Exothermic composition and exothermic body

A heat-generating composition and heat-generating body technology, applied in heat exchange materials, chemical instruments and methods, heating appliances for therapeutic treatment, etc., can solve problems such as poor liquid permeability, reduced water absorption capacity, and damage to drainage. Achieves the effect of maintaining moldability and shape retention, excellent heat generation characteristics, and long-term heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0219] 100 parts by weight of iron powder (DKP, manufactured by Dowa Teppun Co. Ltd.), 8 parts by weight of activated carbon (SA-Super, manufactured by Norit Co. Ltd.), 4 parts by weight of sodium chloride, 0.3 parts by weight of a water-absorbing polymer ( KI-gel 201K, manufactured by Kraray Co. Ltd., 90% or more of particles with a particle diameter of 150 μm or more), 3.0 parts by weight of wood flour (90% or more of particles with a particle diameter of 150 μm or less ) and 0.15 parts by weight of calcium hydroxide were mixed to prepare a non-stick exothermic composition having a liquid permeability of 8, an incremental viscosity of 200 cP, a water migration value of 12 and excess water. The liquid permeability of this non-viscous exothermic composition was 8.

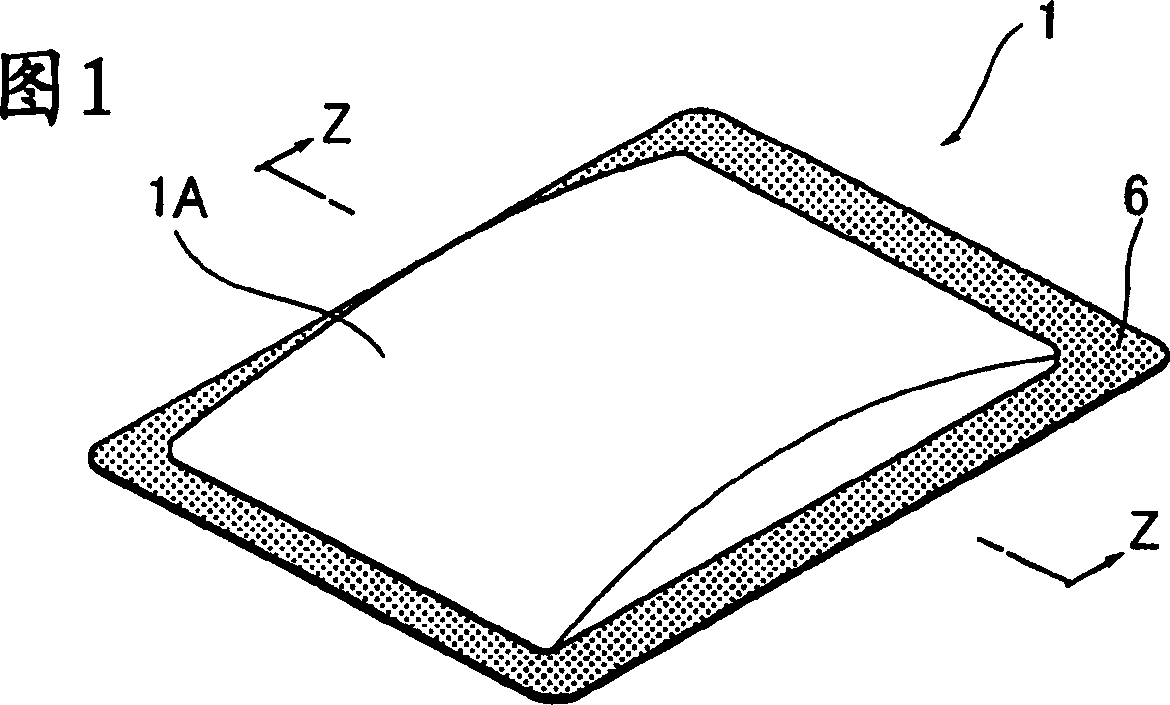

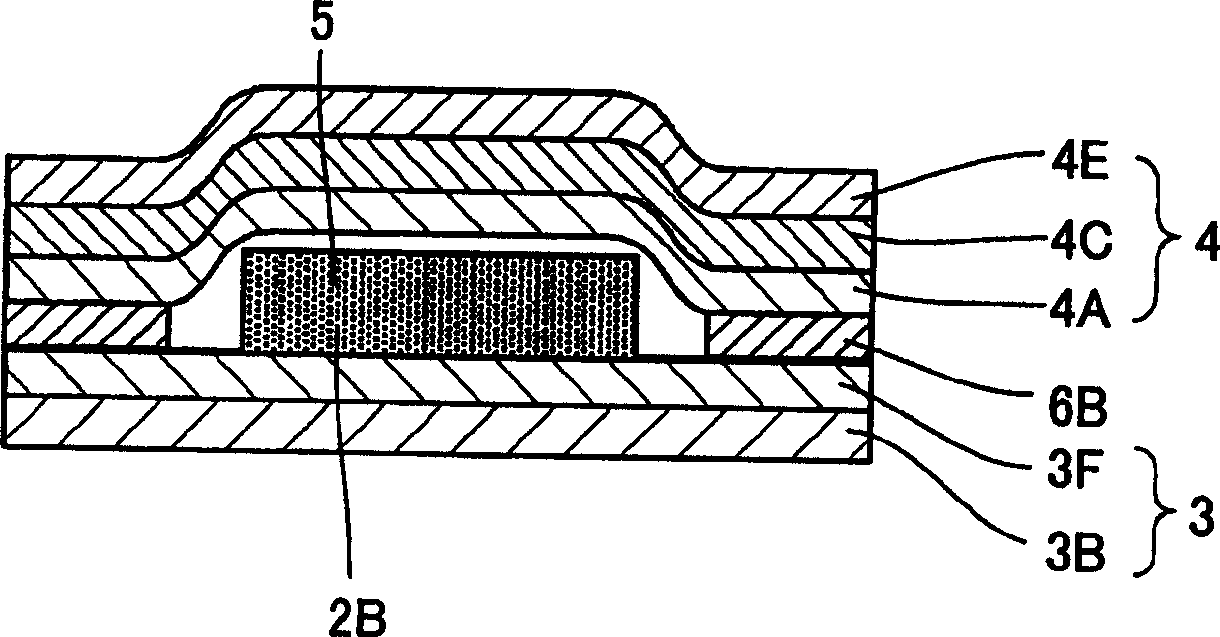

