the mixed solution into a dry stainless steel empty column tube, seal it and place it in a water bath at 55°C for 24 hours, then take it out, connect it to a high-pressure pump, wash out the porogen and unreacted monomer with tetrahydrofuran, and obtain the porous Polymer monolithic materials.

[0021] The microstructure of the porous polymer monolithic material prepared above was observed with a scanning electron microscope. It was a three-dimensional network skeleton structure with a through-pore diameter of 3 μm and an average ske...

Embodiment 3

[0022] Embodiment 3, the preparation of poly(BMA-co-EDMA) porous polymer monolithic material

[0023] 0.37mL n-butyl methacrylate (BMA), 0.20mL ethylene glycol methacrylate (EDMA), 0.114mL cyclohexanone, 1.03mL dodecanol, 0.012g azobisisobutyronitrile (AIBN), 11.5mg poly(BMA) 70 -b-(GMA) 70 The mixed solution was ultrasonically dissolved into a transparent homogeneous solution, and nitrogen gas was passed for 15 minutes to remove oxygen. Then put the mixed solution into a dry stainless steel empty column tube, seal it and place it in a water bath at 55°C for 24 hours, then take it out, connect it to a high-pressure pump, wash out the porogen and unreacted monomer with tetrahydrofuran, and obtain the porous Polymer monolithic materials.

[0024] The microstructure of the porous polymer monolithic material prepared above was observed with a scanning electron microscope. It was a three-dimensional network skeleton structure with a through-pore diameter of 0.2 μm and an average...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Large hole size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com