[0220] As shown in FIGS. 1 and 2 , an air-impermeable packaging material obtained by laminating a polyethylene film 3B on a backing paper 3F was designated as a base material 3 . The molded product 2B of the exoth...

Embodiment 2

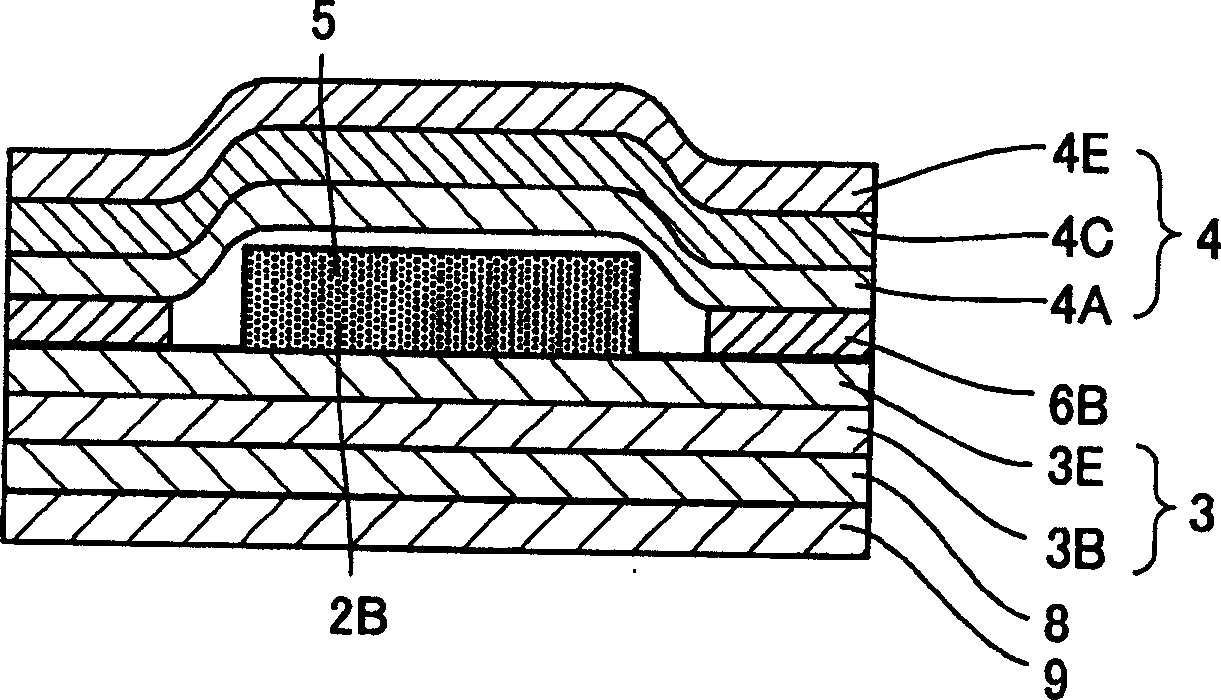

[0230] The backing paper 3F in the base material 3 in Example 1 is replaced with kraft paper 3E, and an anti-slip layer 8 and a release film 9 are laminated under the kraft paper to obtain an assembly, such as image 3 shown. Figure 4 A cross-sectional view of an assembly obtained by providing an acrylic adhesive layer 7 between a kraft paper 3E and a release film 9 is shown.

Embodiment 3

[0232] Except adding 3 parts by weight of terraballoon instead of the wood flour in Example 1, a heating element was prepared in the same manner as in Example 1. Also, the heating element was sealed in an air-tight outer bag, and left to stand at room temperature for 24 hours.

[0233] After 24 hours, take the heating element out of the outer bag, and test the degree of shape retention, which is 100. Using another heating element produced at the same time, the heating element was similarly taken out of the outer bag and subjected to a heat generation test, reaching 36° within 1 minute, and a long time of 8 hours at 36° or higher.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com